Advertisement

Quick Links

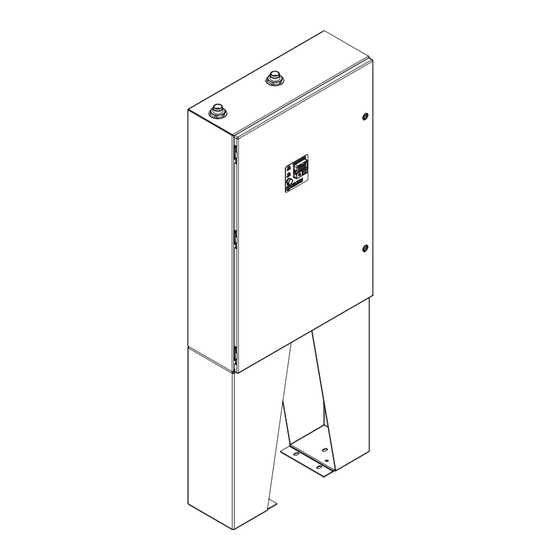

C2N shown with optional leg kit

215-1821 Rev. C

© 2021 Bradley

Page 1 of 17

8/1/2021

Installation

Bradley

Tankless Water

®

Heaters Powered by Keltech

C2N-Series

C2N36, C2N50

Voltage options:

600V 3-phase

480V 3-phase

415V 3-phase

400V 3-phase

380V 3-phase

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plumbing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electric Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start Up Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Digital Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operational Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–11

Product Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–13

Special Installation & Operating Instructions . . . . . . . . 14–17

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

P.O. Box 309

+1 262 251 6000

bradleycorp.com

™

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Bradley C2N Series

- Page 1 Special Installation & Operating Instructions . . . . . . . . 14–17 P.O. Box 309 215-1821 Rev. C Menomonee Falls, WI 53052 USA © 2021 Bradley 800 BRADLEY (800 272 3539) +1 262 251 6000 Page 1 of 17 8/1/2021 bradleycorp.com...

- Page 2 C2N Series Tankless Heater Installation DANGER Tip over hazard. System can crush you resulting in serious injury or death. Read and follow precautions in this installation manual that accompanied the heater for instructions on how to safely transport and anchor heater.

- Page 3 . Operation and Setup C2N Series heaters supply an unlimited amount of hot water with specific flow and temperature rise capabilities . These heaters are energy efficient, reliable, and provide optimum performance in the most demanding applications .

- Page 4 C2N Series Tankless Heater Installation Packaging Crates are constructed from 3/4" (19mm) OSB . Crate dimensions approx: 44" x 28" x 12" (1118mm x 711mm x 305mm) Crates should not be stacked more than 2 high . All crates must be stacked evenly and horizontally .

- Page 5 Suggested Installation Configuration (222) 24" (610) for Power Components provided by installer unless Entrance - otherwise specified . Reference the product Provided By options sections or contact your local Installer Bradley Representative for product options . Bradley • 215-1821 Rev. C 8/1/2021...

- Page 6 WARNING Install product to rated line voltage in accordance to current local and national codes and regulations. WARNING All Bradley heaters must be fused in accordance with National Electric Code (NEC) for the full load amperage listed on the nameplate rating for each heater.

- Page 7 C2N Series Tankless Heater Installation Start Up Check List Plumbing System is set in a vertical, level, and upright position with the outlet located at the top . System is mounted to the wall using the (4) mounting brackets on the back of the enclosure or bolted to the floor with the optional leg kit .

- Page 8 C2N Series Tankless Heater Installation Start Up WARNING Make sure the circuit breaker for the heater is OFF. Be sure that plumbing and electrical are complete per Start Up Check List. Slowly turn on water supply to the unit Energize the electrical service to the with the enclosure door open and the unit by switching on the circuit breaker .

- Page 9 C2N Series Tankless Heater Installation Digital Controller Operation The preprogrammed digital controller is mounted through the bezel on the enclosure door. The digital controller will be powered but the bottom display will read OFF until water is flowing through the heater.

- Page 10 C2N Series Tankless Heater Installation Perform Operational Test No. 1 Ensure the enclosure door is closed Press the up or down arrow keys prior to performing operation test. to adjust the set temperature . The controller displays the temperature of Set the 3-pole switch or circuit breaker to water measured at the outlet .

- Page 11 FDA Approved for Food Contact (use in deionized water applications) . EXP2 (Explosion Proof Purge System): Bradley's EXP2 option makes heaters compliant for classified areas; Class I Division 2, Groups A, B, C, D, Temp Code: T5 . The Purge System requires a supply of clean instrument air or inert gas (provided by installer) .

- Page 12 C2N Series Tankless Heater Installation Maintenance Preventative maintenance is important for optimal performance of the heater . To ensure the heater works properly, always keep the inside of the enclosure dry . Moisture inside an enclosure increases the humidity, which condenses on cooler surfaces . This can cause electrical problems and reduce the efficiency of enclosure insulation .

- Page 13 All internal breakers must be in the ON position for the unit to work . For additional information on Troubleshooting or other information, please call Bradley technical support at 1-800-999-4320 . Please have Model No . and Serial No . available when seeking technical assistance . Serial No .

- Page 14 Tankless Water Heaters With Optional Class I Division 2 Purge EXP2 Option General Information All Bradley Tankless Water Heaters with a model number suffix of – EXP2 have been fitted with a Z purge system to pressurize the enclosure suitable for use in Class I Division 2 Hazardous Locations .

- Page 15 C2N Series Tankless Heater Installation Purge Gas Supply Notes An alarm shall be provided to indicate failure of the protective gas supply to maintain the required pressure . Piping for the protective gas shall be protected against mechanical damage .

- Page 16 “Pressurized” indicator is green! Commissioning Test Commissioning Continuous Flow Bradley Option EXP2 System: 1 . Open the air or gas supply shutoff valve . 2 . Adjust the Flow Control Valve (FCV) so that the enclosure pressure rises to the point where the "Pressurized"...

- Page 17 C2N Series Tankless Heater Installation Special Installation Maintenance Routine Maintenance of the System (Every 6 months) Recommended maintenance of the systems is as follows: Repeat Commissioning test at least every six months . The test includes checking the opening pressure of the Relief Valve, setting of the Minimum Pressure Sensor, the “Normal Working Pressure”...

Need help?

Do you have a question about the C2N Series and is the answer not in the manual?

Questions and answers