Summary of Contents for Romstal MTIU-07HWFNX-QRD0W

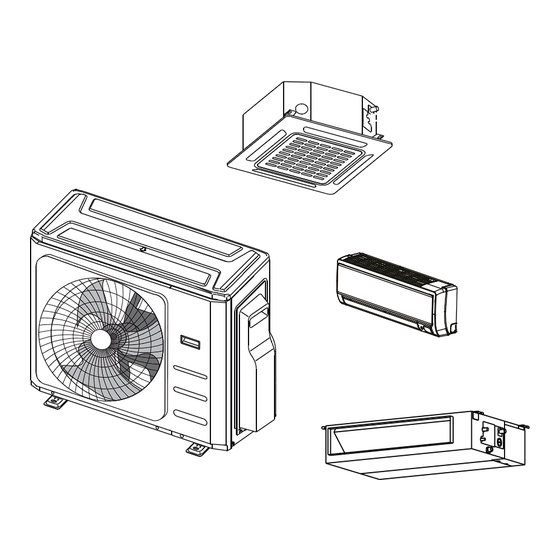

- Page 1 TM_MULTI_R32_3D INV_EU_S_NA_2202 MULTI SPLIT TYPE R32 INVERTER CONTROL TECHNICAL MANUAL...

-

Page 2: Table Of Contents

Table of Contents Page 1. Specifications ....................4 Model Reference Functions General Specifications Indoor Unit Combination Dimensional Drawings Air Velocity and Temperature Distributions Electrical Wiring Diagrams Refrigerant Cycle Diagrams Noise Criterion Curves Electrical Characteristics Static Pressure 2. Product Features ................... 108 Operation Modes and Functions Remote Controller Functions 3. - Page 3 Table of Contents Page Engineering of Insulation Engineering of Electrical Wiring Test Operation 4. Static Pressure Design .................. 165 Introduction Charts for friction losses in round ducts Dynamic losses Corresponding relation between Rectangular duct and Round duct Method for duct calculation Unit conversion Recommended outlet velocity for different occasions...

-

Page 4: Specifications

Specifications Contents Model Reference ....................5 Functions ........................6 General Specifications ...................8 Indoor Unit Combination ..................28 Dimensional Drawings ..................30 Air Velocity and Temperature Distributions ............42 Electrical Wiring Diagrams ..................66 Refrigerant Cycle Diagrams ................84 Noise Criterion Curves ..................89 Electrical Characteristics ..................103 Static Pressure ....................105... -

Page 5: Model Reference

1. Model Reference Refer to the following table to determine the specific indoor and outdoor unit model number of your purchased equipment. Indoor Unit Outdoor Unit Power Supply MTIU-07HWFNX-QRD0W MTIU-07HWFNX-QRD0W(GA) MTIU-09HWFNX-QRD0W(GA) A6 Duct type M2OG-14HFN8-Q MTIU-09HWFNX-QRD0W M2OD-18HFN8-Q M2OC-18HFN8-Q MTIU-12HWFNX-QRD0W M3OF-21HFN8-Q... - Page 6 Indoor Unit Outdoor Unit Power Supply MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW Wall mounted type- Forest MSAFBU-12HRDN8-QRD0GW MSAFCU-18HRFN8-QRD0GW M2OG-14HFN8-Q MSAFDU-24HRFN8-QRD0GW M2OD-18HFN8-Q MSABAU-09HRFN8-QRD0GW M2OC-18HFN8-Q MSABBU-12HRFN8-QRD0GW M3OF-21HFN8-Q Wall mounted type-Aurora M3OF-27HFN8-Q MSABDU-18HRFN8-QRD0GW M3OE-27HFN8-Q MSABEU-24HRFN8-QRD0GW M4OE-28HFN8-Q 1Ph, 220- MSAEBU-09HRFN8-QRD6GW 240V~, 50Hz M4OB-36HFN8-Q MSAEBU-12HRFN8-QRD0GW M5OD-42HFN8-Q Wall mounted type-All Easy MSAECU-18HRFN8-QRD0GW M5OE-42HFN8-Q M2OH-14HFN8-Q...

-

Page 7: Functions

2. Functions Functions Model A6 Duct type Compact Cassette type • Standard filter Flange Healthy filter • Drainage pump IDU auxiliary electric heater • Infrared wired controller (KJR-12B, KJR-90A) 485 wired controller (KJR-120C, KJR-120G2) 2 cores non-polarity wired controller (KJR-120G) Wifi •... - Page 8 Functions All Easy Aurora Forest XTREME Model • • • • High Density Filter • • • • Cold Catalyst Filter • • • • Fire Proof • • • • Turbo • • • • Sleep • • • •...

-

Page 9: General Specifications

3. General Specifications Indoor model MTIU-07HWFNX-QRD0W MTIU-09HWFNX-QRD0W MTIU-12HWFNX-QRD0W MTIU-18HWFNX-QRD0W Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 7000 9000 12000 18000 Cooling Input Current Capacity Btu/h 8000 10000 13000 19000 Heating Input current Model ZKFN-55-8-22 ZKFN-55-8-22... - Page 10 MTIU-07HWFNX- MTIU-09HWFNX- MCA3U-07HRFNX- MCA3U-09HRFNX- Indoor model QRD0W(GA) QRD0W(GA) QRD0W(GA) QRD0W(GA) Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 7000 9000 7000 9000 Cooling Input Current 0.18 0.18 Capacity Btu/h 8000 10000 7500 10000 Heating Input current 0.18 0.18 Model...

- Page 11 Indoor model MCA3I-07HRFNX-QRD0 MCA3I-09HRFN8-QRD0 MCA3U-12HRFNX-QRD0W MCA3U-18HRFNX-QRD0W Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 7000 9000 12000 18000 Cooling Input Current 0.18 0.18 0.18 0.44 Capacity Btu/h 7500 10000 14000 18500 Heating Input current 0.18 0.18 0.18 0.44 Model...

- Page 12 Indoor model MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW MSAFBU-12HRDN8-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 7000 9000 12000 Cooling Input Current 0.09 0.09 0.09 Capacity Btu/h 8000 10000 13000 Heating Input current 0.09 0.09 0.09 Model YKFG-13-4-38L YKFG-13-4-38L YKFG-13-4-38L Input Indoor fan motor Capacitor...

- Page 13 Indoor model MSAFCU-18HRFN8-QRD0GW MSAFDU-24HRFN8-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 Capacity Btu/h 18000 24000 Cooling Input Current 0.15 0.28 Capacity Btu/h 19000 25000 Heating Input current 0.15 0.28 Model ZKFP-30-8-3 ZKFP-58-8-1 Input 58.0 Indoor fan motor Capacitor Speed(Hi/Mi/Lo) r/min 1130 / 900 / 800 1150 / 1000 / 850...

