Table of Contents

Advertisement

Quick Links

Duct/pipe cleaning

nozzles

Operating instructions

Year of manufacture 1989 ... + Production quarter

KA

KA05-100, KA05-105, KA05-110, KA20-100, KA20-

105, KA20-110, HRR-16, KRD-16, HRR-22, KRD-

22, HRR-29, KRD-29, HRR-40, KRD-40, HRR-60,

KRD-60

BA 0305029 R01 2021-11

Operating instructions for Duct/pipe cleaning nozzles.

Advertisement

Table of Contents

Summary of Contents for TEV Jager KA

- Page 1 Duct/pipe cleaning nozzles Operating instructions Year of manufacture 1989 ... + Production quarter KA05-100, KA05-105, KA05-110, KA20-100, KA20- 105, KA20-110, HRR-16, KRD-16, HRR-22, KRD- 22, HRR-29, KRD-29, HRR-40, KRD-40, HRR-60, KRD-60 BA 0305029 R01 2021-11 Operating instructions for Duct/pipe cleaning nozzles.

-

Page 2: Table Of Contents

Table of contents Basics Safety notices Explanatory information Overview of the rotor nozzle components Scope of delivery Tools required for assembly and repair Tools required for repair How does the Duct nozzle work? Components and their function How does the rotary nozzle work? Components and their function Intended use Requirements for the surface to be cleaned... - Page 3 Table of contents Commissioning Preparation and connection of the Duct/pipe cleaning nozzle Unpacking and checking Install the Duct/pipe cleaning nozzle on the high-pressure hose Working with the Duct/pipe cleaning nozzle Find the right position for the safety marking Installation of a separation unit Set the working pressure Connect the Duct/pipe cleaning nozzle to the high water pressure Operation...

- Page 4 Table of contents Install the repair kit in the pipe cleaning nozzle Open the pressure housing Remove the drive plug on the pipe cleaning nozzle Remove the drive plug on the pipe cleaning nozzle Remove the bearing unit Insert a new bearing unit Insert a new rotor Change the O-ring on the drive plug Change the O-ring on the drive nipple...

- Page 5 Notes Notes BA 0305029 R01 2021-11...

- Page 6 It is IMPORTANT that you read these operating instructions CAREFULLY BEFORE USE and RETAIN THEM FOR FUTURE REFERENCE. Visit our homepage at regular intervals and check for the latest version of the operating instructions. The operating instructions are intended for... Duct/pipe cleaning nozzles from year of construction 1989.

-

Page 7: Basics

Basics Components of a Duct/pipe cleaning nozzles and their function Here you will find information about: the components of the Duct/pipe cleaning nozzles. BA 0305029 R01 2021-11... -

Page 8: Safety Notices

Basics Explanation of warning notices Safety notices These warning notices are for your safety. The warning notices can be found in the general chapter on safety and are always depicted when referring to an action that requires a separate warning notice. Failure to comply will lead to serious injury or death. -

Page 9: Explanatory Information

Basics Explanatory information This information can be found in the grey shaded area in a diagram. This helps you to find the right diagram for the heading in the text, understand the details better, follow steps, understand movements and identify the position in the room. The title of the image indicates the Clean the thread text... -

