Summary of Contents for Ralston Instruments DP0V

- Page 1 EN Pneumatic Cylinder Hand Pumps (DP0V) Operation Manual For all models of DP0V Pneumatic Cylinder Hand Pumps...

- Page 3 Table of Contents Specifications ................2 Requirements................3 Important Safety Notices ............4 Pneumatic Cylinder Hand Pump Overview .......5 Setting Up ..................6 Calibration ..................10 Venting System ................13 Storage and Transport ..............14 Maintenance ................15 Troubleshooting ................16 Support ..................17...

- Page 4 Specifications Pressure Range 0 to 125 psi (0 to 9 bar) Media Pressure Reference Port Male Ralston Quick-test™ outlet port, no check valve, brass Pressure Outlet Port Male Ralston Quick-test™ outlet port with cap and chain, brass Temperature Range 0 to 130 °F (-18 to 54 °C) Seal Materials Buna-N, Delrin, Teflon Construction...

- Page 5 Requirements ", 15mm * ralstoninst.com/adapters What you need to use your Pneumatic Cylinder Hand Pump: 1. Device Under Test 2. Wrench 3. Thread Tape 4. Ralston Quick-test™ Adapters 5. Ralston Quick-test™ Hose 6. Pressure Reference...

- Page 6 Important Safety Notices WARNING: Do not exceed Maximum Working Pressure for this product or damage may result. WARNING: Device under test should be isolated from the process, vented and vent valve closed prior to use. WARNING: Do not attempt to operate this pump until you have read and fully understand the instructions and hazards of the product.

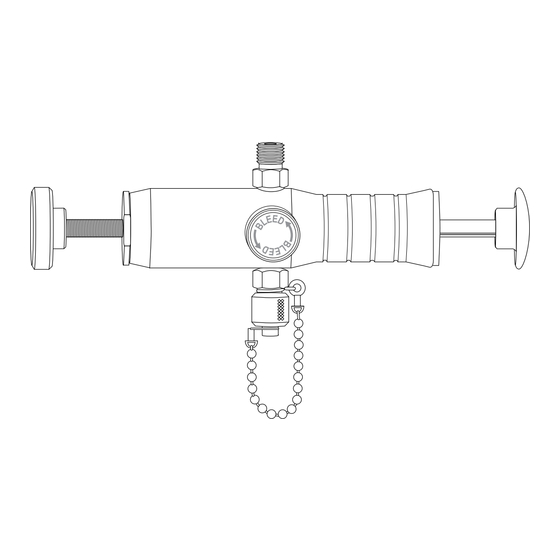

- Page 7 Pneumatic Cylinder Hand Pump Overview Back Front 1. Pumping Piston 2. Pressure Reference Port 3. Bleed Valve 4. Pressure Outlet Port 5. Fine Adjust Piston 6. External Check Valve 7. Internal Check Valve...

- Page 8 Setting Up Connecting Reference Gauge Male NPT Reference Gauge 1. Reference Gauge with NPT male connection 2. NPT Female Ralston Quick-test™ Gauge Adapter 3. Ralston Quick-test™ Hose 4. NPT Female Ralston Quick-test™ Adapter...

- Page 9 Male BSPP Reference Gauge 1. Reference Gauge with BSPP male connection 2. BSPP Washer 3. BSPP Female Ralston Quick-test™ Adapter 4. Ralston Quick-test™ Hose 5. BSPP Female (RG) Ralston Quick-test™ Adapter...

- Page 10 Female NPT Pressure Reference Gauge 1. Reference Gauge with NPT female port 2. NPT Male Ralston Quick-test™ Gauge Adapter 3. Ralston Quick-test™ Hose 4. NPT Male Ralston Quick-test™ Adapter...

- Page 11 Connecting Device Under Test (DUT) Isolate the Device Under Test (DUT) from the process and vent DUT prior to connecting to it. 1. Device under test (DUT) 2. NPT Male Ralston Quick-test™ Adapter 3. Ralston Quick-test™ Hose...

- Page 12 Calibration Prepare the Pump Open Bleed Valve. Set Fine Adjust to 50%. 100% Close Bleed Valve.

- Page 13 Increase Pressure Pump to just below test point. Test point Fine-adjust to exact test point. Test point Repeat steps 1 through 2 for each test point up-scale.

- Page 14 Decrease Pressure Slowly bleed to just above the test point. Then, close Bleed Valve. Test point Fine-adjust to exact test point. Test point Repeat steps 1 and 2 for each test point down-scale.

- Page 15 Venting System When finished testing, open the Bleed Valve and vent the remaining pressure from the system.

- Page 16 Storage and Transport * Ralston Pneumatic Cylinder Hand Pump Carrying Case (DP0V-CASE). Sold separately.

- Page 17 Maintenance Maintenance Interval Every 300 uses or 3 months Maintenance Procedure • Lubricate External Check Valve by squirting 2 ml of oil into it, and then drawing the oil into the Check Valve by pumping the piston several times. • Lubricate Internal Check Valve by removing pumping piston and squirting 2 ml of oil into hole in Check Valve at bottom of pumping piston cavity.

- Page 18 Troubleshooting The pump will pump up, but pressure slowly decreases If the pump will pump up, but pressure slowly decreases, then there is an exter- nal leak. Follow these instructions to locate and repair the leak: 1. Connect the pump to a Device Under Test (DUT) with a Ralston Quick- test™...

- Page 19 Support Hours: 8:30 am – 5:00 pm EST Phone: 1 440-564-1430 • Toll Free: 1 800-347-6575 (US and Canada) Web: ralstoninst.com/support Email: support@ralstoninst.com Parts and Service: ralstoninst.com/dp0v...

- Page 20 Pneumatic Cylinder Hand Pumps (DP0V) Operation Manual For all models of DP0V Pneumatic Cylinder Hand Pumps ralstoninst.com Hours: 8:30 am – 5:00 pm EST Phone: 1 440-564-1430 Toll Free: 1 800-347-6575 (US and Canada) Support: ralstoninst.com/support • Parts and Service: ralstoninst.com/dp0v Email: support@ralstoninst.com...

Need help?

Do you have a question about the DP0V and is the answer not in the manual?

Questions and answers