- Page 14 Indoor model MSABAU-09HRFN8-QRD0GW MSABBU-12HRFNX-QRD0GW MSABDU-18HRFNX-QRD0GW MSABEU-24HRFNX-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 9000 12000 18000 25000 Cooling Input Current 0.11 0.11 0.15 0.28 Capacity Btu/h 10000 13000 19000 26000 Heating Input current 0.11 0.11 0.15 0.28 Model...

- Page 15 Indoor model MSAEAU-09HRFNX-QRD0GW MSAEBU-12HRFNX-QRD0GW MSAECU-18HRFNX-QRD0GW MSAEDU-24HRFNX-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 9000 12000 18000 25000 Cooling Input Current 0.11 0.11 0.15 0.28 Capacity Btu/h 10000 14000 19000 26000 Heating Input current 0.11 0.11 0.15 0.28 Model...

- Page 16 Indoor model MSAGAU-09HRFNX-QRD0GW MSAGBU-09HRFN8-QRD1GW(GA) MSAGBU-12HRFNX-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 9000 9000 12000 Cooling Input Current 0.09 0.10 0.10 Capacity Btu/h 10000 10000 13000 Heating Input current 0.09 0.10 0.10 Model ZKFP-20-8-6-7 ZKFP-13-8-4 ZKFP-13-8-4 Input 18.2 18.2...

- Page 17 Indoor model MSAGBU-12HRFN8-QRD1GW(GA) MSAGCU-18HRFNX-QRD0GW MSAGDU-24HRFN8-QRD0GW Power supply (Indoor ) V- Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 12000 18000 24000 Cooling Input Current 0.10 0.17 0.30 Capacity Btu/h 13000 19000 25000 Heating Input current 0.10 0.17 0.30 Model ZKFP-13-8-4 ZKFP-30-8-3 ZKFP-58-8-1-5 Input 18.2 36.0...

- Page 18 Outdoor model M2OG-14HFN8-Q M2OC-18HFN8-Q M2OD-18HFN8-Q Indoor unit combination MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW MSAFBU-09HRDN8-QRD0GW Power Supply (Outdoor) V-Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 14000(6210~16400) 18000(3860~18000) 18000(3860~19000) Input 1270(168~1714) 1630(150~2000) 1630(150~2000) Cooling Rated current 5.52(0.73~9.3) 7.1(0.7~9.27) 7.1(0.7~9.21) 3.24 3.24 Capacity Btu/h 15000(5220~17400) 19000(6120~19000) 19000(6120~20000) Input 1185(265~1707) 1390(300~1670)

- Page 19 Design pressure 4.3/1.7 4.3/1.7 4.3/1.7 Liquid side/ Gas side mm(inch) 2 x Φ6.35/Φ9.52(1/4”/3/8”) 2 x Φ6.35/Φ9.52(1/4”/3/8”) 2 x Φ6.35/Φ9.52(1/4”/3/8”) Max. length for all rooms Max. length for one indoor unit Refrigerant piping Max. height difference be- tween indoor and outdoor unit Max.

- Page 20 Outdoor model M3OE-27HFN8-Q M3OF-21HFN8-Q M3OF-27HFN8-Q Indoor unit combination MSAFBU-09HRDN8-QRD0GW MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW Power Supply (Outdoor) V-Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 27000(7370~27000) 21000(6619~23420) 27000(10100~29000) Input 2440(200~3070) 1950(180~2240) 2450(235~3220) Cooling Rated current 10.6(0.9~13.5) 9.0(1.09~9.9) 13.7(2.2~14.3) 3.24 3.23 3.23 Capacity Btu/h 28800(6400~31500) 22500(5900~24740) 28000(6950~32000) Input 2270(320~2850)

- Page 21 Design pressure 4.3/1.7 4.3/1.7 4.3/1.7 Liquid side/ Gas side mm(inch) 3 x Φ6.35/Φ9.52(1/4"/3/8") 3 x Φ6.35/Φ9.52(1/4”/3/8”) 3 x Φ6.35/Φ9.52(1/4”/3/8”) Max. length for all rooms Max. length for one indoor unit Refrigerant piping Max. height difference between indoor and outdoor unit Max.

- Page 22 Outdoor model M4OE-28HFN8-Q M4OB-36HFN8-Q M5OD-42HFN8-Q M5OE-42HFN8-Q Indoor unit combination MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW MSAFBU-09HRDN8-QRD0GW MSAFBU-09HRDN8-QRD0GW Power Supply (Outdoor) V-Ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 Capacity Btu/h 28000(8000~34200) 36000(12430~37000) 42000(10170~42000) 42000(10300~42000) Input 2550(204~3446) 3300(330~4250) 4320(280~4580) 3810(280~4650) Cooling Rated current 11(1.17~15) 15.0(1.5~18.5) 18.9(1.2~20.0) 16(1.4~20.7) 3.23 2.85 3.23 Capacity...

- Page 23 4 x Φ6.35/3x Φ9.52+1xΦ12.7(4x1 4 x Φ6.35/3x Φ9.52+1xΦ12.7(4x1 5 x Φ6.35/4x Φ9.52+1xΦ12.7(5x1 5 x Φ6.35/4x Φ9.52+1xΦ12.7(5x1 Liquid side/ Gas side mm(inch) /4”/3x3/8”+1x1/2”) /4”/3x3/8”+1x1/2”) /4”/4x3/8”+1x1/2”) /4”/4x3/8”+1x1/2”) Max. length for all rooms Max. length for one Refrigerant indoor unit piping Max. height difference between indoor and outdoor unit Max.

- Page 24 Outdoor model M2OH-14HFN8-Q M2OE-18HFN8-Q Indoor unit combination MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW Power Supply (Outdoor) V-Ph-Hz 220~240-1-50 220~240-1-50 Capacity Btu/h 14000(5100~17000) 18000(7800~19500) Input 1270(115~1672) 1635(690~2000) Cooling Rated current 5.8(1.12~7.35) 7.3(3.20~9.00) 3.23 3.23 Capacity Btu/h 15000(5200~17000) 19000(8200~19600) Input 1185(253~1592) 1500(600~1780) Heating Rated current 5.4(1.9~7.0) 6.6(2.80~7.95) 3.71 3.71...

- Page 25 Liquid side/ Gas side mm(inch) 2 x Φ6.35/Φ9.52(1/4”/3/8”) 2 x Φ6.35/Φ9.52(1/4”/3/8”) Max. length for all rooms Max. length for one indoor unit Refrigerant piping Max. height difference between indoor and outdoor unit Max. height difference between indoor units Cooling °C -15~50 -15~50 Ambient temperature...

