Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ECR International freewatt FWHRJ

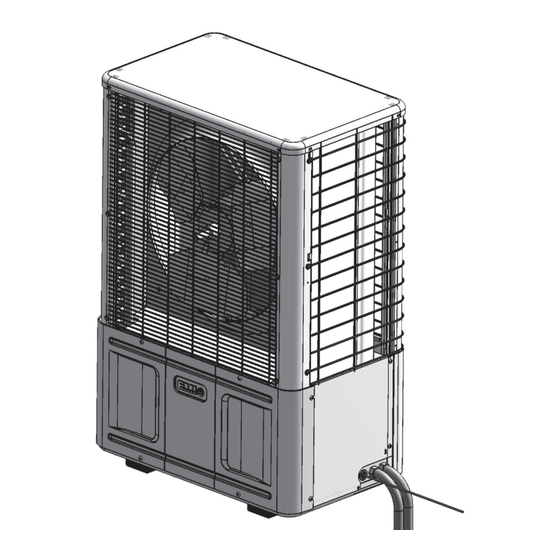

- Page 1 ® Air Cooled Heat Rejection System Model FWHRJ INSTALLATION, OPERATION & MAINTENANCE MANUAL P.O. Box 4729 Utica, NY 13504-4729 www.freewatt.com www.ecrinternational.com P/N# 240008182, Rev. B [08/2010] An ISO 9001-2008 Certified Company MEMBER: The Hydronics Institute...

-

Page 2: Table Of Contents

The air cooled heat rejection system, Model FWHRJ is Retain this manual and warranty for future reference. Before manufactured by ECR International and is tested and rated in leaving the premises, review this manual to be sure the unit has accordance with AHRI Standard 210/240-2008 and UL-1995. -

Page 3: Safety Information

safeTy InformaTIon Recognize This Symbol As An Indication Of Important Safety Information. WARNING Safety Instructions This manual is intended as an aid to qualified service per- Read completely all instructions prior to assembling, sonnel for proper installation, operation, and maintenance installing, operating, or repairing this product. -

Page 4: Installation Instructions

InsTallaTIon InsTruCTIons locating the unit unit mounting Instructions Side discharge units allows for permanent mounting through the • Locate the unit as close to the PLUS System freewatt feet. This is highly recommended due to the vertical design of the as possible (See Tubing Specifications Chart on Page 7). - Page 5 InsTallaTIon InsTruCTIons figure 4 - Tighten lag bolts figure 6 - remove side Panels Replace the front panel, do not tighten the side screws at this time. The screws adjacent to the front panel should already be loose (don’t remove them). electrical Wiring Slide the side panel out to access the high/low electrical connections and wire diagram.

- Page 6 InsTallaTIon InsTruCTIons figure 8 - High Voltage Connections figure 10 - Completed electrical Connections To replace side panel slide the slotted holes of the panel onto High Volt Input the loosened screws of the front panel so that the edge of the front panel covers the edge of the side panel.

- Page 7 InsTallaTIon InsTruCTIons Coolant Please follow the guidelines found below: INTERCONNECT PIPING SPECIFICATIONS Pipe/tube sizing: It is recommended to use 3/4" tubing or piping to a maximum equivalent length of 150 ft. The flow rate of the 30-50% Copper Piping Max. Copper Piping propylene glycol coolant through the piping system should be above Lift...

-

Page 8: Electrical Wiring & Connections

eleCTrICal WIrIng & ConneCTIons WARNING NOTICE FOR YOUR SAFETY, TURN OFF ELECTRICAL POWER IMPORTANT: Wiring must be N.E.C. class 1. System SUPPLY AT THE SERVICE PANEL BEFORE MAK- must be electronically grounded as required by National ING ANY ELECTRICAL CONNECTIONS TO AVOID Electric Code ANSI/NFPA 70 - latest edition. - Page 9 eleCTrICal WIrIng & ConneCTIons figure 15 - full Wiring diagram and schematic...

-

Page 10: Start-Up Procedure/Commissioning

sTarT-uP ProCedure/CommIssIonIng Preparation for start-up Propylene glycol solution - filling Procedure • Check electrical connections, breakers and switches for The following steps should be followed to fill the system piping with FWHRJ unit. the propylene glycol solution. Prepare the propylene glycol solution. •... -

Page 11: Remote Operation

sTarT-uP ProCedure/CommIssIonIng remote operation PLUS System also has remote start capability to assist freewatt the Electrical Utility in supplying electric power in brownout condi- tions. Distributed generation allows the Utility to remove electric load from the Utility Grid by turning ON generators throughout the Smart Grid. -

Page 12: Specifications And Dimensions

Performance data listed in this manual is subject to change without notice. For the most current unit/system performance data, please refer to the ECR International listing of certified products in the AHRI directory, at www.ahridirectory.org. Due to ongoing product development, designs, specifications, and performance are subject to change without notice. Please consult the factory for further information. -

Page 13: Maintenance / Repairs

maInTenanCe / rePaIrs The unit is equipped with a permanently lubricated motor. Al- WARNING though oiling is not necessary, adding a few drops of oil through the oiling ports twice yearly will extend the life of the motor. Disconnect the electrical power supply to the furnace before attempting any maintenance. -

Page 14: Troubleshooting

TroublesHooTIng WARNING WARNING Disconnect the electrical power supply to the furnace This unit has high voltage components with rotating parts. before attempting any maintenance. Failure to do so can To prevent personal injury, keep clear of rotating parts. cause electrical shock resulting in personal injury or loss of life. - Page 16 ® P.O. Box 4729 Utica, NY 13504-4729 www. freewatt .com www.ecrinternational.com An ISO 9001-2008 Certified Company MEMBER: The Hydronics Institute...

Need help?

Do you have a question about the freewatt FWHRJ and is the answer not in the manual?

Questions and answers