Table of Contents

Advertisement

Quick Links

WILLIBALD EP 5500 Shark 5

with MAN engine EU stage V

TRANSLATION OF THE

ORIGINAL INSTRUCTIONS

J. Willibald GmbH

Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150

Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18

As of

June 2021

Operation Manual

Operating Instruction

Mobile Processing Shredder

info@willibald-gmbh.de

EP 5500 Shark

www.willibald-gmbh.de

Page 1 of 120

Advertisement

Table of Contents

Summary of Contents for Willibald EP 5500 Shark

- Page 1 Operation Manual EP 5500 Shark Operating Instruction Mobile Processing Shredder WILLIBALD EP 5500 Shark 5 with MAN engine EU stage V TRANSLATION OF THE ORIGINAL INSTRUCTIONS J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel.

-

Page 2: Table Of Contents

Operation Manual EP 5500 Shark Table of contents Page GENERAL Foreword Operator's obligation Undertakings to be given by the personnel Explanation of symbols Guarantee and liability 1.5.1 Warranty and fair trading requests 1.5.2 Acknowledgement and compensation 1.5.3 Special agreements Copyright... - Page 3 COMMISSIONING / START-UP Introduction Transport of EP 5500 Shark Start-up of the machine 6.3.1 Safety information 6.3.2 Setting up the EP 5500 Shark 6.3.3 Motor hood opening 6.3.4 Checking the hydraulic oil level 6.3.5 Checking the motor oil level 6.3.6 Checking the diesel fuel level 6.3.7...

- Page 4 Transfer of machine 7.5.1 Transfer machine without wheel drive 7.5.2 Transfer machine with wheel drive Turning of the EP 5500 Shark, start of a new compost windrow forming procedure Replacement of wear parts 7.7.1 Taking the discharge conveyor in maintenance position 7.7.2...

- Page 5 Operation Manual EP 5500 Shark PRODUCT IDENTIFICATION Machine type : EP 5500 Shark Year of construction : ..........Machine-No. :..........:………………………………… Chassis-No. Motor type : ..........Motor-No. :..........Manufacturer address J.Willibald GmbH Bahnhofstrasse 6 D-88639 Wald-Sentenhart +49 (0) 7578 / 189 0...

-

Page 6: General

Operation Manual EP 5500 Shark 1.0 GENERAL 1.1 Foreword Thoroughly read and observe all information, warnings and safety notes contained in this operation manual before commissioning of the machine. • Knowledge of all basic safety information and warnings contained in this... -

Page 7: Explanation Of Symbols

Operation Manual EP 5500 Shark 1.4 Explanation of symbols In this operation manual the following safety symbols, warnings and descriptions are used to mark possible dangers: This symbol indicates an imminently dangerous situation which will result in death or serious injury if the safety measures are not followed. -

Page 8: Guarantee And Liability

• Use of parts that aren't original WILLIBALD spare parts; • Unauthorized constructional modification of the machine; • Unauthorized modification of the EP 5500 Shark (e.g. gear ratios, output and r.p.m.), hydraulic pressure; • Insufficient control of machine parts subject to wear;... -

Page 9: Acknowledgement And Compensation

Subject to our discretion: all expenditure of works as deemed necessary for the replacement of parts and components under said guarantee coverage. c) Subject to our discretion: costs spent on travelling to WILLIBALD, which applied only, however, if the customer – due to important reasons – cannot be expected to visit an after-sales-workshop. -

Page 10: Copyright

The above guarantee does not include wear parts, such as flails, plug-in shaft, tool kit, V-belts, filters, bearing etc. 1.6 Copyright The company J. WILLIBALD GmbH holds the sole copyright in present operation manual. This operation manual is for the exclusive use by the operator and his personnel. -

Page 11: Description Of The Product

Operation Manual EP 5500 Shark 2.0 DESCRIPTION OF THE PRODUCT The Machine EP 5500 Shark is built according to the state of the art and the recognized safety rules. 2.1 Tasks of the machine • Defibration of organic material of thicknesses of up to 30 cm for composting (gardening wastes, material from the landscape development, sawn timber, wastes from cemeteries). -

Page 12: Intended Use

The wheel drive is no substitute the parking brake! Danger of inappropriate use Inappropriate use of the EP 5500 Shark may cause bigger damages to the machine and may also affect safety devices and protective gear to the result that the operator's personal safety can no longer be guaranteed. -

Page 13: Working Place

EP 5500 Shark 2.3 Working place Using area The machine EP 5500 Shark can be used for the processing of bulky coarse wood (wood packaging, wood, garbage, industrial waste wood, building demolition wood) as a basis for operating biomass cogeneration plants and for the crushing of green waste for composting. - Page 14 Operation Manual EP 5500 Shark Method The operation of the EP 5500 Shark is carried out by control cabinet or remote control. Optical function and fault of the central cabinet comply with the latest safety regulations. All important functions can be easily operated via remote control from the user.