- Page 26 Outdoor model M3OG-21HFN8-Q M3OA-27HFN8-Q Indoor unit combination MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW Power Supply (Outdoor) V-Ph-Hz 220~240-1-50 220~240-1-50 Capacity Btu/h 21000(6800~22500) 27000(10850~28000) Input 1905(180~2200) 2450(290~3100) Cooling Rated current 8.3(1.8~10.0) 11.2(2.0~13.5) 3.23 3.23 Capacity Btu/h 22000(6800~22800) 28000(7800~29000) Input 1738(350~1800) 2210(370~2900) Heating Rated current 7.6(2.6~8.0) 10.1(2.4~13) 3.71 3.71...

- Page 27 Liquid side/ Gas side mm(inch) 3 x Φ6.35/Φ9.52(1/4”/3/8”) 3 x Φ6.35/Φ9.52(1/4”/3/8”) Max. length for all rooms Max. length for one indoor unit Refrigerant piping Max. height difference between indoor and outdoor unit Max. height difference between indoor units Cooling °C -15~50 -15~50 Ambient temperature...

-

Page 28: Indoor Unit Combination

4. Indoor Unit Combination M2OG-14HFN8-Q, M2OH-14HFN8-Q One Unit Two Units 9+12 7+12 M2OC-18HFN8-Q, M2OD-18HFN8-Q, M2OE-18HFN8-Q One Unit Two Units 9+12 7+12 12+12 M3OF-21HFN8-Q, M3OG-21HFN8-Q One Unit Two Units Three Units 7+7+7 7+9+9 9+12 7+7+9 9+9+9 7+12 9+18 7+7+12 7+18 12+12 M3OE-27HFN8-Q, M3OF-27HFN8-Q, M3OA-27HFN8-Q One Unit Two Units... - Page 29 M4OB-36HFN8-Q One Unit Two Units Three Units 12+12 7+7+7 7+9+12 7+18+18 9+12+18 9+12 12+18 7+7+9 7+9+18 9+9+9 9+12+24 7+12 9+18 12+24 7+7+12 7+9+24 9+9+12 9+18+18 7+18 9+24 18+18 7+7+18 7+12+12 9+9+18 12+12+12 7+24 7+7+24 7+12+18 9+9+24 12+12+18 7+9+9 7+12+24 9+12+12 Four Units 7+7+7+7 7+7+9+12...

-

Page 30: Dimensional Drawings

5. Dimensional Drawings Indoor Unit A6 Duct type Capacity unit (Btu/h) 7k~12k inch 27.56 7.87 19.92 17.72 5.39 21.14 1.18 5.98 23.58 7.32 1.97 29.17 14.17 3.31 5.51 3.31 3.31 inch 34.65 8.27 26.54 23.62 5.51 27.8 1.97 5.35 30.79 7.48 1.57 36.22... - Page 31 Compact Cassette type Page 31 ...

- Page 32 Forest Capacity(Btu/h) unit W(mm) D(mm) H(mm) 9k/12k inch 31.7 11.2 inch 37.7 11.9 1040 inch 40.9 12.9 Page 32 ...

- Page 33 Aurora Capacity(Btu/h) W(mm) D(mm) H(mm) 1080 Page 33 ...

- Page 34 All Easy Capacity(Btu/h) W(mm) D(mm) H(mm) 9k/12k 1106 Page 34 ...

- Page 35 XTREME Model W(mm) D(mm) H(mm) MSAGAU-09HRFNX-QRD0GW MSAGBU-12HRFNX-QRD0GW MSAGBU-09HRFN8-QRD1GW(GA) MSAGBU-12HRFN8-QRD1GW(GA) MSAGCU-18HRFNX-QRD0GW MSAGDU-24HRFN8-QRD0GW 1083 Page 35 ...

- Page 36 Outdoor Unit M2OG-14HFN8-Q, M2OC-18HFN8-Q, M2OD-18HFN8-Q Page 36 ...

- Page 37 M3OF-21HFN8-Q, M3OE-27HFN8-Q, M3OF-27HFN8-Q Page 37 ...

- Page 38 M4OE-28HFN8-Q, M4OB-36HFN8-Q Page 38 ...

- Page 39 M5OD-42HFN8-Q, M5OE-42HFN8-Q Page 39 ...

- Page 40 M2OH-14HFN8-Q, M2OE-18HFN8-Q Page 40 ...

- Page 41 M3OG-21HFN8-Q, M3OA-27HFN8-Q Page 41 ...

-

Page 42: Air Velocity And Temperature Distributions

6. Air Velocity and Temperature Distributions Compact Cassette type -7k, 9k &12k Discharge Angle 30° Cooling airflow velocity distributions Cooling temperature distributions Page 42 ... - Page 43 Compact Cassette type -7k, 9k &12k Heating airflow velocity distributions Heating temperature distributions Page 43 ...

- Page 44 Compact Cassette type -7k, 9k &12k Discharge Angle 60° Cooling airflow velocity distributions Cooling temperature distributions Page 44 ...

- Page 45 Compact Cassette type -7k, 9k &12k Heating airflow velocity distributions Heating temperature distributions Page 45 ...

- Page 46 Compact Cassette type -18k Discharge Angle 30° Cooling airflow velocity distributions Cooling temperature distributions Page 46 ...

- Page 47 Compact Cassette type -18k Heating airflow velocity distributions Heating temperature distributions Page 47 ...

- Page 48 Compact Cassette type -18k Discharge Angle 60° Cooling airflow velocity distributions Cooling temperature distributions Page 48 ...

- Page 49 Compact Cassette type -18k Heating airflow velocity distributions Heating temperature distributions Page 49 ...

- Page 50 XTREME-9k Discharge Angle 58° Cooling airflow velocity distributions Cooling temperature distributions Page 50 ...

- Page 51 XTREME-9k Discharge Angle 90° Heating airflow velocity distributions Heating temperature distributions Page 51 ...

- Page 52 XTREME-12k Discharge Angle 58° Cooling airflow velocity distributions Cooling temperature distributions Page 52 ...

- Page 53 XTREME-12k Heating airflow velocity distributions Discharge Angle 90° Heating temperature distributions Page 53 ...

- Page 54 XTREME-18k Discharge Angle 50° Cooling airflow velocity distributions Cooling temperature distributions Page 54 ...

- Page 55 XTREME-18k Discharge Angle 84° Heating airflow velocity distributions Heating temperature distributions Page 55 ...

- Page 56 XTREME-24k Discharge Angle 50° Cooling airflow velocity distributions Cooling temperature distributions Page 56 ...

- Page 57 XTREME-24k Discharge Angle 67° Heating airflow velocity distributions Heating temperature distributions Page 57 ...

