Summary of Contents for Leuze MA 248i

- Page 1 Original operating instructions MA 248 Fieldbus gateway – PROFINET-IO We reserve the right to make technical changes EN 2022/04/22 - 50113019...

- Page 2 © 2022 Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen / Germany Phone: +49 7021 573-0 Fax: +49 7021 573-199 http://www.leuze.com info@leuze.de Leuze electronic GmbH + Co. KG MA 248...

-

Page 3: Table Of Contents

Connecting the Leuze device ........ - Page 4 Modular structure of the parameter ..........54 Leuze electronic GmbH + Co. KG...

- Page 5 Specifications for Leuze end devices ........

- Page 6 17.1 ASCII Table ..............79 Leuze electronic GmbH + Co. KG...

-

Page 7: General Information

NOTE The Declaration of Conformity for these devices can be requested from the manufacturer. The manufacturer of the product, Leuze electronic GmbH + Co. KG in D-73277 Owen, possesses a certi- fied quality assurance system in accordance with ISO 9001. -

Page 8: Definition Of Terms

• Leuze device (DEV): Leuze devices, e.g., bar code readers, RFID readers, VisionReader… • Online command: These commands refer to the respective, connected ident device and may be different depending on the device. -

Page 9: Safety

Intended use The MA 248 modular connection unit is used for connecting Leuze devices such as bar code or 2D-code readers, hand-held scanners, RFID read/write devices, etc. directly to the fieldbus. CAUTION! Observe intended use! ... -

Page 10: Competent Persons

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed. Exemption of liability Leuze electronic GmbH + Co. KG is not liable in the following cases: • The device is not being used properly. • Reasonably foreseeable misuse is not taken into account. -

Page 11: Fast Commissioning / Operating Principle

3.3.1 Connecting the Leuze device To connect the Leuze device to the internal RS 232 device interface, open the housing of the MA 248 and lead the corresponding device cable (see Chapter 14.6) through the middle threaded opening. Connect the cable to the internal device interface (X30, X31 or X32, see Chapter 7.5.1). -

Page 12: Connecting The Power Supply And The Bus Cable

Install the GSD file associated with the device in the PROFINET-IO Manager of your control. Leuze electronic GmbH + Co. KG MA 248... -

Page 13: Configuration

2 bytes smaller than the selected data module. E.g., when using the data module with 12 bytes, there are effectively 10 bytes available for user data on the Leuze device after subtracting the 2 bytes for status and control bytes. Recommendation In most cases, the 4-byte module is sufficient for the output module. -

Page 14: Configuration Of The Device Name - Device Naming

Assigning the device names to the configured IO devices Select the respective gateway MA 248i for the "device naming" based on its MAC address. The unique "device name" (which must match the participant in the HW Config) is then assigned to this participant. -

Page 15: Device Name Check

Device name check After completing the configuration phase, recheck the "device names" that have been assigned. Please ensure that these names are unique and that all participants are located in the same subnet. Leuze electronic GmbH + Co. KG MA 248... -

Page 16: Device Description

Leuze devices, such as the BCL 8, BCL 22, etc., directly to the fieldbus. This is accomplished by transmitting the data from the Leuze device via an RS 232 (V.24) interface to the MA 248 where a module converts it into the fieldbus format. -

Page 17: Operating Modes

For fast commissioning, the MA 248 offers an additional operating mode, the "Service mode", in addition to the "Standard mode". In this operating mode, the Leuze device can, for example, be configured on the MA 248 and the communication can be tested on the fieldbus. To do this, you need a PC/laptop with a suitable terminal program, as BCL-Config from Leuze or similar. -

Page 18: Fieldbus Systems

ATTENTION! For the service PC to function, the RS 232 parameters must be the same as those of the MA. The Leuze standard setting of the interface is 9600bd, 8N1 and STX, data, CR, LF. Fieldbus systems Various product variants of the MA 2xx series are available for connecting to different fieldbus systems such as PROFIBUS DP, PROFINET-IO, DeviceNet and Ethernet. - Page 19 The PLC must communicate this device name to the participant during the "device naming". MA 248 PC / PLC host interface "192.168.0.100" Other network participants Figure 4.4: PROFINET-IO in a star topology Leuze electronic GmbH + Co. KG MA 248...