-

Page 15: Technical Characteristics

12 V / 135 Ah Number of axes: 2 (tandem type) Brake system: 2 circuit compressed air brake Engine power EP 5500 Shark 352 kW / 480 PS 338 kW / 521 PS Rotor r.p.m.: Variant V1 with 48 flails 1.150 to 1.250 min... -

Page 16: Equipment

Operation Manual EP 5500 Shark 2.5 Equipment Standard version of a mobile processing shredder: Base frame with running gear, spring born twin axle for drive speeds up to 80 km/h, pneumatic brake system, 385/65 R22.5 tire equipment, endless floor with cleaning worm, top mounted built-on motor, rotor driven via power belts,... - Page 17 * Wheel drive (Driving forward device) By wheel drive of an advance EP 5500 Shark on a level and firm ground with a tractor is unnecessary. (The machine can drive automatically (radio)). This has the advantage of continuous filling.

- Page 18 Operation Manual EP 5500 Shark * Tail-board increase The tail-board increase increases the loading area of filling tub. * Hydraulic front wheel The front wheel on the drawbar is used to keep the machine at standstill and disengaged in balance. As a standard design the front wheel can raise and lower by turning the crank manually.

- Page 19 Type designation: EP 5500 Shark Machine no.: J. Willibald GmbH, D - 88639 - Wald – Sentenhart Manufacturer: due to designing and make and the type version marketed by our company meets with the basic and relevant safety and health requirements as specified and set forth in the corresponding EC Directives.

-

Page 20: Safety Prescriptions

Operation Manual EP 5500 Shark 3.0 SAFETY PRESCRIPTIONS 3.1 Personnel requirements 3.1.1 Skills In the operating manual the following skills for various activities are identified: • Trained staff is a person who was in a teaching via its assigned tasks and potential hazards of improper behaviour taught. -

Page 21: Personal Protective Equipment

Operation Manual EP 5500 Shark 3.1.3 Personal protective equipment At work is the wear of personal protective equipment required to minimize health hazards. • The required personal protective equipment must be provided by the operator. • All safety equipment must be checked regularly. -

Page 22: Informal Safety Measures

Operation Manual EP 5500 Shark 3.1.4 Informal safety measures • This operation manual must permanently be kept and be at hand at the place of operation of the machine; • Present operation manual and all prescriptions contained herein are supplemented by generally operative and local regulations in regard to accident prevention and to environmental protection. -

Page 23: Overview Labels And Warning Signs

Prior to any repair, maintenance or cleaning work make sure the 199-01-132 engine and main battery switch are in "OFF" position! CE-sign 665-81-017 Machines Quick Guide for Willibald - Shredder 199-01-1218 Notice sign: "gearbox, oil quantity, quality" 199-01-369 Notice sign: “Attention! Grease nipple“... -

Page 24: Illustration Labels And Warning Signs

Operation Manual EP 5500 Shark 3.1.4.3 Illustration labels and warning signs 199-01-705 J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18... - Page 25 Operation Manual EP 5500 Shark J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

- Page 26 Operation Manual EP 5500 Shark 1. Unscrew the red button on both seat valves on the cylinder block of the desired function. 2. Execute the function in the desired direction by operating the hand pump and setting the lever on the hand pump.

-

Page 27: Position Labels And Warning Signs

Operation Manual EP 5500 Shark 3.1.4.4 Position of the stickers on the machine J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18... - Page 28 Operation Manual EP 5500 Shark J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

- Page 29 Operation Manual EP 5500 Shark J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

- Page 30 Operation Manual EP 5500 Shark J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

-

Page 31: Safety Information And Potential Dangers In Use Of The Machine

Operation Manual EP 5500 Shark 3.2 SAFETY INFORMATION and potential dangers in the use of the machine 3.2.1 Protective devices Danger of non-functioning protective devices • Emergency stop device must be always freely accessible. • Make sure and control each time before actuation of the machine that all safety devices and protective gear are mounted properly and operative;... -

Page 32: Emergency Stop Device

Operation Manual EP 5500 Shark 3.2.4 EMERGENCY STOP device The emergency stop device is connected so that during interruption of power supply, or the activation energy supply after an interruption, dangerous situations for persons and property are excluded. Emergency stop device must be always freely accessible. -