- Page 58 AURORA-9k Discharge Angle 58° Cooling airflow velocity distributions Cooling temperature distributions Page 58 ...

- Page 59 AURORA-9k Discharge Angle 90° Heating airflow velocity distributions Heating temperature distributions Page 59 ...

- Page 60 AURORA-12k Discharge Angle 58° Cooling airflow velocity distributions Cooling temperature distributions Page 60 ...

- Page 61 AURORA-12k Discharge Angle 90° Heating airflow velocity distributions Heating temperature distributions Page 61 ...

- Page 62 AURORA-18k Discharge Angle 50° Cooling airflow velocity distributions Cooling temperature distributions Page 62 ...

- Page 63 AURORA-18k Discharge Angle 84° Heating airflow velocity distributions Heating temperature distributions Page 63 ...

- Page 64 AURORA-24k Discharge Angle 50° Cooling airflow velocity distributions Cooling temperature distributions Page 64 ...

- Page 65 AURORA-24k Discharge Angle 67° Heating airflow velocity distributions Heating temperature distributions Page 65 ...

-

Page 66: Electrical Wiring Diagrams

7. Electrical Wiring Diagrams Indoor unit A6 Duct type MTIU-07HWFNX-QRD0W, MTIU-09HWFNX-QRD0W Page 66 ... - Page 67 MTIU-12HWFNX-QRD0W Page 67 ...

- Page 68 MTIU-07HWFNX-QRD0W(GA), MTIU-09HWFNX-QRD0W(GA), MTIU-18HWFNX-QRD0W Page 68 ...

- Page 69 Compact Cassette type: MCA3I-07HRFNX-QRD0, MCA3I-09HRFN8-QRD0 Page 69 ...

- Page 70 MCA3U-12HRFNX-QRD0W Page 70 ...

- Page 71 MCA3U-07HRFNX-QRD0W(GA), MCA3U-09HRFNX-QRD0W(GA), MCA3U-18HRFNX-QRD0W Page 71 ...

- Page 72 Wall mounted type MSAFBU-07HRDNX-QRD0GW, MSAFBU-09HRDN8-QRD0GW, MSAFBU-12HRDN8-QRD0GW, MSAFCU-18HRFN8-QRD0GW, MSAFDU-24HRFNX-QRD0GW, MSAEBU-09HRFN8-QRD6GW MSAEBU-12HRFN8-QRD0GW, MSAECU-18HRFN8-QRD0GW, MSAEDU-24HRFN8-QRD0GW MSAGAU-09HRFNX-QRD0GW, MSAGBU-09HRFN8-QRD1GW(GA), MSAGBU-12HRFN8-QRD1GW(GA), MSAGBU-12HRFNX-QRD0GW, MSAGCU-18HRFNX-QRD0GW Page 72 ...

- Page 73 MSABAU-09HRFN8-QRD0GW, MSABBU-12HRFN8-QRD0GW, MSABDU-18HRFN8-QRD0GW, MSABEU-24HRFN8-QRD0GW, MSAGDU-24HRFN8-QRD0GW Page 73 ...

- Page 74 Outdoor Unit M2OG-14HFN8-Q Page 74 ...

- Page 75 M2OC-18HFN8-Q Page 75 ...

- Page 76 M2OD-18HFN8-Q Page 76 ...

- Page 77 M3OE-27HFN8-Q Page 77 ...

- Page 78 M3OF-21HFN8-Q, M3OF-27HFN8-Q Page 78 ...

- Page 79 M4OE-28HFN8-Q Page 79 ...

- Page 80 M4OB-36HFN8-Q Page 80 ...

- Page 81 M5OD-42HFN8-Q, M5OE-42HFN8-Q Page 81 ...

- Page 82 M2OH-14HFN8-Q, M2OE-18HFN8-Q AC-FAN AMBIENT TEMP. SENSOR CONDENSER TEMP. SENSOR OPTIONAL: DC-FAN Page 82 ...

- Page 83 M3OG-21HFN8-Q, M3OA-27HFN8-Q 16022000035910 Page 83 ...

-

Page 84: Refrigerant Cycle Diagrams

8. Refrigerant Cycle Diagrams Piping length (m) Pipe Size Elevation (m) (Diameter:ø) Additional Model Refrigerant Rated IDU and Between Liquid Single Total IDUs M2OG-14HFN8-Q M2OC-18HFN8-Q 2x9.52 2x6.35 12g/m M2OD-18HFN8-Q Note: For M2OC-18HFN8-Q, there is no Accumulator. Page 84 ... - Page 85 Piping length (m) Pipe Size Elevation (m) (Diameter:ø) Additional Model Refrigerant Rated IDU and Between Liquid Single Total IDUs M2OH-14HFN8-Q 2x9.52 2x6.35 12g/m M2OE-18HFN8-Q Page 85 ...

- Page 86 Piping length (m) Pipe Size Elevation (m) (Diameter:ø) Additional Model Refrigerant Rated IDU and Between Liquid Single Total IDUs M3OF-21HFN8-Q M3OE-27HFN8-Q M3OF-27HFN8-Q 3x9.52 3x6.35 22.5 12g/m M3OG-21HFN8-Q M3OA-27HFN8-Q Page 86 ...

- Page 87 Piping length (m) Pipe Size (Diameter:ø) Elevation (m) Additional Model Refrigerant Rated IDU and Between Liquid Single Total IDUs M4OE-28HFN8-Q 3x9.52+1x12.7 4x6.35 12g/m M4OB-36HFN8-Q 3x9.52+1x12.7 4x6.35 12g/m Page 87 ...

- Page 88 Piping length (m) Pipe Size (Diameter:ø) Elevation (m) Additional Model Refrigerant Rated IDU and Between Liquid Single Total IDUs M5OD-42HFN8-Q 4x9.52+1x12.7 5x6.35 37.5 12g/m M5OE-42HFN8-Q 4x9.52+1x12.7 5x6.35 37.5 12g/m Page 88 ...

-

Page 89: Noise Criterion Curves

9. Noise Criterion Curves 10.1 Indoor Unit A6 Duct type Notes: -Sound measured at 1.5m away from the center of the unit. -Data is valid at free field condition -Data is valid at nominal operation condition -Reference acoustic pressure OdB = 20μPa -Sound level will vary depending on a range of factors such as the construction -(acoustic absorption coefficient) of particular room in which the equipment is installed. - Page 90 MTIU-07HWFNX-QRD0W/MTIU-07HWFNX-QRD0W(GA) MTIU-09HWFNX-QRD0W/MTIU-09HWFNX-QRD0W(GA) MTIU-12HWFNX-QRD0W NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz MTIU-18HWFNX-QRD0W NC-70 NC-60 NC-50 NC-40 NC-30 1000 2000 4000 8000 Band Center Frequency /Hz ...

