Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Evco EVDRIVE05

- Page 1 EVDRIVE05 Driver for unipolar stepper and pulse motorised electronic expansion valves WARNING Make sure you read and fully understand the manual before using this device. Non-observance of these instructions may result in death or serious injury. Operating manual 114EV05E4.00 - 10/2024...

-

Page 2: Table Of Contents

2. TECHNICAL SPECIFICATIONS ....................11 2.1 Technical specifications ........................11 2.1.1 EVDRIVE05 ..............................11 2.2 I/O specifications ..........................12 2.2.1 EVDRIVE05 Unipolar ..........................12 2.2.2 EVDRIVE05 Pulse............................12 3. MECHANICAL ASSEMBLY ......................13 3.1 Before you start ...........................13 3.2 Information concerning installation and the surrounding environment ........13 3.3 Dimensions ............................14... - Page 3 11.1 Table of alarms ...........................36 12. MODBUS RTU FUNCTIONS AND RESOURCES ................37 12.1 Introduction ............................37 12.2 Modbus message structure ......................37 12.3 Modbus functions and registers ......................37 12.3.1 Available Modbus commands and data areas ..................38 114EV05E4.00 - EVDRIVE05 | 3 | Contents | 10/2024...

- Page 4 CONTENTS 12.4 Address configuration ........................38 12.5 Connections ............................38 12.6 Modbus table content ........................38 12.7 Modbus addresses ..........................39 12.7.1 Modbus parameter and address table ....................39 12.7.2 Modbus resource and status table .......................43 114EV05E4.00 - EVDRIVE05 | 4 | Contents | 10/2024...

-

Page 5: Important Legal Information

LIABILITY AND RESIDUAL RISKS EVCO assumes no liability for any damage caused by the following (by way of example; this is not an exhaustive list): • Installation/use for purposes other than those specified and, in particular, not adhering to the safety provisions set out by current regulations in the country in which the product is installed and/or contained in this manual;... -

Page 6: Important Safety Information

UNAUTHORISED PERSONNEL The device must not be used by persons (including children) with reduced physical, sensory or mental capabilities or persons with no experience or knowledge. 114EV05E4.00 - EVDRIVE05 | 6 | Important safety information | 10/2024... -

Page 7: Safety Precautions Concerning The Product And Its Use

• Do not install or use this device in applications which are capable of generating hazardous atmospheres, such as applications that use flammable refrigerants. 114EV05E4.00 - EVDRIVE05 | 7 | Safety precautions concerning the product and its use | 10/2024... -

Page 8: Information Concerning The Document

Make sure you read and fully understand the manual before using this device. Non-observance of these instructions may result in death or serious injury. PURPOSE OF THE DOCUMENT This document describes the driver for EVDRIVE05 unipolar stepper and pulse motorised electronic expansion valves. The information provided includes: • Safety;... -

Page 9: Introduction

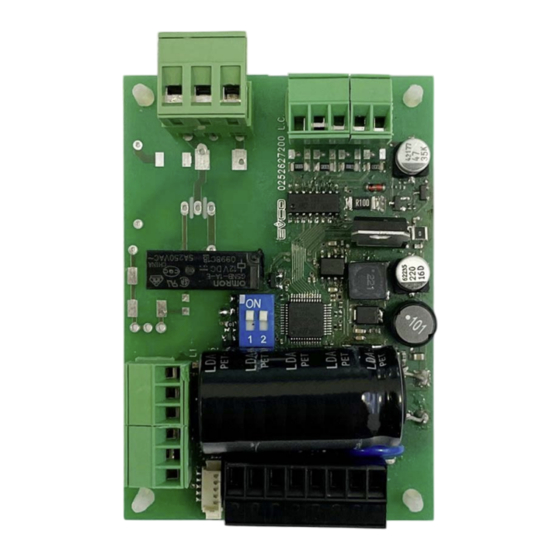

1. INTRODUCTION 1.1 DESCRIPTION The EVDRIVE05 series driver is EVCO’s comprehensive solution for managing unipolar stepper and pulse motorised electronic expansion valves to meet the requirements of the HVAC/R market. Among the numerous functions, it is worth mentioning its ability to operate in both stand-alone mode and under the supervision of a controller, manage generic electronic expansion valves and the most common Sporlan, Danfoss, Sanhua valves, and manage backup probes. -

