Advertisement

Quick Links

Advertisement

Summary of Contents for Aalberts flamco Flexfiller Mini 130 G4

- Page 1 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Installation and operating manual...

- Page 2 Table of contents Warranty ........................ 4 Liability ........................6 Copyright .......................7 About this manual ..................... 8 4.1. Conventions symbols in this manual .................... 8 4.2. Typography ............................9 4.3. Where to find more information? ....................9 Safety ........................10 5.1. Incoming goods..........................10 5.2.

- Page 3 Flexfiller Mini 130, 230 G4 & Midi 160 G4 10. Maintenance ....................... 32 10.1. Maintenance intervals ........................32 10.2. Visual inspection ..........................33 10.3. Interrogate controller ........................34 10.4. Test unit operation ........................... 34 11. Decommissioning / Dismantling ..............35 12. Appendix 1. Icon library .................36 13.

- Page 4 1. Warranty The Flamco warranty on equipment supplied covers manufacturing defects, under our standard terms and conditions of sale, where items with a proven manufacturing defect are replaced at the point of sale. We understand the importance of providing timely support to ensure a smooth and satisfactory experience with our product.

- Page 5 That these operating and maintenance instructions are followed. That the equipment is used for the purpose for which it was designed. For general Terms and Conditions of this sale, see General Conditions of Sale Flamco Group on the Flamco website in link below: https://flamco.aalberts-hfc.com/uk-en/ page/terms-and-conditions > Warranty...

- Page 6 2. Liability All technical specifications, data and instructions for executable actions and contained herein are correct at time of publication. This information is the result of our current findings and experience to the best of our knowledge. We reserve the right to make technical changes subject to the future development of the Flamco product referred to in this publication.

- Page 7 Flexfiller Mini 130, 230 G4 & Midi 160 G4 3. Copyright All documentation is protected by copyright. Distribution or other forms of reproduction of documents, even extracts, exploitation or notification of the contents hereof is not permitted, where not otherwise specified. Infringements are liable to prosecution and payment of compensation.

- Page 8 4. About this manual The following pages list the information, specifications, measures and technical data that allow the relevant personnel to use this product safely and for the intended purpose. Responsible persons or those engaged by them carrying out the required services must read this manual attentively and understand it.

- Page 9 A message/fault code displayed on the digital controller symbols> 4.3. Where to find more information? For the Quick Start Guide and further documentation in various languages, visit: https://flamco.aalberts-hfc.com/manuals For further information please visit the Flamco Limited Website at the following URL: https://flamco.aalberts-hfc.com/uk-en > About this manual...

- Page 10 5. Safety This equipment is intended to fill and/or top-up sealed water-based heating and cooling systems, in which temperature-induced changes in the volume of the system water (the heat transferring agent) is governed by a separate expansion vessel and safety relief valve. This product is suitable and appropriate for the operation in heat generating systems according to BS7074, BSEN 12828, BSEN 12952 and BSEN 12953.

- Page 11 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Unit Internal access The unit internals can be accessed for service or repair, by a Qualified Person. The unit can only be accessed by using a specialized tool. Any attempts to access the internals of the unit without the correct equipment will invalidate the Flamco Warranty and will be classified as use in an improper manner, according to our General Conditions of Sale.

- Page 12 5.4. Staff qualification Definitions: • Operator: A person or legal entity who is the owner of the product and uses the aforementioned product, or is nominated to use it, under the terms of a contractual agreement. • Principal: The legally and commercially responsible party in the execution of construction projects.

- Page 13 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Operating instructions are transferred by Flamco representatives or others assigned by them during delivery negotiations or on demand. On-site services include transportation, the preparation of an operations room with the requisite foundation engineering to accommodate the system, and the requisite hydraulic and electrical connections, the electrical installation for the power source of the expansion automat and installation of the signal leads for the IT equipment.

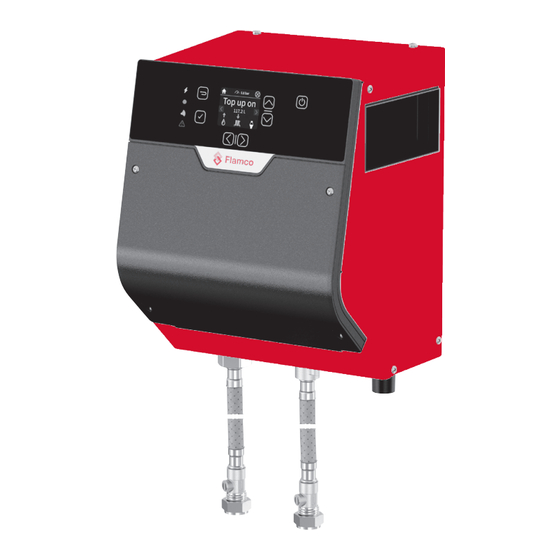

- Page 14 6. Product description The Flexfiller Mini 130 / 230 G4 & Midi 160 G4 is compact, wall-mounted, pressurisation unit. The function of this pressurisation unit is to provide a means of automated water filling and top-up to sealed heating and cooling systems. The equipment is designed to provide periodic water top-up to compensate for minor losses in system pressure (e.g.

