Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sigma SL 60 PLUS

- Page 1 Via Artigianato 85 – 25030 Torbole Casaglia. (BRESCIA) – ITALY – Tel 030 265 04 88 –Fax 030 265 01 43 INSTRUCTIONS, USE AND MAINTENANCE MANUAL SL 60 PLUS MIXER MACHINE Translation of the original instructions Edition date 13/02/2015...

-

Page 2: Table Of Contents

13.1.2. Working with the machine......................28 14. Scheduled maintenance and/or replacement interventions ............30 14.1. Master switch ..........................30 14.2. Master switch ..........................30 14.3. Stop circuit and grid safety micro-switch ..................30 Instructions, use and maintenance manual Pag. 2/53 SL 60 PLUS... - Page 3 17.1. Recommended spare parts ......................46 17.2. Recommended spare electrical parts ....................46 18. Electrical Drawing ..........................47 19. Demolition and disposal ........................53 19.1. Obligations of informing users ......................53 Instructions, use and maintenance manual Pag. 3/53 SL 60 PLUS...

-

Page 4: General Information

PERSONNEL QUALIFICATIONS: symbols used to indicate the specific competence required for the operation (they will be discussed further in the GLOSSARY chapter). ATTENTION: indicates hazardous situations for which particular caution is required. Instructions, use and maintenance manual Pag. 4/53 SL 60 PLUS... -

Page 5: Content Of The Declaration Of Conformity

VAT number: 03121980175 Through Mrs. Ornella Salvadori, as Chairwoman; DECLARES that the machine: SL 60 PLUS MIXER MACHINE Year of manufacture: complies with the relevant provisions provided by: -Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery and amending Directive 95/16/EC (transposed by the Italian state with L.D. -

Page 6: Warranty Conditions

Parts subject to wear: transmission belts, chain and bearings. Instructions, use and maintenance manual Pag. 6/53 SL 60 PLUS... -

Page 7: General Safety Standards

During maintenance and cleaning operations, the operator must release the master switch (OFF) and secure the system (for example, by removing the plug and leaving it in a clearly visible position). Instructions, use and maintenance manual Pag. 7/53 SL 60 PLUS... -

Page 8: Educating And Training Of Machine Operators

Organisation of the manual and how to consult it Machine description Control panel description 10.2 Storage and conservation of the 10.4 machine Noise emitted by the machine 10.6 Machine handling and 11.1 transportation Instructions, use and maintenance manual Pag. 8/53 SL 60 PLUS... - Page 9 Adopted safety devices Instructions on using and loading the ingredients (machine use and how to insert the ingredients) Replacements and/or scheduled maintenance (routine and extraordinary maintenance) Cleaning the machine 14.6 Troubleshooting Instructions, use and maintenance manual Pag. 9/53 SL 60 PLUS...

-

Page 10: Customer Set-Ups

5.1. Instructions for ordering spare parts SIGMA S.r.l., reserves to make all changes it deems necessary to its machine models. It is, therefore, always necessary to specify: •... -

Page 11: Safe Work Methods And Procedures

Electrocution hazard: the machine must not be used without adequate earthing, and it must be connected to a system built according to building regulations in force in the country of installation. Instructions, use and maintenance manual Pag. 11/53 SL 60 PLUS... - Page 12 Do not put any objects through the bowl guard with the parts in motion. Before any manoeuvre wait for the machine to completely stop, turn it off and disconnect it from the mains. Instructions, use and maintenance manual Pag. 12/53 SL 60 PLUS...

-

Page 13: Residual Risks

As far as possible and relevant, adequate safety signs have been affixed on the machine; the affixed signs and their position on the machine are described in the instruction manual. Instructions, use and maintenance manual Pag. 13/53 SL 60 PLUS... -

Page 14: Organisation Of The Manual And How To Consult It

Email: info@sigmasrl.info This type of signal urges to pay particular attention in the indicated operations. Failure to comply may ATTENTION cause injury to people in charge or damage the machine. Instructions, use and maintenance manual Pag. 14/53 SL 60 PLUS... -

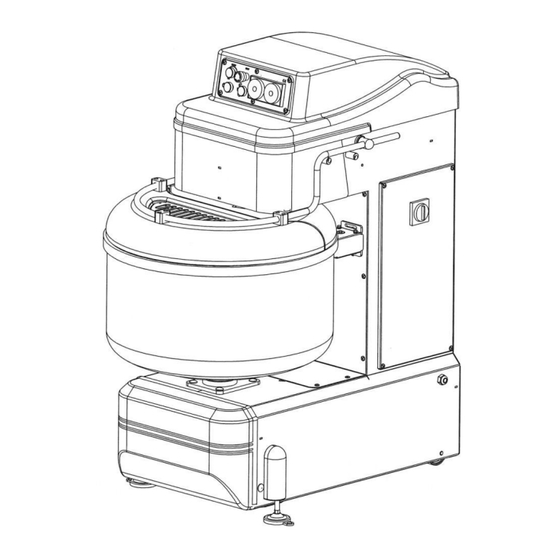

Page 15: Machine Description

8) BOWL CONTRAST WHEEL: used to facilitate rotating the bowl; 9) SPIRAL: tool used to mix the dough, through rotational movement; 10) BEARING STRUCTURE: machine body; 11) LIFTING FEET: used to stabilise the machine during operation. Instructions, use and maintenance manual Pag. 15/53 SL 60 PLUS... -