Page 10: Accessories

1.4 ACCESSORIES The accessories available for the EVDRIVE05 are: Type Description EVTPN530F202 NTC FAST temperature probes (intake temperature) NTC temperature probes up to 150 °C (discharge EVTPN815S201 temperature) EVTPMC15V200 Pt1000 temperature probes 0...350 °C with fibreglass cable TTL RS-485 EVlinking... -

Page 11: Technical Specifications

Use metal casing to improve EVDRIVE05 system immunity to electromagnetic fields. This equipment satisfies the EC requirements as indicated in the tables below. -

Page 12: I/O Specifications

2.2 I/O SPECIFICATIONS 2.2.1 EVDRIVE05 Unipolar Type Description Digital inputs 1 voltage-free digital input (3.3 Vdc, 1 mA) Analogue inputs 1 analogue input for NTC, Pt1000, 0...5 V, 0...20 mA or 4...20 mA 1 analogue input for NTC or Pt1000... -

Page 13: Mechanical Assembly

• Only install and use this device in sites that are not at risk. • Do not install or use this device in applications which are capable of generating hazardous atmospheres, such as applications that use flammable refrigerants. 114EV05E4.00 - EVDRIVE05 | 13 | Mechanical assembly | 10/2024... -

Page 14: Dimensions

• Do not connect wires to unused terminals and/or terminals marked with the text “No connection” (“N.C.”). 3.3 DIMENSIONS 3.3.1 EVDRIVE05 mm (in.) FIG. 1. EVDRIVE05 dimensions 3.4 INSTALLATION Only install the EVDRIVE05 on plastic spacers (not supplied) in the electrical panel. 114EV05E4.00 - EVDRIVE05 | 14 | Mechanical assembly | 10/2024... -

Page 15: Electrical Connections

• Do not use this equipment for machine functions that are critical to safety. • Do not disassemble, repair or modify the equipment. • Do not connect wires to unused terminals and/or terminals marked with the text “No connection” (“N.C.”). 114EV05E4.00 - EVDRIVE05 | 15 | Electrical connections | 10/2024... -

Page 16: Guidelines For Screw Terminals

• When connecting the RS-485 serial line, use cables that are no longer than 1000 m (3280 ft). • When connecting the digital outputs, use cables that are no longer than 10 m (32.80 ft). 114EV05E4.00 - EVDRIVE05 | 16 | Electrical connections |... -

Page 17: Wiring Diagram

4.2 WIRING DIAGRAM 4.2.1 EVDRIVE05 Unipolar Out1 M T D ~ 12 V 12 V Power supply FIG. 4. EVDRIVE05 Unipolar connection diagram TERMINALS C Common AI T analogue input AI T 2B Coil 2 ID1 digital input Unipolar valve stepper motor... -

Page 18: Evdrive05 Pulse

4.2.2 EVDRIVE05 Pulse Pulse M T D ~ 12 V 12 V Power supply FIG. 5. EVDRIVE05 Pulse connection diagram TERMINALS Power supply 0...5 V ratiometric transducers Power Supply Input (5 Vdc ±5 %, 40 mA maximum) ID1 digital input... -

Page 19: User Interface

5. USER INTERFACE LED1 LED2 FIG. 6. LED EVDRIVE05 5.1 HOW LEDs WORK Lit steadily Flashing rapidly Flashing slowly Positioning completed EEV positioning Positioning completed Positioning completed LED 1 (EEV position <5 %) in progress (EEV position >95 %) (5 % < EEV position <95 %) -

Page 20: Machine Statuses

EVDRIVE05 waits for valve synchronisation to be completed and moves on to the next status. 6.2.3 Awaiting positioning end EVDRIVE05 waits for valve positioning to be completed at 0 absolute steps and moves on to the next status. 6.2.4 Standby When the valve is disabled and has completed positioning it stops in this status. -

Page 21: Equalisation (Phase 1) / Stabilisation (Phase 2)

S25 Manual positioning setpoint. NOTICE MALFUNCTIONING OF THE EQUIPMENT Writing continuously to R07 may damage the EVDRIVE05 memory and compromise device operation. 6.4 ALGORITHM EVDRIVE05 is working properly in the selected algorithm. -

