Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Bewo CPO 350

- Page 1 Manual CPO 315 & CPO 350 05-01-2004 CPO 315 & 350 Page 1 / 34...

-

Page 2: Dear Customer

Dear Customer, We at Machinefabriek BEWO take great pride in the manufacture of the CPO sawing machines and are confident that you will enjoy efficient productive Service for many years. We kindly request you to return the warranty certificate you find in the back of the manual as soon as possible. -

Page 3: Table Of Contents

Lubrication ........................14 Grinding the saw blades ..................... 14 Troubleshooting Lubrication and coolant supplies Overview of the available saw blades Providing spare parts Parts lists ever since page 17 Electric diagram 05-01-2004 CPO 315 & 350 Page 3 / 34... -

Page 4: Ec-Declaration Of Conformity For Machinery

Kroonstraat 15 5048 AP Tilburg The Netherlands Herewith declares that Machinetype : CPO 315 / 350 LT / HT Serial number : _______________________ Year of building : _______________________ is in conformity with the provisions of the Machinery Directive (Directive 89/392/EEC), as... -

Page 5: Introduction

• In case of danger resulting from defects, immediately contact the person in charge of the machine. • Support long workpieces. Your machine can easily be extended with Bewo roller conveyors. • Do not saw workpieces larger than those for which the machine was designed. - Page 6 Comply with the lubricating instructions and keep the machine clean. • Use original Bewo spare parts and accessories only. • Disconnect the mains while carrying out repairs or replacing parts. • Make sure the saw blade is not resting on the material when the machine is switched on.

-

Page 7: Guarantee

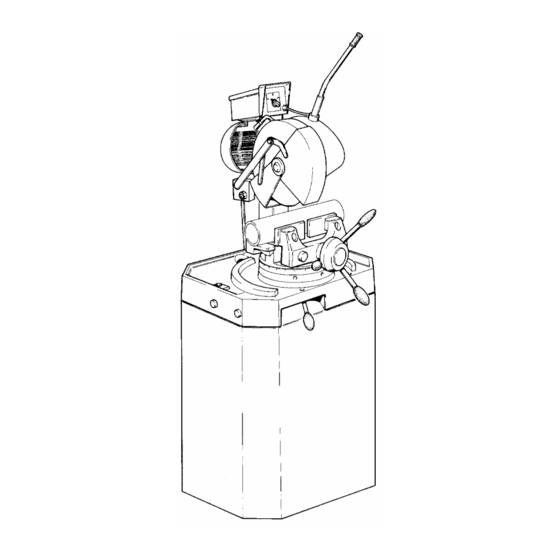

These are similar before LT and HT execution. CPO 315 Height: 1750 mm breadth: 555 mm Depth: 970 mm Weight: 187 kg CPO 350 Height: 1750 mm Breadth: 555 mm Depth: 970 mm Weight: 197 kg Fig 2.01 05-01-2004 CPO 315 & 350 Page 7 / 34... -

Page 8: Description Of Machine

• Check on the level gauge of the saw head whether it contains sufficient oil. If necessary fill up (fig. 4.01, see arrow). • Install the cover at the rear of the machine base. • Install the saw blade (see chapter 5.4). 05-01-2004 CPO 315 & 350 Page 8 / 34... -

Page 9: Non-Recurrent Adjustments

Fill the tank with coolant. Use sawing coolant and absolutely NO cutting oil. Bewo recommends Bewo Oil S, avaible from your dealer. The coolant must be diluted in waer in a ratio between 1:10 and 1:20, depending on the kind of material. Add the oil slowly to the water while stirring it continually. -

Page 10: Selection Of The Saw Blade

Selection of the tooth form. Besides a well selected pitch the following factors, too, are of great importance to facilitate the correct machining of the material (fig. 5.02): 05-01-2004 CPO 315 & 350 Page 10 / 34... -

Page 11: Sawing Capacity

For the maximum capacity in mm see the schedule for the profile figure/cross-cut in relationship with the mitre angle. Whit 90º we mean straight sawing. Use the table from the machine type you have, CPO 315 or CPO 350 90º... -

Page 12: Installing And Replacing The Saw Blade

The sawspeed will be selected by the switch (fig. 5.04A) The following cutting speeds are possible: CPO 315 LT > speed in position 1: 18,5 m/min in pos. 2: CPO 315 HT > speed in position 1: 37 m/min in pos. 2: CPO 350 LT >... -

Page 13: Clamping The Material

This will prevent a jolting saw, which results in damage and breakage. Bewo Oil S forms a lubricating film on the saw tooth points, so that, in case of increased saw feed, the high pressure between chip and tooth (chip surface of the saw tooth) will not lead to overheating of the saw. -