- Page 91 Compact Cassette type Notes: -Sound measured at 1.4m away from the noisiest location of the unit. -Data is valid at free field condition -Data is valid at nominal operation condition -Reference acoustic pressure OdB = 20μPa -Sound level will vary depending on a range of factors such as the construction -(acoustic absorption coefficient) of particular room in which the equipment is installed.

- Page 92 MCA3I-07HRFNX-QRD0/MCA3U-07HRFNX-QRD0W(GA) MCA3I-09HRFN8-QRD0/MCA3U-09HRFNX-QRD0W(GA) MCA3U-12HRFNX-QRD0W NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz MCA3U-18HRFNX-QRD0W NC-70 NC-60 NC-50 NC-40 NC-30 1000 2000 4000 8000 Band Center Frequency /Hz ...

- Page 93 Wall mounted type 0.8m Microphone Notes: -Sound measured at 1.0m away from the center of the unit. -Data is valid at free field condition -Data is valid at nominal operation condition -Reference acoustic pressure OdB = 20μPa -Sound level will vary depending on a range of factors such as the construction -(acoustic absorption coefficient) of particular room in which the equipment is installed.

- Page 94 MSAFBU-07HRDNX-QRD0GW MSAFBU-09HRDN8-QRD0GW MSAFBU-12HRDN8-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz MSAFCU-18HRFN8-QRD0GW MSAFDU-24HRFNX-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000...

- Page 95 MSABAU-09HRFN8-QRD0GW MSABBU-12HRFN8-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz MSABDU-18HRFN8-QRD0GW MSABEU-24HRFN8-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000...

- Page 96 MSAEBU-09HRFN8-QRD6GW MSAEBU-12HRFN8-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz MSAECU-18HRFN8-QRD0GW MSAEDU-24HRFN8-QRD0GW NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000...

- Page 97 MSAGAU-09HRFNX-QRD0GW MSAGBU-09HRFN8-QRD1GW(GA) MSAGBU-12HRFN8-QRD1GW(GA) MSAGBU-12HRFNX-QRD0GW Page 97 ...

- Page 98 MSAGCU-18HRFNX-QRD0GW MSAGDU-24HRFN8-QRD0GW Page 98 ...

- Page 99 Outdoor Unit Note: H= 0.5 × height of outdoor unit Notes: -Sound measured at 1.0m away from the center of the unit. -Data is valid at free field condition -Data is valid at nominal operation condition -Reference acoustic pressure OdB=20μPa -Sound level will vary depending on arrange off actors such as the construction (acoustic absorption coefficient) of particular room in which the equipment is installed.

- Page 100 M2OD-18HFN8-Q M3OF-27HFN8-Q Cooling Heating Cooling Heating NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz M3OF-21HFN8-Q M3OE-27HFN8-Q Cooling Heating Cooling Heating NC-70 NC-70 NC-60 NC-60 NC-50...

- Page 101 M4OE-28HFN8-Q M4OB-36HFN8-Q Cooling Heating Cooling Heating NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 1000 2000 4000 8000 1000 2000 4000 8000 Band Center Frequency /Hz Band Center Frequency /Hz M5OD-42HFN8-Q M5OE-42HFN8-Q Cooling Heating NC-70 NC-60 NC-50 NC-40 NC-30 1000 2000...

- Page 102 M2OH-14HFN8-Q M2OE-18HFN8-Q M3OG-21HFN8-Q M3OA-27HFN8-Q Page 102 ...

-

Page 103: Electrical Characteristics

10. Electrical Characteristics Indoor Unit Power Supply Model Phase Voltage MTIU-07HWFNX-QRD0W 0.055 1.11 MTIU-07HWFNX-QRD0W(GA) 0.055 1.11 MTIU-09HWFNX-QRD0W(GA) 0.055 1.11 MTIU-09HWFNX-QRD0W 0.055 1.11 MTIU-12HWFNX-QRD0W 0.055 1.11 MTIU-18HWFNX-QRD0W 0.16 1.48 MCA3I-07HRFNX-QRD0 0.046 0.146 MCA3U-07HRFNX-QRD0W(GA) 0.046 0.146 MCA3U-09HRFNX-QRD0W(GA) 0.046 0.146 MCA3I-09HRFN8-QRD0 0.046 0.146 MCA3U-12HRFNX-QRD0W 0.046... - Page 104 Outdoor Unit Power Supply Compressor Model Phase Voltage M2OG-14HFN8-Q 11.5 0.034 0.39 M2OC-18HFN8-Q 0.04 M2OD-18HFN8-Q 0.058 0.39 M3OF-21HFN8-Q 15.5 0.05 0.55 M3OE-27HFN8-Q 0.05 0.55 M3OF-27HFN8-Q 17.5 9.45 0.05 0.55 220-240 M4OE-28HFN8-Q 9.45 0.12 1.21 M4OB-36HFN8-Q 21.5 5.38 0.12 1.39 M5OD-42HFN8-Q 5.38 0.12 1.39...

-

Page 105: Static Pressure

11. Static Pressure 7K/9K Page 105 ... - Page 106 Page 106 ...

- Page 107 Page 107 ...

- Page 108 Product Features Contents Display Function ....................109 Operation Modes and Functions ..............113 Abbreviations ....................113 Safety Features ..................113 Fan ......................114 Cooling Mode ...................114 Heating Mode (Heat pump models) ............114 Auto Mode ....................114 Drying Mode .....................115 Timer Function ..................115 Sleep Function ...................115 2.10 Forced Operation Function ................115 2.11 Auto-Restart ....................116 2.12 Follow Me ....................116 2.13 Drain Pump Control ...................116...

-

Page 109: Display Function

1. Display Function Unit display functions Wall mounted type-Foreset: fresh defrost run timer fresh defrost run timer fresh defrost run timer Display A Display B Display C Display D Display Function Fresh(available on select units only) fresh or Defrost defrost or When the unit is on run or When TIMER is on... - Page 110 Wall mounted type-Aurora: Display Function Fresh(available on select units only) ECO function (available on select units only) Lights up in different colour according to the operation mode(some units): Under COOL and DRY mode, it displays as cool colour.Under HEAT mode, it displays as warm colour. when Wireless Control feature is activated(some units) Temperature value Temperature...