Page 22: Functions

Re-syncing is used to align the relevant valve at 0 % opening (zero steps), so that no steps are missed during regulation. Re-sync activation takes place: • At each power-on (power-on via power supply connection) of the EVDRIVE05 (full sync); • If set, at each interval P13 (partial synchronisation);... -

Page 23: Operation With Shared Pressure Probe

(in which the pressure probe is installed) can be shared with all the others. In this operating mode, the AI_M and AI_ T inputs must be connected to only one EVDRIVE05, while only the AI_ T input may be connected to the other EVDRIVE05 devices. -

Page 24: Valve Operation In Duty Cycle

7.5 VALVE OPERATION IN DUTY CYCLE EVDRIVE05 can be used to manage motorised electronic expansion valves which need to run in duty cycle mode, so as to protect that valve from overheating. The configuration parameters are: Par. Description Range P14 Duty cycle. -

Page 25: Regulation

8.3.1 SH SH regulation can be used to keep the overheating temperature at a selected value. EVDRIVE05 calculates the process overheating using the two analogue inputs AI M (evaporation pressure/temperature sensor) and AI T (intake temperature probe). It uses a PID regulator to modulate the valve opening so that overheating reaches the setpoint R05. -

Page 26: Economizer

R07 Valve proportional band threshold constant. R06...R08 Low regulation temperature threshold. 1.0...99.9 (Only applies when R01 = 1 and/or R01 = 2). R09 High regulation temperature threshold. -58.0...80.0 R10 Valve fast action level. 1...100 114EV05E4.00 - EVDRIVE05 | 26 | Regulation | 10/2024... -

Page 27: Stable Sh Minimum

FIG. 13. Operation 8.3.3 Stable SH minimum If the SH value remains stable (within the neutral regulation zone) for a time R20, the EVDRIVE05 reduces the SH setpoint by 0.1 The procedure may be repeated until the SH setpoint reaches value R17. -

Page 28: Hot Gas Bypass Algorithm

• If SH is in the Fast Action band, a fast action PID regulator algorithm is used. Normal Smart Neutral Neutral Smart Normal Control Control Band zone zone Band Control Control Valve opening Valve closure FIG. 14. Hot Gas Bypass operation 114EV05E4.00 - EVDRIVE05 | 28 | Regulation | 10/2024... -

Page 29: Evaporator Pressure Regulator (Epr)

In SH and Economizer control, the alarm is activated when the MOP bypass time (A19A16) from PID activation has elapsed and: • Evaporation temperature > MOP temperature (A10) • MOP alarm delay elapsed (A12) The alarm resets when: • Evaporation temperature > MOP temperature (A10) + MOP Alarm Hysteresis (A11) 114EV05E4.00 - EVDRIVE05 | 29 | Regulation | 10/2024... -

Page 30: Lop | Low Pressure Alarm

If the LOP alarm occurs during the start-up phase (when the evaporation temperature is effectively low), the algorithm forces valve opening. If the LOP alarm is reset, EVDRIVE05 stops the valve. This phase can be optimised by configuring the valve opening correctly in the start-up parameters (Equalisation position (R14), Equalisation time (R13), Start-up position (R16), Start-up time (R15). -

Page 31: Parameters

Minimum stable setpoint control time. 0...250 Maximum stable SH control time. 0...250 Number of oscillations for minimum stable SH control. 0...100 AI T temperature offset. °C/°F -10.0...10.0 AI M temperature offset. °C/°F -10.0...10.0 114EV05E4.00 - EVDRIVE05 | 31 | Parameters | 10/2024... - Page 32 Re-sync interval. 0...1000 Generic valve duty cycle. 5...100 EPoCA log sampling interval. 0...255 Email notification of alarms in EPoCA. 0 = Disabled; 1 = Enabled. ALARM CONFIGURATION group Communication alarm delay. 0...250 114EV05E4.00 - EVDRIVE05 | 32 | Parameters | 10/2024...

- Page 33 3 = 0...10 V; 4 = NTC. Maximum AI M x-axis value. 0.00...20.00 20.00 Minimum AI M x-axis value. 0.00...20.00 0.00 Maximum AI M y-axis value. -32768...32767 Minimum AI M y-axis value. -327.68...327.67 0.00 114EV05E4.00 - EVDRIVE05 | 33 | Parameters | 10/2024...