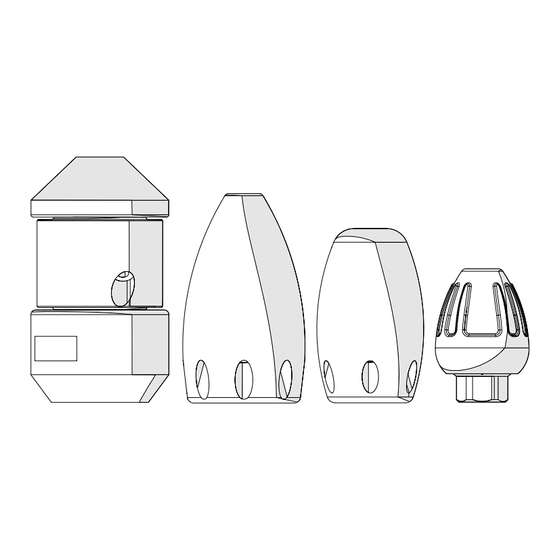

Page 10: Overview Of The Rotor Nozzle Components

Basics Overview of the rotor nozzle components Protective cap (if installed) Rotor Pressure housing O-Ring O-Ring Drive plug Bearing unit � Pressure housing Drive plug � Bearing unit Recoil nozzle Rotor Scope of delivery The Duct/pipe cleaning nozzles are delivered fully assembled and are adapted to a specific pressure-flow ratio. - Page 11 Basics � � Pressure housing Drive plug � � Bearing unit Recoil nozzle � Rotor � � Cylinder screw M8 x 20 mm Stator � � Recoil nozzle � Rotor BA 0305029 R01 2021-11...

-

Page 12: Tools Required For Assembly And Repair

Basics Tools required for assembly and repair Combination spanner suitable for the Duct/pipe cleaning nozzle or the high-pressure duct hose used. Pipe wrench for fastening the duct high-pressure hose, if there is no hexagon nut. Tools required for repair Mounting aid or, for example, ballpoint pen for removing the bearing unit. - Page 13 Notes Notes BA 0305029 R01 2021-11...

-

Page 14: How Does The Duct Nozzle Work

Basics How does the Duct nozzle work? This duct nozzle consists of a pressure housing, a drive plug or nipple, a rotor, 7. Because the water moves in an axial a bearing unit and recoil nozzles. The motion through the holes of the drive duct nozzle generates a hard, cone- plug, a rotating field is created by the shaped spot jet of high-pressure water... -

Page 15: Components And Their Function

Basics The O-rings seal the pressure area on the drive plug and on the bearing unit. The recoil nozzle creates together with the round nozzle of the rotor, the maximum pressure and, with the help of the recoil effect, pushes the Components and their function Duct/pipe cleaning nozzle forward. -

Page 16: How Does The Rotary Nozzle Work

Basics How does the rotary nozzle work? 5. The backwards slanting/outwards This duct nozzle consists of a stator, pointing and horizontally/upward a rotor and a lid that holds everything pointing round nozzles push the rotary together. nozzle into the pipe and set the rotor into rotation . -

Page 17: Components And Their Function

Basics Components and their function The stator forms the base. It is here that the connection mechanism and water distribution are located. In addition, it forms the axis around which the rotor can rotate. The rotor is the base for the spot jet nozzles. - Page 18 Basics Intended Here you will find the following information: For what purposes may the Duct/pipe cleaning nozzle be used? Where can the Duct/pipe clean- ing nozzle be used? Who may use the Duct/pipe cleaning nozzle? BA 0305029 R01 2021-11...

-

Page 19: Intended Use

Basics Intended use cialised personnel are able to carry out the work assigned to them and inde- The Duct/pipe cleaning nozzle is intend- pendently identify possible hazards and ed for cleaning pipes with non-organic avoid hazards. surfaces with high-pressure water. The following groups of people are not Requirements for the surface to allowed to operate the rotor nozzle:... -

Page 20: Maximum Performance Data

Basics Maximum performance data The performance data depends on the type and can be found in the technical data of the individual versions. The per- formance data given here are general data on our Duct/pipe cleaning nozzles. � Operating pressure: between 150 and 300 bar �... -

Page 21: Ec Declaration Of Conformity

Basics EC Declaration of Conformity BA 0305029 R01 2021-11... - Page 22 Basic safety General safety instructions Important instructions for safe use of the system and for ensuring safe cleaning. BA 0305029 R01 2021-11...