- Page 15 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Schematic overview Level Sensor Pressure sensor Tap water inlet Flow Limiter Solenoid valve System Out Pump 1 Breaktank Cat.5 Pump2 (optional) 6.2. Technical datasheet Regulation 4 approval number 2301711 (KUKreg4) General Size of the unit (Height x Width x 297 x 226 x 197 mm Depth)

- Page 16 Maximum load BMS relays 5A @ 240VAC (non-inductive) Protection class IP2X Environmental data Power consumption (Standby) Power consumption (Filling) Mini 130 / 230 G4 28W Midi 160 G4 180W Operation conditions Maximum temperature at inlet: 45°C Maximum temperature at outlet: 85°C Ambient temperature range: 5°C / 45°C...

- Page 17 For general assembly instructions and commissioning steps of the product, see Flexfiller Mini 130 / 230 G4 & Midi 160 G4 Quick Start Guide in link below: https://flamco.aalberts-hfc.com/manuals/flexfiller-direct All Flamco products should be installed by a Qualified Person with regard to the relevant requirements described in section 5.4: ‘’Staff...

- Page 18 The unit is equipped with a Category 5 Weir overflow arrangement and must not be installed where damage to the local environs can occur on water egress from the weir. A mains cable is provided with the unit. A mains cable length of 2 meters may not be exceeded if replacement of a cable is necessary.

- Page 19 Flexfiller Mini 130, 230 G4 & Midi 160 G4 7.1. Installation diagram Flow Return Boiler Boiler Isolation Valves Isolation Isolation Valves Valves 3-Way FlexBalance Valve Hydraulic Balancer Drain Isolation Point Valve Isolation Isolation Valves Valves FlexFiller Mini G4 FlexF Flexcon Pressurisation Unit Expansion Vessel Mains...

- Page 20 7.2. Clearance requirements Clearance guidelines for service and repair. 21.5mm overflow coupling 21.50 Note: Overflow must take full flow of product, use manual mode P35 to test or activate Anti-legionella We reserve the right to change designs and technical specifications of our products.

- Page 21 Flexfiller Mini 130, 230 G4 & Midi 160 G4 7.3. Hydraulic connections From the “Manual-mode” in the controller menu, a testing routine can be triggered to check if the device is set up correctly and working accordingly. Each actuator (valve) can be operated separately with a maximum run-time of 2 minutes.

- Page 22 7.4. Controller A clarification of menu icons, function and location can be found in Appendix 1: Icon library. RS485 P16 P17 P18 P19 P20 P21 P22 P23 P24 P25 P26 L N PE P28 P29 1 23 P28 P29 Flexfiller Mini 130 / 230 G4 & Midi 160 G4 Identification Description Pinout Power indicator (orange=power)

- Page 23 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Fuse 2 (P34&P36) 5x20 10AT Mains power connector 3 PE Mains grommet Not Available System pressure sensor 1 +VDC 2 signal 3 GND Tank level sensor 1 +VDC 2 signal 3 GND Not Available Not Available Not Available...

- Page 24 8. Electrical installation The provision of power supply, (protective) ground wire connection and line protection must be made in accordance with the local regulations (responsible power company) and the applicable National standards. The required electrical information can be found on the product label at the side of the Flexfiller Mini 130 / 230 G4 & Midi 160 G4, the terminal plan (labelling) and in “Chapter 6.2 Technical datasheet’’.

- Page 25 Flexfiller Mini 130, 230 G4 & Midi 160 G4 8.1. Alarm installation The pressurisation unit has alerts that are categorized as Warnings or Alarms. Any of the individual warnings or alarms can be selected in the software to trigger the fault relays P27, P28 and P29.

- Page 26 VFC1 (P27 terminal): Use for a fail-safe common alarm / boiler interlock for serious issues to shut down heating /cooling and for immediate action to be taken, e.g. emergency engineer callout. This includes high and low pressure alarms. Connect to COM and NO; set these options: •...

- Page 27 Flexfiller Mini 130, 230 G4 & Midi 160 G4 8.3. Wiring table for VFC relay and BMS: VFC Relay Alerts if BMS State Alerts Comment Terminal Software Wiring product’s on Alarm if BMS Menu; power is cable Invert is cut Polarity NO + COM Open...

- Page 28 9. Operation Below is an overview of how the settings on a pressurisation unit must be considered for normal top-up operation. Close, conflicting or overlapping settings will cause system instability and nuisance alarm conditions. If in any doubt please seek advice from a Sealed System professional.