- Page 20 "device naming". Further information may be found in chapter "Step 6 – Configuration of the device name – device naming" on page 52. The maximum length of a segment (connection from the hub to the last participant) is limited to 100m. Leuze electronic GmbH + Co. KG MA 248...

-

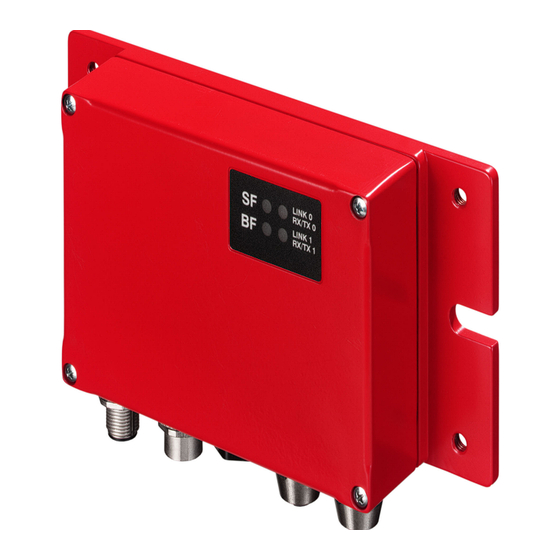

Page 21: Technical Data

SF LED red Collection error Mechanical data Degree of protection IP 65 (with screwed-on M12 and connected Leuze device) Weight 700g Dimensions (H x W x D) 130 x 90 x 41mm / with plate: 180 x 108 x 41mm... -

Page 22: Dimensioned Drawings

Figure 5.1: MA 248 dimensioned drawing Type overview The following versions of the MA 2xx gateway family are available for facilitating the integration of Leuze RS 232 devices in the various fieldbus types. Fieldbus Device type Part no. PROFIBUS DP V0... -

Page 23: Installation And Mounting

Device name plate MA 248 Save the original packaging for later storage or shipping. If you have any questions concerning your shipment, please contact your supplier or your local Leuze sales office. Observe the applicable local regulations when disposing of the packaging materials. -

Page 24: Mounting

• The housing cover should be easily accessible, so that the internal interfaces (device interface for connecting the Leuze device via PCB connectors, service interface) and other operational controls are easy to reach. • Maintaining the required environmental conditions (temperature, humidity). -

Page 25: Electrical Connection

Two additional M12 sockets are used for connection to the fieldbus. Both of these connections are D-coded. An internal RS 232 interface is used for connecting the respective Leuze device. Another internal RS 232 interface functions as a service interface for configuring the connected device via a serial null modem cable. -

Page 26: Pwr In - Voltage Supply / Switching Input/Output

(on SWIN_1, PWRIN) Table 7.2: Device-specific function of the SWIOs Supply voltage ATTENTION! For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National Electric Code). Leuze electronic GmbH + Co. KG MA 248... -

Page 27: Pwr Out Switching Input/Output

PWR IN to PWR OUT can be interrupted by means of a jumper. In this case, only the switching input and output on PWR IN are active. The function of the switching inputs and outputs is dependent on the connected Leuze device. Detailed information on this topic can be found in the respective operating instructions. -

Page 28: Bus Out

Use CAT 5 cables for the connection. NOTE For the MA 248 as standalone device or as the last participant in a linear topology, termination on the BUS OUT socket is not mandatory! Leuze electronic GmbH + Co. KG MA 248... -

Page 29: Device Interfaces

MA 248 Open 7.5.1 RS 232 device interface (accessible after opening the device, internal) The device interface is prepared for the system plugs (PCB connectors) for Leuze devices RFI xx, RFM xx, BCL 22. Figure 7.5: RS 232 device interface The standard devices are connected with 6- or 10-pin connector piece to X31 or X32, respectively. -

