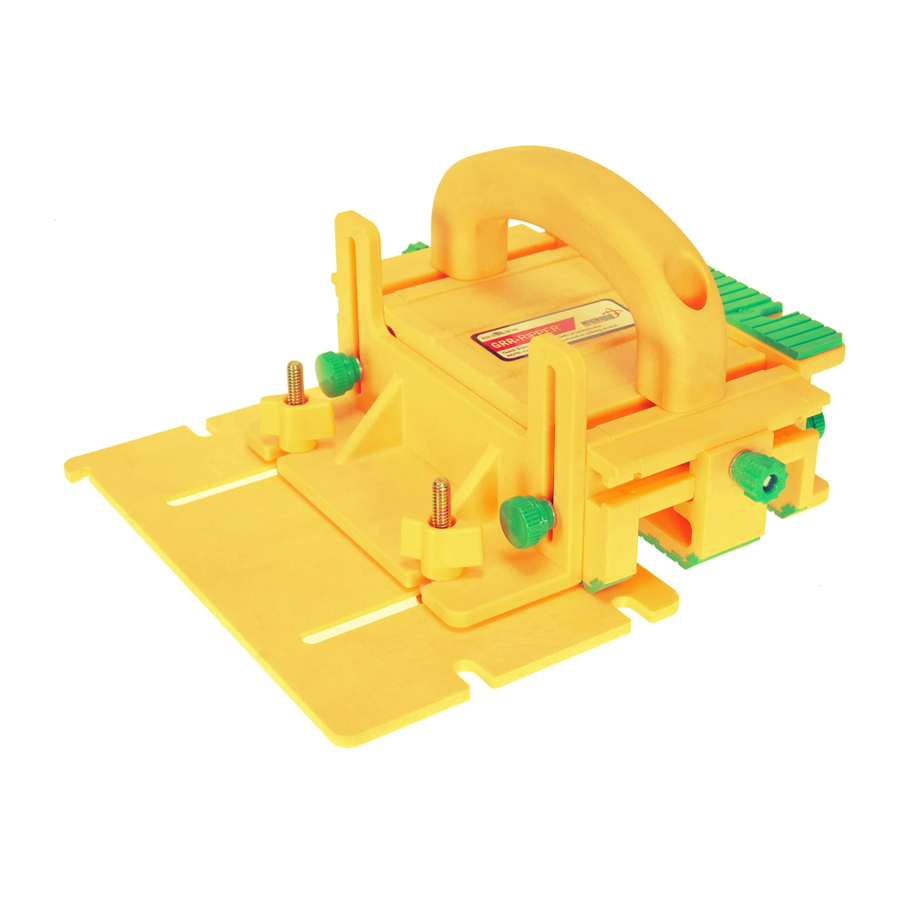

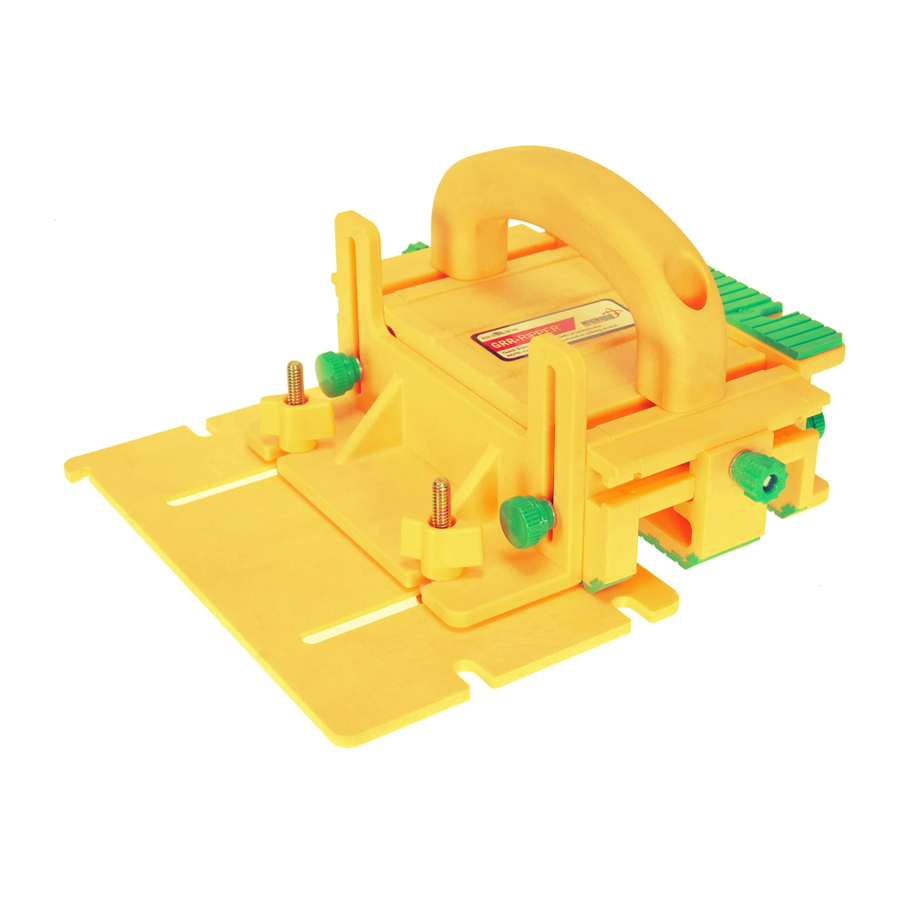

microjig GRR-RIPPER GR-100, GRR-RIPPER GR-200 Manual

- Instruction manual (12 pages) ,

- Instruction manual (22 pages)

Advertisement

Overview

NOTE: Please check to ensure that you have all parts and hardware before assembling.

If you have purchased the GRR-RIPPER Upgrade Kit (GRAK-404) please reference Step 6 for installation instructions.

| GRR-RIPPER PARTS | GR-100 | GR-200 | |

| 1 | GR-P1 - Handle | 1 | 1 |

| 2 | GR-P2 - Main Body | 1 | 1 |

| 3 | GR-P3 - Center Leg | 1 | 1 |

| 4 | GR-P4 - 1/2" Side Leg | 1 | 1 |

| 5 | GR-P5 - 1/4" Side Leg | 1 | 1 |

| 6 | GR-P6 - Balance Support | 1 | 1 |

| 7 | GR-P7 - Stabilizing Plate | 1 | |

| 8 | GR-P8 - Adjustable Spacer | 1 | |

| GR-100 | GR-200 | ||||

| HARDWARE | Red Bag | Blue Bag | |||

