Summary of Contents for Trane Technologies Thermo King TouchLog

- Page 1 Operator’s Manual TouchLog (Was TouchPrint Datalogger Until 2019) T T K K 6 6 1 1 0 0 0 0 9 9 - - 1 1 2 2 - - O O P P - - E E N N September 2019...

-

Page 2: Table Of Contents

Table of Contents I I n n t t r r o o d d u u c c t t i i o o n n ....................7 7 C C u u s s t t o o m m e e r r S S a a t t i i s s f f a a c c t t i i o o n n S S u u r r v v e e y y . - Page 3 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Quick Print ..........26 Enhancements Implemented with Firmware 515.029 .

- Page 4 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Short Logging Interval........39 Firmware Update .

- Page 5 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Recording Duration ........54 Data Archiving .

- Page 6 T T a a b b l l e e o o f f C C o o n n t t e e n n t t s s Telematics Communication ......68 Other Errors reported from TouchLog.

- Page 7 Introduction This manual is published for informational purposes only and the information furnished herein should not be considered as all-inclusive or meant to cover all contingencies. If more information is required, consult your Thermo King Service Directory for the location and telephone number of the local dealer.

-

Page 8: Customer Satisfaction Survey

Customer Satisfaction Survey Let your voice be heard! Your feedback will help improve our manuals. The survey is accessible through any internet-connected device with a web browser. Scan the Quick Response (QR) code or click Technical Publications EMEA Feedback to complete the survey. TK 61009-12-OP-EN... -

Page 9: Safety Information

Safety Information Danger, Warning, Caution, and Notice Thermo King®/ FRIGOBLOCK recommends that all service be performed by a Thermo King/FRIGOBLOCK dealer and to be aware of several general safety practices. Safety advisories appear throughout this manual as required. Your personal safety and the proper operation of this unit depend upon the strict observance of these precautions. -

Page 10: General Practices

S S a a f f e e t t y y I I n n f f o o r r m m a a t t i i o o n n General Practices Thermo King recommends that all services be performed by a Thermo King dealer. -

Page 11: Electrical Hazards

S S a a f f e e t t y y I I n n f f o o r r m m a a t t i i o o n n Electrical Hazards D D a a n n g g e e r r H H a a z z a a r r d d o o u u s s V V o o l l t t a a g g e e ! ! Risk of fatal injury from electric shocks! Do not touch exposed cables with your bare hands. - Page 12 S S a a f f e e t t y y I I n n f f o o r r m m a a t t i i o o n n W W a a r r n n i i n n g g H H a a z z a a r r d d o o u u s s V V o o l l t t a a g g e e ! ! Never work alone on high voltage circuits in the refrigeration unit.

-

Page 13: First Aid

S S a a f f e e t t y y I I n n f f o o r r m m a a t t i i o o n n First Aid R R E E F F R R I I G G E E R R A A N N T T •... - Page 14 S S a a f f e e t t y y I I n n f f o o r r m m a a t t i i o o n n If the victim must be removed from a live circuit, pull the victim away with a non-conductive material.

-

Page 15: Product Overview

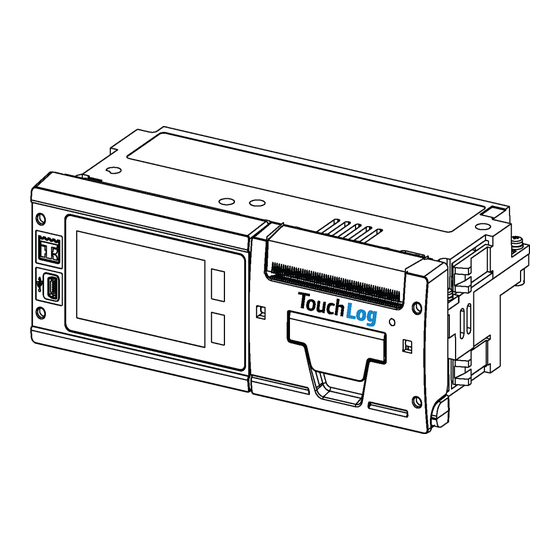

Product Overview TouchLog has been designed specifically to meet the recommendations of Food Hygiene Regulations with the regard to transport and delivery of chilled and frozen foodstuffs in refrigerated vehicles. TouchLog is approved to the EN 12830 (and other national requirements) meeting the objectives of European Regulations 37/2005 and 852/2004. -

Page 16: P P R R O O D D U U C C T T O O V V E E R R V V I I E E W

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w TouchLog measures temperatures and status (ON/OFF) conditions and automatically stores these in the form of individual files. TouchLog can then provide a record of any specific period, including the full current day’s measurements or any previous day retained in memory as either a paper ticket printout or in a format that can be transferred to an industry standard... -

Page 17: Printer

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w The ignition input may be used to backlit the display continuously and independently of any key operations, by specific setting (select Auto) of the backlight parameter of the User menu. -

Page 18: Micro Controller

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w previously required, from the last section, in order to have complete printed data. -