Page 30: Profinet-Io Wiring

ATTENTION! For the service PC to function, the RS 232 parameters must be the same as those of the MA. The Leuze standard setting of the interface is 9600Bd, 8N1 and STX, data, CR, LF. NOTE To configure the devices connected to the external interface, e.g., BCL 8 (JST pin strip "X30"), a cable specially configured for this purpose is necessary. -

Page 31: Status Displays And Operational Controls

For details, see chapter 15 "Diagnostics and troubleshooting" LINK 0/RX/TX 0 LED Green, continuous light LINK0 Link 0 RX/TX 0 - Connection exists Yellow, flashing RX/TX0 Link 0 RX/TX 0 - Data exchange Leuze electronic GmbH + Co. KG MA 248... -

Page 32: Internal Interfaces And Operational Controls

B Rotary switch S4 for device selection C Service switch D RS 232 Sub-D service interface E Jumper for bridging, separating switching input/output PWR IN/OUT F 3 JST pin strips: connection of the Leuze devices G MA 248 : not equipped Figure 8.2: Front view: operational controls of the MA 248 Leuze electronic GmbH + Co. -

Page 33: Connections Of The X30

Second BUS interface for creating a network with other participants in a linear topology JST pin strip with 12 pins Leuze device Connection of the Leuze devices with 5V / 1A (BCL 8, BPS 8 and hand-held scanner) JST pin strip with 10 pins Leuze device Connection of the Leuze devices (BCL, RFI, RFM,…) -

Page 34: Rs 232 Service Interface - X33

8.2.3 RS 232 service interface – X33 The X33 RS 232 interface facilitates the configuration of the Leuze device and the MA 248 via PC, which is connected by means of a serial null modem cable. X33 pin assignment – service connector... - Page 35 Reset to factory setting The gateway is set via the switch position on the Leuze device. If the switch position is changed, the device must be restarted, since the switch position is only queried after switching off completely and then restarting the device.

-

Page 36: Configuration

MA with the help of a suitable configuration program. The respective configuration programs – e.g. for bar code readers the BCL-Config, for RFID devices the RF-Config etc. – and the associated documentation are provided on the Leuze home page www.leuze.com in the download area. NOTE In order to display the help texts, a PDF viewer program (not included in the scope of delivery) must also be installed. - Page 37 Firmware Date Firmware date. Table 9.2: General firmware information Selected scanner Currently selected Leuze device (selected via switch S4). Gateway mode Transparent or Collective mode. Ring Buffer fill level Current fill level of the ring memory in Collective mode (ASCII->Fieldbus).

-

Page 38: Telegram

Only the data part with the corresponding frame (e.g., STX, CR & LF) is then transmitted between the fieldbus gateway and the Leuze end device. The two control bytes are processed by the fieldbus gateway. The corresponding control and status bits and their meaning are specified in Section 10.2 and Section 10.3. -

Page 39: Detailed Description Of The Bits (Input Byte 0)

0: Device in operating "DEV", i.e. if the device is in either fieldbus gateway or mode Leuze device service mode. This is also indicated by a 1: Device in service flashing PWR LED on the front side of the device. Upon mode changing to the normal operating mode "RUN", the bit... - Page 40 The memory size of the gateway for the data of both the PLC and the Leuze end device is 1 kByte. Bit 7: New Data: ND This bit is only relevant in Transparent mode.

