Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Zator MZB300

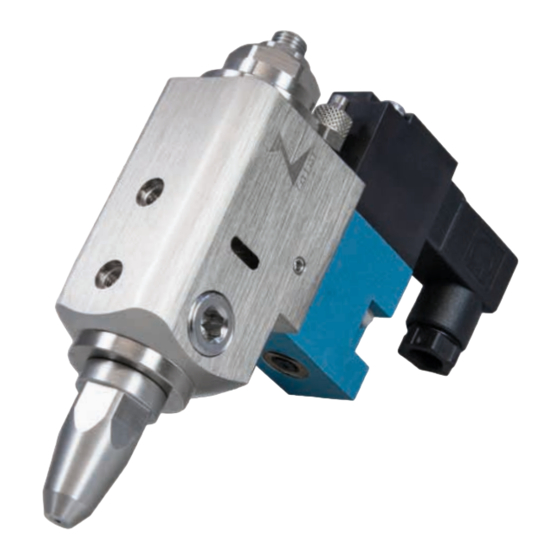

- Page 1 MZB300 electro pneum atic va l ve USER AND MAINTENANCE gluing solutions MANUAL...

- Page 2 ZATOR SRL Via Galvani, 11 20095 Cusano Milanino (MI) Italy Tel. +39 02 66403235 Fax +39 02 66403215 info@zator.it www.zator.it USER AND MAINTENANCE MANUAL MZB300_v01 JULY 2024...

- Page 3 UE Declaration of Conformity Manufacturer: ZATOR Srl Via Galvani 11 20095 Cusano Milanino (MI) Italy Tel.+39 02 66403235 Fax +39 02 66403215 Email: info@zator.it DECLARES Under its responsibility that the electropneumatic valve: Model MZB300 Year of manufacture Is in compliance with UE directives, with relation to the following ones and/or parts of them applicable to this product: •...

- Page 4 ndex GENERAL INFORMATION Introduction Warranty Warranty restrictions Maintenance service request Spare parts request SAFETY RULES AND REGULATIONS Safety and environment general informations P.P.E. Personal protective equipment Risks, protections, warnings and cautions 2.3.1 General safety 2.3.2 Unavoidable dangers and risks unavoidable 2.3.3 Safety devices adopted 2.3.4...

- Page 5 VALVE ADJUSTMENTS Fluid quantity adjustment Needle travel adjustment MAINTENANCE General norms Maintenance program Cleaning and/or replacement of the nozzle Valve disassembly Valve assembly TROUBLE SHOOTING MODELS PARTS LIST DIMENSIONS...

- Page 7 USER AND MAINTENANCE MANUAL el e ct ro pneu mati c valve MZ B3 0 0...

-

Page 8: General Information

Instructions, drawings and documentation contained in this manual are of reserved technical disposition, only for Zator Srl property and may be not reproduced in any way, neither in full or partially reproduction; not translated into another language, or transmitted in any electronic or mechanical means or form, without written permission of Zator Srl. -

Page 9: Application Fields

The flawed parts under warranty are fixed or replaced free from Zator Srl in the time compatibly necessary, understood that the Zator Srl is exempted from each responsibility for any title, while the buyer give up to ask damages or costs, including those resulting from the temporary not use of the purchased machinery for all the time is necessary to put it back in efficiency;... - Page 10 • The packaging is intact • The exact correspondence of the commissioned material In case of damages or wrong delivery contact immediately Zator Srl. The buyer, on penalty of warranty decadence, must report in writing the flaw conformity or fault of the electropneumatic valve to the seller, specifying in detail the nature, within eight days from their discovery.

- Page 11 The disassembly and assembly operations must be performed according to the manufacturer’s instructions. Contact the Technical Office of Zator Srl which will give to you the specifications to do the request of the parts and will provide the information about their replacement.

-

Page 12: Safety Rules And Regulations

Only trained personnel is authorized to install and use the valve. For the electropneumatic valve MZB300 are provided only and exclusively the application fields describe in this manual. All data and parameters indicated in this manual must be respected. Any other use is considered improper. -

Page 13: Personal Protective Equipment

A competent person must get to know with the specific norms for the safety on work and for the accident prevention and generally with the technical knowledge rules. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it... - Page 14 D - Risk due to the projection of fluids under pressure In case of improper maintenance of the hydraulic system parts. E - Risk of fire Prohibition of smoking and/or high temperature objects near the electropneumatic valve. ELECTROPNEUMATIC VALVE MZB300...

- Page 15 The manufacturer declines all responsibility for the safety of the electropneumatic valve in case of omitted observance of the prohibition. CE norms signage: examples of danger symbols Danger High voltage Flammable Toxic Corrosive Combustive agent Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

-

Page 16: Operating Environmental Conditions

The customer is responsible for ensuring an appropriate lighting of the local where the valve is installed, according to the laws in force in your country and the EU directives. Vibrations The electropneumatic valve doesn’t make vibrations. ELECTROPNEUMATIC VALVE MZB300... -

Page 17: I N Sta L L Ati O N - Ge N E Ra L I N St R U C T I O Ns

I n sta l l ati o n - Ge n e ra l i n st r u c t i o ns Zator’s products are manufactured in compliance with the laws in force during its construction. The personnel will be trained and qualified to take advantage of the installed valve requirements. - Page 18 • The fluid has not been exposed to temperatures near or below than zero therefore it has deteriorated • The packaging of the fluid are sealed For the use of special adhesives, glues or fluids we recommend to contact the Zator company to verify the compatibility of the application.

