Advertisement

SYMBOLS

In this manual, on the labels, packages and all other information provided with this tool. The following signal words and meanings are intended to explain the levels of risk associated with this tool.

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury.

(Without symbol) Indicates a situation that may result in property damage.

GENERAL SAFETY RULES

WORK AREA

- Keep the work area clean and well lighted. Cluttered benches and dark areas increase the risks of accidents.

- Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. The tool creates a spark which may ignite flammable liquids, gases or dust.

- Keep bystanders, children, and others away while operating the tool. Distractions could result in improper use and cause injury.

- Avoid unintentional misfires. Always use caution to avoid accidentally firing. Do not point towards yourself or anyone whether it contains fasteners or not.

PERSONAL SAFETY

- Always wear eye protection. Operator and others in the work area should always wear ANSI-approved safety goggles with side shields. Eye protection is used to guard against flying fasteners and debris, which may cause severe eye injury. You can use the goggles packed with the tool.

- Always wear hearing protection when using the tool. Prolonged exposure to high intensity noise may cause hearing loss.

- Use safety equipment. A dust mask, non-skid safety shoes and a hard hat must be used for the applicable conditions. Wear a full face shield if you are producing metal filings or wood chips.

- Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the tool may cause serious injury.

- Avoid unintentional firing. Keep fingers away from trigger when not driving fasteners, especially when connecting the tool to the air supply.

- Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

- Do not use on a ladder or unstable supports. Stable footing on a solid surface enables better control of the tool in unexpected situations.

- Make sure the hose is free of obstructions or snags. Entangled or snarled hoses can cause loss of balance or footing and may become damaged, resulting in possible injury.

TOOL USE AND CARE

- Know this tool. Read manual carefully, learn its applications and limitations, as well as the specific potential hazards related to this tool.

- Use only fasteners that are recommended for your models. Do not use the wrong fasteners or load the fasteners incorrectly.

- Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tool's operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

- Maintain tools with care. Keep tool clean. A properly maintained tool, reduces the risk of binding and is easier to control.

- Store tools out of the reach of children and other untrained people. Tools are dangerous in the hands of untrained users.

- Check operation of the tool before use. Do not use the tool if the workpiece contact mechanism is not working correctly as accidental driving of a fastener may occur.

- Do not use tool if trigger does not actuate properly. Any tool that cannot be controlled with the trigger is dangerous and must be repaired.

- Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

- Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding a tool by hand or against the body is unstable and may lead to loss of control.

- Keep the tool and its handle dry, clean and free from oil and grease. Always use a clean cloth when cleaning. Never use brake fluids, gasoline, petroleum — based products, or any strong solvents to clean your tool.

- Do not use the tool as a hammer.

- Never use this tool in a manner that could cause a fastener to be directed toward anything other than the workpiece.

- Always carry the tool by the handle. Never carry the tool by the air hose.

- Do not use the tool if it leaks air or does not function properly.

- Do not operate the tool if it does not contain a legible warning label.

TOOL SERVICE

- Use only accessories that are identified by the manufacturer for the specific tool model.

- Use of unauthorized parts or failure to follow maintenance instructions may create a risk of injury.

- Use only the lubricants supplied with the tool or specified by the manufacturer.

- Tool service must be performed only by qualified repair personnel.

OPERATION

- Do not drive fasteners near edge of material. The workpiece may split causing the fastener or ricochet, injuring you or people around.

- Do not carry the tool from place to place holding the trigger. Accidental discharge could result. Choice of triggering method is important. Check manual for triggering options.

- During normal use the tool will recoil immediately after driving a fastener. this is a normal function of the tool. Do not attempt to prevent the recoil by holding the tool against the work. Restriction to the recoil can result in a second fastener being driven from the tool. Grip the handle firmly and let the tool do the work. Failure to heed this waming can result in serious personal injury.

- Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as this may cause deflection of fasteners which could cause injury.

- Do not actuate the tool unless you intend to drive a fastener into the workpiece.

- Always handle the tool with care:

- Respect the tool as a working implement.

- Never engage in horseplay.

- Never pull the trigger unless nose is directed toward the work.

- Keep others a safe distance from the tool while tool is in operation as accidental.