-

Page 41: Detailed Description Of The Bits (Input Byte 1)

Command mode This bit is used to activate Command mode. In Com- mand mode, no data is sent by the PLC to the Leuze end 0: Default, transparent device via the gateway. In Command mode, various bits Command mode... -

Page 42: Detailed Description Of The Bits (Output Byte 1)

Toggle bit: changing this bit causes all data which was 1->0: Data to RS 232 copied to the transmission buffer of the fieldbus gateway via the CTB bit to be transmitted to the RS 232 interface or the connected Leuze device. Leuze electronic GmbH + Co. KG MA 248... -

Page 43: Reset Function / Deleting Memory

OUT data byte 1/parameter byte 1: This sets the memory or status/control bits to 00h. Please observe that the data image may need to be updated by toggling the R-ACK in Collective mode. Leuze electronic GmbH + Co. KG MA 248... -

Page 44: Modes

11.1.1 Reading slave data in Collective mode (gateway -> PLC) If the Leuze device transmits data to the fieldbus gateway, the data is stored temporarily in a buffer. The PLC is signaled via the "DEX" bit that data is ready for retrieval in the memory. Data is not automatically transmitted. - Page 45 The data is then sent in the order received from the buffer to the connected Leuze device via the serial interface with the command: "SFB" (Send data from transmit buffer). Please don't forget the suitable data frame! Afterward, the buffer is again empty and can be written with new data.

-

Page 46: Command Mode

(e.g., v, +, -, etc.). If, for example, the version of the Leuze end device is to be queried, the corresponding bit is to be set so that a "v" is sent to the Leuze device with the <STX>... - Page 47 Examples for the activation of a Leuze device In Command mode, control or output byte 0.0 is to be set for activating the Command mode. Only the corresponding bit (control or output byte 2.1) then needs to be set for activating and deactivating the reading gate.

- Page 48 Figure 11.3: Activating DEV and reading data NOTE Further information on fieldbus telegram structure can be found in Chapter 10.1. A specification of all usable commands can be found in chapter "Specifications for Leuze end devices" on page 66. Leuze electronic GmbH + Co. KG...

-

Page 49: Commissioning And Configuration

Before connecting the supply voltage, recheck all connections and ensure that they have been properly made. The Leuze device must be connected to the internal RS 232 device interface. Connecting the Leuze device Open the housing of the MA 248 and lead the corresponding device cable (see Chapter 14.6) through... -

Page 50: Configuration Steps For A Siemens Simatic S7 Control

During operation of the MA 248 on the PROFINET-IO, all parameters are set to default values. If these parameters are not changed by the user, the device functions with the default settings delivered by Leuze. For the default settings of the MA 248 , please refer to the following module descriptions. -

Page 51: Step 3 - Hardware Configuration Of The S7 Plc: Configuration

2 bytes smaller than the selected data module. E.g., when using the data module with 12 bytes, there are effectively 10 bytes available for user data on the Leuze device after subtracting the 2 bytes for status and control bytes. Recommendation In most cases, the 4-byte module is sufficient for the output module. -

Page 52: Step 5 - Transmission Of The Configuration To The Controller (S7 Plc)

PROFINET-IO defines the "naming of the device" as the creation of a name-based relationship for a PROFINET-IO device. Assigning the device names to the configured IO devices Figure 12.3: Assigning the device names to the configured IO devices Leuze electronic GmbH + Co. KG MA 248... -

Page 53: Step 7 - Check Device Names

After completing the configuration phase, it is sensible to recheck the "device names" that have been assigned. Please ensure that these names are unique and that all participants are located in the same subnet. Leuze electronic GmbH + Co. KG MA 248... -

Page 54: Commissioning Via The Profinet-Io

By using an application-specific configuration tool, such as, e.g. Simatic Manager for the Siemens PLC, the required modules are integrated into a project during commissioning and its settings and param- eters are configured accordingly. These modules are provided by the GSD file. Leuze electronic GmbH + Co. KG MA 248... -

Page 55: Permanently Defined Parameters/Device Parameters

7, 8, 9 Parity Yes, None None Stop bit Use separator Yes, No Use status and Yes, No control bits Table 12.1: Device parameters Parameter length: 33 bytes Input data None Output data None Leuze electronic GmbH + Co. KG MA 248... -