| A | GR-H1 - #10 x 7/16" OD Washer |  | 8 | 8 | 2 |

| B | GR-H2 - 1/4 x 1/2" OD Washer |  | 2 | 2 | |

| C | GR-H3 - 9/32" OD O-Ring (#10 screw) Black |  | 6 | 6 | 2 |

| D | GR-H4 - 5/16" OD O-Ring (1/4-20 screw) Orange |  | 2 | ||

| E2 | GR-H56 - 10-32 x 1/2" Green Thumb Screw |  | 2 | 2 | 2 |

| F2 | GR-H6 - 10-32 Green Round Knob |  | 2 | 2 | |

| G | GR-H7 - 1/4-20 Oval Nut |  | 2 | 2 | |

| H2 | DV-H1 - 10-32 x 1" Green Dovetail T-Bolt |  | 2 | 2 | |

| K | GR-H10 - 1/4-20 x 3/4" Pan Head Screw |  | 2 | 2 | |

| L | GR-H11 - 10-32 x 1/2" Pan Head Screw |  | 4 | 4 | |

| M | GR-H12 - 1/4-20 x 1 3/4" T-Bolt |  | 2 | ||

| N2 | GR-H55 - 1/4-20 Yellow Wing Knob |  | 2 | ||

| P | GR-H14 - Nylon Shoulder Washer |  | 2 | ||

The GRR-RIPPER 3D Pushblock system is able to control stock narrower

or shorter than the GRR-RIPPER on woodworking machines. You must make sure that the

