Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Tar River Implements BFM-100 Series

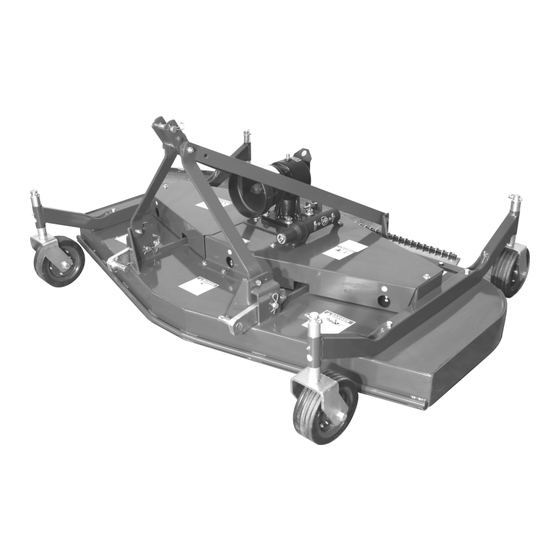

- Page 1 Rear Discharge Finishing Mower BFM-100 Series Operator’s Manual Rev. 08/24...

- Page 2 BFM-100 Series Finish Mower Page left blank intentionally...

- Page 3 BFM-100 Series Finish Mower TO THE DEALER: Assembly and proper installation of this product is the responsibility of the Tar River dealer. Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Owner’s/Operator’s Manual are completed before releasing equipment to the owner.

-

Page 4: Table Of Contents

BFM-100 Series Finish Mower Table of Contents Introduction……………………………………………………………………………………………... 5 Technical Specifications………………………………………………………………………………... 5 Safety……………………………………………………………………………………………………. 6 Safety Signal Words…………………………………………………………………………………….. 6 General Safety Guidelines………………………………………………………………………………. 7 Safety Decal Care……………………………………………………………………………………….. 7 Before Operation………………………………………………………………………………………... 8 During Operation………………………………………………………………………………………... 9 Highway And Transport Operations……………………………………………………………………. 10-11 Assembly……………………………………...………………………………………………………… 12-14 Attaching Machine to Tractor………………………………………………………………………...… 15 PTO Driveline Instructions……………………………………………………………………...…..…... -

Page 5: Introduction

BFM-100 Series Finish Mower Introduction Thank you for purchasing your BFM-100 Series Finishing Mower. Keep your grassy areas looking good with the 100 Series Economy Finishing Mower by Tar River Implements. These mowers are great for compact tractors maintaining home estates and light landscaping. Available in working widths of 58”, 71” and 82”. -

Page 6: Safety

BFM-100 Series Finish Mower Important Safety Information Safety It is important that you read the entire manual and to become familiar with this product before you begin using it. This product is designed for certain applications only. The manufacturer cannot be responsible for issues arising from modification. -

Page 7: General Safety Guidelines

BFM-100 Series Finish Mower Important Safety Information General Safety Guidelines Safety of the operator is one of the main concerns in designing and developing a new piece of equipment. Designers and manufacturers build in as many safety features as possible. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. -

Page 8: Before Operation

BFM-100 Series Finish Mower Important Safety Information How to install Safety Signs: Be sure that the installation area is clean and dry. • Decide on the exact position before you remove the backing paper. • Remove the smallest portion of the split backing paper. -

Page 9: During Operation

BFM-100 Series Finish Mower Important Safety Information During Operation Children should not be allowed on the machine. • Clear the area of small children and bystanders before moving the machine. • If using a towing unit, securely attach machine by using a hardened 3/4” pin, a metal retainer, and safety •... -

Page 10: Highway And Transport Operations

BFM-100 Series Finish Mower Important Safety Information Highway and Transport Operations Adopt safe driving practices. • Keep the brake pedals latched together at all times. Never use independent braking with machine in tow • as loss of control and/or upset of unit can result. - Page 11 BFM-100 Series Finish Mower Important Safety Information Highway and Transport Operations Maneuver the tractor or towing vehicle at safe speeds. • Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury or death. • Avoid loose fill, rocks and holes, they can be dangerous for equipment operation or movement.

-

Page 12: Assembly

BFM-100 Series Finish Mower Assembly Step 1: Attach the rear brace bars to the lugs on the rear of deck with M12-1.75x40 hex bolt and M12-1.75 locking nut. Attach the A-frame bars to the lugs on the front of the mower deck with M12-1.75x40 bolts and M12-1.75 locking nuts. - Page 13 BFM-100 Series Finish Mower Assembly Step 3: Install the wheel support braces with M12 bolts (BFM105&106), M16 bolts (BFM107) and locking nuts as shown below. Step 4: Install rear discharge chute and safety chains using M12 bolts and locking nuts as shown below.

- Page 14 BFM-100 Series Finish Mower Assembly Step 6: Place the covers (13) on the belts, tighten the handles on the frame (14) and on the gearbox support (15). Attach the PTO shield (16) by means of four screws (17) and the washers (18).

