Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for DualLift SP408 CE9

- Page 1 DualLift GmbH Original Operating and Installation Instructions DualLift Manriding hoists DualLift Material Hoists DualLift OSL / ISL Safety Devices These operating instructions are to be kept available for users at all times! Last updated: January 2022...

-

Page 3: Table Of Contents

LATFORMS ......................24 TABILITY AND ORKING OSITIONS ........................25 ORESEEABLE ISAPPLICATIONS ..........................25 PTIONAL CCESSORIES COMMISSIONING THE DUALLIFT HOIST AND SAFETY DEVICES ............... 26 ........................... 26 EQUIRED OMPONENTS ........................ 27 OUNTING THE OIST ......................28 ONNECTING THE OIST ............................28... - Page 4 NSPECTION BY A UALIFIED ERSON 11.3 ..........................44 ENERAL VERHAUL 11.4 ............................ 44 EPAIRING OISTS 11.5 ........................44 AINTENANCE AND PKEEP DISPOSAL ............................... 44 APPENDIX............................... 46 © DualLift GmbH Page 2 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx...

-

Page 5: Revision History

Hoist type SP508 added 2019-12 ASME content updated 2019-12 Appendix CE Declaration OSL CCV updated (12.12.19) 2021-06 Several Updates for new type approval 2022-01 Service intervals updated © DualLift GmbH Page 3 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx... -

Page 6: Notes On These Operating And Installation Instructions

Technical changes may take place at any time. The system operator should regularly ask DualLift GmbH to inform them of any changes that take/have taken place. Users of the system must have read and understood these operating instructions and potential customer specific supplements and addons. -

Page 7: Notes For Manufacturers

A VFD hoist is equipped with a control unit, which is equipped with a variable frequency drive. 1.2 Notes for Manufacturers DualLift manriding hoists and material hoists and their associated safety devices and accessory parts are designed for Group A3 SAE constructions and tested for safety in accordance with the specifications of type M4 SAE. -

Page 8: Explanation Of The Symbols Used In These Operating Instructions

Danger of injury or material damage caused by a hazardous situation Danger of injury or death due to high voltage Danger of injury or death © DualLift GmbH Page 6 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx... -

Page 9: Important Safety Regulations

The installation and maintenance of DualLift manriding hoists and material hoists or DualLift safety devices is only allowed to be carried out by persons who are familiar with the equipment and who the system operator has entrusted with its installation and maintenance. - Page 10 All other inspections, tests, checks or repairs must be performed by DualLift GmbH or a workshop authorized by DualLift GmbH. t) DualLift hoists with a control unit fitted directly to the hoist may only be used for temporary access systems, because they only have one input for the limit switch UP.

-

Page 11: Warranty And Liability

3 Warranty and Liability The DualLift terms and conditions are applied. Claims are excluded, if based on at least one of the following reasons. Improper use of the product Improper assembling, commissioning, operating or service of the product Using the Product with defective Safety Equipment Non-observing the Notes regarding Transportation, Storing Operating and service. -

Page 12: Description Of The Duallift Hoist

(also see Section 7.4 "Foreseeable Misapplications”). Notification of Residual Risks A possibility of residual risks exists, which DualLift GmbH is incapable of covering in the construction design. General residual risks when operating manriding hoists and material hoists can never be ruled out. For this reason, only appropriately trained persons (operators) should be assigned to operate the hoists. -

Page 13: Functioning Of The Hoist

DualLift P- and M- hoists are electrically operated hoists for personnel and material transport. The wire rope is not stored in the DualLift hoist, but transported through it at a constant speed by the hoist. For this reason, the wire rope length, i.e. the lifting height, is virtually unlimited (see Section 6.2) length). -

Page 14: Technical Data

C:265 mm C: 266 mm C: 266 mm C: 246 mm F: 257 mm F: 259 mm F: 268 mm CE-approval UL/CSA SP408 CE9 SP408 ULCS10 SP408 CE18 SP408 ULCS20 SP408CE9/18 SP508 CE9 SP508 ULCS10 SP508 CE18 SP508 ULCS20 SP508CE9/18... -