Page 33: Dangers Caused By Electric Energy

Operation Manual EP 5500 Shark 3.2.5 Dangers caused by electric energy Danger due to electrical current In case of contact with live parts is immediate danger to life. Damage the insulation or components can be fatal. • All works on the electric system must be performed by an expert electrician only;... -

Page 34: Passing Out Of Noxious Steams And Gases

Operation Manual EP 5500 Shark 3.2.7 Passing out of noxious steams and gases Danger of escape of hazardous gases and vapors The machine is equipped with a diesel engine that can be emitted during operation of the harmful gases and vapors. The integrated exhaust and filter system prevents at normal use of the machine the escape of harmful substances and gases and ensure compliance with legal limits. -

Page 35: Constructional Modification Of Machine

• Use Willibald-original spare and wear parts only. NOTICE Give in all messages and inquiries the machine chassis number. Order replacement parts by dealers or direct from WILLIBALD. J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. -

Page 36: Cleaning Of Machine And Disposal

Operation Manual EP 5500 Shark 3.2.11 Cleaning of machine and disposal Regular cleaning is a basic condition to the preservation of service life and functional capability of the machine. Use approved cleaning agents only. The cleaning agents must be coordinated with the appropriate material, which should be examined before starting work. -

Page 37: Fire Hazard In Motor Compartment

Operation Manual EP 5500 Shark 3.3 WARNINGS and special dangers in the use of the machine 3.3.1 Fire hazard in motor compartment Highly flammable materials - diesel fuel, oils and fats Fire hazard due to highly flammable materials! Pieces of wood and wood dust are inflammable! -

Page 38: Danger Resulting Coolants -Antifreeze And Anti-Corrosion Agent

Operation Manual EP 5500 Shark 3.3.3 Danger resulting coolants -antifreeze and anti- corrosion agent Risk of injury from coolants harmful to health Coolant contains substances that are harmful to health. • Observe and follow the safety data sheets of the manufacturer. -

Page 39: Dangers Due To Hot Surface Or Liquid

Operation Manual EP 5500 Shark Ammonia Ammonia is a colorless, pungent smelling gas. Inhalation of vapors irritates and is corrosive to mucous membranes and eyes. Brief inhalation can cause inflammation in the airways or pulmonary edema. Danger to health from ammonia vaporous If AdBlue®... -

Page 40: Danger Due To Strong Magnetic Fields

Danger to life due to strong magnetic field in machines with magnetic metal separators The EP 5500 Shark can be constructed with the metal separator with magnet roller as an option. Strong magnetic fields can cause serious injury or death, as well as considerable property damage. -

Page 41: Danger By Filling The Machine

• Make sure nobody stays within the danger zone (Illustration 2.2 Danger zones) of the EP 5500 Shark except operator with tractor or loader when starting the motor! • Make sure that nobody can succeed into the danger area of the EP 5500 Shark except operator with tractor or loader when the machine is running! •... -

Page 42: Danger By Hydraulic Feed-Hopper

• Make sure nobody stays within the danger zone (Illustration 2.2 Danger zones) of the EP 5500 Shark when starting the motor! • Make sure that nobody can succeed into the danger area of the EP 5500 Shark when the machine is running! This label is located on the both side of the machine. -

Page 43: Danger Due Rotating Rotor

• Do not come into the draw-in and discharge area of the EP 5500 Shark! • Before starting the motor makes sure that there is no person between the rotor and discharge conveyor. -

Page 44: Functioning

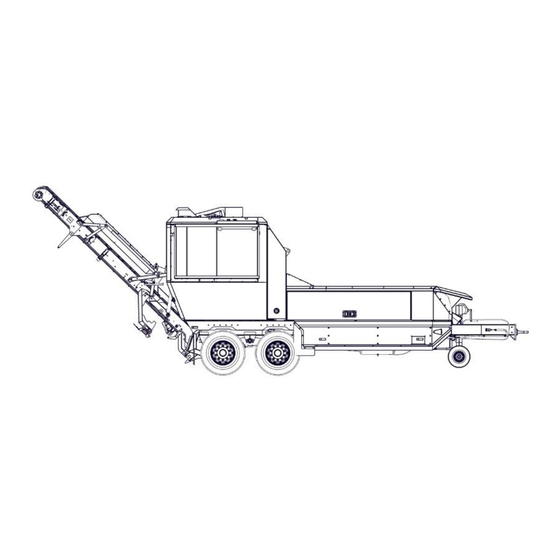

Operation Manual EP 5500 Shark 4.0 FUNCTIONING 4.1 Processing task The mobile shredding unit has been constructed and designed for the shredding and defibration of organic materials. 4.2 Construction (Illustration 4.1) Illustration 4.1 EP 5500 Shark Construction 1. Chassis 2. Filling tub with leadership 3. - Page 45 3. Basket 4. Crushing flap 5. Draw-in roller 6. Endless floor Shredding unit Functional principle 1. Rotor Variant EP 5500 Shark 5 - 2. Flail V3 with 16 flails 3. Basket 4. Crushing flap 5. Draw-in roller 6. Endless floor J.