Page 56: Overview Of The Project Modules

Data content with max. 18 bytes 32 bytes output Data content with max. 30 bytes 64 bytes output Data content with max. 62 bytes 128 bytes output Data content with max. 126 bytes Table 12.2: Module overview Leuze electronic GmbH + Co. KG MA 248... -

Page 57: Preparing The Control For Consistent Data Transmission

You can download the config tool from www.leuze.com for BCL, RFID, etc. In order to communicate with the connected Leuze device, the STX, data, CR, LF framing must be set on the PC terminal program, as the Leuze device is preconfigured ex works for this frame character. -

Page 58: Specific Feature For The Use Of Hand-Held Scanners (Bar Code And 2D Devices, Combi Devices With Rfid)

Switch the MA 248 to switch position "RUN" (operation). The Leuze device is now connected to the fieldbus. Activation of the Leuze device can now occur via the switching input on the MA 248 , via the process data word Out bit 1 (bit 0.2) or by transmitting a "+"... - Page 59 Example: Control byte 0 Control byte 1 Data CHAR Plain text Leuze electronic GmbH + Co. KG MA 248...

-

Page 60: Diagnostics And Troubleshooting

Avoid EMC coupling caused by power cables laid parallel to device lines. Check max. network expansion as a Overall network expansion exceeded. function of the max. cable lengths. Figure 13.2: Interface error Leuze electronic GmbH + Co. KG MA 248... -

Page 61: Service And Support

13.3 Service and support Service hotline You can find the contact information for the hotline in your country on our website www.leuze.com under Contact & Support. Repair service and returns Defective devices are repaired in our service centers competently and quickly. We offer you an extensive service packet to keep any system downtimes to a minimum. -

Page 62: Type Overview And Accessories

Overview of MA 2xx types 14.3 Accessories – Connectors Order codes for M12 connectors on our website www.leuze.com under Products - Network and connection technology - Cables and connectors - User-configurable connectors 14.4 Accessories – Preassembled cables for voltage supply 14.4.1 Contact assignment of PWR connection cable... -

Page 63: Technical Data Of The Cables For Voltage Supply

Bending radius > 50mm 14.4.3 Order codes of the cables for voltage supply Order codes for 5-pin M12 connection cable with socket on our website www.leuze.com under Products - Network and connection technology - Cables and connectors - Connection cables 14.5 Accessory –... -

Page 64: Accessory - Preassembled Cables For Connecting Leuze Ident Devices

Ethernet interconnection cables M12 D-coded to M12 D-coded or M12 D-coded to RJ 45 on our website www.leuze.com under Products - Network and connection technology - Cables and connectors - Intercon- nection cables 14.6 Accessory – Preassembled cables for connecting Leuze Ident devices 14.6.1 Order codes for the device connection cables... -

Page 65: Maintenance

Contact your Leuze distributor or service organization should repairs be required. The addresses can be found on the inside of the cover and on the back. NOTE When sending devices to Leuze for repair, please provide an accurate description of the error. 15.3 Disassembling, packing, disposing Repacking For later reuse, the device is to be packed so that it is protected. -

Page 66: Specifications For Leuze End Devices

The corresponding Leuze end device can be selected while configuring the fieldbus gateway (see chapter 9 "Configuration"). The exact specifications for the individual Leuze end devices can be found in the following sections and in the device description. The corresponding serial command is sent to the Leuze end device in Command mode. To send the corre- sponding command to the RS 232 device after activating the Command mode in byte 0 (control bit 0.0),... -

Page 67: Bar Code Reader Bcl 8 (S4 Switch Position 1)

• Input module: dependent on the number of digits of the bar code that is to be read. With an 18-digit bar code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 68: Bar Code Reader Bcl 22 (S4 Switch Position 2)

• Input module: dependent on the number of digits of the bar code that is to be read. With an 18-digit bar code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 69: Bar Code Reader Bcl 300I, Bcl 500I, Bcl 600I (S4 Switch Position 4)

• Input module: dependent on the number of digits of the bar code that is to be read. With an 18-digit bar code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 70: Bar Code Reader Bcl 90, Bcl 900I (S4 Switch Position 5)