Page 15: Technical Data Sheet

4.5 Technical Data Sheet [kg] [lbs] [kg] [mm] [m/min] [fpm] [m/min] [kW] dB(A) SP408 CE9 0,75 SP408 ULCS10 SP408 CE18 SP408 ULCS20 SP408 CE9/18 9/18 35/70 10/20 2,8/5,0 0,9/1,8 SP408 ULCS10/20 SP508 CE9 0,75 SP508 CE18 SP508 CE9/18 9/18 2,8/5,0... -

Page 16: Safety Devices

4.6.10 manufacturer* * Can be performed by DualLift GmbH at the request of the customer following consultation (in parts) (e.g. by using a control hoist) The manufacturer of a control system for an SAE needs to be aware of the requirements regarding the Performance Level according to Table 14 of the EN 1808. - Page 17 (this may take several seconds). 4.6.6 Hoist Limit Switch Depending on the area of application of the DualLift hoist, different hoist limit switches need to be provided for. The following table shows which limit switches are needed for which application:...

-

Page 18: Scope Of Delivery

Wire rope certificates (if ropes are in scope of delivery) • CE declaration of conformity If a delivery does not contain the items listed, please contact DualLift GmbH. Optionally, the delivery can contain controls, operating elements and the accessories described in Section 7.5 as well as customized accessories. -

Page 19: Duallift Safety Devices

BS EN 1808, which secures the load on a safety rope, separate to the support rope, to prevent it from falling. Depending on the application, DualLift type OSL or ISL safety devices can be used for this purpose. DualLift safety devices are generally attached directly to the PAE, and, for example, moves up and down a rope hanging in front of a building facade. -

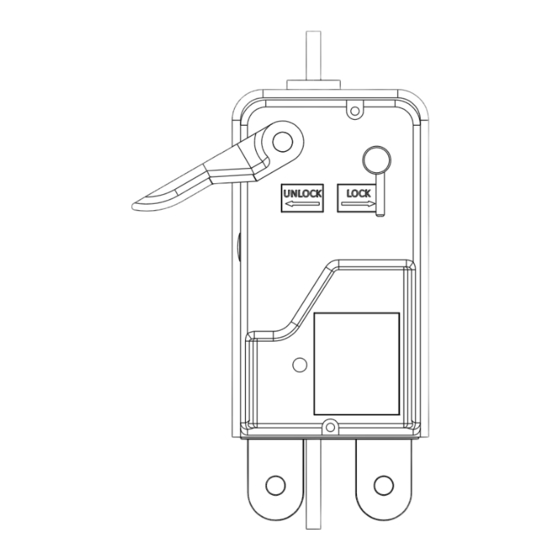

Page 20: Overspeed Safety Lock (Osl)

Wire rope outlet e. Mounting holes Ø 12.5 mm Sight glass Figure 11: DualLift OSL components The following equipment exist to ensure the safety of the OSL: A) Tripping lever Rotating the tripping lever to the right (anti-clockwise) manually actuates the clamping mechanism to stop downward movement (e.g. - Page 21 OSL to DualLift GmbH for inspection. This is the responsibility of the system operator. 5.2.3 Technical Data (ASME A Dimensions 1808) 17.7) DualLift m/min DualLift Height Width Depth equipment m/min ° equipment type (lbs) type ASME...

-

Page 22: Inclination Safety Lock (Isl)

(PT100) Heating mat with insulation Figure 13: DualLift CCV OSL The CCV OSL is only allowed to be used in combination with a special control unit, which also meets the requirements of the extended temperature range. 5.3 Inclination Safety Lock (ISL) The ISL is a safety device that is suitable for detecting inclinations (tilt) and slack ropes. -

Page 23: Wire Ropes

The following table shows all permissible rope types that can be used in combination with DualLift hoists. Use of a rope with a diameter that is too large or too small (for permitted values see Section 11.1.1) leads to an impairment of the hoist function and can result in the load falling from a height. -

Page 24: Maximum Wire Rope Length

The Manufacturer of the System must perform a separate calculation related to the specific application – according to the terms of the EN1808, chapter 6.7! © DualLift GmbH Page 22 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx... -

