Advertisement

Quick Links

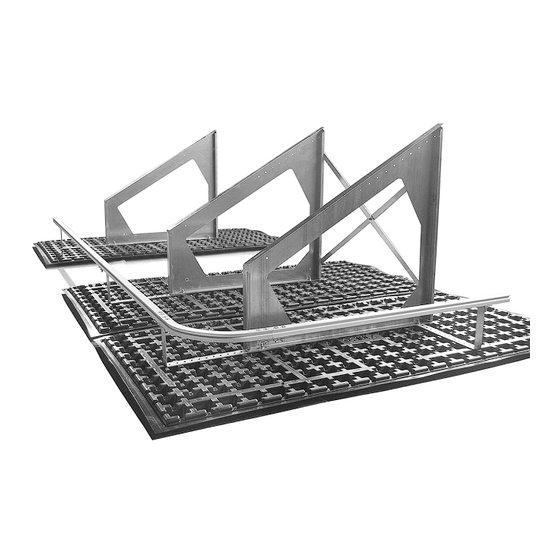

Installation Instructions

®

Fallnet

SB 200-Rail

Fallnet

®

SB 200 Rail in combination with a solar installation (photovoltaic

or solar thermal) or a railing system and a correspondingly high load of

suitable bulk material (e.g. ZinCo system soil, Zincolit

or slabs in a chippings bed) represents an anchoring device in accordance

with DIN EN 795:2012 types D and E for fall protection on flat roofs

with a roof pitch of up to 5°.

A fixing point (the so-called runner) may only be used by one person (up

to 100 kg) at a time and this person should be wearing personal protective

equipment (PPE, e.g. ZinCo PPE-Set) in accordance with EN 363. The

safety harness, in accordance with EN 361, can only be used in conjunction

with tested and approved components.

Important note:

We would like to state explicitly that, regardless of product liability, ZinCo

shall only assume liability for the consultancy process where installation

has been carried out in line with ZinCo site planning. Installation without

planning carried out by ZinCo is at your own risk. The assembly and

installation instructions as well as the instructions for use, both of which

are supplied with the products, must be observed regardless of this.

®

We recommend having Fallnet

SB 200-Rail planned or checked by ZinCo

Technical Department before starting installation.

1. Prior to installation

1.1 Check of the scope of delivery and condition of system components

The delivery of an object-specific Fallnet

comprises:

®

a. Fallnet

SB 200-Rail components, like e.g.

®

ZinCo Solar Base

SB 200, of hard plastic (ABS), length ca. 2.0 x 1.0 m,

height ca. 43 mm, with integrated aluminium profiles and

two fastening screws; can be used as support plates,

e.g. for the ZinCo SGR solar base frames

or in conjunction with corresponding

post holders made of galvanised steel

for a wide range of railing solutions.

SB Rail holder made of stainless steel, for connecting the rail to the solar

base, available in lengths of 600 mm and 1200 mm.

Rails made of a high quality aluminium alloy in standard lengths of 2.0 m,

3.0 m and 6.0 m, butt joint connectors, end pieces, runners, etc.

The required quantities and characteristics of the components can be

found in the delivery note.

ZinCo GmbH

Lise-Meitner-Strasse 2 ∙ 72622 Nürtingen ∙ Germany

Phone +49 7022 6003-0

info@zinco-greenroof.com ∙ www.zinco-greenroof.com

®

, gravel 16/32 mm

®

SB 200-Rail safety device

b. Documents included with each order:

Installation Instructions, User Instructions and Control Card.

The installation plan (if planned by the ZinCo GmbH) is provided separately to

the person stating the order and is to be handed to the client.

Please note:

Incomplete, incorrect or defective deliveries are to be objected

immediately.

1.2 Check of the initial situation

The basis for a perfect function of Fallnet

SB 200 solar bases (in a row or across a corner), mechanically connected

to each other by mounting profiles or guardrail rails, are present and serve

as a load-bearing surface (total area thus at least 10 m²).

Before starting installation, check whether the roof construction is suitable

for the loads to be applied, make sure that the maximum possible roof

pitch (5°) is not exceeded, check whether the waterproofing, root protection,

etc. have been applied professionally. If there are any doubts, these

must be clarified and if necessary eliminated before installation.