Balance Support and the Adjustable Spacer are properly adjusted to keep the GRR-RIPPER

balanced on the stock so it will not tip in any direction. Example shown in Figure 16

You must pay attention to the gripping effectiveness of the Green

GRR-RIP ® non-slip pads before every use. Do not use the GRR-RIPPER if you feel it is not

gripping the stock. Clean with denatured/rubbing alcohol or replace the leg(s) with new

Green GRR-RIP non-slip pads, if necessary.

TIP: Parts listing page folds out for your convenience. Reference this page during assembly.

Have questions? Need support? Contact MICROJIG directly.

Phone: 1-855-RIP-SAFE

International: 1-407-696-6695

Email: support@microjig.com

Online: MICROJIG.com/support

Work safer. Work smarter.

INTRODUCTION

Over 5,000 hours of engineering, 45 design concepts and prototypes went into making the GRR-RIPPER the safest, most precise pushblock available. Before using your GRR-RIPPER, read through this manual to familiarize yourself with the GRR-RIPPER and how it works.

The following is a general overview of the way the GRR-RIPPER is designed to work:

The GRR-RIPPER uses grooved non-slip pads (Green GRR-RIP ® ) to hold down and feed your workpiece through the cutting element. The tool can be rotated endto-end to for use with either the 1/2" or 1/4" Side Leg against the fence.

With the rip fence set parallel to the saw blade, the GRR-RIPPER glides against the rip fence to ensure a parallel feed. It also keeps both sides of the workpiece in their original positions throughout the cutting process, which virtually prevents the possibility of kickback and burning. With bare-hand feeding eliminated, finger injury is greatly reduced.

The GRR-RIPPER feeds the workpiece as the saw blade passes through either its right or left tunnel. This feature virtually eliminates the need for barehand feeding when used properly. The GRR-RIPPER is a protective guard that you hold throughout the cutting operation.

Fully adjustable for your project needs

- The Adjustable Handle can be relocated directly above the cut-line, providing balanced and concentrated pressure.

- The height-adjustable Balance Support accommodates different thicknesses of stock.

- The adjustable Center Leg precisely supports different widths of cuts, providing complete control of both sides of stock.

- Wooden riser spacers can be added for use with stock thicker than 2". Attach with #8 pan head wood screws and washers (not included).

- A wooden spacer can also be added between the GRR-RIPPER and the fence to increase the cutting width capacity of the GRR-RIPPER.

- Fully adjustable GRR-RIPPER controls wood of different widths and thicknesses.

RECEIVE THE MICROJIG E-NEWSLETTER

Get our free whitepaper on "4 Easy Ways to Tune Up Your Table Saw" by signing up for the MJ INSIDER. Join the smartest woodworkers worldwide today. Go to microjig.com/newsletter and enter your email address. Work smarter.

OPERATION PRECAUTIONS & SAFETY

SAFETY

Operation of the GRR-RIPPER 3D Pushblock system includes the use of a table saw or other tools that are not part of the GRR-RIPPER. Micro Jig, Inc. assumes no liability for any product not sold and manufactured by Micro Jig, Inc. You must take all necessary precautions when operating a table saw or other tools as recommended by their manufacturers or as required by any prudent tool user. You must also read and agree to the safety precautions and terms listed below before using the GRR-RIPPER 3D Pushblock system. Your assembly of the GRR-RIPPER 3D Pushblock system indicates your agreement to follow these safety precautions and terms when using this tool.

The following operation precautions of using the GRR-Ripper on table saw are based on the rip fence is installed to the right of saw blade.