• Input module: dependent on the number of digits of the bar code that is to be read. With an 18-digit bar code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 71: Lsis 122, Lsis 222 (S4 Switch Position 6)

• Input module: dependent on the number of digits of the 2D code that is to be read. With an 18-digit code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 72: Lsis 4X2I, Dcr 202I (S4 Switch Position 7)

• Input module: dependent on the number of digits of the 2D code that is to be read. With an 18-digit code (+ 2 bytes of status bytes), for example, the input module with 20 bytes is advisable. • Output module: 4 bytes Leuze electronic GmbH + Co. KG MA 248... -

Page 73: Hand-Held Scanner (S4 Switch Position 8)

• Input module: dependent on the number of digits of the bar code or 2D code that is to be read. With a 12-digit code (+ 2 bytes of status bytes), for example, the input module with 16 bytes is advis- able. • Output module: none Leuze electronic GmbH + Co. KG MA 248... -

Page 74: Rfi, Rfm, Rfu Rfid Readers (S4 Switch Position 9)

• Output module: 4 bytes If data are to be written, it is advisable to use the setting with 24 bytes or 32 bytes. The RFID devices expect the telegrams / data in HEX format. Leuze electronic GmbH + Co. KG MA 248... -

Page 75: Bps 8 Bar Code Positioning System (S4 Switch Position A)

In this switch position, the MA automatically sends a position request to the BPS 8 every 10ms until another command comes via the control. Automatic request only restarts when a new position request is sent by the PLC or when the MA is restarted. Leuze electronic GmbH + Co. KG MA 248... -

Page 76: Interface (S4 Switch Position B)

Transfer position and velocity value cyclically C0F939 Transfer marker information C0FA3A Not used / reserved Transfer diagnostic information C0FC3C Activate standby C0FD3D Recommended settings • Input module: 8 bytes • Output module: 8 bytes Leuze electronic GmbH + Co. KG MA 248... - Page 77 The ODSL 9/96B is to be operated in the "Precision" measure mode. The mode is set through the display menu via Application -> Measure mode -> Precision. You can find more details on this in the technical description. Leuze electronic GmbH + Co. KG MA 248...

-

Page 78: Modular Connection Unit Ma 3X (S4 Switch Position C)

Switch the voltage on and wait until it is ready for operation. If necessary, switch the voltage off to prepare for commissioning. Set service switch S10 to the "RUN" position. Leuze electronic GmbH + Co. KG MA 248... -

Page 79: Appendix

& AMPERSAND Ampersand APOSTROPHE Apostrophe OPENING PARENTHESIS Opening parenthesis CLOSING PARENTHESIS Closing parenthesis ASTERISK Star PLUS Plus sign COMMA Comma HYPHEN (MINUS) Hyphen (minus) PERIOD (DECIMAL) Period (decimal) SLANT Slant COLON Colon Leuze electronic GmbH + Co. KG MA 248... - Page 80 GREATER THAN Greater than QUESTION MARK Question mark COMMERCIAL AT Commercial AT OPENING BRACKET Opening bracket REVERSE SLANT Reverse slant CLOSING BRACKET Closing bracket CIRCUMFLEX Circumflex UNDERSCORE Underscore ‘ GRAVE ACCENT Grave accent Leuze electronic GmbH + Co. KG MA 248...

- Page 81 CTRL DESIGNATION MEANING OPENING BRACE Opening brace VERTICAL LINE Vertical line CLOSING BRACE Closing brace TILDE Tilde DELETE (RUBOUT) Delete Leuze electronic GmbH + Co. KG MA 248...

- Page 82 Service fieldbus gateway ....17 Service Leuze Device ....17 Output byte 0 Fast commissioning .

- Page 83 Type overview ..... . . 22 Writing slave data ..... . . 44 Leuze electronic GmbH + Co. KG MA 248...

Need help?

Do you have a question about the MA 248i and is the answer not in the manual?

Questions and answers