Advertisement

Quick Links

E1

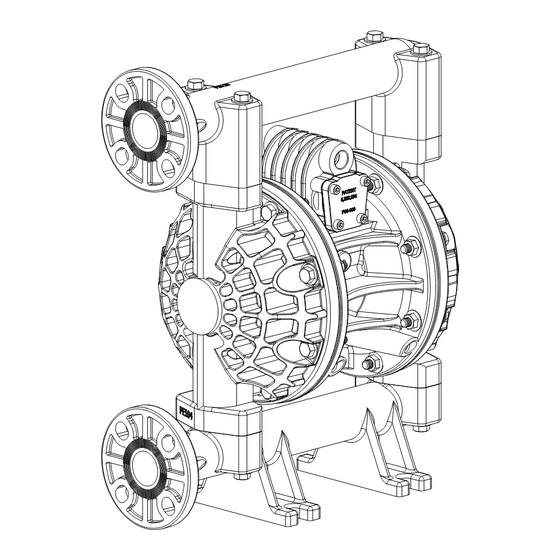

1" Elima-Matic Bolted Non-Metallic – ATEX

with Metallic Center Sections

E1 Non-Metallic Pumps

• Conductive Polypropylene

VERSA-MATIC

®

• Warren Rupp, Inc. • A Unit of IDEX Corporation

800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com

© Copyright 2014 Warren Rupp, Inc. All rights reserved

Advertisement

Summary of Contents for versa VT Series

- Page 1 1" Elima-Matic Bolted Non-Metallic – ATEX with Metallic Center Sections E1 Non-Metallic Pumps • Conductive Polypropylene VERSA-MATIC ® • Warren Rupp, Inc. • A Unit of IDEX Corporation 800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com...

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. - Page 3 Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..5 • Principle of Pump Operation • Typical Installation Guide • Troubleshooting SECTION 3: EXPLODED VIEW ......8 • Composite Drawings •...

- Page 4 3 (FKM) Fluorocarbon 3 (FKM) Fluorocarbon T Tef-Matic (2-piece) 4 Nordel 4 Nordel Diaphragm Series Valve Ball Material Valve Seat/Valve Seat O-Ring Material Construction Design B Versa-Tuff (1-piece) 5 PTFE 5 PTFE R Rugged 1 Neoprene 1 Neoprene 9 Bolted...

- Page 5 Materials Material Profile: Operating Polypropylene: A thermoplastic polymer. Moderate tensile 180°F 32°F and flex strength. Resists stong acids and alkali. Attacked by 82°C 0°C Temperatures: chlorine, fuming nitric acid and other strong oxidizing agents. CAUTION! Operating temperature limitations are as follows: Max.

- Page 6 Performance E1 1" Bolted Plastic Rubber and TPE Fitted Displacement Per Stroke, 0.11 Gal. (0.42 L) Flow Rate Adjustable to ..0-45 gpm (170.3 LPM) AIR CONSUMPTION IN SCFM Port Size AIR PRESSURE IN PSI Suction .

- Page 7 Dimensional Drawings E1 Non-Metallic Bolted Dimensions in inches (mm dimensions in brackets) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. 13.52 343.41 8.13 206.38 N 325 1" ANSI 150# / DIN 325 3/8"...

- Page 8 Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen. The main directional (air) control valve distributes ① compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm .

-

Page 9: Available Accessories

Recommended Installation Guide Available Accessories: 1. Surge Suppressor Unregulated Air Supply to Surge 2. Filter/Regulator Surge Suppressor Suppressor 3. Air Dryer Pressure Gauge Shut-Off Valve Pipe Connection Note: Surge Suppressor and (Style Optional) Piping must be supported after Flexible Connector Discharge the flexible connection. -

Page 10: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). Air valve or intermediate gaskets installed incorrectly. - Page 11 Torque Setting: 120 in-lbs. Composite Repair Parts Drawing FUSION DIAPHRAGM ASY Torque Setting: 120 in-lbs. Torque Setting: 180 in-lbs. Torque Setting: 40 in-lbs. PTFE TWO-PIECE DIAPHRAGM ASY Torque 120 in- Torque Setting: 180 in-lbs. Torque Setting: 180 in-lbs. Torque Setting: 180 in-lbs.

- Page 12 Composite Repair Parts List Air Valve Assembly Item # Qty. Description Part Number Air Valve Assembly (includes items 1-10) 031.V006.156 Valve Body P98-102UB Valve Spool Assembly (Includes items 3&4) P98-105UB ASY Large Valve Spool U-Cup P98-105B Small Valve Spool U-Cup P98-105A Metal End Cap P98-300...

- Page 13 Versa-Matic warrants to the original end-use purchaser that no product sold by Versa-Matic that bears a Versa-Matic brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Versa-Matic’s factory.

- Page 14 EC DECLARATION OF CONFORMITY in accordance with ANNEX VIII of Directive 94/9/EC - Equipment for use in Potentially Explosive Atmospheres Date of Issue: 10 May 2014 Technical File No.: 203104000-1410/MER Quality System Registration No: ISO 9001-2000 Directive: 94/9/EC 23 March 1994 Annex VIII Conforming Apparatus: Air-Operated Conductive Polypropylene and Conductive Acetal Double Diaphragm Pumps...

Need help?

Do you have a question about the VT Series and is the answer not in the manual?

Questions and answers