- Page 19 SECTION 2 - SAFETY RULES AND REGULATIONS Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

-

Page 20: Technical Description

USER AND MAINTENANCE MANUAL TECHNICAL DESCRIPTION Val ve f un c ti on s The electropneumatic extrusion valve MZB300 has been designed and realized for its use on various kind of production machines: its design and versatility make it ideal for any applications that require the use of extrusion valves. -

Page 21: F Un C T I O N I N G D E S C R I Pti On

Then the piston Fluid moves back together with the needle, allowing the fluid flow to come out from the nozzle. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it... -

Page 22: Installation

INSTALLATION 4 .1 Fix in g o f t h e va l ve The MZB300 valve must be fixed on a proper bracket by using the M6 threaded holes machined on the valve body. A vibration-free environment and a good accessibility... - Page 23 (2 lateral and 1 rear). Unused holes should be closed with G1/4 plugs. Fluid supply connection G1/4 *Parts are supplied separately Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

- Page 24 Dr ive a i r co n n e c t i o n Air connection Connect a pipe 6x4 to the air connection on the Ø solenoid valve. The air pressure must be between 5÷6 bar. *Parts are supplied separately ELECTROPNEUMATIC VALVE MZB300...

-

Page 25: Valve Adjustments

Don’t tighten with excessive force the needle adjustment screw to avoid damage to the nozzle and the needle. 3. Finally tighten the nut by holding the screw. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it... -

Page 26: Maintenance

Every year or after 4000 working hours • Replace possible worn parts *Approximate values that can change depending on the type of glue, adhesive or fluid used. For the use of special fluid we recommend to contact the Zator company for any questions. ELECTROPNEUMATIC VALVE MZB300... - Page 27 Repeat the step until you have removed all the impurities inside and outside the nozzle; Screw the nozzle on the valve with a 15mm wrench. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

- Page 28 Loosen the needle adjustment with the adjustment nut (see section 5.2 - Needle travel adjustment), by turning it counter- clockwise until it doesn’t resist anymore; Unscrew the nozzle with a 15mm wrench; ELECTROPNEUMATIC VALVE MZB300...

- Page 29 Molla in compressione Extract the spring; Unscrew the air fitting with 8mm wrench; Pull out the needle with the help of a smooth plier; Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

- Page 30 Variseal (POS. 13) and, if it is necessary, replace it. Always grease* the new O-rings before assembling them. POS.12 *Use silicon-based grease or oil specific for O-rings. For any questions or POS.5 information contact the Zator company. POS.13 ELECTROPNEUMATIC VALVE MZB300...

- Page 31 Zator company. POS.13 Insert the lock bush inside the valve body, then screw it with a tubular spanner; Insert the needle and grease the piston O-ring; Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

- Page 32 Screw the air connections with a 8mm wrench; Insert the spring: Screw* the adjustment block in the valve body with a 19mm wrench; *Pay attention that adjustment block is not tilted during the screwing to avoid damage to the thread. ELECTROPNEUMATIC VALVE MZB300...

- Page 33 (or that the solenoid valve is activated). To loosen the adjustment nut, turn it counter-clockwise until it doesn’t resist anymore. Mount the solenoid valve using a 3mm hex key to fasten the mounting screws. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

-

Page 34: Troubleshooting

No or weak drive pressure Check the drive air pressure (5 bar) The valve is activated with a lag The needle is not moving Replace the piston O-ring (POS.5) properly ELECTROPNEUMATIC VALVE MZB300... - Page 35 ZB08B05000 Extrusion valve MZB30014 1/4” 24 Volt code desc r i pt io n ZB09B05000 Extrusion valve MZB300SY 24 Volt Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italy www.zator.it - info@zator.it...

-

Page 36: Parts List

Nozzle KL 10 mm H855202XX Nozzle KL 15 mm H855203XX Nozzle KL 20 mm Replace XX value with nozzle diameter desired Available nozzle diameters from 2,0 to 5,0 mm H85100130 Nozzle Syrin H85100140 Nozzle 1/4 KGN000020 Gasket kit¹ ELECTROPNEUMATIC VALVE MZB300... - Page 37 The images in this document are considered for illustration only. The company reserves the right for any changes without notice. Names, trademarks and logos are property of the author. Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italia www.zator.it - info@zator.it...

- Page 38 USER AND MAINTENANCE MANUAL DIMENSIONS MZ B3 X X LV G1/4 M6x1.0 MZ B 3 XX KV G1/4 M6x1.0 ELECTROPNEUMATIC VALVE MZB300...

- Page 39 SECTION 10 - DIMENSIONS MZB3XX KL 1 0 m m G1/4 M6x1.0 MZB3XX KL 1 5 m m G1/4 M6x1.0 Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italia www.zator.it - info@zator.it...

- Page 40 USER AND MAINTENANCE MANUAL M Z B3X X KL 2 0m m G1/4 M6x1.0 MZ B3 001 4 G1/4 M6x1.0 G1/4 ELECTROPNEUMATIC VALVE MZB300...

- Page 41 SECTION 10 - DIMENSIONS MZ B 30 0SY G1/4 M6x1.0 Zator Via Galvani, 11 - 20095 - Cusano Milanino (MI) - Italia www.zator.it - info@zator.it...

- Page 44 ZATOR SRL Via Galvani, 11 20095 Cusano Milanino (MI) Italy Tel. +39 02 66403235 Fax +39 02 66403215 info@zator.it www.zator.it...

Need help?

Do you have a question about the MZB300 and is the answer not in the manual?

Questions and answers