- Page 34 1 = 2 stop bits. Epoca TTL usage. 0...247 IB serial address. 0 = Node 7; 1 = Node 8. PASSWORD group User password. -32768...32767 Maintenance password. -32768...32767 Manufacturer password. -32768...32767 114EV05E4.00 - EVDRIVE05 | 34 | Parameters | 10/2024...

-

Page 35: Valve Configuration

The configurations listed below are presented in compliance with the technical documentation from the corresponding manufacturers. EVCO is not responsible for any changes made to the values by the manufacturers. Always refer to the latest available version of the manufacturer’s technical documentation. -

Page 36: Diagnostics

• Valve in alarm position connections working AL09 valve • Regulation OFF • Switch EVDRIVE05 off then on again • No connection • Manual reset • Reconfigure the parameters Default values of the parameters Alarm: memory Device memory in error •... -

Page 37: Modbus Rtu Functions And Resources

The Modbus registers for the device are organised around the four types of basic data reference indicated above, and this type of data is further identified by the first number of the address. 114EV05E4.00 - EVDRIVE05 | 37 | Modbus RTU functions and resources |... -

Page 38: Available Modbus Commands And Data Areas

• SHORT = 16 bit with sign • WORD = 16 bit • Byte = 8 bit • The “n” bits = 0...15 bit depending on the value of “n” 114EV05E4.00 - EVDRIVE05 | 38 | Modbus RTU functions and resources | 10/2024... -

Page 39: Modbus Addresses

R24 AI M temperature offset. 1559 R/W SHORT °C/°F -10.0...10.0 R25 AI M pressure offset. 1560 R/W SHORT bar/10*psi -10.00...10.00 R26 Manual valve percentage position. 1561 R/W BYTES 0...100 114EV05E4.00 - EVDRIVE05 | 39 | Modbus RTU functions and resources | 10/2024... - Page 40 ALARM CONFIGURATION group A01 Communication alarm delay. 1632 R/W BYTES 0...250 A02 Low temperature alarm hysteresis. 1633 R/W BYTES 0.0...25.0 A03 Low temperature alarm delay. 1634 R/W BYTES 0...250 114EV05E4.00 - EVDRIVE05 | 40 | Modbus RTU functions and resources | 10/2024...

- Page 41 I06 Maximum AI M x-axis value. 1685 R/W BYTES 0.00...20.00 I07 Minimum AI M x-axis value. 1686 R/W BYTES 0.00...20.00 I08 Maximum AI M y-axis value. 1687 R/W SHORT -32768...32767 114EV05E4.00 - EVDRIVE05 | 41 | Modbus RTU functions and resources | 10/2024...

- Page 42 1 = Node 8. PASSWORD group C14 User password. 1738 R/W SHORT -32768...32767 C15 Maintenance password. 1739 R/W SHORT -32768...32767 C16 Manufacturer password. 1740 R/W SHORT -32768...32767 114EV05E4.00 - EVDRIVE05 | 42 | Modbus RTU functions and resources | 10/2024...

-

Page 43: Modbus Resource And Status Table

Step rate value in debugger mode. 1306 4378 R/W WORD 0...1000 Minimum position in debugger mode. 1307 4379 R/W BYTES 0...100 Maximum position in debugger mode. 1309 4381 R/W BYTES --- 0...100 114EV05E4.00 - EVDRIVE05 | 43 | Modbus RTU functions and resources | 10/2024... - Page 44 Alarm: AI T probe. 1 BIT AL07 Alarm: AI M probe. 1 BIT AL08 Alarm: valve motor. 1 BIT AL09 Memory alarm. 1 BIT AL10 Alarm: configuration. 1 BIT AL11 114EV05E4.00 - EVDRIVE05 | 44 | Modbus RTU functions and resources | 10/2024...

-

Page 45: Made In Italy

Neither EVCO nor any of its associates or subsidiaries shall be held responsible or liable for improper use of the information contained herein.

Need help?

Do you have a question about the EVDRIVE05 and is the answer not in the manual?

Questions and answers