Page 16: Machine Identification

• The Sigma packages fully meet the requirements of Directive 94/62/EC and Legislative Decree 05/02/97 no. 22 (and subsequent amendments and additions) and so become waste similar to urban, that can be easily inserted in any separate collection program. -

Page 17: Technical Data And Features

Litres [l] 10.1.1. Technical data MACHINE BOWL ELECTRICAL POWER MODEL POWER [kW] MASS [kg] [litres] SUPPLY SL 60 PLUS 2/3.7 400V 50Hz 3 phases + PE 10.1.2. Dimensions MODEL SL 60 PLUS 1310 1140 Instructions, use and maintenance manual Pag. 17/53... -

Page 18: Packaging

10.1.3. Packaging MODEL SL 60 PLUS 1340 1450 SHIP CONNECTION (OPTIONAL) Machine stability: in case of slipping on wet or greasy surfaces, equipment positioning in unstable places (ships, air-planes or other), use the specific connections for stable fixing (4 anchoring devices with 300 kg resistance, M8 screws). -

Page 19: Control Panel

INDICATORS THERMAL GUARD MICRO ALARM 9) FIRST OR SECOND SPEED LIGHT INDICATORS 10) SELECT BUTTON (to set times for first or second speed) 11) TIME INCREASE/DECREASE BUTTON 12) STOP BUTTON Instructions, use and maintenance manual Pag. 19/53 SL 60 PLUS... -

Page 20: Programming The Silverline Automatic Panel

The first speed has 3 digits on the display: 2 for the minutes and 1 for the seconds. While the second speed consists of 4 digits on the display: 2 for the minutes and 2 for the seconds. Instructions, use and maintenance manual Pag. 20/53 SL 60 PLUS... -

Page 21: Type Of Drive, Motors

Lighting: the light available to the operator must comply with the type of work performed, in relation to general lighting, according to current regulations and, however, sufficient to read the controls, the hazard signals and such not to blind the operator. Instructions, use and maintenance manual Pag. 21/53 SL 60 PLUS... -

Page 22: Type And Features Of Machine Emissions

It results that the machine emits an equivalent continuous A-weighted sound pressure level of below 70 dB[A], even taking into account an estimated maximum measurement error equal to 2 dB[A]. Instructions, use and maintenance manual Pag. 22/53 SL 60 PLUS... -

Page 23: Transport And Installation

Use the required P.P.E. (e.g. shoes with reinforced tip and non-slip sole, gloves and helmet). During lifting the machine may be slightly tilted (10-15 degrees) Instructions, use and maintenance manual Pag. 23/53 SL 60 PLUS... -

Page 24: Transportation Standard Of Wheeled Machine

Loosen support "A" completely, the machine will totally rest on the wheels. Push the machine as shown in the figure. Once in position, tighten the two supports "A" until the front wheels are lifted from the ground. Instructions, use and maintenance manual Pag. 24/53 SL 60 PLUS... -

Page 25: Description Of The Adjustment And Commissioning Operations

300 kg (M8) with the specific anchors that can be supplied on request. ATTENTION: Do not operate the machine on wheels only, always tighten the two supports "A" until the wheels are completely lifted. Instructions, use and maintenance manual Pag. 25/53 SL 60 PLUS... -

Page 26: Electric Line Connection

Make sure that the system voltage and frequency match those on the machine identification plate, incorrect connection voids the warranty. Instructions, use and maintenance manual Pag. 26/53 SL 60 PLUS... -

Page 27: Adopted Safety Devices

This micro works as follows: by lifting the mobile guard (by 20-30 mm) a cam is connected to it that stops the machine (in 4 seconds) by acting on the micro-switch. Crouzet micro-switch of the mobile guard ATTENTION: Do not use the safety device as STOP Instructions, use and maintenance manual Pag. 27/53 SL 60 PLUS... -

Page 28: Work Load And Operating Instructions

If necessary, add small amounts of flour to the dough in progress, gradually pour it without strong jolts, again to minimise the dispersion of dust in the environment. These operations are necessary to prevent Instructions, use and maintenance manual Pag. 28/53 SL 60 PLUS... - Page 29 DOUGH CAPACITY [kg] WATER [%] SL 60 PLUS The use of flour rich in gluten gives rise to very elastic doughs, which absorb a lot of power. In this case, like in the case of dough with lower percentage of water to that indicated in the table, it is necessary to reduce the maximum dough capacity of the machine.