- Page 46 Operation Manual EP 5500 Shark Shredding unit 1. Rotor Functional principle 2. Flail Variant EP 5500 Shark 5 3. Basket – V4 with 32 flails 4. Crushing flap 5. Draw-in roller 6. Endless floor 1. Rotor Shredding unit 2. Tools Functional principle 3.

-

Page 47: Safety Equipment

Operation Manual EP 5500 Shark Emergency off button on the control cabinet 4.4 Safety equipment 4.4.1 Emergency off button Two stop buttons are mounted on the machine. If one of those, or the one on Emergency off switch the control, will get pushed in, the engine will Stop immediately. -

Page 48: Siren

Operation Manual EP 5500 Shark 4.4.4. Siren Siren A siren is attached to the machine. The siren is located on the left side in the direction of travel of the machine next to the control box. The siren switches on, if a command from the control cabinet or radio remote control is triggered for functions. -

Page 49: Safety Equipment For Maintenance And Repair Work

Operation Manual EP 5500 Shark 4.5 Safety equipment for maintenance and repair work 4.5.1 Motor hood securing Crushing hazard due to open and closed the hood! Lowering the hood can result in serious injury to death. Motor hood securing Therefore hood is equipped with a hood securing. -

Page 50: Coupling Securing

Operation Manual EP 5500 Shark 4.5.2 Coupling securing Crushing hazard by all maintenance and repair work! The rotor is no longer balanced if the plug-in shaft is removed by pulling it out. The rotor will turn! For all maintenance and repair work without coupling securing the rotor could start to move and cause serious injury. -

Page 51: Infeed Roller Securing

Operation Manual EP 5500 Shark 4.5.3 Infeed roller securing WARNING Crushing hazard by all maintenance and repair work in draw-in area! For all maintenance and repair work, the infeed roller must move hydraulically to top in order to achieve better the rotor or crushing basket... -

Page 52: Discharge Conveyor Securing

Operation Manual EP 5500 Shark 4.5.4 Discharge conveyor securing Danger of crushing in all maintenance and repair work! There is a free space, danger zone D, between crushing unit and discharge conveyor at maintenance position. When the hydraulic cylinders come in motion, is occurred mortal danger to human life. -

Page 53: Operation Manual T-Wision

Operation Manual EP 5500 Shark 5.0 OPERATION MANUAL T-Wision See separate operating instructions in the machine documentation, point 2. J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18... -

Page 54: Commissioning / Start-Up

• Make sure that the machine cannot be started by unauthorized persons! DANGER Danger of rolling away the EP 5500 Shark The EP 5500 Shark weighs about 19 tons and when the machine is in motion unintentionally, can result in serious injury to death. • Take care of approximately horizontal place! •... - Page 55 Danger caused from flying parts during working at the machine The shredded and defibrated material, the caused by foreign bodies (for example stones) is thrown out of the EP 5500 Shark at very high speed! • Nobody must come into discharge area of the EP 5500 Shark.

- Page 56 5500 Shark when the machine is running! Hearing loss from noise The noise level of the EP 5500 Shark is approximately 83 dB (A). During operation of the EP 5500 Shark has therefore always have suitable hearing protection must be worn.

-

Page 57: Transport Of Ep 5500 Shark

• Are the chassis and EP 5500 Shark at the licensing office registered? 2. Are the permissible trailer weight at the towing vehicle sufficient, in order to pull the EP 5500 Shark? 3. Has the EP 5500 Shark been coupled properly to the trailer coupling of the towing vehicle? Transport position 4. - Page 58 Brake air distributor Brake air distributor If the EP 5500 Shark of a towing vehicle without ABS is pulled or if the ABS at the towing vehicle or at the EP 5500 Shark is defective, must be counted during a danger braking on a longer stopping distance.

