Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

IMPORTANT INFORMATION

Installation and Warranty Requirements

Installation must be by a Competent Person registered with HETAS Ltd.

Safe and Efficient Operation

Proper installation and operation are key to safe and efficient wood burning.

INTRODUCTION

Boiler Specifications and Use

Describes the 10kW output boiler for central heating and dwelling spaces.

Key Features and Benefits

Highlights long burn times, efficiency, stable heat, and superior design for modern homes.

TECHNICAL DESCRIPTION

Boiler Construction and Components

Details the construction of the boiler body, heat exchanger, and combustion gas flow.

Control Systems and Power Supply

Covers heat output regulation, stable heat mode, and the 12V power supply.

ASSEMBLY AND INSTALLATION

General Installation Guidelines

Covers compliance with regulations, standards, and pre-installation checks.

Location and Hearth Requirements

Specifies minimum distances from combustible surfaces and hearth requirements.

Air Supply to Boiler

Combustion Air Sources and Vents

Discusses room air intake, external air supply options, and air vent specifications.

External Air Supply and Troubleshooting

Details external air supply kits, connection requirements, and troubleshooting for smoking.

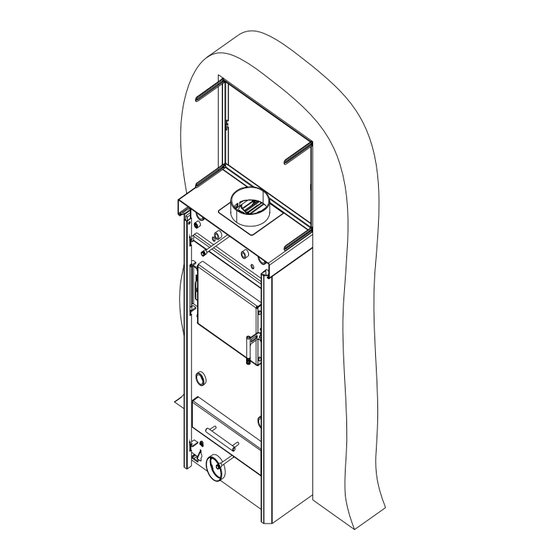

Building In (Rear Stoking Model)

Metal Liner Installation and Dimensions

Explains the use of a metal liner for wall installation and provides wall opening dimensions.

Connection to the Chimney

Chimney Safety, Draught, and Materials

Emphasizes clearances, non-combustible materials, insulation, and minimum draught requirements.

Flue Pipe and Masonry Chimney Standards

Details correct flue pipe material, joints, length, and standards for masonry chimneys.

Chimney Systems and Termination

Liners, Prefabricated Chimneys, and Termination Clearances

Discusses approved liners, insulated twin wall chimneys, and required flue outlet clearances.

Connection to the Heating System

System Design and Boiler Connections

Covers open/sealed systems, pressure limits, and boiler water connections.

Pumped Circulation and Sealed System Safety

Details methods for preventing overheating and safety measures for sealed systems.

Automatic Cooling Loop System

Installation, Operation, and Safety Valve

Explains how to connect and test the automatic cooling loop for safety.

CASING ASSEMBLY INSTRUCTIONS

Initial Inspection and Preparation

Advises on checking casing parts for damage before assembly.

CASING ASSEMBLY INSTRUCTIONS (Continued)

Power Cable Routing and Side Cover Installation

Details routing the power cable and attaching the side covers correctly.

CASING ASSEMBLY INSTRUCTIONS (Continued)

Fitting Front and Top Covers

Instructions for attaching the front and top covers, including securing bolts.

Damper Rod and Front Stoking Assembly

Covers fitting the damper rod and components for the front stoking design.

CASING ASSEMBLY INSTRUCTIONS (Continued)

Flue Connection and Warming Plate Mounting

Instructions for mounting the flue connection and warming plate.

Rear Stoking Design Knobs

Covers screwing knobs onto the damper and riddling rods for the rear stoking design.

OPERATION INSTRUCTIONS

General Operating Principles

Outlines requirements for safe and efficient operation by adults.

Lighting the Boiler

Step-by-step guide for safely lighting the boiler.

OPERATION INSTRUCTIONS (Continued)

Lighting Aids and Chimney Warm-up

Tips for speeding up lighting and ensuring proper chimney warm-up.

Stoking Procedure

Guidance on when and how to add fuel for optimal burning.

Output Control

Regulating Heat Output

Explains how to adjust heat output using the control wheel and air inlets.

Combustion Control

Assessing and Optimizing Combustion

Discusses how to assess and maintain efficient combustion by observing flames and smoke.

Stable Heat Operation

Automatic Stable Heat Mode Functionality

Explains the stable heat mode function, calibration, and checking procedures.

Fuel

Fuel Types, Properties, and Restrictions

Covers recommended fuels, moisture content, and wood density for optimal burning.

Fuel and Ash Management

Fuel Burning Advice and Ash Handling

Warns against burning green wood, moist wood, plastics, or synthetics and provides ash handling instructions.

Boiler Cooking Functionality

Mentions the use of the top plate for warming food.

Maintenance and Repair

Routine Maintenance Schedule and Cleaning

Outlines regular inspection, cleaning, and testing of safety devices.

Essential Maintenance Checks

Lists essential checks during maintenance, such as water temperature and seal condition.

Door Adjustment and Disposal

Door Seal Adjustment and Packaging Disposal

Instructions for adjusting the door catch and methods for recycling packaging.

Boiler End-of-Life Disposal and Accessories

Covers boiler disposal at end-of-life and lists supplied accessories.

SAFETY INFORMATION

General Safety Precautions and Handling

Covers installation, handling, and personal safety measures.

Emergency Procedures and Child Safety

Details actions for overheating, chimney fires, and emphasizes child safety.

BOILER CONNECTION EXAMPLES

Heat Store and Pumped System Configurations

Illustrates connection to a heat store via a semi-gravity circuit and a fully pumped system.

BOILER CONNECTION EXAMPLES (Continued)

Partial Gravity and Sealed System Diagrams

Shows diagrams for systems with partial gravity circulation and fully pumped sealed systems.

BOILER CONNECTION EXAMPLES (Continued)

Underfloor Heating and Additional Boiler Systems

Illustrates systems for underfloor heating and augmenting existing solid fuel boilers.

BOILER CONNECTION EXAMPLES (Continued)

Integration with Existing Gas/Oil Boilers

Shows how to link the boiler with existing gas or oil heating systems, preferably via a heat store.

GUARANTEE CONDITIONS

Guarantee Eligibility, Period, and Claims

Details requirements for installation, warranty period, and how to make claims.

Warranty Exclusions and Support

Lists warranty exclusions and provides information on technical support and spares.

Need help?

Do you have a question about the 10 and is the answer not in the manual?

Questions and answers