-

Page 23: For Your Safety

Basic safety For your safety Here you will find information about choosing a safe cleaning location, sources of danger in the work area and sources of danger when working. DANGER Danger to life in severe weather conditions A Never work during a storm. This prevents the risk of being struck by lightning. - Page 24 Basic safety CAUTION Illness and hypothermia caused by bad weather A In bad weather, wear suitable protective clothing. This will protect you from illness caused by hypothermia. CAUTION Damage to hearing on account of too much noise A Wear hearing protection while working. 95dB This will protect your hearing from damage caused by excessive noise.

- Page 25 Basic safety CAUTION Risk of injury due to slippery surface A Check the surface for any situations that may facilitate slipping. This will protect you from falling and injuring yourself. CAUTION Risk of injury due to bypassing safety devices A Never disable safety devices. This protects you from injuries caused by uncontrolled movements of the pipe drain nozzle during starting.

-

Page 26: Safe Operation

Safe operation Safe cleaning operation Here you will find information about: choosing a safe cleaning location, sources of danger in the working area, sources of danger when working. BA 0305029 R01 2021-11... -

Page 27: Safe Operation

Safe operation Safe operation CAUTION Risk of injury due to slippery surface Safe operation of the Duct/pipe cleaning A Check the surface for any situations nozzle is described here. that may facilitate slipping. This will protect you from falling and Select a safe position injuring yourself. -

Page 28: Commissioning

Commissioning Commissioning of the Duct/pipe cleaning nozzle Here you will find information on preparing the Duct/ pipe cleaning nozzle for operation. BA 0305029 R01 2021-11... -

Page 29: Preparation And Connection Of The Duct/Pipe Cleaning Nozzle

Commissioning Preparation and connection of the Duct/pipe cleaning nozzle Clean the thread Unpacking and checking � Unpack the Duct/pipe cleaning nozzle. � Check the Duct/pipe cleaning nozzle for external damage. � Check that all components are present. � Check the functional efficiency of the high-pressure gun. - Page 30 Commissioning Seal using sealing thread � If there is no O-ring for sealing: Use sealing thread made of polyamide or fluoroplastic, which you apply to the threads of the threaded connection. � Screw the Duct/pipe cleaning nozzle here also right up to the end of the threaded connection.

-

Page 31: Working With The Duct/Pipe Cleaning Nozzle

Commissioning Working with the Graphic for determining the position for Duct/pipe cleaning [<>] nozzle [<>] Find the right position for the safety marking � In order to be able to work safely, at- tach a safety mark to your pipe cleaning hose Position of the safety marking: �... -

Page 32: Installation Of A Separation Unit

Commissioning Connect the high-pressure cleaner Installation of a separation unit � Connect the low-pressure water, the power supply and a high-pressure hose to the high-pressure cleaner accord- ing to the operating instructions of the high-pressure cleaner. � Connect a suitable high-pressure separation unit to this high-pressure hose [1]. -

Page 33: Set The Working Pressure

Commissioning Connect the high-pressure lance Set the working pressure � Mount on the high-pressure gun: a high-pressure lance with a nozzle suitable for the pressure area of your pressure cleaner (Flat jet or rotor). � Start the pressure cleaner [6]. �... -

Page 34: Operation

Operation Working with the Duct/pipe cleaning nozzles Here you will find information about working with the Duct/pipe cleaning nozzle. BA 0305029 R01 2021-11... -

Page 35: Working With The Duct/Pipe Cleaning Nozzle

Operation Working with the Clear the pipe [Ø Pipe x 2 = safety marking] Duct/pipe cleaning nozzle Clearing the entrance area of the pipe � Clear the pipe of dirt INFO: For this purpose, for example, a rotor nozzle or flat jet nozzle can also Insert the Duct/pipe cleaning nozzle be used. - Page 36 Operation Take up a secure position at start-up � Take up a safe position when starting the Duct/pipe cleaning nozzle (about 2 metres distance to the pipe opening). � Take the separation unit in your hand. � Take the pipe cleaning hose in your hand and pull the high-pressure hose straight...