BEFORE USE

- The GRR-RIPPER 3D Pushblock System includes three legs with non-slip pads. A minimum of two legs MUST be installed during any cutting operation.

- Use at least one leg to the right and one leg to the left of the saw blade whenever possible.

- Before every cut, you must look through from the end of the tool after it is in an operational position to make sure the cutter will go through the tunnel between the legs throughout the cutting operation without touching any component of the tool or other objects except the workpiece.

- The bottom of the workpiece must be flat enough so that it does not rock on the table top. The top of the workpiece must be flat enough so all non-slip surfaces are in full contact with the top surface of the workpiece.

- In table saw operation, the face of the Side Leg on the right must be in full contact with the rip fence at all times in order to create a parallel guide for forward feeding and inward pressure against the rip fence.

- The saw blade must not be set more than 3/4" higher than the top surface of a flat workpiece. The ideal height is when the top gullet is slightly above the top surface of the workpiece.

- In table saw operations, the rip fence must be securely locked parallel to the saw blade within the usable range of the GRR-RIPPER 3D Pushblock system.

- When using this tool in conjunction with any other tool, first read and follow all instructions and safety information in the owner's manual for that tool.

- Always wear safety glasses and hearing protection. Follow all normal shop safety practices.

- It is the sole responsibility of the purchaser of this product to ensure that any third party reads and agrees to all safety precautions and terms prior to their use of this tool.

PROPER USE

- In table saw operations, the GRR- RIPPER 3D Pushblock system must be used so it is in full contact with the rip fence at all times, and the saw blade MUST pass through and without cutting into any part of the GRR-RIPPER.

- Use maximum possible coverage of the non-slip pads on the workpiece.

- The GRR-RIPPER 3D Pushblock system must be used in an absolute stable condition. When a workpiece is narrow and is not covered by the leg on the left (away from fence), the Balance Support must be secured to the left leg so the bottom surface of the Balance Support is in full contact with the table top to secure the steadiness of the tool during the entire cutting operation.

- The non-slip pads placed on the top surface of the workpiece must be in full contact with the workpiece. Frequently inspect the effectiveness of the non-slip pads. Remove built-up dust as necessary with denatured or 91% rubbing alcohol.

- When using only one GRR-RIPPER, we suggest both hands on the tool; one gripping the handle, and the other placed on top of the main body.

- Use the Balance Support, Adjustable Spacer and Stabilizing Plate as appropriate to help support and control small or irregularly shaped parts. Figure 16. If the GRR-RIPPER does not appear stable, or you are not confident in making the cut, do not proceed.

- Use saw blades that are designed for the intended cutting operation.

- All components must be inspected for damage and securely fastened before every use. Stop using the tool if any damage occurs.

- Do not use this product while under the influence of drugs, alcohol or any medication.

MAINTENANCE

- To clean this product, use denatured alcohol (available in the paint department of home improvement centers) or 91% rubbing alcohol (available at drug stores).

- Do not use this tool if any of the components are damaged. Contact your dealer or the manufacturer for replacement parts.

- When not in use, store this product on a flat and clean surface.

TABLE SAW PREPARATION

- The machine tabletop used in conjunction with this tool must be flat and free from obstructions other than the required fence and one cutting element. The tabletop must be reasonably level and below the waistline.

- You must have a sturdy and straight rip fence with a flat front surface preferably at least 3" in height and square to the table saw top. The rip fence must be long enough to cover the entire depth from the front to the rear of your table saw top. The rip fence must also be equipped with a locking mechanism to secure it on the table saw top so that it is parallel to the saw blade at all scale settings.

DO NOT SKEW THE RIP FENCE! The GRR-RIPPER is designed to feed wood parallel to the saw blade. - The rip fence should also be accurately calibrated to a fixed scale to secure a precise cutting width setting.

- sharp and clean carbide-tipped saw blade should be used with this tool for ripping, unless otherwise specified.

