Summary of Contents for PRECISION MACHINES CSS16

- Page 1 OPERATION MANUAL CSS16 Attention: No advise will be made for any changes of structure . Read and understand this manual before operate this tool...

- Page 2 POST THESE SAFETY RULES FOR REFERENCE. SA FET Y RU L ES FOR SCROL L SA WS FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY. READ AND UNDERSTAND the instruction 15. NEVER REACH UNDER THE TABLE while the manual before operating this machine.

-

Page 3: General Notes

15 amp time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn, cut or damaged in any way. Do not use in wet conditions. SPECIFICATIONS-CSS16 550-1650 Sound level at max. speed during idle running... - Page 4 GENERAL SAFETY RULES FOR SCROLL SAWS shock and personal injury. Read all these instructions before attempting to operate this product. Save these instructions for future reference. r. Cluttered areas and benches invite injuries. eep other people not let others, especially children, not involved in the k touch or the properly.

-

Page 5: Electrical Connection

ELECTRICAL EXTENSION CORDS Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the product’s plug.When using a power product at a considerable distance from the power source, use an extension cord heavy enough to carry the current that the product will draw. An undersized extension cord will cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat. -

Page 6: Additional Safety Rules For Scroll Saws

ADDITIONAL SAFETY RULES FOR SCROLL SAWS PROPER USE CSA/US ”... -

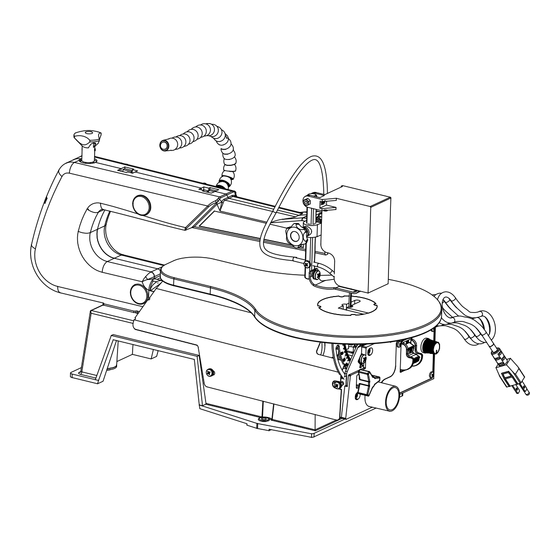

Page 7: Installation

SCROLL SAW DESIGN FEACURES 1. Safety guard 2. Working piece holder 3. Shaving blower: Keeps the work piece area free from dust. 4. Variable speed switch 5. on/off power switch 6. Angle scale: Scale shows the tilting angle of table. 7. - Page 8 Before Operation Scroll saw base Mounting the saw on a work bench A workbench made from solid wood is better than one made of plywood, As interfering vibrations and noise are more noticeable with plywood. o i t The necessary tools and small parts for assembling Workbench the saw on a workbench are not supplied with the saw.

- Page 9 Allen screws. Inserting the saw-blade to the adapters and securely tighten the other setscrew with the wrench provided.Then place the blade and adaptors into the gauge to set the blade to the proper length as shown, Adjust the blade tension according to pin type blade adjust on last section. Wrench Blade Adaptor...

-

Page 10: Maintenance

MAINTENANCE : In the interests of operational safety, always switch off the saw and remove the cord from power supply before carrying out maintain work. General Re-application of the wax coating on the work table makes feeding the work piece to the blade easier. Motor The power cord should be replaced immediately if pulled out, cu\ or damaged in any other way. - Page 12 Name Spec Name Spec Base HT150 Screw 45 M4×6 Bolt 45 M6×20 Gasbag Fixing flat Q235 Gasbag cover Top rocker ZL102 Screw 45 M6×25 Spring washer 65Mn Package support Hexagon nut 45 M6 Foot Oil bearing F1165M Lucite pipe Oil cover Lucite pipe Lower rocker ZL102...

Need help?

Do you have a question about the CSS16 and is the answer not in the manual?

Questions and answers