Page 14: Maintenance

Besides that it is advisable to check the saw optically in your own factory after they have been reground. In these optical checks special attention must be paid to the rake angle and the clearance angle. 05-01-2004 CPO 315 & 350 Page 14 / 34... -

Page 15: Troubleshooting

Cooling system does not 1. Cock on saw guard in work closed position. 2. Pump incorrectly connec- ted. 3. Pump defective 4. Cooling tank empty 5. Suction pipe of cooling pump obstructed. 05-01-2004 CPO 315 & 350 Page 15 / 34... -

Page 16: Lubrication And Coolant Supplies

Lubrication/cooling agents Packing Article number Cooling oil Bewo oil S 2 litres 34.0020 5 litres 34.0040 25 litres 34.0060 Gear box oil BP GRXP 680 2 litres 34.0100 Hydraulic oil BP BARTRAN 15 2,5 litres 34.0170 5 litres 34.0280 Survey of available saw blades... -

Page 17: Providing Spare Parts

Your order must contain the following information: Type of machine..................Mains voltage....................Year ofconstruction..................Description spare part................Quantity required…..................Article number…..................Besides spare parts you can also order coolant and saw blades. Parts lists 05-01-2004 CPO 315 & 350 Page 17 / 34... - Page 18 05-01-2004 CPO 315 & 350 Page 18 / 34...

- Page 19 44.2454 Sticker electro 48.3700 Sticker Bewo general 48.0021 Pump set 230/400V 50 HZ 65.2267 Screw M6x25 44.1335 *) Pump set contents: 111 A Pump 91.0500 111 B Hose 2 m 22.7052 05-01-2004 CPO 315 & 350 Page 19 / 34...

- Page 20 05-01-2004 CPO 315 & 350 Page 20 / 34...

- Page 21 Group 200 Pos.nr. Description Part nr. Anglescale 50.1199 Typeshield 50.1291 Rivet 44.3100 Ring 44.2344 Bold 44.1187 Filter (metal) 50.2041 Socket Screw 44.0134 Baseplate 50.1067 Swivel Block 50.0928 Greasingnipple 48.3510 Shaft 50.7490 05-01-2004 CPO 315 & 350 Page 21 / 34...

- Page 22 05-01-2004 CPO 315 & 350 Page 22 / 34...

- Page 23 Threaded shaft 50.0888 COMPOSED SPARES: > Repair set material vice, composed whit the position numbers 303, 339, 349, 350 and 353 95.0004 > Complete material vice, composed with all 95.0076 position numbers. 05-01-2004 CPO 315 & 350 Page 23 / 34...

- Page 24 05-01-2004 CPO 315 & 350 Page 24 / 34...

- Page 25 Socket screw 44.0159 Packing 21.9901 ALSO AVAILABLE: > Transmission oil sawhead 34.0100 1,1 l 1,1 l 1,1 l 1,1 l COMPOSED SPARES: > Composed saw spindle 95.0151 > Composed worm shaft 95.0152 05-01-2004 CPO 315 & 350 Page 25 / 34...

- Page 26 05-01-2004 CPO 315 & 350 Page 26 / 34...

- Page 27 50.0034 * including 506+508+505 ** including 506+508+512 COMPOSED SPARES: > Complete safety guard, CPO315 composed with all position numbers. 95.0073 > Complete safety guard, CPO350 composed with all position numbers. 95.0074 05-01-2004 CPO 315 & 350 Page 27 / 34...

- Page 28 05-01-2004 CPO 315 & 350 Page 28 / 34...

- Page 29 20.0520 Hood 47.6018 Seal 21.9901 * Including pos. 611, 613, 614 & 615 ** Be carefull: Maybe you have an another voltage machine. Please, make contact With your local Bewo dealer. 05-01-2004 CPO 315 & 350 Page 29 / 34...

- Page 30 05-01-2004 CPO 315 & 350 Page 30 / 34...

- Page 31 Pos.nr. Description Art.nr. Switch box 60.0579 Cover 50.0955 Sealing tape 21.9950 Screw M4x10 44.1000 Screw M5x12 44.1583 Spring washer 44.2451 Motor switch contactor (Dahlander switch) 46.0902 Earth bolt 46.6350 Sticker 48.3700 05-01-2004 CPO 315 & 350 Page 31 / 34...

- Page 32 05-01-2004 CPO 315 & 350 Page 32 / 34...

-

Page 33: Electric Diagram

05-01-2004 CPO 315 & 350 Page 33 / 34... - Page 34 05-01-2004 CPO 315 & 350 Page 34 / 34...

Need help?

Do you have a question about the CPO 350 and is the answer not in the manual?

Questions and answers