- Page 111 Wall mounted type-All Easy: fresh timer fresh timer Display A Display B Display Function fresh When Fresh feature is activated(some units) timer When TIMER is set When the unit is on WiFi control (available on select units only) Set temperature value Temperature Room temperature Temperature (fan and Drying mode)

- Page 112 Wall mounted type-XTREME fresh defrost run timer Display A Display B Display Function fresh Fresh(available on select units only) defrost Defrost When the unit is on timer When TIMER is on WiFi control (available on select units only) Temperature value Temperature Activation of Timer ON, Fresh, Swing, Turbo, or Silent (3s)

-

Page 113: Operation Modes And Functions

2. Operation Modes and Functions • When the unit starts, the louver is automatically activated and the indoor fan will operate after a period of 7 seconds. Abbreviation • If the unit is in heating mode, the indoor fan is regulated by the anti-cold wind function. -

Page 114: Fan

Fan Mode QRD0W(GA),MCA3U-09HRFNX-QRD0W(GA), MTIU- 07HWFNX-QRD0W(GA), MTIU-09HWFNX-QRD0W(GA), When fan mode is activated: MTIU-18HWFNX-QRD0W, MSAGAU-09HRFNX-QRD0GW, MSAGBU-09HRFN8-QRD1GW(GA), MSAGBU-12HRFNX- • The outdoor fan and compressor cease operation. QRD0GW, MSAGBU-12HRFN8-QRD1GW(GA), MSAGCU- • Temperature control is disabled and no temperature 18HRFNX-QRD0GW, MSAGDU-24HRFN8-QRD0GW, the setting is displayed. auto fan acts according to the value of T1-Tsc. -

Page 115: Drying Mode

changed. • Low indoor room temperature protection • In drying mode, if room temperature is lower than 10°C, the indoor fan will stop and not resume until room temperature exceeds 12°C. • All protections are activated and operate the same as they do in cooling mode. -

Page 116: Auto-Restart

• Forced auto mode: • The system checks the water level every 5 seconds. Forced auto mode operates the same as normal auto mode • When the A/C operates in cooling (including auto with a preset temperature of 24°C. cooling) or forced cooling mode, the pump begins running immediately and continuously until cooling •... -

Page 117: Remote Controller Functions

3. Remote Controller Functions Infrared Wireless Remote Controller NOTE: No heating mode for cool only type unit. 4. SWING Button: Used to stop or start horizontal 3.1.1 RG51Q1/BGE(Standard for cassette) louver movement. The louver will swing up and down automatically if push this button. Remote Controller Specifications 5. - Page 118 3.1.2 R51M/E(Standard for Forest series) 5. RESET Button (inner located): Once the recessed RESET button is pressed, all of the current settings will Remote Controller Specifications be cancelled and the controller will return to the initial settings. Model R51M/E 6. AIR DIRECTION Button: Press this button to change the 3.0V (Dry batteries R03/ swing angle of the louver.

- Page 119 3.1.3 RG51F1/E(Standard for Aurora series) Under cooling mode, press this button, the remote controller will adjust the temperature automatically to Remote Controller Specifications C, fan speed of Auto to save energy(but only if the set temperature is less than 24 C).

- Page 120 4. SWING ↕ Button: Used to stop or start horizontal louver at cooling or heating operation in the shortest time(if the indoor unit does not support this function, there is no movement or set the desired up/down air flow direction. corresponding operation happened when pressing this The louver changes 6 degree in angle for each press.

- Page 121 to 10 hours, then at 1 hour increments up to 24 hours. To cancel the Auto-off time setting, just press the button until the time setting is 0.0. 14. LOCK Button(inner located): When you press the recessed LOCK button, all current settings are locked in and the remote controller does not accept any operation except that of the LOCK.

- Page 122 3.1.5 RG10A(B2S)/BGEF(Standard for XTREME series &MCA3U-07HRFNX-QRD0W(GA), MCA3U- 09HRFNX-QRD0W(GA)) Remote Controller Specifications Model RG10A(B2S)/BGEF 3.0V (Dry batteries R03/ Rated Voltage LR03×2) Reaching Distance Environment Temperature -5℃~60℃(23℉~140℉) Range Buttons and Functions MODE ON/OFF Turns the unit on or o ff. Scrolls th rough operation modes as follows: AUTO ...

-

Page 123: Lcd Wired Remote Controller

LCD Wired Remote Controller 3.2.1 LCD Wired Remote Controller KJR-12B/DP(T) (Standard) The KJR-12B/DP(T) wired remote controller is standard for Duct type. i) Buttons and Functions MODE BUTTON ON/OFF BUTTON • Used to start/stop the air • Used to select the operating mode conditioner. - Page 124 iii) Installation • Dimensions 120mm 21mm 13.1mm (4.7”) (0.8”) (0.5”) 19.5mm (0.7”) 120mm 85.5mm (4.7”) (3.3”) 50mm (1.9”) • Wiring diagram Refer to the following diagram to wire the Wall mounted type remote control to the indoor unit. Wire Joint, 5p Infrared Pipe 5-Core Shield Cable Indoor Unit Switch Board...

- Page 125 Putty Trap Putty Putty Trap Trap Note: DO NOT allow water to enter the remote control. Use the trap and putty to seal the wires. • For exposed mounting, cut holes on four of the sides according to the picture below. Cut three holes Cut one holes for wire outlet...

- Page 126 The KJR-120C/TF-E wired remote controller is optional for all types. i) Buttons and Functions ë ï á å Ö ë ï á å Ö 1. POWER button 7. FOLLOW ME(PTC) button Turn on of turn off the unit. Allows the remote control to act as a remote thermostat and send temperature information from its current 2.

- Page 127 1 Operation mode indication 9 C° / F° indication 2 Fan speed indication 10 Temperature display 3 Left-right swing indication 11 Lock indication 4 Up-down swing indication 12 Room temperature indication 5 Faceplate function indication 13 Clock display 6 Main unit and secondary unit indication 14 On/Off timer 7 Follow me function indication 15 Timer display...

- Page 128 iii) Installation • Dimensions 18.5 • Wiring diagram Refer to the following diagram to wire the Wall mounted type remote control to the indoor unit. Insert of the mainboard CN40 ----------------------------------- ----------------------------------- black black yellow ----------------------------------- yellow ----------------------------------- brown brown 4-Core Shield Cable, the length Wire controller Indoor unit mainboard...

- Page 129 Putty Trap Putty Putty Trap Trap Note: DO NOT allow water to enter the remote control. Use the trap and putty to seal the wires. • For exposed mounting, four outletting positions. There are three need cutting. Cutting place of right Cutting place of left Cutting place of top side wire outlet...

- Page 130 3.2.3 LCD Wired Remote Controller KJR-120G/TF-E(Optional) The KJR-120G/TF-E wired remote controller is optional for all types. i) Buttons and Functions Copy/ Swing Timer Back/Turbo Follow me Mode Fan speed (Lock) MODE button 6. TIMER button Used to select the operation mode: Auto / Cooling / Drying / To set timer on and timer off time of one day Heating / Fan;...