Page 19: Analogue Input

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w TouchLog models have six configurable inputs, to be used either for temperature measurement (analogue) or status and on/off inputs derived from volt free contacts (digital). -

Page 20: Digital Input

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w the Thermo King C C a a r r g g o o W W a a t t c c h h TouchLog). The default sensor measured temperature range is between -40°C and +70°C. -

Page 21: Communication Interfaces

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w t t e e l l e e m m a a t t i i c c s s s s y y s s t t e e m m s s a a r r e e c c o o n n n n e e c c t t e e d d , , p p o o w w e e r r n n e e e e d d s s t t o o b b e e a a p p p p l l i i e e d d t t o o p p i i n n 2 2 a a n n d d 3 3 . -

Page 22: Serial Port

P P r r o o d d u u c c t t O O v v e e r r v v i i e e w w • When sending the data to the USB flash drive, the display shows a clear indication. -

Page 23: Getting Started

Getting Started Factory Settings Here are the settings of the TouchLog as programmed during the production process. The default values for the parameters of the user menu – (See “User Menu,” p. 32 for more details) – are as follows: Table 1. -

Page 24: Probe Installation

G G e e t t t t i i n n g g S S t t a a r r t t e e d d 4. Buzzer enable: No 5. Serial ports setting: Port Type RS-232 RS-232 RS-485 Protocol ModBus... -

Page 25: Check The Time And Date

G G e e t t t t i i n n g g S S t t a a r r t t e e d d Check the Time and Date The time and date which are printed at the end of the Journey and Delivery ticket are factory set to Central European Time(CET), that is GMT+1, as dispatch from production. -

Page 26: Basic Operations

Basic Operations Basic operation covers the most commonly used functions such as using the display, choosing the print style, obtaining printouts, checking the inputs, changing the logging interval and configuring alarms. For additional operational information see “Advanced Operation,” p. A complete list of all these commands are described below. Quick Print The quick print button enables to print a journey ticket including all the data for the day since midnight. -

Page 27: Enhancements Implemented With Firmware 515.029

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s 4. Change of setpoint 5. Power On event 6. Separate column for each Input (I2, I3 etc.) 7. - Page 28 B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s S S a a m m p p l l e e o o f f T T i i c c k k e e t t o o n n S S L L X X e e S S p p e e c c t t r r u u m m Figure 6.

-

Page 29: Quick Info

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Door sensor from TouchLog (2 wire door switch to Input 3) has been opened – it triggers an alarm. -

Page 30: Print Menu

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Print Menu The user has 3 options in the print Menu: 1. -

Page 31: Journey Ticket Tabular

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Journey Ticket Tabular This function enables to print the recorded temperature measurements over a period of time in a tabular format, 7 columns maximum;... -

Page 32: Journey Ticket Graph

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Journey Ticket Graph This function enables to print the recorded temperature measurements over a period of time in a graph format. -

Page 33: Language

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Language This menu enables to select the language in which the user menu is displayed and the ticket is printed among the 15 languages available. -

Page 34: Daylight Saving Time Set

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Daylight Saving Time Set Similarly to brightness, this function allows to adjust the display background for easier reading. -

Page 35: Export In Pdf/Txt

B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s Export in PDF/TXT The user can decide which file format to export the data to the USB Flash drive. - Page 36 B B a a s s i i c c O O p p e e r r a a t t i i o o n n s s There is a comprehensive alarm menu in order to setup temperature out of range alarms, see the details below: Description Alarm Menu...

-

Page 37: Advanced Operation

Advanced Operation Advanced operation covers the less commonly used functionalities such as selecting the graph scale, checking the date and time, changing the date format, updating the firmware and setting up the serial ports. For basic operational information see “Basic Operations,” p. Service Menu By pressing this key for more than 2 seconds, the user will be directed to the service menu. -

Page 38: Touchlog Model Name

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n TouchLog Model Name This menu allows to review the TouchLog model name as well as the serial number. -

Page 39: Time Scale For Graph Printing

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n Time Scale for Graph Printing This menu enables to define the graph scale based on time vs cm ratio. - Page 40 A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n 1. Via a PC and no specific application, the user will copy the new firmware version onto a USB memory key.

-

Page 41: Wintrac Interface Via Usb

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n files have been copied into the external flash memory, the following image will appear. -

Page 42: Format Zone Selection

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n Alarm Key- Record- Alarm -Temp Out- CAS- -Door out of range... -

Page 43: Trailer Vs Truck Installation

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n TracKing protocol is selected. Alternatively, this COM port can be used as an interface to a 3rd party communication device (Modbus protocol). -

Page 44: Updating Glosarries Menu

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n The RTC clock is supported by an internal battery guaranteed to last at least 5 years. -

Page 45: Enable Door And Defrost Information In Ticket

A A d d v v a a n n c c e e d d O O p p e e r r a a t t i i o o n n Enable Door and Defrost Information in Ticket Door open and close and defrost start and end are captured as events by the TouchLog if it is connected to servicewatch. -

Page 46: Establishing The Connection

Wintrac Communication and Data Export Establishing the Connection Use Wintrac version 5.7.1 or above. Using Wintrac the user can update the settings of the TouchLog (Trailer Id, Customer name, Sensor description,...) and can perform full or date based downloads. N N o o t t e e : : In the case that Wintrac does not recognise your TouchLog, you may need to download the drivers. -

Page 47: Update And Download Via Wintrac

W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t In the display unit tab, the user can select the unit of measure (degree Fahrenheit or degree Celsius) of the temperature values to be displayed in Wintrac. - Page 48 W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t that case, a flexfield will open in a separate window allowing the user to type any name.