Page 25: Examples Of Applications And Foreseeable Misapplications

7 Examples of Applications and Foreseeable Misapplications Several applications exist for DualLift hoists and safety devices. The following sections present a selection of some of these possibilities. DualLift GmbH will gladly assist you in configuring a corresponding application. 7.1 Types of Suspension Figure 15, Figure 16 and Figure 17 show three applications for DualLift hoists in schematic form. -

Page 26: Work Platforms

Figure 18: Overhead hoists with a variety of accessories 7.2 Work Platforms A typical example of an application for DualLift hoist and ISL safety devices are work platforms and facade lifts (BMU - Building Maintenance Units). The example illustrated in Figure 19 shows a work platform that can be moved along two drive ropes in a vertical direction. -

Page 27: Foreseeable Misapplications

Disregarding the maximum permitted rope length, see Chapter 6.2. 7.5 Optional Accessories DualLift GmbH offers a range of different accessories for DualLift wire rope hoists. We briefly introduce some of them in the following sections. Please find out more by consulting DualLift GmbH when configuring your system. -

Page 28: Commissioning The Duallift Hoist And Safety Devices

For transporting people: DualLift safety devices with at least the same payload capacity as the DualLift hoist(s) c) A sufficiently long wire rope, which is approved by DualLift GmbH, with a diameter that matches the corresponding hoist(s) and safety device(s), and a 10-kg wire... -

Page 29: Mounting The Duallift Hoist

8.2.2 Mounting the DualLift Hoist The DualLift hoist is to be mounted in such a way that the support rope under a load is always vertical from all directions when it enters the hoist (see Figure 25)! We recommend consulting DualLift GmbH when planning mounting the hoist. -

Page 30: Connecting The Duallift Hoist

USA/Canada: 460V (3P+N+PE), 60 Hz with 16 A CEE plug Some DualLift Controls don’t rely on the neutral wire of the power supply. The proper function of the hoist does not state a proper power supply. 2) Always comply with the minimum cross-section figures for the supply cable in following table! Otherwise, correct operation of the hoist cannot be guaranteed, particularly when the distance to the mains supply/generator becomes larger. -

Page 31: Safety Devices

Section 8.2.1 when selecting the fastening material. DualLift safety devices are to be mounted in such a way that the safety rope always enters the safety device vertically seen from all directions! A deflection of a maximum of 2° to the vertical is permitted as with the hoists (see Figure 25). -

Page 32: Wire Ropes

Be careful when handling wire rope. Make sure you always wear protective gloves. 1) Only use wire rope approved by DualLift GmbH. Make sure that the wire rope has the right thickness and is of a sufficient length (see Section 6.1 and Section 11.1.1). -

Page 33: Operating The Duallift Hoist And Safety Devices

9 Operating the DualLift Hoist and Safety Devices Before using DualLift hoists and safety devices, a series of safety checks need to be performed, which may need to be repeated regularly depending on the type of check. Details of these checks are explained in more detail in Sections 9.2 and 9.3. -

Page 34: Logbook

The system should stop immediately. 9.3 Checks to be Performed by the Operator before each Use a) Check that the DualLift hoist is correctly attached to the system (see Section 8.2.2). b) Check the condition of all moving wire ropes, limit switches, PAE construction parts and wire ropes (See section 8.6.1) and exclude any defects. - Page 35 That the wire ropes are not dirty, or covered in ice, frost or other frozen substances If a control unit supplied by DualLift GmbH is used, check the functionality as follows: The hoist and control unit are to put into an operational state.

-

Page 36: Drive Operation

9.4 Drive Operation DualLift hoists allow drive operation in two directions. The following sections describe how movement is initiated and then stopped again. 9.4.1 Stop and EMERGENCY STOP a) To stop the hoist, release the UP or DOWN button. If the hoist fails to stop: b) Press the EMERGENCY STOP button =>... -

Page 37: Emergency Operation

A centrifugal brake integrated into the hoist ensures that the speed of descent is limited. You can stop the descent by releasing the brake release lever. © DualLift GmbH Page 35 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx... - Page 38 Now stow the hand wheel and brake release lever back in their original storage location and replace the plastic cover over the motor hood. © DualLift GmbH Page 36 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx...