- Page 59 Operation Manual EP 5500 Shark Illustration 6.3 EP 5500 Shark Start-up of the machine J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

-

Page 60: Start-Up Of The Machine

WILLIBALD only. 6.3.2 Setting up the EP 5500 Shark Pull the EP 5500 Shark to the provided operation place. Take care of approximately horizontal place! • Block the locking brake by turning the crank handle (1) clockwise. -

Page 61: Motor Hood Opening

Operation Manual EP 5500 Shark 6.3.3 Motor hood opening Crushing hazard due to open the hood! Lowering the hood can result in serious injury to death. • No one must be in the danger zone during opening the hood! •... -

Page 62: Checking The Hydraulic Oil Level

Operation Manual EP 5500 Shark Check of hydraulic oil, engine oil level and fuel level before any operation. Filling socket 2 Refill hydraulic oil, engine oil, diesel fuel if necessary. 6.3.4 Checking the hydraulic oil level Check the hydraulic oil level. -

Page 63: Checking The Diesel Fuel Level

Operation Manual EP 5500 Shark NOTICE Component damage caused by overfilling Motor damage can occur when filling of motor over the max-marking. • Motor oil does not fill over the max mark on the dipstick. 6.3.6 Checking the diesel fuel level Check the diesel fuel level (9). -

Page 64: Checking The Adblue® - System

Operation Manual EP 5500 Shark 6.3.8 Checking the AdBlue® - System When the first commissioning, ensure that: • AdBlue® has a quantity of at least 15 litres in the tank. • work area is clean and in order. • coolant pipes, compressed air lines and carbamide lines are checked for sealing. -

Page 65: Operation

Operation Manual EP 5500 Shark 7.0 OPERATION General safety information The operation of the machine must be performed by trained personnel or by professional staff only. Danger of incorrect operation Improper operation can cause serious person or property damage. • Make sure before starting work, all covers and safety devices are working properly. - Page 66 • Check, that nobody stays within the danger zones. • Set the ignition switch to position "1". • The controller boots when the Willibald logo appears • After the boot process, the display is briefly dark and then initializes the display pages, during which time a loading bar is displayed.

-

Page 67: Adjustments

Operation Manual EP 5500 Shark 7.2 Adjustments (Illustration 7.1) Infeed roller, wheel drive, endless floor, discharge conveyor There are two control blocks in the machine: cylinder block and rotation block. The rotary block has valves for regulating the speeds of the infeed roller, wheel drive, endless floor and discharge conveyor. -

Page 68: Turning Out, Short Description

The rotor will be running for several minutes after switching off the motor, and all dangers existing, when the motor is running will last on! • Do not come into the draw-in and discharge area of the EP 5500 Shark. Danger caused from flying parts during working at the machine... -

Page 69: Press Back The Idler Roll

• Closed the protection doors of power belts. • Start the EP 5500 Shark, proceed as described in Chapter 7.1, "Starting". J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. - Page 70 Operation Manual EP 5500 Shark Illustration 7.3 Illustration 7.3: Idler roll (1) is released, hydraulic cylinder (2) is completely to EP 5500 Shark back repressed, the power belts are released Coupling J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel.

-

Page 71: Transfer Of Machine

• Before starting the motor makes sure that there is no person between the rotor and discharge conveyor. At its latest, the EP 5500 Shark must be transferred, i.e. driven away from the new formed compost windrow by some meters if the rotor starts scraping the new formed up windrow or if the windrow reaches the same height as of the discharge belt. -

Page 72: Transfer Machine With Wheel Drive

• Before starting the motor makes sure that there is no person between the rotor and discharge conveyor. At its latest, the EP 5500 Shark must be transferred, i.e. driven away from the new formed compost windrow by some meters if the rotor starts scraping the new formed up windrow or if the windrow reaches the same height as of the discharge belt. -

Page 73: Turning Of The Ep 5500 Shark, Start Of A New Compost

DANGER Danger of rolling away the EP 5500 Shark The EP 5500 Shark weighs about 19 tons and when the machine is in motion unintentionally, can result in serious injury to death. • When transferring the EP 5500 Shark, always make sure both towing vehicle and EP 5500 Shark are protected against wheeling away! •... -

Page 74: Replacement Of Wear Parts

Incorrect or faulty spare parts can cause damage, malfunction or failure and impair safety. • No parts other than original WILLIBALD spare parts must be used to replace worn off wear parts. If otherwise, we cannot guarantee for the proper functioning and operating safety of the unit •... -

Page 75: Taking The Discharge Conveyor In Maintenance Position

Operation Manual EP 5500 Shark 7.7.1 Taking the discharge conveyor in maintenance position Transport position 1. Take the discharge conveyor from the transport position to in the work position; Function 2. Select the function “Conveyor lift / lower, lift the conveyor „Conveyor lift / lower“... - Page 76 Operation Manual EP 5500 Shark Arm fix with bolts 3. Attach the parallel arm into position and fix with bolts; 4. Open and pull out the linch pin; 5. Remove the bolt; Control danger area, nobody may stay in danger area!