- Zero-Clearance Throat Plate or insert (ZCI) should always be used when cutting narrow strips. INFO: Watch our online video on how to install a Zero- Clearance Throat Plate: microjig.com/zci

Never wear loose clothing, gloves, bracelets or other jewelry that may get caught in the moving parts or cutting elements.

ASSEMBLY

ASSEMBLY – GRR-RIPPER MODEL GR-100

Assembly video available online at microjig.com/gr-assembly

INFO: If you purchased a GRR-RIPPER Handle Bridge Kit (GRHB-010), please refer to its instruction manual for installation first, and then resume GRR-RIPPER assembly at Step 2.

Assemble Handle (1) to the top slots of Main Body (2).

- Attach mounting hardware to Center Leg (3).

- Assemble Center Leg (3) to the end slots of Main Body (2) (see Figure 6A).

Close-up view with Handle and Center Leg installed on Main Body

Close-up of O-Ring embedded in counter-bore

- Install both Side Legs (4) and (5) in the same manner on opposite sides of the Main Body (2).

- Insert the screws and washers through the front screw holes, insert the O-Rings from the back side. See Figure 8 for detail.

INFO: If you purchased the GR-200, do not confuse the smaller Black (C) and larger Orange O-Rings (D).

- Attach Thumb Screws (E2) to Balance Support (6).

- Assemble Balance Support (6) to either Basic Model GR-100 completed Side Leg (4) or (5).

COMPLETED GR-100

TIP: To keep the non-slip pads working most effectively, clean the contact surfaces with denatured alcohol or 91% rubbing alcohol and a shop rag prior to use. Repeat cleaning during use as necessary when saw dust accumulates. Do not use if Green GRR-RIP is not effectively gripping the workpiece. Please contact MICROJIG in regards to product issues.

ASSEMBLY – GRR-RIPPER ADVANCED MODEL GR-200 (GR-100+GRAK-404)

Assembly video available online at microjig.com/gr-assembly

With hardware installed, snap the Stabilizing Plate (7) into the open slots of the Balance Support (6). Do not tighten completely. Attach to Balance Support (6) and tighten when desired position is achieved. It is by design that the open slots are narrower than the Shoulder Washer (P), so that the Stabilizing Plate (7) will remain in place during adjustments. The Stabilizing Plate (7) can also be used with its straight edge facing the GRR-RIPPER.

TIP: Push the Orange O-Ring (D) through the T-Bolt (M) all the way down, making contact with the Stabilizing Plate (7) before inserting the Shoulder Washer (P) and the Thumb Knob (N).

The Adjustable Spacer (8) can be attached to either side of the GRR-RIPPER as needed. It can be used with the non-slip pad downward to provide additional gripping surface pressure. Lower it to achieve two levels of pushing surfaces. It can also perform as a "balancing device" with the non-slip pad facing upward.

COMPLETED GR-200

HOW TO USE

HOW TO USE THE GRR-RIPPER

- The GRR-RIPPER 3D Pushblock System is designed to glide along the rip fence of a table saw, therefore the rip fence must be parallel to the saw blade in order to maintain the parallel feed.

- The saw blade should be raised just enough in height to clear the gullets from the top surface of wood pieces, normally about 1/4" to 3/8". Pay extra attention on workpieces that are not equal in thickness such as tapered stock. The tunnel has a clearance of 15/16" in height.

- The saw blade must pass through the adjustable tunnel and between the legs for maximum safety. Visually check the Saw Blade Tunnel before turning on your saw to make sure that the saw blade will not cut into any component of the GRR-RIPPER.

- When using only one GRR-RIPPER, we suggest both hands on the tool; one gripping the handle, and the other placed on top of the main body. Place one hand in the inclined position and grip the Handle (1). Place the other on the top of the Main Body (2) to provide added pressure against the rip fence, additional forward feeding and firm downward pressure on the workpiece.

NEVER feed stock using bare hands when using the GRR-RIPPER.

