Summary of Contents for Bently Nevada 3500/33

- Page 1 Part number 162291-01 Revision NC, July 2002 3500/33 16 CHANNEL RELAY MODULE OPERATION AND MAINTENANCE MANUAL...

- Page 2 All Rights Reserved. The information contained in this document is subject to change without notice. The following are trademarks of Bently Nevada in the United States and other countries: Actionable Information™, Actionable Information to the Right People at The Right Time™, ADRE®, Bently Nevada®, CableLoc™, Data Manager®, Decision...

-

Page 3: Additional Information

3500/33 Operation and Maintenance Additional Information NOTICE: This manual does not contain all the information required to operate and maintain the 16 Channel Relay Module. Refer to the following manuals for other required information. 3500 Monitoring System Rack Installation and Maintenance Manual (129766-01) •... -

Page 4: Table Of Contents

Troubleshooting............... 33 Self-test ......................... 33 LED Fault Conditions ..................... 34 System Event List Messages ................. 35 Alarm Event List Messages..................44 Ordering Information ............... 45 16 Channel Relay Module ..................45 Specifications................47 3500/33 16 Channel Relay Module ..............47... -

Page 5: Receiving And Handling Instructions

Receiving Inspection Visually inspect the module for obvious shipping damage. If shipping damage is apparent, file a claim with the carrier and submit a copy to Bently Nevada. Handling and Storing Considerations Circuit boards contain devices that are susceptible to damage when exposed to electrostatic charges. - Page 6 3500/33 Operation and Maintenance...

-

Page 7: General Information

3500/33 Operation and Maintenance 2 General Information General Information The 16 Channel Relay Module can be used for most monitoring applications. It uses a single relay to drive the output for each channel. See section 2.1 for additional information on the 16 Channel Relay Module. -

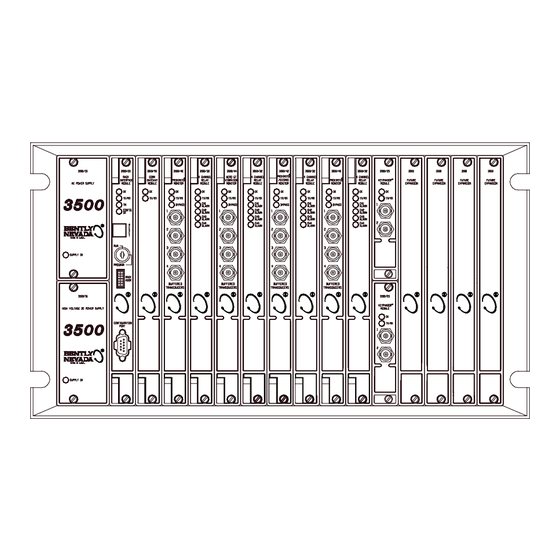

Page 8: The 16 Channel Relay Module

2 General Information 3500/33 Operation and Maintenance The 16 Channel Relay Module The 16 Channel Relay Module is a full-height module that provides 16 relay outputs. Any number of 16 Channel Relay Modules can be placed in any of the slots to the right of the Rack Interface Module. - Page 9 3500/33 Operation and Maintenance 2 General Information Bussed Relays (Alert and Danger) ##A1 = Any Active Alert ##A2 = Any Active Danger ((S02C##A1) OR (S03C##A1) OR ... OR (S15C##A1)) è Trip Relay Channel 1 ((S02C##A2) OR (S03C##A2) OR … OR (S15C##A2)) è Trip Relay Channel 2...

- Page 10 2 General Information 3500/33 Operation and Maintenance Individual Relays (Alert and Danger) (S02C01A1) OR (S02C02A1) è Trip Relay Channel 1 (Alert Relay) (S02C01A2) OR (S02C02A2) è Trip Relay Channel 2 (Danger Relay) (S02C03A1) OR (S02C04A1) è Trip Relay Channel 3 (Alert Relay) (S02C03A2) OR (S02C04A2) è...