- Page 37 Operation Open the separation unit carefully � Carefully fully open your separation unit . The Duct/pipe cleaning nozzle will begin to work its way into the pipe work. TIP: If the Duct/pipe cleaning nozzle sticks slightly, the forward movement can be improved again by briefly pull- ing it back.

- Page 38 Operation Pull out to the safety mark � Pull the pipe cleaning hose out until the safety mark becomes visible at the pipe entrance. � Close the separation unit [3]. � Lock the trigger of the separation unit. Close the separation unit Lock the trigger BA 0305029 R01 2021-11...

-

Page 39: Repair

Repair Repairing the Duct/pipe cleaning nozzle Here you will find information about repairing the Duct/ pipe cleaning nozzle. BA 0305029 R01 2021-11... -

Page 40: Defective Pipe Cleaning Nozzle

Repair Defective pipe � No rotation of the spot jet » Nozzle or bearing worn out cleaning nozzle Troubleshooting measure � If the nozzle or bearing is defective or Possible error patterns worn, a new rotor and bearing unit must �... -

Page 41: Remove The Drive Plug On The Pipe Cleaning Nozzle

Repair Unscrew the pipe cleaning nozzle � Unscrew the pipe cleaning hose. � If there is no hexagon nut on the pipe cleaning hose: use a pipe wrench to unscrew. Remove the drive plug on the pipe cleaning nozzle � Suitably secure the pipe cleaning noz- zle to the pressure housing so that it cannot twist or turn. -

Page 42: Remove The Bearing Unit

Repair Remove the rotor Remove the bearing unit � Take the old rotor from the pres- sure housing [2]. � Take the mounting aid and press the bearing unit out of the inside of the pressure housing. TIP: Instead of the mounting aid, you can also use a rounded object that has the diameter of the hole in the pressure housing. -

Page 43: Insert A New Bearing Unit

Repair Grease the O-ring Insert a new bearing unit � Take the new bearing unit apply grease to the O-ring. � Place the bearing unit, bearing seat first on the mounting aid. TIP: Instead of the mounting aid, you can also use, for example, a ballpoint pen. -

Page 44: Insert A New Rotor

Repair Insert a new rotor Insert rotor � Take the new rotor and insert it nozzle first into the pressure housing. � Push the rotor until it rests properly in the bearing unit. Change the O-ring on the drive plug �... -

Page 45: Assemble The Pipe Cleaning Nozzle

Repair Insert the drive plug Assemble the pipe cleaning noz- � Stick the rotor, [10] nozzle tip up- wards, into the drive plug [11]. � Hold the pressure housing [12] hori- zontally with the opening pointing to the side. Screw in the drive plug �... -

Page 46: Storage

Storage Storing the Duct/pipe cleaning nozzle Here you will find information storing the Duct/pipe cleaning nozzle. BA 0305029 R01 2021-11... -

Page 47: Storing The Duct/Pipe Cleaning Nozzle

Storage Storing the Duct/ Empty the Duct/pipe cleaning nozzle pipe cleaning nozzle Drain the Duct/pipe cleaning nozzle � Disconnect the Duct/pipe cleaning nozzle from the pipe cleaning hose. � Hold the Duct/pipe cleaning nozzle vertically and let the water drain out of the Duct/pipe cleaning nozzle. -

Page 48: Disposal

Disposal Disposal of the Duct/pipe cleaning nozzles Here you will find information on how to dispose of the product and the associated components. BA 0305029 R01 2021-11... -

Page 49: What Happens To The Waste

Disposal What happens to the waste? Packaging � The packaging is made of cardboard and can be recycled. Protective cap, rotor, bearing unit � These components can be disposed of with non-recyclable waste. Pressure housing, drive plug � These components can be given to metal recycling. - Page 50 TEV Jäger mbH | Grundweg 10 | 89250 Senden | +49 (0)7307 - 97606 0 | info@tev-jaeger.de | www.tev-jaeger.com...

Need help?

Do you have a question about the Jager KA and is the answer not in the manual?

Questions and answers