- For best cutting results, use one nonstop feed from start to finish - do not pause during the cutting operation. Push the workpiece completely clear of the saw blade, stop the motor, and wait for the saw blade to come to a complete stop before releasing pressure from the workpiece.

- Depending on your table saw model, the GRR-RIPPER system should be placed about 1" to 4" from the trailing end of the workpiece, otherwise, the tool will be off the table saw top at the rear before the workpiece will be clear of the saw blade.

- If workpiece is longer than 16", the use of two GRR-RIPPER systems is recommended.

Use the "leap-frogging" technique for cutting stock of unlimited length. INFO: Watch the online video: microjig.com/leapfrog

GRR-RIPPER Quickstart Video available online at microjig.com/worksafer

ADJUSTING THE GRR-RIPPER

- The Handle (1) can be secured at an angle in relation to the Side Legs (see Figure 17 ). Angling the handle allows for individual ergonomic comfort.

- The non-slip pads are molded from a thermal plastic that compresses slightly when downward pressure is applied. When setting the height of the Balance Support (6), it is best to set the non-slip pads over the workpiece, put normal downward pressure from the Handle (1), lower the Balance Support (6) until it fully contacts the table saw top, then secure the Balance Support (6) in that position before releasing pressure from the Handle (1). Double-check the setup by applying downward pressure on the tool with one hand and slightly pulling the workpiece under the tool. If not enough contact pressure in either the front or rear, adjust the Balance Support (6) accordingly.

- If the width of the cut is between 1/4" to 5/8" on the Inside Cut, use the 1/4" Side Leg (5) on the right against the rip fence. If the width of the cut is less than 1/4", it should be obtained from Outside Cut as shown in Figure 15. One advantage of using the GRR-RIPPER for cutting thin strips over the conventional push block method is that the width of your prepared stock on the Inside Cut area is substantially reduced. Yield is greatly increased by saving material, thus reducing costs. Most importantly, the saw blade is always within the tunnel, which provides protection for your fingers.

- For a wider Inside Cut that is beyond the limits of the GRR-RIPPER system, wooden spacers of an appropriate width can be added to the Side Leg against the fence (see Figure 3). Drill a couple of counter bored holes (5" center-to-center) for 10-32 pan head screws and secure it to the brass inserts on the Side Legs. Alternately, you can use #8 pan head wood screws from the inside wall of the 1/2" Side Leg (4).

Always visually check to ensure that the Saw Blade Tunnel has enough clearance for the saw blade to pass through safely before turning on the saw.

USING THE 1/4" LEG

Use the 1/4" Leg (5) against the fence for cutting width (Inside Cut) of 1/4" to 5/8". Note the location of the Handle (1) above the cut line in order to apply balanced pressure to both sides of the stock.

GRR-RIPPER Quickstart Video available online at microjig.com/worksafer

USING THE 1/2" LEG

Use the 1/2" Leg (4) against the fence for cutting width (Inside Cut) of 5/8" to 3 3/16". Use the Balance Support (6) when stock is not wide enough to be under the Side Leg on the left. The Handle (1) is secured more towards the right side of the saw blade since no pressure is required on the left side of the cut.

IRREGULARLY SHAPED STOCK

BALANCE SUPPORT SPACER

Using the Balance Support (6) against the fence will provide an additional 2" of cutting width. The Adjustable Spacer (8) can be used on the left as a balancing device.

Resawing: You can resaw narrow stock in one pass without a bandsaw, planer or flat-bed sander.

Stock must be square before resawing.

RESAWING

Resaw to 1/4" (Inside Cut) or thicker in one pass as shown in Figure 18. Note Handle (1) location.

Resawing stock thinner than 1/4", or resawing wider stock, can be achieved in two passes by setting the saw blade slightly higher than one half of the width of the stock in the first pass. Flip the stock over and finish with a second cut.

Suggestion: Resawing stock thinner than 1/4" should be obtained from the outside cut.

A wooden spacer can be added to the Balance Support (6) for stock wider than 2" (see Figure 3).