-

Page 15: Attaching Machine To Tractor

BFM-100 Series Finish Mower Attaching Machine to Tractor Warning: When attaching the BFM Series Finish Mower, Never allow anyone to stand between the BFM Series Finish Mower and the tractor. Serious injury or death can occur! Attaching the BFM Series Finish Mower Carefully read this instruction manual and the manuals of the tractor and PTO shaft manufacturer. -

Page 16: Pto Driveline Instructions

BFM-100 Series Finish Mower PTO Driveline Instructions Instructions for Installing a PTO Driveline: (Refer to Fig. 1) 1. Begin by parking the tractor and implement on a level, solid surface. Attach the implement to the trac- tor’s hitch arms, upper and lower. Adjust the tractor’s 3-point hitch so that the tractor’s output shaft is level with the implement’s input shaft. - Page 17 BFM-100 Series Finish Mower PTO Driveline Instructions Instructions for Shortening a PTO Driveline: (Refer to Fig. 2) Note: If you are not confident modifying the PTO Driveline, you should contact a Qualified Professional. Separate the inner and outer PTO Drivelines. Leave separated at this time.

- Page 18 BFM-100 Series Finish Mower PTO Driveline Instructions Checking PTO Driveline Extended Length: (Refer to Fig. 3) Apply multi-purpose grease to the outside of the inner driveline section. Assemble the outer and inner drivelines. When fully extended, the maximum allowable length must have a minimum overlap of 1/3 the free length of the inner and outer sections.

- Page 19 BFM-100 Series Finish Mower PTO Driveline Instructions Checking for PTO Driveline Interference: (Refer to Fig. 4) Begin with the PTO Driveline level (0 degrees). Raise the implement at an angle no greater than 25 degrees from level. Check for any interference and the length of the PTO Driveline extended. Do not exceed the maximum extended length! ...

-

Page 20: Operating Instructions

BFM-100 Series Finish Mower Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Operating Instructions Cutting Height Adjustment: The cutting height of the equipment depends on the position of the wheels. If the wheels are raised, the cutting height increases; if the wheels are lowered, the cutting height decreases. -

Page 21: Maintenance

BFM-100 Series Finish Mower Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Maintenance Maintenance: Maintenance is crucial for the working life and efficiency of any agricultural equipment. If the equipment is properly maintained and operated, a long working life and operator safety are assured. - Page 22 BFM-100 Series Finish Mower Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Maintenance Every 20 working hours Lubricate the pulley support bearing (C ). Every 30 working hours Check belt tensioning. Every 40 working hours Lubricate the wheel supports (A).

-

Page 23: Trouble Shooting

BFM-100 Series Finish Mower Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Trouble Shooting Problem Possible Cause Solution Operate PTO at 540 RPM Slow blade tip speed Replace with new OEM blades Worn blade tips Sharpen, balance old blades or replace with... -

Page 24: Torque Specifications

BFM-100 Series Finish Mower Notes: This chart is an approximate estimate of torque values. Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual. -

Page 25: Parts Breakdown

Rear Discharge Finishing Mower BFM-100 Series Parts Manual Rev. 08/24... - Page 26 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106...

- Page 27 BFM-100 Series Finish Mower Hopper Assembly Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106 Item Part # Description Qty. LNM1815 Nut locking M18-1.5 LFW18 Washer large fender M18 FMB4002 Blade 5” 505 x 50 x 6 FMB4003 Blade 6”...

- Page 28 BFM-100 Series Finish Mower Hopper Assembly Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106...

- Page 29 BFM-100 Series Finish Mower Hopper Assembly Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106 Item Part # Description Qty. BM1620140 Bolt HH M16-20x140 8.8 zinc FM10102 Wheel 210 x 80 FM10067...

- Page 30 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106...

- Page 31 BFM-100 Series Finish Mower Hopper Assembly Frame Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM105 & BFM106 Item Part # Description Qty. LW12 Washer lock M12 NM12175 Nut HH M12-1.75 KM100835 Key M10 x 8 x 35 BM101525 Bolt HH M10-1.5x25 8.8 zinc, BFM-105...

- Page 32 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM-107...

- Page 33 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM-107 Item Part # Description Qty. NM1815 Nut HH M18-1.5 LW18 Washer lock M18 FW18 Washer flat M18 FM60004 Blade 710x60x6 FM10129...

- Page 34 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM-107...

- Page 35 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Mower Assembly BFM-107 Item Part # Description Qty. FM10138 LH belt guard BM1620100 Bolt HH M16-2.0x100 FM10139 Upper hitch FM10140 LYNPN08 Lynch pin M8...

- Page 36 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Decals...

- Page 37 BFM-100 Series Finish Mower Hopper Assembly Operating Instructions Attaching PTO Shaft Attaching to Tractor Operating Instructions Decals Item Part # Description Qty. Decal Model # BFM-105 Decal Model # BFM-106 Decal Model # BFM-107 RT1016 Decal Tar River Manufacturing D1314...

-

Page 38: Warranty

BFM-100 Series Finish Mower Warranty LIMITED WARRANTY Belco Resources Equipment warrants to the original purchaser of any new piece of machinery from Belco Resources Equipment, purchased from an authorized Belco Resources Equipment dealer, that the equipment be free from defects in material and workmanship for a period of one (1) year for non-commercial, state, and municipalities’... - Page 39 BFM-100 Series Finish Mower Page left blank intentionally...

- Page 40 401 Jeffreys Road Tel: 252-822-7140 Rocky Mount, NC 27804 Fax: 252-787-5855 www.tarrivermfg.com Sales@tarrivermfg.com...

Need help?

Do you have a question about the BFM-100 Series and is the answer not in the manual?

Questions and answers