1.3 Admissible types of installation

The following types of installation are admissible for Fallnet

a. With multi-layer build-ups:

®

Fallnet

SB 200-Rail is applied above the drainage layer (e.g. Fixodrain

XD 20-Bahnen) directly over the corresponding filter sheet.

b. With mono-layer build-ups:

®

Fallnet

SB 200-Rail is applied directly over the protection layer (> 300 g/m²),

whereby drainage elements of a comparable height (e.g. Floradrain

FD 40-E) are subsequently to be fitted into the spaces between the SB 200

elements.

2. Installation instructions

2.1 Completing the Solar Base SB 200/Attaching the Rail Supports

®

Fallnet

SB 200-Rail can be combined with the ZinCo Solar Base

SB 200 in two different ways:

®

- ZinCo Solar Base

SB 200 and Solar Base Frame SGR (see variant 1):

The rail supports are to be placed on the screws of the Solar Base

SB 200. Then the Solar Base Frame is to be placed on the rail

supports and attached (> 20 Nm) to the SB 200 base plate using both

nuts.

- Guardrail Base GB-Rail / GB-Rail Corner (see variant 2):

The rail supports are placed on the posts of the post supports of the

GB-Rail / GB-Rail Corner. It should be connected (> 20 Nm) using a

carriage bolt (including U-washer and a stop-nut).

To achieve the frictional connection between rail supports and grid units,

the first grid element unit is moved over the rail support with its colour

coding and pressed by foot to snap. Install all grid units in such a way

that the rail support is located centrally in the grid unit (one more in the

centre resp. two more at the beginning and the end of the rail). All grid

elements of a grid unit must be plugged together at the connection

points and thus form a tension distributing disc.

Page 1 of 9

®

SB 200-Rail is that at least five

®

SB 200-Rail:

®

®

®

Advertisement

Summary of Contents for Zinco Fallnet SB 200-Rail

- Page 1 (e.g. ZinCo system soil, Zincolit , gravel 16/32 mm The installation plan (if planned by the ZinCo GmbH) is provided separately to or slabs in a chippings bed) represents an anchoring device in accordance the person stating the order and is to be handed to the client.

-

Page 2: Installation Instructions

Screw end pieces onto the ends of the rail using butt joint connectors. The end pieces are threaded over the rail support of the grid unit AE We recommend that you let the ZinCo technical department plan or and fastened between the first or last butt joint connector and the check the requirement and location plans. - Page 3 Sedum Carpet. 40 mm thick concrete slabs laid in a 40 mm thick gravel own specific building project, please contact ZinCo GmbH, Hotline bed, including backfilling, result in a superimposed load of approx. 180 kg/m².

- Page 4 PV modules) for roof pitches up to 2° or 140 kg/m² for roof pitches mat (mono-layer build-up), see Installation Instructions. >2° to 5° can be applied e.g. in the form of ZinCo system soil, gravel 16/32 mm or comparable bulk material or, in the case of railing Important: Direct contact between the load (bulk material) and the grid solutions, in the form of slabs in a bed of chippings.

- Page 5 ® Fallnet SB 200-Rail requires no special cleaning procedures; if necessary, dirt can be removed with a damp cloth. ZinCo GmbH Lise-Meitner-Strasse 2 ∙ 72622 Nürtingen ∙ Germany Phone +49 7022 6003-0 info@zinco-greenroof.com ∙ www.zinco-greenroof.com...

- Page 6 We wish to state explicitly that, regardless of product liability, ZinCo shall only assume liability for the consultancy process where installation has been carried out in line with ZinCo site planning. Installation without site planning carried out by ZinCo is at your own risk.

- Page 7 7. Attach the end pieces with the stop screws at each 8. Applying the required load (min. 120 kg/m² dry weight) end of the rail. ZinCo GmbH Lise-Meitner-Strasse 2 ∙ 72622 Nürtingen ∙ Germany Phone +49 7022 6003-0 info@zinco-greenroof.com ∙ www.zinco-greenroof.com...

-

Page 8: Control Card

100 kg) at a time, and this person should be wearing personal protective - Readability of the product label equipment (PPE, e.g. ZinCo-PPE-Set) in accordance with EN 363. The safety harness, in accordance with EN 361, can only be used in conjunction Note: with tested and approved components. - Page 9 Date for next inspection year year year year year year year year year year Authorise a full inspection by the manufacturer Person/company authorised by the manufacturer: …………………………………..………… ZinCo GmbH Lise-Meitner-Strasse 2 ∙ 72622 Nürtingen ∙ Germany Phone +49 7022 6003-0 info@zinco-greenroof.com ∙ www.zinco-greenroof.com...

Need help?

Do you have a question about the Fallnet SB 200-Rail and is the answer not in the manual?

Questions and answers