-

Page 39: Action To Be Taken When An Incident Occurs With A Safety Device

9.6 Action to be taken when an Incident occurs with a Safety Device Safety devices are to be replaced at all times and sent to DualLift GmbH for inspection following a safety incident! The renewed use of safety devices... -

Page 40: Troubleshooting

Always disconnect the power supply before accessing the electrical box on the hoist or the control unit! 2) Repairs to DualLift hoists and safety devices are only permitted to be carried out by DualLift GmbH or a hoist workshop authorized by DualLift GmbH! - Page 41 M) Incorrect connection, Compare the connection and e.g. neutral conductor missing wiring diagram and have DualLift GmbH perform a conversion if necessary N) Protective shutdown due to overheating a) One of the phases is a) Check/Repair the fuses,...

- Page 42 15 minutes. overheating. If the before mentioned steps do not result in clarification and rectification of the cause, please call DualLift GmbH or a hoist service authorized by DualLift GmbH. © DualLift GmbH Page 40 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx...

-

Page 43: Repairs And Tests, Checks And Inspections

200 operating Equipment) hours, whichever comes first! DualLift GmbH or a service partner authorized by DualLift The system operator is responsible for ensuring that all applicable regulations and national laws are complied with regarding repairs, tests, checks and inspections. - Page 44 5xK26WS SFC 2160 B sZ 10.2 - 10.5 mm 10.0 mm 10.2 mm Vornbäumen 5xK26WS SFC 2160 B sZ 10.2 - 10.5 mm 10.0 mm 10.2 mm Figure 36: Measurement of rope diameter © DualLift GmbH Page 42 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx...

-

Page 45: Annual Inspection By A Qualified Person

11.2 Annual Inspection by a Qualified Person In order to ensure the safe use of the equipment an annual safety review of DualLift hoists safety devices must be performed at least once a year by qualified person authorized by DualLift GmbH. -

Page 46: General Overhaul

11.3 General Overhaul In order to ensure the safe use of the equipment until the next inspection the DualLift manriding hoists or material hoists and safety devices need to be overhauled according to the table at the beginning of this Chapter. Determining to this period is the date on the last (general overhaul) test report. - Page 47 The disposal of the products described in this manual has to be done according to the EU- Directive 2008/98/EC or corresponding national regulations. For the electrical components the EU-Directive 2012/19/EC or corresponding national regulations apply. © DualLift GmbH Page 45 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx...

-

Page 48: Appendix

Appendix © DualLift GmbH Page 46 BA SP408 % SP608 % P508-1010 englisch 2022-01 - 12724.docx... - Page 49 ID No. 0400 (Liftinstituut B.V.), Certificate No: NL-21- 400-1001-204-07 Authorized representative for compiling technical documents: Nils Scharbius, Design Engineer Town/Date: Osterholz-Scharmbeck, 31. May 2021 Name: Eike Rulfs Function: Head of Engineering, DualLift GmbH authorized Signature © DualLift GmbH...

- Page 50 Safety of machinery - Electrical equipment of machines, Part 32 Authorized representative for compiling the technical documents: Nils Scharbius, Design Engineer Town/Date: Osterholz-Scharmbeck, 24, October 2019 Name: Eike Rulfs Function: Head of Engineering, DualLift GmbH authorized Signature: © DualLift GmbH...

- Page 51 ID No. 0400 (Liftinstituut B.V.), Certificate No: NL19- 400-1001-204-05. Authorized representative for compiling the technical documents: Nils Scharbius, Design Engineer Town/Date: Osterholz-Scharmbeck, 31, May 2021 Name: Eike Rulfs Function: Head of Engineering, DualLift GmbH authorized Signature: © DualLift GmbH...

- Page 52 DualLift GmbH Edisonstraße 22 27711 Osterholz-Scharmbeck Germany www.dual-lift.com info_de@powerclimber.com Phone +49 (0) 4791 964 07-0 Fax +49 (0) 4791 964 07-27 CEO: Jozef van Eyndt DualLift is a registered trademark. Commercial Register: HR Walsrode, B201091 © DualLift GmbH...

Need help?

Do you have a question about the SP408 CE9 and is the answer not in the manual?

Questions and answers