AIR SUPPLY AND CONNECTIONS

- The connector on the tool must not hold pressure when air supply is disconnected. If an incorrect fitting is used, the tool can remain charged with air after disconnecting and thus will be able to drive a fastener even after the air line is disconnected, possibly causing injury.

- Do not use oxygen, combustible gases or bottled gasses as a power source for this tool. Explosion may occur, causing injury or death.

- Do not connect with an air compressor which can potentially exceed 200 Psi.

As tool may burst, possibly causing injury. - Always disconnect air resource:

- Before making adjustments.

- When servicing the tool.

- When clean a jam.

- When tool is not in use.

- When moving to a different work area, as accidental actuation may occur, causing.

LOADING TOOL

- Do not load the tool with fasteners when any one of the operating controls is activated.

- Never place a hand or any part of body in fastener discharge area of tool.

- Never point tool at anyone.

- Do not pull the trigger or depress the workpiece contact as accidental actuation may occur, possibly causing injury.

The warnings and precautions discussed above cannot cover all possible conditions and situations that may occur. It must be understood by the user that common sense and caution are factors which cannot be built into this product, but must be supplied by the user.

UNPACKING

- This tool has been shipped completely assembled.

- Make sure that all items listed in the packing list are included.

- Carefully remove the tool and any accessories from the box.

- Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

- Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

- If any parts are damaged or missing, please call 1-888-669-5672.

PACKING LIST

Mini flooring tool

Air connector

Adjustment tools

Lubricating oil

Instruction manual

Safety goggle

Brad nailer/Stapler nose cover

If any parts are missing do not operate this tool until the missing parts are replaced. Failure to do so could result in possible serious personal injury.

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such alteration or modification is misuse and could result in hazardous condition leading to possible serious personal injury.

FEATURES

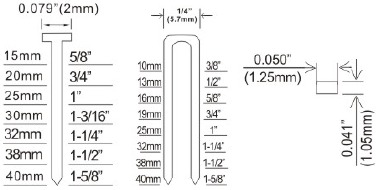

SPECIFICATIONS

| Operation pressure: | 70-110psi |

| Nails capacity: | 100pcs |

| Tool weight: | 4 lbs |

| Air inlet: | 1/4"NPT |

| Fasteners: | 18 Gauge |

Compatible with All Generic 18 Gauge nails and staples.

FEATURES

- 360° ADJUSTABLE EXHAUST

Allows user to direct air away from debris. - OIL-FREE DESIGN

For less maintenance. - ANODIZED ALUMINUM CYLINDER AND MAGAZINE

For long lasting durability. - COMFORT-GRIP HANDLE

For increased comfort and control. - ERGONOMICALLY ENGINEERED BODY

Rugged and Comfortable resulting in a light — weight tool great for extended use. - AIR FILTER

Keeps interior components debris free, extending tool life. - ADJUSTABLE DEPTH

Depth is easily adjustable for various applications.

OPERATION

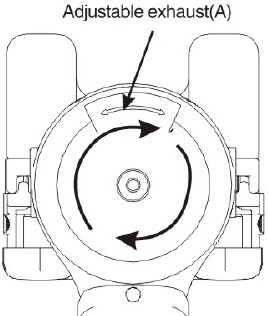

ADJUSTING THE EXHAUST

The adjustable exhaust (A) on the cap of the tool allows users to direct the exhaust according to operator preference. To adjust the direction, tum the exhaust cap in the desired direction.

CHANGE THE NOSE COVER

The tool is packed with another regular nose cover, with which the nailer can be changed to be a regular brad nailer/stapler.

- Disconnect the tool from air resource.

- Remove fasteners from the tool. Failure to do so will cause the fasteners to eject from the front of the tool.