- Page 11 3500/33 Operation and Maintenance 2 General Information Independent Relays (Alert and Danger) (S02C01A1) è Trip Relay Module in slot 3 Channel 1 (S02C02A1) è Trip Relay Module in slot 3 Channel 2 (S02C03A1) è Trip Relay Module in slot 3 Channel 3 (S02C04A1) è...

-

Page 12: Statuses

2 General Information 3500/33 Operation and Maintenance Statuses The 16 Channel Relay Module will return both module and channel statuses. This section describes the available statuses and where they can be found. Module Status This indicates if the 16 Channel Relay Module is functioning correctly. A not OK status is returned under any of the following conditions: •... - Page 13 3500/33 Operation and Maintenance 2 General Information Bypass This indicates if the associated 16 Channel Relay Module channel has been bypassed. Any of the following conditions can cause the channel to be bypassed: • The channel has never been configured •...

-

Page 14: Led Descriptions

2 General Information 3500/33 Operation and Maintenance LED Descriptions The LEDs on the front panel of the 16 Channel Relay Module indicate the operating status of the module as shown in the following figures. Refer to Section 6.2 for all of the available LED conditions. -

Page 15: Configuration Information

0 and the Rack Interface module goes into slot 1. Slots 2 through 15 are called “monitoring positions”. The 3500/33 module can be installed into any of the monitoring positions. However, if the 3500/20 Rack... -

Page 16: Relay Module Configuration Considerations

3 Configuration Information 3500/33 Operation and Maintenance 3.2.1 Relay Module Configuration Considerations • Add monitor modules to the rack configuration before configuring the Relay Module. • Activate only the Relay Module channels that will be used. • Only monitor modules may be used in the alarm drive logic. -

Page 17: Relay Module Configuration Options

3500/33 Operation and Maintenance 3 Configuration Information 3.2.2 Relay Module Configuration Options Available Monitors A field that shows the monitors in the rack. Rack Type The type of Rack Interface Module installed in the rack (Standard or TMR). Config ID A unique six character identifier which is entered when a configuration is downloaded to the 3500 rack. - Page 18 3 Configuration Information 3500/33 Operation and Maintenance Alarm Drive Logic Build the alarm drive logic in this area using the available monitor alarms. AND Voting Setup This option allows you to determine the type of AND voting for a standard rack type.

- Page 19 3500/33 Operation and Maintenance 3 Configuration Information Normal AND Voting (Default) With this option selected, if an alarming parameter is Not OK or bypassed (either by user selection or monitor failure), then the parameter will be removed from the relay logic. Please note: A “Not-OK” alarming parameter (a parameter intended to alarm on a Not-OK condition) will not be removed from the alarm logic equation.

-

Page 20: Software Switches

3 Configuration Information 3500/33 Operation and Maintenance Software Switches Software switches for relay modules let you temporarily bypass or inhibit the relay module and channel functions. Set these switches on the Software Switches screen under the Utilities Option on the main screen of the Rack Configuration Software. - Page 21 3500/33 Operation and Maintenance 3 Configuration Information Bypass When enabled (x), the channel will be turned off and not allow alarming. The channel switch number is used in the Communication Gateway Module. Channel Switch Number Switch Name Bypass...

- Page 22 3 Configuration Information 3500/33 Operation and Maintenance...

-

Page 23: Output Module Description

3500/33 Operation and Maintenance 4 I/O Modules Description Output Module Description This section describes the Output module that is associated with the 16 Channel Relay Module. This section also describes how to use the connectors on the Relay Output Module and describes where to install each Output module. - Page 24 4 I/O Modules Description 3500/33 Operation and Maintenance Configuring the Normally Energized and De-Energized Relays 1) Screwdriver 2) Module Cover 3) DIP Switch CAUTION Proper dipswitch configuration technique requires the Output module to be removed from the rack. Failure to follow this warning...

- Page 25 3500/33 Operation and Maintenance 4 I/O Modules Description Note Relay contacts are marked NC (Normally Closed), NO (Normally Open), and ARM (Armature). NC and NO define the state of the relay contacts with no power applied to the relay coil (de-energized , non-alarm state).