- Page 131 1 Operation mode indication 8 Turbo/PTC function indication 2 Fan speed indication 9 C° / F° indication 3 Left-right swing indication 10 Temperature display 4 Up-down swing indication 11 Lock indication 5 Faceplate function indication 12 Room temperature indication 6 Main unit and secondary unit indication 13 Clock display 7 Follow me function indication 14 On/Off timer...

- Page 132 iii) Installation • Dimensions 120mm 18.5mm 46mm (4.7”) (0.7”) (1.8”) 83.5mm 123mm (3.3”) (4.8”) 62mm (2.4”) • Wiring diagram 1) Connection For Cassette type: The wired controller connects to main control board directly. Main control board ADSS HA HB HA HB Wired controller For Duct, Ceiling&...

- Page 133 2) Address setting Unit1 Unit2 Unit16 HA HB HA HB HA HB HA HB Wired controller a. One non-polarity controller can control up to 16 indoor units. b. When the non-polarity controller is connected to several units, every air-conditioner in network has only one network address to distinguish each other.

- Page 134 Putty Trap Putty Putty Trap Trap Note: DO NOT allow water to enter the remote control. Use the trap and putty to seal the wires. • For wiring the indoor unit, there are three methods: • From the rear; • From the bottom; •...

-

Page 135: Centralized Controller

Centralized Controller 1) Connection For Light commercial air conditioner with XYE port, it can be directly connected to Centralized Controller (CCM03, CCM09). 2) Address setting When setting the address, please make sure the unit is powered off. The address can be set from 0 to 63 by the switch. Turn on the unit, then the address will be effective. -

Page 136: Using The Wire Controller To Set External Static Pressure

Using the wire controller to set external ventilation paths, be sure to reset automatic airflow adjustment. static pressure • If there is no change to ventilation paths after airflow • You can use the unit’s automatic airflow adjustment adjustment,contact your dealer, especially if this occurs function to set external static pressure. - Page 137 Installation Contents Accessories ........................138 Installation Overview ..................142 Location Selection .....................145 Indoor Unit Installation(A6 Duct type) ............146 Indoor Unit Installation(Compact cassette type)..........148 Indoor Unit Installation(Wall mounted type) ..........152 Outdoor Unit Installation ..................160 Drainage Pipe Installation .................161 Refrigerant Pipe Installation ................163 Vacuum Drying and Leakage Checking ............164 Additional Refrigerant Charge .................165 Engineering of Insulation .................165 Engineering of Electrical Wiring ..............166...

-

Page 138: Accessories

Accessories-A6 Duct type: Name Shape Quantity Soundproof / insulation sheath Tubing & Fittings Seal sponge (some models) Orifice (some models) Drainpipe Fittings Drain joint (some models) (for cooling & Seal ring (some models) heating) Magnetic ring(Wrap the electric wires S1 & S2 ( P EMC Magnetic &... - Page 139 Accessories-Compact cassette type: Name Shape Quantity Installation paper template Indoor unit installation (some models) Soundproof/insulation sheath Refrigeration Fittings (some models) Outlet pipe sheath(some models) Outlet pipe clasp(some models) Drainpipe Fittings Drain joint (some models) Seal ring (some models) Ceiling hook Copper nut(some units) Used to make the connective pipes Installation Accessory...

- Page 140 Accessories-wall-mounted type Name Shape Quantity Mounting plate Clip anchor Mounting plate fixing screw ST3.9 X 25 Remote controller Mode ON/OFF Timer Follow Self TurboI clean Fixing screw for remote controller holder ST2.9 x Optional Parts Remote controller holder Dry battery AAA.LR03 Seal 1(for cooling &...

- Page 141 1. Installation Overview Installation Order-A6 Duct type Install the indoor unit Install the outdoor unit Connect the refrigerant pipes Evacuate the refrigeration system Connect the wires Install the drainpipe Perform a test run Page 141 ...

-

Page 142: Installation Overview

Installation Order-Compact cassette type Install the indoor unit Install the outdoor unit Install the drainpipe Evacuate the refrigeration system Connect the wires Connect the refrigerant pipes Install the front panel Perform a test run Page 142 ... - Page 143 Installation Order-Wall mounted type 15cm (5.9in) 12cm 12cm (4.75in) (4.75in) 2.3m (90.55in) Select Installation Location Determine Wall Hole Position Attach Mounting Plate Drill Wall Hole Page 143 ...

- Page 144 Connect Piping Prepare Refrigerant Connect Wiring piping W rap Piping and Cable (not applicable for some locations in the US ) STEP Mount Indoor Unit Page 144 ...

-

Page 145: Location Selection

2. Location selection Unit location selection can refer to installation manual. DO NOT install the unit in the following locations: • Where oil drilling or fracking is taking place. • Coastal areas with high salt content in the air. • Areas with caustic gases in the air, such as near hot springs. -

Page 146: Indoor Unit Installation(A6 Duct Type)

3. Indoor Unit Installation(A6 Duct 6. Secure the bolt using the included washers and nuts. type) 7. Install the four suspension bolts. 8. Mount the indoor unit with at least two people to Service space for indoor unit lift and secure it. Insert suspension bolts into the unit’s hanging holes. - Page 147 5. Refer to the following static pressure guidelines when installing the indoor unit. Capacity(Btu/h) Static Pressure(Pa) 7k/9k 0-40 0-60 0-100 Change the fan motor static pressure according to external duct static pressure. NOTE: 1. Do not put the connecting duct weight on the NOTE: All the figures in this manual are for demonstration indoor unit.

-

Page 148: Indoor Unit Installation(Compact Cassette Type)

3. Indoor Unit Installation(Compact Cassette Type 3.1 Service space for indoor unit Suspension bolt pitch dimensions Body dimensions Decoration panel dimensions Refrigerant piping Suspension bolt (×4) Ceiling opening dimensions Hanger bracket Ceiling board 2. Drill 4 holes 5cm (2”) deep at the ceiling hook positions in the internal ceiling. - Page 149 unit and the four sides of false ceiling are even. The 3.3 Compact Cassette Panel Installation bottom of the unit should be 24mm / 0.9in higher than ceiling board. 3.3.1 Remove the front grille Generally, L should be half the length of the suspension 1.

- Page 150 3.3.6 Close the front grille, and close the two grille hooks. 3.3.3 Mount the grille Ensure that the buckles at the back of the grille be properly seated in the groove of the panel. 3.3.4 Connect the two wires of the panel to the main board of the unit.

