Summary of Contents for RW RWCOM8S

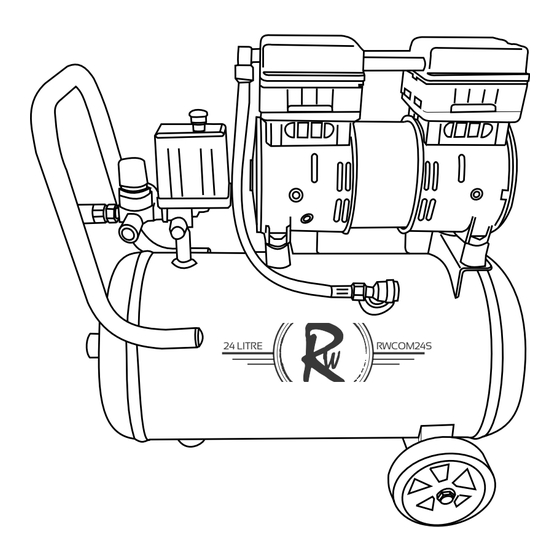

- Page 1 INSTRUCTION MANUAL PLEASE RETAIN DO NOT USE APPLIANCE WITHOUT READING THIS FIRST 24 LITRE RWCOM24S THIS MANUAL COVERS RWCOM8S RWCOM24S RWCOM50S SILENT OIL FREE ELECTRIC AIR COMPRESSORS...

-

Page 2: Table Of Contents

INDEX CONTENTS PAGE NO.S SAFETY 3 - 7 MACHINE SPECIFIC SAFETY 7 - 8 ASSEMBLY PREPERATION STARTING PROCEDURE STOPPING PROCEDURE USING THE MACHINE MAINTENANCE 12 - 13 TROUBLESHOOTING SPECIFICATION RECYCLING & PRODUCT DISPOSAL... -

Page 3: Safety

1. SAFETY General Safety Notes. The operator of the machine is responsible for, and has a duty of care in making sure that the machine is operated safely and in accordance with the instructions in this user manual. Keep the manual safe and pass it on if the machine is loaned or sold to another user. - Page 4 1.10 Carbon Monoxide (where applicable). 1.11 Carbon monoxide is a colourless and odourless gas. Inhaling this gas can cause death as well as serious long term health problems such as brain damage. 1.12 The symptoms of carbon monoxide poisoning can include but are not limited to the following;...

- Page 5 1.20 General Fuel Safety (where applicable). CAUTION ALL FUELS ARE FLAMABLE Fire Hazard – keep fuel away from all sources of ignition for example heaters. 1.21 Lamps, sparks from grinding or welding. 1.22 DO NOT carry out hot work on tanks that have contained fuel. 1.23 ALWAYS keep the work area tidy.

- Page 6 1.46 All trailing cables should be routed so as not to cause any kind of trip hazard. 1.47 NEVER work on or near electricity with wet hands, wet clothing and wet gloves. 1.50 Batteries (where present). 1.51 Batteries present a risk if they become damaged by the possible leaking of electrolyte.

-

Page 7: Machine Specific Safety

recommended to observe the condition of your hands and fingers. Seek medical attention immediately if any of the above symptoms should occur. 1.70 Noise (where applicable). 1.71 The operating noise of the machine can damage your hearing. Wear hearing protection such as earplugs or ear defenders to protect your hearing. Long-term and regular users are advised to have hearing checked regularly. - Page 8 2.13 DO NOT touch the compressor cylinder, cylinder head or pipe from the head to the tank as these may be hot and will remain so for some time after shutdown. 2.14 DO NOT operate the compressor without all the safety guards in place. 2.15 DO NOT attempt to move the compressor by pulling the air hose.

-

Page 9: Assembly

3. ASSEMBLY NOTE Before assembly, make sure the air tank is not damaged. Inspect all parts for damage and check that all pipes are firmly attached. DO NOT use the air compressor if any damage is found. If damaged contact your dealer. Attach the air filter to the top of the motor head by screwing in to place. -

Page 10: Preperation

4. PREPARATION WARNING Seek assistance when removing the compressor from its packaging. Remove the compressor from its packaging and inspect for any damaged parts. If anything is found to be missing or damaged, contact your supplier. Take care to transport the compressor correctly, do not overturn it or lift it with hooks or ropes. -

Page 11: Starting Procedure

5. STARTING PROCEDURE Check that the power switch is in the OFF position. Attach the air hose to the ¼” quick disconnect coupler. Close the drain valve and ensure the air filter is installed. Close the drain valve. Plug the compressor in to a working plug socket. Turn the power switch to the ON position. -

Page 12: Maintenance

8. MAINTENANCE WARNING Service and maintenance must be performed by an authorised agent. DO NOT tamper with, or attempt to adjust the pressure switch or safety valve. Before moving or carrying out any maintenance on the compressor, make sure that the ignition switch is OFF and the air tank pressure has been vented and the compressor allowed to cool down for a period of time. - Page 13 CLEANING 8.12 Clean the compressor with a soft brush or moist cloth. 8.13 DO NOT use a pressure washer or hose pipe as water can penetrate the motor and cause failure that will not be covered by the warranty. 8.14 DO NOT use solvent based cleaning products, these could damage parts.

-

Page 14: Troubleshooting

9. TROUBLESHOOTING PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION Pressure drop in the tank Air leaks at the connections Let the compressor build up pressure in the tank to maximum pressure if possible. Brush soapy water on the air connections and look for air bubbles. -

Page 15: Specification

10. SPECIFICATION... -

Page 16: Recycling & Product Disposal

11. RECYCLING AND PRODUCT DISPOSAL 11.0 We do not offer a take back scheme for the recovery of Waste Electrical Electronic Equipment (WEEE) & Batteries. Instead the responsibility to dispose of WEEE and or Batteries is passed onto you by So when it becomes necessary to dispose of your machine you must take it to your local Civic Amenity Site.

Need help?

Do you have a question about the RWCOM8S and is the answer not in the manual?

Questions and answers