-

Page 26: Wiring Euro Style Connectors

4 I/O Modules Description 3500/33 Operation and Maintenance Wiring Euro Style Connectors To remove a terminal block from its base, loosen the screws attaching the terminal block to the base, grip the block firmly and pull. Do not pull the block out by its wires because this could loosen or damage the wires or connector. - Page 27 3500/33 Operation and Maintenance 4 I/O Modules Description Refer to the 3500 Field Wiring Diagram Package for the recommended wiring. Do not remove more than 6 mm (0.25 in) of insulation from the wires.

- Page 28 5 Maintenance 3500/33 Operation and Maintenance...

-

Page 29: Maintenance

Refer to the Rack Installation and Maintenance Manual (part number 129766-01) for the proper procedure. This section shows how to verify the operation of the 3500/33 16 Channel Relay Module. Verifying a 3500 Rack - Relay Module The 3500 Monitoring System is a high precision instrument that requires no calibration. -

Page 30: Required Test Equipment

5 Maintenance 3500/33 Operation and Maintenance 5.1.2 Required Test Equipment The test equipment needed to simulate the inputs for the relay channel will depend on the type of monitor providing inputs to the Relay Alarm Drive Logic. This equipment can be found under Required Test Equipment in the Maintenance section of the specific monitor manual. - Page 31 3500/33 Operation and Maintenance 5 Maintenance 1) Connect test equipment here. 2) Inputs 3) Monitor I/O Module (Internal Termination) 4) External Termination Block (Euro Style Connectors) 5) External Termination Block (Terminal Strip Connectors)

-

Page 32: Using The Rack Configuration Software

5 Maintenance 3500/33 Operation and Maintenance 1) Outputs 16 Channel Relay Output Module 5.1.4 Using the Rack Configuration Software The laptop computer that is part of the test setup uses the Rack Configuration Software to display output from the rack and to reset certain operating parameters in the rack. -

Page 33: Standard Relay Channels

3500/33 Operation and Maintenance 5 Maintenance The Verification screen displays relay channel output from a 3500 rack as shown in the following figure. Information such as Alarm Drive Logic, Channel Alarm State and Channel OK State are used to verify relay channels. -

Page 34: If A Channel Fails A Verification Test

2. Replace the module with a spare. Refer to the installation section in the 3500 Monitoring System Rack Installation and Maintenance Manual (part number 129766-01). 3. Return the faulty module to Bently Nevada for repair. 4. Download the configuration for the spare module using the Rack Configuration Software. -

Page 35: Performing Firmware Upgrades

16 Channel Relay Firmware Upgrade Procedure Occasionally it may be necessary to upgrade the original firmware that is shipped with the 3500/33 16 Channel Relay Module. The following instructions describe how to upgrade the existing firmware using the 3500 Configuration software. - Page 36 5 Maintenance 3500/33 Operation and Maintenance Select the module to be updated and click on the OK button. The software will request the file to be downloaded. Select the file and click on the Open button. The software will now download the file.

-

Page 37: Troubleshooting

3500/33 Operation and Maintenance 6 Troubleshooting Troubleshooting This section describes how to use the module self-test, the LEDs, and System Event List to troubleshoot a problem with the 16 Channel Relay Module or the Output module. Self-test To perform a self-test: 1. -

Page 38: Led Fault Conditions

6 Troubleshooting 3500/33 Operation and Maintenance LED Fault Conditions The following table shows how to use the LEDs to diagnose and correct problems with the 16 Channel Relay Module. OK LED TX/RX Condition Solution 1 Hz 1 Hz Relay Module is not configured. -

Page 39: System Event List Messages

3500/33 Operation and Maintenance 6 Troubleshooting System Event List Messages This section describes the System Event List Messages that are entered by the 16 Channel Relay Module and gives an example of one. Example of a System Event List Message:... - Page 40 6 Troubleshooting 3500/33 Operation and Maintenance The following System Event List Messages may be placed in the list by the 16 Channel Relay Module and are listed in numerical order. If an event marked with a star (*) occurs the relays on the 16 Channel Relay Output Module will not be driven.