- Page 151 3. Indoor Unit Installation(wall Correct orientation of Mounting Plate mounted type) Service space for indoor unit 15cm (5.9in) or more For Forest series: 398mm(15.98in) 12cm (4.75in) 12cm (4.75in) 241mm(9.48in) 228.5mm(8.99in) or more or more Indoor unit outline Right rear wall Left rear wall 2.3m (90.55in) or more hole 65mm (2.5in)

-

Page 152: Indoor Unit Installation(Wall Mounted Type)

426mm (16.8in) 599mm(23.6in) 232mm (9.15in) Indoor unit outline 558mm(21.97in) 320mm(12.60in) 192mm (7.55in) 128mm (5.05in) Indoor unit outline pipe hole pipe hole 65mm φ 130mm φ 65mm (2.56 in) (5.12in) (2.56 in) 174mm Right rear wall Left rear wall (6.85in) hole 65mm (2.5in) 802mm (31.6in) hole 65mm (2.5in) 1106mm(43.5in) - Page 153 and insert the sleeve anchors provided. Then secure the unit, remove the plastic knock-out panel from that side of mounting plate to the wall by tightening the screws the unit. This will create a slot through which your piping directly into the clip anchors. can exit the unit.

- Page 154 container that will collect water. Make sure there are no kinks or dent in drain hose to ensure proper drainage. Connect signal cable 3.6.1 Before performing electrical work, read these regulations 1. All wiring must comply with local and national electrical codes, and must be installed by a licensed electrician.

- Page 155 materials. 8. After checking to make sure every connection is secure, use the cable clamp to fasten the signal cable to the unit. 12. BEFORE PERFORMING ANY ELECTRICAL OR WIRING Screw the cable clamp down tightly. WORK, TURN OFF THE MAIN POWER TO THE SYSTEM. 9.

- Page 156 unit: T3.15AL/250VAC, T5AL/250VAC, T3.15A/250VAC, T5A/250VAC, T20A/250VAC, T30A/250VAC, etc.(The fuse Front view is made of ceramic.) Terminal block Wire cover • Pay attention to live wire While crimping wires, make sure you clearly distinguish the Live (“L”) Wire from other wires. Screw Cable clamp •...

- Page 157 unwrapped. You need to access them to test for leaks at the end of the installation process. Mount indoor unit 3.8.1 If you installed new connective piping to the outdoor unit, do the following: 1. If you have already passed the refrigerant piping through the hole in the wall, proceed to step 4.

- Page 158 Step 4. Keep pipe connection point exposed to perform the leak test (refer to Electrical Checks and Leak Checks section of this manual). Step 5. After the leak test, wrap the connection point with insulation tape. Step 6. Remove the bracket or wedge that is propping with insulation tape.

- Page 159 4. Outdoor unit installation Install Outdoor Unit Fix the outdoor unit with anchor bolts(M10) Service space for outdoor unit Bolt pitch Cation Since the gravity center of the unit is not at its physical center, so please be careful when lifting it with a sling. Never hold the inlet of the outdoor unit to prevent it from deforming.

-

Page 160: Outdoor Unit Installation

5. Drainage Pipe Installation For horizontal drainage pipe (The following table is for reference) Install the drainage pipe as shown below and take Allowable measures against condensation. Improperly installation Reference maximum water could lead to leakage and eventually wet furniture and value of inner flowrate (l/h) Remark... -

Page 161: Drainage Pipe Installation

• Refer the following picture for installation reference. 5. The horizontal pipe layout should avoid converse flow or bad flow 8. Blowhole setting • For the concentrated drainage pipe system, there should design a blowhole at the highest point of main pipe to ensure the condensate water discharge smoothly. - Page 162 even water shall run over the water collector. • Continuously infusing water until water level alarmed, check whether the drainage pump could discharge water at once. If water level does not decline under warning water level 3 minutes later, it shall cause shutdown of unit. When this situation happens, the normal startup only can be recovered by turning down power supply and Stow tube...

-

Page 163: Refrigerant Pipe Installation

6. Refrigerant Pipe Installation Maximum length and drop height o ç ì Ö Ü l Ä ä á è ì É t ~ ê é É Ç Ensure that the length of the refrigerant pipe and the drop height between the indoor and outdoor units meets the requirements shown in the following table. -

Page 164: Vacuum Drying And Leakage Checking

bellmouthing, and too small torque may cause -755mmHg after 1 hour of drying, it indicates that there is leakage. Refer the following table for different pipe moisture or leakage in pipeline system and need to go on connection. with drying for half an hour. Torque 3. -

Page 165: Additional Refrigerant Charge

8. Additional Refrigerant Charge 9. Engineering of Insulation • After the vacuum drying process is carried out, the additional refrigerant charge process need to be Insulation of refrigerant pipe performed. • 1. Operational procedure of refrigerant pipe The outdoor unit is factory charged with refrigerant. insulation The additional refrigerant charge volume is decided by the diameter and length of the liquid pipe be-... -

Page 166: Engineering Of Electrical Wiring

10. Engineering of Electrical Wiring insulation and cause easy aging of the material. Insulation of drainage pipe 10.1 Highlights of electrical wiring installation 1. Operational procedure of refrigerant pipe insulation • All field wiring construction should be finished by qualified electrician. Select the suitable pipe →... -

Page 167: Test Operation

11. Test Operation Drainage Test a. Ensure the drainpipe flows smoothly. New buildings 11.1 The test operation must be carried out should perform this test before finishing the ceiling. after the entire installation has been b. Remove the test cover. Add 2000ml of water to the tank completed. - Page 168 Static Pressure Design Contents Introduction .......................169 Charts For Friction Losses in Round Ducts ............169 Dynamic Losses ....................170 Corresponding Relation Between Rectangular Duct and Round Duct ..171 Method For Duct Calculation ................172 Unit Conversion ....................172 Recommended Outlet Velocity For Different Occasions .........172...

-

Page 169: Introduction

1. Introduction Duct system losses are the irreversible transformation of mechanical energy into heat. The two types of losses are (1) friction losses and (2) dynamic losses. Friction losses are due to fluid viscosity and result from momentum exchange between molecules (in laminar flow) or between individual particles of adjacent fluid layers moving at different velocities (in turbulent flow). -

Page 170: Dynamic Losses

3. Dynamic Losses For dynamic losses, please refer to below image. Page 170 ... -

Page 171: Corresponding Relation Between Rectangular Duct And Round Duct

4. Corresponding Relation Between Rectangular Duct and Round Duct Page 171 ... -

Page 172: Method For Duct Calculation

5. Method For Duct Calculation (equal friction method) 1)Draw schematic view of the duct system. 1)Make notes for air volume and mark clearly the elbow, the branch parts, the air discharge outlet. 1)Select one main ducting route (where the maximum static pressure loss occurs). 1)Select the air velocity for the main duct in accordance with the desirable air velocity.

Need help?

Do you have a question about the MTIU-07HWFNX-QRD0W and is the answer not in the manual?

Questions and answers