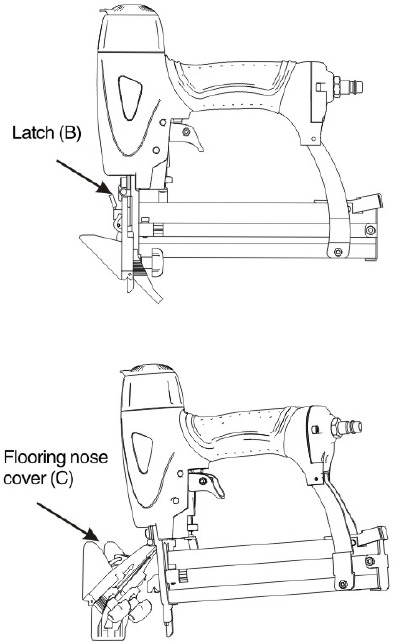

- Pull up on the latch (B) and open the flooring nose cover (C).

![Freeman - PFBC940 - Change the Nose Cover - Step 1 Change the Nose Cover - Step 1]()

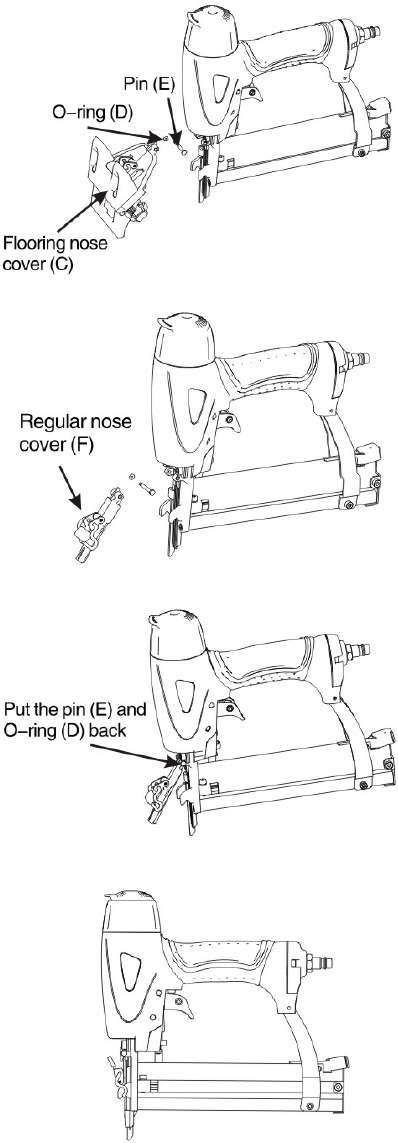

- Remove the O-ring (D) and pin (E).

![Freeman - PFBC940 - Change the Nose Cover - Step 2 Change the Nose Cover - Step 2]()

- Remove the Flooring nose cover (C).

- Pull the Regular nose cover (F) on the nose of the nailer.

- Put the Pin (E) and O-ring (D) back.

- Push the latch back to the Nose cover on the nailer's nose.

NOTE:

It's the same to change the regular nose cover to the flooring nose cover.

LOADING FASTENERS

- Connect the tool to the air resource.

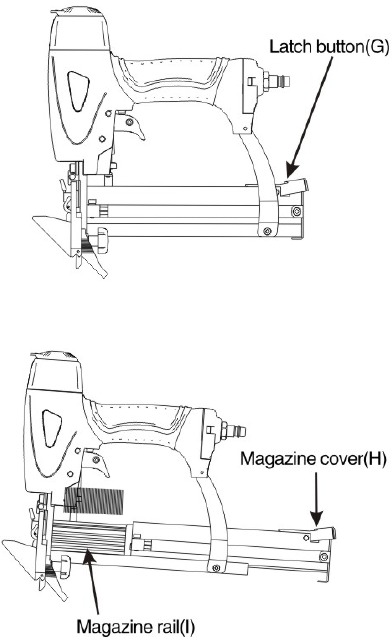

- Push down on the latch button (G). Pull back on the magazine cover (H).

![Freeman - PFBC940 - Loading Fasteners Loading Fasteners]()

- Insert a stick of fasteners into the magazine rail (l). Make sure the pointed ends of the fasteners are resting on the bottom ledge of the magazine when loading. Make sure the fasteners are not dirty or damaged.

- Push the magazine cover (H) forward until latch button pops up.

The tool may fire when it is first connected to the air resource. Always connect the tool to the air resource before loading fasteners to prevent injury from unintended cycling. Always make sure the tool's magazine is empty at the beginning of each work session, before connecting to an air resource.