- Page 77 Operation Manual EP 5500 Shark Collision danger! Caution! Press the button until the discharge belt has reached the vertical position only! If the discharge belt is moved over the vertical position also, then touching the belt, the hood and it can cause damage! A red marker will appear on the crushing unit.

-

Page 78: Replacement Of Flails

The rotor will be running for several minutes after switching off the motor, and all dangers existing, when the motor is running will last on! • Do not come into the draw-in and discharge area of the EP 5500 Shark! • Machine parts touch only when they are stopped completely. - Page 79 • Let the EP 5500 Shark continue to work until the complete endless conveyor floor is empty. • Tow the EP 5500 Shark away from the compost windrow by approx. 5 m. Threated hole • Open the hood and check that hood is engaged in hood securing.

- Page 80 Operation Manual EP 5500 Shark Illustration 7.9 The flails fell to the lower basket (Illustration 7.9). 3. Insert new flails Illustration 7.10 • Introduce the guide bar and the greased plug-in shaft again into the rotor and cautiously knock it in using the striking weight. (Illustration 7.10).

- Page 81 The exchanging the flails with hydraulic axle extractor 1. Preparing the machine Illustration 7.12 • Let the EP 5500 Shark continue to work until the complete endless Hydraulic axle extractor conveyor floor is empty. • Tow the EP 5500 Shark away from the compost windrow by approx.

- Page 82 Operation Manual EP 5500 Shark Illustration 7.14 • Screw tight the auxiliary shaft (2) with the swing (1). (Illustration 7.14). • Motor on; stand gas, rejust the panel on funk. By distant control may be use the function “Crushing flap” or “Stop”...

- Page 83 Rotor with 32 flails • Let the EP 5500 Shark continue to work until the complete endless conveyor floor is empty. • Tow the EP 5500 Shark away from the compost windrow by approx. 5m. • Open the hood. • Start the machine.

- Page 84 Operation Manual EP 5500 Shark Manual tool change for the rotor with 10 tools 1. Preparing the machine Illustration 7.19 • Let the EP 5500 continue to work until the complete endless conveyor Rotor with 10 tools floor is empty.

- Page 85 Operation Manual EP 5500 Shark If the blade 1 no cuts effectively, it can be reworked externally or in the rotor (grinding.) The blade loses its length and must be readjusted. The adjustment of the tools takes place in the following steps: •...

- Page 86 Operation Manual EP 5500 Shark If the tools are changed, then: - Turn the rotor on manually, check the free running of tools. - Remove the securing of conveyors cylinder; - Bring the discharge conveyor into work position. - Remove securing sleeve over clutch cylinder, close belt protection.

-

Page 87: Replacement The Rakes Of Crushing Basket

Operation Manual EP 5500 Shark 7.7.3 Replacement the rakes of crushing basket Danger of crushing by changing the rakes! Infeed roller securing The rakes of crushing basket located in the catchment area of the machine, where are the infeed roller and rotor. If these parts come in motion, can be result in serious injury or even death. -

Page 88: Replacement Of The Shredding Flap

Operation Manual EP 5500 Shark 7.7.4 Replacement of the shredding flap Crushing hazard due to discharge conveyor by replacement the Danger zone by shredding flap! replacement of shredding flap By replacement the shredding flap discharge conveyor must be brought into the maintenance position. -

Page 89: Replacement Of Power Belt

Operation Manual EP 5500 Shark 7.7.5 Replacement of power belt Drawing-in danger and crushing hazard due rotating idler roll and Power belt! The drive motor brings the rotor in motion and the rotor rotates at very high speed. Therefore, the pulley and power belts are protected with a fixed fairing. -

Page 90: Adjusting The Angle Sensor

Operation Manual EP 5500 Shark • Unscrew the lower belt protection (2). • Loose the V-belt protection (3). • Loose and pull out the screw (4). • Hanging out the clutch cylinder. • Press back the idler roll. • Remove the used old power belts and fit new belts. - Page 91 Operation Manual EP 5500 Shark Adjustment Carrying out weekly or when changing the power belt according to the maintenance instructions, chapter 8.1, point 9. • Switch off the engine. • Check that the clutch cylinder is completely retracted. • Check operating lever position: The actuating lever of the angle sensor points to approx.

-

Page 92: Fault Indication At The Control

• Perform all maintenance work when the machine is stopped only. • The main battery switch must be turned "OFF". • No persons must stay on the endless floor conveyor or within the discharge area of the EP 5500 Shark! Warning signals Possible... - Page 93 Operation Manual EP 5500 Shark Emergency stop signals Possible Fault / malfunction Possible reason Remedy defect Indication „Overheating“ Cooler polluted Clean it using a broom Temperature sensor Contact the client phone service See indication „Cooling Cooler water” Indication „Lack of oil“...