- Page 29 Flexfiller Mini 130, 230 G4 & Midi 160 G4 A typical venting allowance is 0.3 bar, added to the static height to give the cold fill pressure. The Differential setting represents the allowable pressure loss before the pump activates and restores the cold fill pressure. The Differential setting must not be greater than the system venting allowance.

- Page 30 To resolve the fault, simply click the tick-button “✓” again and the fault will be cleared. To exit the extended explanation screen without resolving the fault, press the return- button “ “. When the fault condition is not resolved it will return on the display. Please use the troubleshooting guide in Appendix 4 to resolve each fault accordingly.

- Page 31 Flexfiller Mini 130, 230 G4 & Midi 160 G4 If it is anticipated that the unit will be out of commission for more than 24 hours, it is advisable to disconnect the hoses from the unit. 9.2. Restarting After long periods of downtime If this downtime was planned or scheduled, turn OFF the control unit and close off the isolating valve to the system and the isolating valve to the top-up line.

- Page 32 10. Maintenance Electrical supply must be disconnected prior to conducting any maintenance. Please refer to chapter 9.1 “Shut-down procedure” and follow the steps. It is forbidden to alter or use non-original components or replacement parts without authorisation. Such acts may result in serious personal injury and endanger operational safety.

- Page 33 Flexfiller Mini 130, 230 G4 & Midi 160 G4 10.1. Maintenance intervals Due to variations in operating conditions, and the varying loads placed on pressurisation units, it is not feasible to provide accurate predictions of component lifespan. The most effective method of maintenance is to inspect the pressurisation unit for early signs of component failure and take action accordingly.

- Page 34 10.2. Visual inspection A basic visual inspection will highlight the majority of potential faults on a pressurisation unit. It is recommended to perform a visual inspection annually. However, due to the simplicity of performing these checks, frequent inspections are encouraged. Check the digital display for fault codes Check for signs of leakage (e.g.

- Page 35 Flexfiller Mini 130, 230 G4 & Midi 160 G4 11. Decommissioning / Dismantling At the end of the of the service life or at planned shut-down of the equipment, please refer to chapter: 9.1 “Shut-down procedure” and follow the steps. The unit is separated from the power supply.

- Page 36 12. Appendix 1. Icon library Icon Description Location Home Accept/Confirm Arrow left & right System OK System at warning System at fault Menu Language > > Date & time > > Date > > > Time > > > Manual Summary System pressure >...

- Page 37 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Expansion vessel > Mains supply > System connection Drain connection Legionella protection > Serial number > Settings General settings > System info > Service info Maintenance > Next maintenance due date Error logbook >...

- Page 38 Manual mode > Login required to activate manual mode (Chapter 10) Factory reset > > Login required to activate manual mode (Chapter 10) Firmware update > > Login required to activate manual mode (Chapter 10) We reserve the right to change designs and technical specifications of our products.

- Page 39 Flexfiller Mini 130, 230 G4 & Midi 160 G4 13. Appendix 2. Markings 100 mm Product label Bracket label The centre of the unit can be determined by drawing a vertical and horizontal line on the wall. A distance of A (150 mm) and B (210 mm) is required to ensure a safe space around the unit when installed.

- Page 40 14. Appendix 3. Troubleshouting guide Please note that incorrect set-up conditions can lead to repeated errors and inhibit the intended use. Error # Notification Problem Solution Warnings High pressure The isolation valve at Open the isolation valves the bottom of the unit is at the bottom of the unit.

- Page 41 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Number of A large amount of water Check system for leaks or refills within has been lost from the traces of water loss. certain time system. exceeded The unit is undersized for Review unit selection the system.

- Page 42 Device The unit has been Clear warning on screen. restarted unplugged and was The warning should not unable to top-up during come back. this time. The unit has lost mains Check for other warnings power due to power cut that resulted due to and was unable to top-up prevention of top-up.

- Page 43 Flexfiller Mini 130, 230 G4 & Midi 160 G4 Low pressure The system pressure has Activate manual fill to lockout fallen far below the low top up if no leakage is pressure set point and detected. is close to 0. Possible leakage.

- Page 44 Pump 1 failure Pump wiring not Check & replace wiring (no current) connected/broken Pump internally broken Replace faulty pump Pump 2 failure Pump wiring not Check & replace wiring (no current) connected/broken (only on 230D) Pump internally broken Replace faulty pump We reserve the right to change designs and technical specifications of our products.

- Page 45 We supply products for the installation industry in more than 70 countries. This is done from Flamco sales offices and via distributors who know the local market, and can give you the right advice at all times. Aalberts hydronic flow control United Kingdom Washway Lane UK-WA10 6PB...

Need help?

Do you have a question about the flamco Flexfiller Mini 130 G4 and is the answer not in the manual?

Questions and answers