Use only the fasteners recommended for use with this tool. The use of any other fasteners could result in tool malfunction, leading to serious injuries.

Keep the tool pointed away from yourself and others when loading fasteners. Failure to do so could result in possible serious personal injury.

Never load fasteners with the workpiece contact or trigger activated. Doing so could result in possible serious personal injury.

UNLOADING FASTENERS

Unloading is the reverse of loading, always disconnect the air resource before unloading.

Always unload all fasteners before removing tool from service.

Always disconnect the air resource before unloading.

CLEARING JAMS

Occasionally, a fastener may become jammed in the firing mechanism of the tool, making the tool inoperable. To remove a jammed fastener, follow these steps:

- Disconnect the tool from air resource.

- Remove fasteners from the tool. Failure to do so will cause the fasteners to eject from the front of the tool.

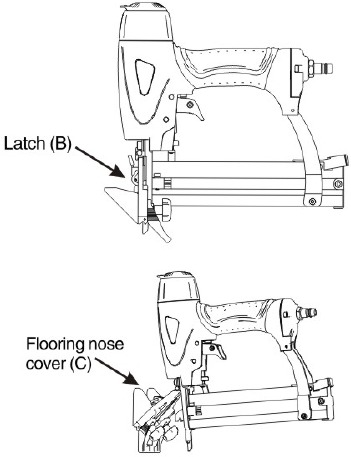

- Pull up on the latch (B) and open the Flooring nose cover (C).

![Freeman - PFBC940 - Clearing Jams Clearing Jams]()

- Using caution not to bend or damage the driver blade, using pliers or a screw driver if required to clear the jammed fastener.

- Close the nose and latch.

- Reconnect the tool to the air resource.

- Reload the tool with fastener.

NOTE:

It's the same to clear the jam with the regular nose cover.

Make sure there is no fastener in magazine before clearing a jam.

Disconnect the tool from the air source whenever clearing a jam. After disconnecting the tool from the air compressor, there should still be enough air pressure to fire the tool. After the air hose is disconnected, always fire the tool into scrap wood repeatedly to make sure all of the compressed air is expended.

Disconnect the tool from the air source whenever clearing a jam. After disconnecting the tool from the air compressor, there should still be enough air pressure to fire the tool. After the air hose is disconnected, always fire the tool into scrap wood repeatedly to make sure all of the compressed air is expended.

NO-MARRING PAD

A no-marring pad is packed with the tool for the regular nose cover use.

The no-marring pad attached to the nose of the tool helps prevent marring and denting when working with finished surfaces.

Disconnect the tool from the air source before removing or replacing the no-marring pad or replacing the no-marring pad. Failure to do so could result in serious personal injury.

SETTING THE AIR PRESSURE

The amount of air pressure required depends on the size of the fasteners and the working material. Begin testing the depth of drive by driving a test nail into the same type of working material used for the actual job.

Drive a test fastener with the air pressure set at 90 - 95psi. Raise or lower the air pressure to find the lowest setting that will perform the job with consistent results.

It may be possible to achieve the desired depth with air pressure adjustments alone.

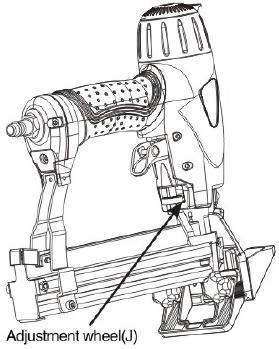

DEPTH ADJUSTMENT

The driving depth of the fasteners are adjustable. To adjust the depth, use the drive depth adjustment wheel (J) on the tool.

- Disconnect the tool from air resource.

- Tum the depth wheel left or right to change the driving depth.

- Reconnect the tool to the air resource.

- Drive a test nail after each adjustment until the desired depth is set.

NOTE:

When using the tool as a flooring nailer, the depth adjustment wheel must be set at the top of the wheel bar.

To set the wheel:

- Turn the wheel right to move the wheel up.

- Set the wheel at the top of the wheel bar.

It is advisable to test the depth on a scrap workpiece to determine the required depth for the application.

To determine depth of drive, first adjust the air pressure and drive a test fastener. Never exceed 120psi.