-

Page 94: Fault Finding Table

Operation Manual EP 5500 Shark 7.9 Fault finding table Fault / malfunction Possible reason Remedy Draw-in roller or endless Motor hot Cooler strongly contaminated floor cannot be deactivated (needs to be cleaned) and com to Stop under low load or start running in reverse sense Low r.p.m. - Page 95 Operation Manual EP 5500 Shark Fault / malfunction Possible reason Remedy Low r.p.m. protection doesn't Low r.p.m. protection not (Contact the client phone respond or pilot lamp shows properly set service) adjust the low r.p.m. light constantly protection Dirt between rotor face and unit...

- Page 96 Operation Manual EP 5500 Shark Fault / malfunction Possible reason Remedy The discharge belt stops, Discharge belt jammed Check the discharge conveyor for moves backwards or foreign debris, remove the foreign permanently changes its debris movement direction Contact the client phone service...

-

Page 97: Maintenance

EP 5500 Shark 8.0 MAINTENANCE Danger of injury due to improper maintenance • Perform all maintenance work on the EP 5500 Shark when the motor is stopped only. • Make sure that the machine cannot be started by unauthorized persons! •... - Page 98 Operation Manual EP 5500 Shark 26,27 35,36,37 42 33,34 14 32 31 Illustration 8.1 J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

- Page 99 Operation Manual EP 5500 Shark 16,17,18 22,23 34,34 Illustration 8.2 J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18...

-

Page 100: Lubrication Plan And Other Maintenance Works

Operation Manual EP 5500 Shark 8.1 Lubrication plan and other maintenance works ( Illustrations 8.1 and 8.2) Maintenance intervals in operating hours Maintenance work Remark Basic machine Lubricate in-feed-roller bearing Roller bearing grease, grease gun Lubricate cylinder holder of Roller bearing... - Page 101 Operation Manual EP 5500 Shark Maintenance intervals in operating hours Maintenance work Remark Fuel system Refill with fuel Change fuel filter Water separator – change filter Engine Clean the engine compartment Compressed air Check oil level, top up engine Use engine oil...

- Page 102 Operation Manual EP 5500 Shark Maintenance intervals in operating hours Maintenance work Remark Change the air dryer cartridge Clean the particle filter Status can be checked via control SCR-system ® Check level Adblue , top up if necessary (only below 75%) ®...

- Page 103 Operation Manual EP 5500 Shark Maintenance intervals in operating hours Maintenance work Remark Central lubrication Fill the grease reservoir from Use EP 2 grease the central lubrication system as specified on the container Machine without central Roller bearing lubrication lubricate on...

-

Page 104: Lubricant Table Ep 5500 Shark

Operation Manual EP 5500 Shark 8.2 Lubricant table EP 5500 Shark Viscosity Operational Filling Manufacturer Component mm²/s Specification materials quantity designation (40°C) 500 l Diesel fuel 2 - 4,5 DIN EN 590 Diesel fuel Engine DIN EN MAN D2676 500 l... -

Page 105: Replacement Of The Trailer Coupling Ring

When the EP 5500 Shark unintentionally set in motion, it can result serious or even fatal injuries. • Secure the EP 5500 Shark against rolling away with wheel wedges. • To change the wheels, the EP 5500 Shark can be lifted at the axis. • Tighten wheels with torque. 8.6 Hydraulic oil change... -

Page 106: Recommended Hydraulic Oil Types

Operation Manual EP 5500 Shark 8.7 Recommended hydraulic oil types Producer Oil type HLP/Type name Viscosity in mm at 40°C ARAL Vitam GF 46 40-50 ARAL Vitam GF 68 60-80 AVIA Fluid RSL 46 M 40-50 AVIA Fluid ZAD 46 M... -

Page 107: Oil Filling Amounts For The Gear

Operation Manual EP 5500 Shark Bio oil types: Based on the characteristics and the releases on hand and issued by the suppliers of the hydraulic system components integrated in the shredding unit, it is recommended to use "HEE" hydraulic liquid types only (synthetic ester). -

Page 108: Engine Oil Change

Operation Manual EP 5500 Shark 8.9. Engine oil change Drain hose For industrial diesel engines are used the engine oils, which one are authorized to manufacture standard. The choice of suitable engine oil is based on planned oil operating time, the used fuel quality and the climatic conditions on site. -