GROOVING A ROUND DOWEL

With one of the Side Legs removed, the Center Leg (3) is registered against the rip fence, and the Stabilizing Plate (7) of a GR-200 holds the dowel against the rip fence. You can also split a round dowel in half.

BEVEL CUTS

When bevel cutting from 0 to 45 degrees, the GRR-RIPPER provides great control and virtually eliminates binding.

PATTERN ROUTING

Securely holds and guides a small workpiece against a template without tipping over. Use Balance Support (6) to stabilize the GRR-RIPPER when working with narrow or small material.

SLOTTING

Use the Stabilizing Plate (7) of the GR-200 as a second fence to box-in the workpiece on the router table.

CONTROL & FEED LONG STOCK

For stock longer than 16", please use two GRR-RIPPERs in a "leap-frog" operation to continuously feed the workpiece.

GRR-RIPPER ACCESSORIES

1/8" Leg

Part Number: GRP-11G

Handle Bridge Kit

Part Number: GRHB-010

Fits all GRR-RIPPER models. Rip 1/8" thin strips safely, accurately, and consistently on a table saw with the GRR-RIPPER 1/8" Leg. SEE IT IN ACTION: Watch the online video: microjig.com/thinleg

Fits all existing GRR-RIPPER models. Unique arch design gives the handle four points of contact to evenly distribute the downward pressure. Allows you to angle the handle for more ergonomic comfort.

Gravity Heel Kit

Part Number: GRGH-040

Fits all GRR-RIPPER models. The Adjustable Heel hooks onto the tail-end of your workpiece and automatically retracts when midboard. Reduces tearout on table saws and router tables. Adjustable depth and can lock into position.

SEE IT IN ACTION: Watch the online video: microjig.com/gravityheel

Upgrade your GRR-RIPPER today.

Buy accessories and more at microjig.com/store

Documents / Resources

References

![microjig.com]() Contact Us | MICROJIG Woodworking Tools

Contact Us | MICROJIG Woodworking Tools![microjig.com]() MICROJIG – Smarter Woodworking Tools

MICROJIG – Smarter Woodworking Tools![microjig.com]() Build a Dual Kerf Zero Clearance Throatplate (ZCI) Plate - YouTube

Build a Dual Kerf Zero Clearance Throatplate (ZCI) Plate - YouTube![microjig.com]() GRR-RIPPER 2018 Instructions | Chapter 01 - Assembly - YouTube

GRR-RIPPER 2018 Instructions | Chapter 01 - Assembly - YouTube![microjig.com]() Cutting Long Stock with two GRR-RIPPERs - YouTube

Cutting Long Stock with two GRR-RIPPERs - YouTube![microjig.com]() MicroJig

MicroJig![bit.ly]() - YouTube

- YouTube![microjig.com]() How to Split a Round Dowel on a Table Saw Safely - YouTube

How to Split a Round Dowel on a Table Saw Safely - YouTube![microjig.com]() Bevel Ripping on a Table Saw Safely - GRR-RIPPER - YouTube

Bevel Ripping on a Table Saw Safely - GRR-RIPPER - YouTube![microjig.com]() GRR-RIPPER 1/8" Leg™ Accessory | #1 Best-Selling Table Saw Push Block

GRR-RIPPER 1/8" Leg™ Accessory | #1 Best-Selling Table Saw Push Block![microjig.com]() GRR-RIPPER Gravity Heel Kit | #1 Best-Selling Table Saw Push Block

GRR-RIPPER Gravity Heel Kit | #1 Best-Selling Table Saw Push Block![microjig.com]() MICROJIG – Smarter Woodworking Tools

MICROJIG – Smarter Woodworking Tools

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Download microjig GRR-RIPPER GR-100, GRR-RIPPER GR-200 Manual

Advertisement

Need help?

Do you have a question about the GRR-RIPPER GR-100 and is the answer not in the manual?

Questions and answers