ADJUST THE FLOORING PLATE

When the flooring nose cover is set on the nailer, the floor plate depth is adjustable for 3/8", 5/8" and 1/2" thickness floor wood.

To adjust the floor plate depth, please follow the steps as listed below:

- Disconnect the tool from air resource.

- Loosen the plastic screws (K) on both side of the Floor plate (L).

![Freeman - PFBC940 - Adjust The Flooring Plate Adjust The Flooring Plate]()

- Slide the Floor-plate up or down to suit your flooring application.

- Fasten the Plastic screws tightly.

- Ensure the correct depth set for the wood floor by firing into a scrap piece of flooring and checking for proper fastener placement.

Disconnect the tool from the air resource whenever you adjust the floor plate. Make sure there is no fastener in the magazine before adjusting the floor plate.

FIRING THE TOOL

(SINGLE FIRING MODE)

The tool is specially designed for single firing mode. This mode requires the trigger to be pulled each time a fastener is driven. The tool can be actuated by depressing the work contact element against the work surface followed by pulling the trigger.

The trigger must be released to reset the tool before another fastener can be driven.

During normal use the tool will recoil immediately after driving a fastener. This is a normal function of the tool. Do not attempt to prevent the recoil by holding the tool against the work. Restriction to the recoil can result in a second fastener being driven from the tool. Grip the handle firmly and let the tool do the work. Failure to heed this warning can result in serious personal injury.

MAINTENANCE

Any time inspection, maintenance, and cleaning are done:

- Disconnect the tool from the air resource.

- Empty the magazine completely.

ANTI-DUST

Each FREEMAN tool is packed with an anti-dust cap on the air connector.

Keep the anti-dust cap cover the air connector when the tool is not in use.

LUBRICATION

The tool is uniquely designed not to need daily lubrication. But lubrication is required for best performance after long periods use. Oil for pneumatic fastening tools is added through the air line connection and will lubricate internal pans. Do not use detergent oil or additives as these lubricants will cause accelerated wear to the seals and bumpers in the tool, resulting in poor tool performance and frequent tool maintenance.

Lubricate tool only with non-detergent Pneumatic tool oil.

CLEANING

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and maybe damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

Do not at any time let brake fluids, gasoline, petroleum-based products, penetration oils, ect. come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which may result in serious personal injury.

COLD WEATHER OPERATION

For cold weather operation, near and below freezing, the moisture in the air line may freeze and prevent tool operation. We recommend the use of air tool lubricant or permanent antifreeze (ethylene glycol) as a cold weather lubricant.

Do not store tools in a cold weather environment to prevent frost or ice formation on the tool's operating valves and mechanisms that could cause tool failure.

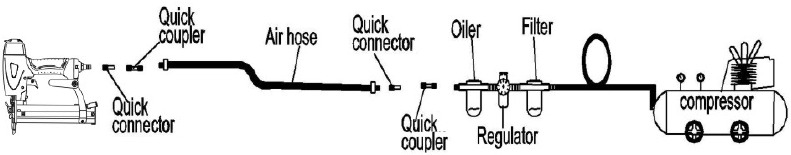

RECOMMENDED HOOKUP

The air compressor must be able to maintain a minimum of 70psi when the tool is being used. An inadequate air supply can cause a loss of power and inconsistent driving.

Do not connect with an air compressor which can potentially exceed 200psi. As tool may burst, possibly causing injury.

TROUBLE SHOOTING

| PROBLEMS | POSSIBLE CAUSES | SUGGESTED SOLUTIONS |

| Air leaking near the top of the tool or in the trigger area. |

|

|

| Air leaking near the bottom of the tool. |

|

|

| Tool does nothing or operates sluggishly. |

|

|

| Fasteners are jammed in the tool frequently. |

|

|

Use only Freeman Authorized Repair Parts. For questions please call 1-888-669-5672 or visit our website at http://www.freemantools.com

WEARING PARTS

Repair parts can be ordered from our website: http://www.freemantools.com

- HTTP://WWW.FREEMANTOOLS.COM

- 1-888-669-5672

- PRIME GLOBAL PRODUCTS, INC.

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the PFBC940 and is the answer not in the manual?

Questions and answers