-

Page 49: Changing Advanced Configuration Parameters

W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t In case of any modification of sensor name or type, the user needs to click on the Update unit button to make this change effective in the TouchLog. -

Page 50: Performing Data Download

W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t Again once a parameter has been changed in Wintrac, to make it effective in the connected TouchLog, the user needs to click on the Update unit button. -

Page 51: View The Data In Graphical And Tabular View

W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t Once the download is complete, the data are saved in the Wintrac folder with the file extension (.wtd) View the Data in Graphical and Tabular View... - Page 52 W W i i n n t t r r a a c c C C o o m m m m u u n n i i c c a a t t i i o o n n a a n n d d D D a a t t a a E E x x p p o o r r t t Once setup, a USB Flash drive while connected to the mini USB port via the provided cable interface (spn 420969) will be automatically detected.

-

Page 53: Specifications

Specifications TouchLog temperature recorders are designed to meet the requirements of EN12830 and other national requirements to support the objectives of directives 37/2005 usually known as the Quick Frozen Food Directive. Type of Application • Suitable for recording storage temperatures. •... -

Page 54: Supply Voltage

S S p p e e c c i i f f i i c c a a t t i i o o n n s s Supply Voltage DC 10.5 V to 32 V. The Maximum absorbed currents are: •... -

Page 55: Time Recording Error

S S p p e e c c i i f f i i c c a a t t i i o o n n s s Time Recording Error The maximum error of the clock in duration of 1 week is < 1 minute. Climatic Environment •... -

Page 56: Cleaning And Maintenance

S S p p e e c c i i f f i i c c a a t t i i o o n n s s Cleaning and Maintenance Visible surfaces may be cleaned with a damp cloth and mild detergent. There are no general maintenance procedures, but replacement of the paper is described in the installation manual. -

Page 57: Compliance Information

Compliance Information The Temperature recorder TouchLog manufactured by Eliwell / Invensys on behalf of Thermo King complies to the following directives: • Commission Regulation (EC) No. 37/2005 of 12 January 2005 on the monitoring of temperatures in the means of transport, warehousing and storage of quick-frozen foodstuffs intended for human consumption. -

Page 58: Frequently Asked Questions

Frequently Asked Questions Unable to Enter the Menus using Touchscreen The Touchscreen is a Capacitive Touch keyboard with 8 keys, 6 on the display and 2 on the side. These 8 keys have different functions, refer to “User Menu,” p. 32 “Service Menu,”... -

Page 59: Touchlog Communication To Wintrac

F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s TouchLog Communication to Wintrac Installing the Drivers 1. - Page 60 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s 4.

-

Page 61: Communicate With Wintrac

F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s When establishing a connection between your Wintrac and TouchLog, seeC C o o n n n n e e c c t t i i o o n n O O K K , , o o n n C C O O M M 4 4 ( ( I I n n t t h h i i s s c c a a s s e e ) ) . -

Page 62: Wintrac Not Establishing A Connection With Your

F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s Wintrac not Establishing a Connection with Your TouchLog N N o o t t e e : : TouchLog has to be connected to the laptop when installing the driver. - Page 63 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s N N o o C C o o n n n n e e c c t t i i o o n n M M a a d d e e When you connect the TouchLog to your laptop for the first time - you will see the prompt below.

- Page 64 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s 4.

- Page 65 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s 6.

- Page 66 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s 8.

-

Page 67: Performance At High Ambient Temperatures

F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s 10. -

Page 68: Error Message - No Data

F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s Error Message –... - Page 69 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s Other Errors reported from TouchLog E E r r r r o o r r C C o o d d e e s s Every error condition will generate an alarm code, as below.

- Page 70 F F r r e e q q u u e e n n t t l l y y A A s s k k e e d d Q Q u u e e s s t t i i o o n n s s In case of multiple error conditions (E.g.

- Page 71 N N o o t t e e s s TK 61009-12-OP-EN...

- Page 72 Thermo King – by Trane Technologies (NYSE: TT), a global climate innovator – is a worldwide leader in sustainable transport temperature control solutions. Thermo King has been providing transport temperature control solutions for a variety of applications, including trailers, truck bodies, buses, air, shipboard containers and railway cars since 1938.

Need help?

Do you have a question about the Thermo King TouchLog and is the answer not in the manual?

Questions and answers