-

Page 30: Scheduled Maintenance And/Or Replacement Interventions

START button, after having completely closed the guard. (In case of failure and/or malfunction, see par. 14.5). VERIFICATION: INTERVAL METHOD Instructions, use and maintenance manual Pag. 30/53 SL 60 PLUS... -

Page 31: System Checks

4) Carefully read the lubricant's technical data sheet and follow its instructions. Need provide adequate training to maintenance personnel. INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 31/53 SL 60 PLUS... -

Page 32: Tensioning Of Belts And Chains

To ensure the correct belt tension, see chap. 14.4.2. ATTENTION: it is recommended to change the full series of belts to prevent the formation of dust. INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 32/53 SL 60 PLUS... - Page 33 Tighten screws (3) and (4), put the base casing back and tighten it to the base. Turn on the machine to test it. To ensure the correct chain tension, see chap. 14.4.2. INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 33/53 SL 60 PLUS...

- Page 34 Put the rear casing back, tighten the screws and repeat the procedure for the upper casing and test the machine. To ensure the correct belt tension, see chap. 14.4.2. INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 34/53 SL 60 PLUS...

-

Page 35: How To Tension Belts And Chains

(otherwise they might come out of the gears). If the user reasonably doubts his ability to to adjust the chain tension, do not use the machine and contact the manufacturer as soon as possible for instructions. http://www.ognibenechaintech.it/. Instructions, use and maintenance manual Pag. 35/53 SL 60 PLUS... -

Page 36: Special Maintenance

Should the power cable be damaged, replace it with a H07RN/F cable with a 3x1.5 mm cross-section. Electrical interventions: they must be carried out by a qualified electrician, referring to the diagrams attached at the end of the manual. Instructions, use and maintenance manual Pag. 36/53 SL 60 PLUS... -

Page 37: Machine Cleaning

(1). ATTENTION: check that the distance between the bowl and its contrast block is 4 mm. DO NOT MODIFY THIS SAFETY VALUE. INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 37/53 SL 60 PLUS... - Page 38 Put the door back and tighten the screws (1). ATTENTION: this operation must be carried out by qualified and trained personnel having adequate technical knowledge INTERVAL METHOD F, M Instructions, use and maintenance manual Pag. 38/53 SL 60 PLUS...

-

Page 39: Troubleshooting

1) Loose chain. 1) Tension the chain. The bowl does not rotate qualified personnel in smoothly. possession of the 2) Worn chain. 2) Replace the chain. technical knowledge of the work. Instructions, use and maintenance manual Pag. 39/53 SL 60 PLUS... -

Page 40: Machine Exploded View

16. Machine exploded view Instructions, use and maintenance manual Pag. 40/53 SL 60 PLUS... - Page 41 Instructions, use and maintenance manual Pag. 41/53 SL 60 PLUS...

- Page 42 Instructions, use and maintenance manual Pag. 42/53 SL 60 PLUS...

- Page 43 01193087 SPAX BELT 12003103 BOWL RETURN PULLEY 01193084 RETURN SHAFT SUPPORT 01193083-1 6204 BEARING 13000015 MOTOR PULLEY 01193024-2 SPIRAL MOTOR PLATE 86193061-2 T132 4/8P 3.7/2.2KW 400V/3/50HZ 11001807 SPIRAL BUSH 85193032-1 Instructions, use and maintenance manual Pag. 43/53 SL 60 PLUS...

- Page 44 193078 UBPF SUPPORT 193083-1 CHAIN 12000210 Z90 BOWL CROWN 01193041-1 BELT TIGHTENER CROWN 01173078 BELT TIGHTENER PLATE 01173070-2 BOWL CROWN HUB 01193040 LOCK-NUT 01022125 BOWL SPACER 01193038 BOWL SHAFT 01193037-2 Instructions, use and maintenance manual Pag. 44/53 SL 60 PLUS...

-

Page 45: Casing Exploded View

16.1. Casing exploded view Pos. Q.ty Description Drawing UPPER CASING 03193060 REAR CASING 86193022-1 LOWER CASING 86193021-2 BASE FRONT CLOSING CASING 86193018 Instructions, use and maintenance manual Pag. 45/53 SL 60 PLUS... -

Page 46: Recommended Spare Parts

13000502 32208 BEARING 13000506 32209 BEARING 13000507 17.2. Recommended spare electrical parts Description Q.ty Drawing CONTROL PANEL 85123145-1 MICRO-SWITCH + LEVER 25001311 MASTER SWITCH 25003013 TIMER 25007021 EMERGENCY BUTTON 25009050 Instructions, use and maintenance manual Pag. 46/53 SL 60 PLUS... -

Page 47: Electrical Drawing

18. Electrical Drawing Instructions, use and maintenance manual Pag. 47/53 SL 60 PLUS... - Page 48 Instructions, use and maintenance manual Pag. 48/53 SL 60 PLUS...

- Page 49 Instructions, use and maintenance manual Pag. 49/53 SL 60 PLUS...

- Page 50 Instructions, use and maintenance manual Pag. 50/53 SL 60 PLUS...

- Page 51 Instructions, use and maintenance manual Pag. 51/53 SL 60 PLUS...

- Page 52 Instructions, use and maintenance manual Pag. 52/53 SL 60 PLUS...

-

Page 53: Demolition And Disposal

Illegal product disposal by the owner results in the application of the administrative sanctions required by the standard in force. Instructions, use and maintenance manual Pag. 53/53 SL 60 PLUS...

Need help?

Do you have a question about the SL 60 PLUS and is the answer not in the manual?

Questions and answers