- Page 41 3500/33 Operation and Maintenance 6 Troubleshooting I/O Module Mismatch Event Number: 62 Event Classification: Potential Problem Action: Check to see if one of the following components is faulty: • the Relay Module • the Relay Output Module I/O Module Compatible...

- Page 42 6 Troubleshooting 3500/33 Operation and Maintenance Fail Main Board +5V-B (Fail Main Board +5V - lower Power Supply) Event Number: 102 Event Classification: Potential Problem Action: Verify that noise from the power source is not causing the problem. If the problem is not caused by noise, check to see if one of the following components is faulty: •...

- Page 43 3500/33 Operation and Maintenance 6 Troubleshooting * Fail Main Board +3.3V (Fail Main Board +3.3V Supply) Event Number: 162 Event Classification: Severe / Fatal Event Action: Verify that noise from the power source is not causing the problem. If the problem is not caused by noise, check to see if one of the following components is faulty: •...

- Page 44 6 Troubleshooting 3500/33 Operation and Maintenance Fail I/O Board +5V-AB (Fail OUTPUT Board +14V Supply) Event Number: 390 Event Classification: Potential Problem Action: Verify that noise from the power source is not causing the problem. If the problem is not caused by noise, check to see if one of the following components is faulty: •...

- Page 45 3500/33 Operation and Maintenance 6 Troubleshooting I/O Module Detect Fault (Pass Output Module DIP switch – there was a detected fault that is no longer present) Event Number: 399 Event Classification: Potential Problem Action: Verify that the Relay Output Module is installed. If the Relay Output Module is installed, replace the Relay Output Module as soon as possible.

- Page 46 6 Troubleshooting 3500/33 Operation and Maintenance Fail I/O Board +15V-A (Fail Output Board +15V - upper Power Supply) Event Number: 554 Event Classification: Potential Problem Action: Verify that noise from the power source is not causing the problem. If the problem is not caused by noise, check to see if one of the following components is faulty: •...

- Page 47 3500/33 Operation and Maintenance 6 Troubleshooting Fail I/O Board +15V-AB (Fail OUTPUT Board +15V - upper and lower Power Supplies) Event Number: 558 Event Classification: Potential Problem Action: Verify that noise from the power source is not causing the problem. If the problem is not caused by noise, check to see if one of the following components is faulty: •...

-

Page 48: Alarm Event List Messages

6 Troubleshooting 3500/33 Operation and Maintenance Alarm Event List Messages The following messages may be placed in the Alarm Event List by the 16 Channel Relay Module. Alarm Event List Message When the message will occur Entered not OK module went not OK... -

Page 49: Ordering Information

3500/33 Operation and Maintenance 8 Specifications Ordering Information This section contains the ordering information for the 3500/33 16 Channel Relay Module. 16 Channel Relay Module Part number 3500/33- Output Module 16 Channel Relay Output Module Agency Approval Option None CSA-NRTL/C... - Page 50 8 Specifications 3500/33 Operation and Maintenance...

-

Page 51: Specifications

3500/33 Operation and Maintenance 8 Specifications Specifications This section contains the specifications for the 3500/33 16 Channel Relay Module. 3500/33 16 Channel Relay Module TYPE Single-pole, double-throw (SPDT) relays ENVIRONMENTAL SEALING Epoxy-sealed ARC SUPPRESSORS 250 Vrms, installed as standard. CONTACT RATINGS (resistive load) - Page 52 8 Specifications 3500/33 Operation and Maintenance MECHANICAL Impact: 10 g for 11 ms Shipping: per mil Std 81D – Category G Equipment Vibration: Sinusoidal, 3 g at 5 to 100 Hz ELECTROMAGNETIC COMPATIBILITY EN50081-2: Radiated Emissions: EN 55011, Class A...

- Page 53 3500/33 Operation and Maintenance 8 Specifications RACK SPACE REQUIREMENTS Main Module: 1 full-height front slot Output Module: 1 full-height rear slot...

Need help?

Do you have a question about the 3500/33 and is the answer not in the manual?

Questions and answers