Page 109: Proper Function Of The Emission Reduction System

Operation Manual EP 5500 Shark 8.11 Proper function of the emission reduction system 8.11.1 AdBlue® / DEF quality AdBlue® is a high purity, synthetically manufactured 32.5% carbamide- water solution, as clear as water. The high-quality solution reduced in the SCR technology diesel-powered machine toxic nitrogen oxides in the exhaust gas to form water vapor and elemental nitrogen. -

Page 110: Eu Stage V - Emission Requirements

EP 5500 Shark 8.11.3 EU Stage V - Emission Requirements In the EP 5500 Shark is a diesel engine installed, which must meet the requirements of EU Stage V. Fulfilment of these requirements requires the use of suitable liquids. Information about the appropriate fuels, lubricants and coolants are taken from the publication "supplies for MAN industrial... -

Page 111: Proof Of Service Routines

Operation Manual EP 5500 Shark 8.12 Proof of service routines Date Mach. hours Service routine Signature J. Willibald GmbH Bahnhofstr. 6 * D-88639 Wald-Sentenhart * Tel. +49 (0) 7578/ 189-0, Fax. +49 (0) 7578/ 189-150 Im Wolfsgraben 5 * D-36414 Unterbreizbach * Tel. +49 (0) 36962/ 514-10, Fax. +49 (0) 36962/ 514-18... -

Page 112: Service Addresses

Operation Manual EP 5500 Shark 8.13 Service addresses J. Willibald GmbH Recyclingtechnik Bahnhofstraße 6 D- 88639 Wald-Sentenhart Tel.: +49 (0) 7578 / 1890 Fax: +49 (0) 7578 / 189150 E-Mail: info@willibald-gmbh.de www.willibald-gmbh.de Willibald Service & Instandsetzungzentrum Im Wolfgraben 5 D-36414 Unterbreizbach Tel.: +49 (0) 3 69 62 / 5 14 10... -

Page 113: Repair

(Chapter 8.13 Service addresses). 10.0 PUTTING THE MACHINE OUT OF ACTION The decommissioning and recommissioning of the EP 5500 Shark may be performed by trained personnel only. WARNING Danger of injury due to improper works Improper works can cause serious personal injury and property damage. -

Page 114: Cleaning And Caring

Operation Manual EP 5500 Shark 11.0 CLEANING AND CARING Regular care helps maintain the value of the machine. Clean the machine on a designated wash area only. Dispose of empty containers and used cleaning materials environmentally friendly manner. 11.1 Indoor cleaning 11.1.1 Motor compartment... -

Page 115: Disposal

Operation Manual EP 5500 Shark 12.0 DISPOSAL Environmental hazard by incorrect handling At an incorrect handling of environmentally hazardous substances, especially at a incorrect disposal, significant damage can occur to the environment. • Observe always the below prescribed information. • When accidentally get environmentally hazardous substances reach into the environment, take immediate and appropriate action. -

Page 116: Instructions For Ordering Of Spare Parts

When ordering parts, the part number of which cannot be determined safely, a sample piece must be provided to WILLIBALD to avoid delivery of wrong parts. If no demand to return said samples is made, these will be scrapped. -

Page 117: Inventory List

Operation Manual EP 5500 Shark 14.0 Inventory list Designation Picture Willibald-No. Quantity Fire extinguisher 660-81-012 Protective film for fire extinguishers 660-81-013 Wheel wedges 053-01-001 Ladder 665-80-028 Radio remote control 913-90-050 Charging holder radio 913-90-035 Securing rod, coupling securing 665-80-007 Bolt, coupling securing 660-30-010 J. - Page 118 Operation Manual EP 5500 Shark Designation Picture Willibald-No. Quantity Striking weight, flail shaft extractor 423-80-018 Auxiliary shaft, Hydraulic flail shaft 660-81-027 extractor Screw, Hydraulic flail shaft extractor 660-80-011 U-Profile, Hydraulic flail shaft extractor 665-80-006 Lever for the hand pump 665-22-501...

-

Page 119: Annex: Undertakings To Be Given By The Personnel

Operation Manual EP 5500 Shark 15.0 Annex to chapter 1.3 Undertakings to be given by the personnel As proof, please enter all employees who have read these operating instructions in the following list. Read confirmation Date Forename Name of operation... -

Page 120: General Terms And Conditions

Operation Manual EP 5500 Shark 16.0 General terms and conditions J. Willibald GmbH Recyclingtechnik, 88639 Wald-Sentenhart For all business transactions such as ordering spare parts, etc., our following general terms and conditions apply in the current version without exception. For use towards: 1.

Need help?

Do you have a question about the EP 5500 Shark and is the answer not in the manual?

Questions and answers

After machine has been switched off. Started back up, the deisel gage is not working and remote wont connect