Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for DUROLL PRO ZED68515

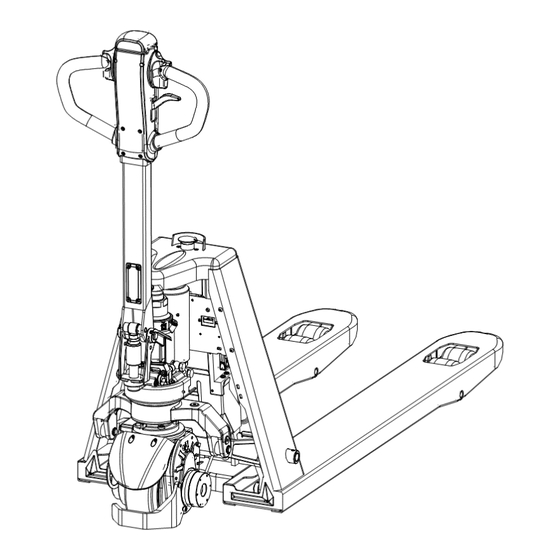

- Page 1 CBD15/20 Pallet Truck with Lithium Battery Operation Manual Parts Catalogue...

-

Page 2: Table Of Contents

Thank you for buying CBD15/20 electric pallet truck! Hope it will provide great convenience for your work! ⚫ Please read the manual carefully before starting the truck. ⚫ This operation manual is general, and the right to make any technical modifications to the tractors are reserved. Contents provided in this manual for reference only and if wrong in real, prevail in kind. -

Page 3: Safety Regulations

1. Safety regulations Safety shoes are always required to handle the pallet truck. Safety glasses are recommended to avoid personal accidents while assembling or disassembling the pallet truck. CAUTION When the truck is damaged or has safety problems, stop using it immediately. CAUTION The pallet truck is designed for hard and flat floor only. - Page 4 CAUTION Operators must be very carefully when handling the pallet truck on a slope. See the drawing, the operator should stand ahead of the truck. Operators must be very carefully when handling the pallet truck on a slope. See the drawing, the operator should stand ahead of the truck.

-

Page 5: Allowed Environment For Using

2. Allowed environment for using This truck is suitable for use on hard and flat indoor surfaces. -The altitude does not exceed 1000 meters; -The ambient air temperature shall not exceed+40 ℃ and not be lower than - 10 ℃; -When the ambient temperature is+40 ℃, the relative humidity does not exceed 50%, and at lower temperatures, a larger relative humidity is allowed;... - Page 6 Model CBD20 Way of driving Electric 电动 Drive type Walkie 步行式 Load capacity Q(kg) 1500 2000 Load center distance C(mm) Fork height,lowered (mm) Tread Y(mm) 1236/1306 1236/1306 Wheel type 聚氨酯 Tyre size,front Φ210X75 Φ210X75 Tyre size,rear Φ80 Φ80 Wheel number, front/rear ( x = driving 1X/2(4)...

-

Page 7: Handle Installment

4. Handle installment The handle is removed before shipment in the consideration of the requirement of packing and the safety over transportation, and the steps to install the hand are list as following: 4.1 Refer to Figure 1,remove the pin 1 from pin 2, then pull out the pin 2. 4.2 Refer to Figure 2,Loose the screw 3, remove the cover plate 4 from handle assembly 5. -

Page 8: Operation

Cable tie Cable tie Figure 5 Figure 6 4.4 Refer to Figure 4、6, fix the screw and nut at the end of chain 8 into the groove of lever plate 11 4.5 Pass the pin 2 through pin 2 and fix, install the cover plate 4 onto handle assembly 5. 5. - Page 9 Traveling of the pallet truck Rotate the handle to the traveling section, A and C are breaking section. B is the traveling section Rotate the accelerator to start the truck slowly (for safety’s reason, no rapid acceleration). Backwards Forward Parking Release the accelerator for normal braking, the truck stops slowly by the regenerative brake of the motor until the brake lock the wheels.

-

Page 10: Charge And Battery Replacement

Emergency reverse button Safe parking Release speed control button to stop the truck. Lower the fork to the lowest position. Turn off the key switch. Disconnect the battery harness in order to park for a long time Disconnect the connector Open rear cover 6. - Page 11 Taking down the battery by holding the plug, instead of pulling the charging line. ◆ The battery may be hot after charging, cool it down in a ventilated environment. ◆ Do not put batteries in water or sea water; ◆ Do not try to separate, squeeze, or hit the battery.

-

Page 12: Maintenance

3.Seperate power 2.Open rear cover 1.Shut off the Emer. connector stop switch plate 4.Pull out the battery 6.4 Precautions on battery charging Must use the special Li-ion charger of our company; working voltage of charger is 24V; maximum charging voltage is 29V, charging current is 5A. Do not reversely charge the battery, Stop charging immediately if the battery is found abnormal hot during charging, recharge after cooling down naturally. - Page 13 should be made regularly, abnormal phenomena should be eliminated in time, and faulty cars should not be used to ensure safety and prolong the service life of cars. Maintenance of this pallet truck is generally divided into three levels: daily maintenance, weekly maintenance and Periodic Maintenance .

-

Page 14: Truck Hoisting

Remove the screw at the oil filler with No.5 hexagon wrench, the oil volume is 250ml. Lifting and lowering the handle for two to three times after oil filling, then lift the fork to max. height and tighten the screw. Replace the washer if its damaged. -

Page 15: Trouble Shooting

9. Trouble shooting The table below provides some common failures of the truck in operation and the trouble shooting Faults Analysis of cause Trouble shooting 1.Failed oil seal 1.Replace the oil seal Hydraulic 2.Slight damage or wear on the 2.Replace damaged leakage surface of one or two components... -

Page 16: Electrical Schematic Diagram And Error Code

12. Electrical schematic diagram and error code Electrical schematic diagram ⚫ ⚫ CBD15 ⚫ CBD20 ~ 16 ~... - Page 17 Diagnosis and trouble shooting ⚫ Error display code Description Error diagnosis THERMAL FAULT Over / low 1) Temperature > 80 ℃ or < - 10 ℃ temperature 2) Truck overload cut-off 3) Operating in extremely harsh environments 4) Electromagnetic brake does not release normally THROTTLE FAULT Potentiometer...

-

Page 18: Packing List

CURRENTSENSE FAULT Current detection 1) Motor or motor wiring short circuit fault 2) Controller failure HARDWARE FAILSAFE Motor voltage out 1) Motor voltage does not match accelerator of range input 2) Motor or motor coil short circuit 3) Controller failure EEPROM CHECKSUM EEPROM failure 1) EEPROM failure...

Need help?

Do you have a question about the ZED68515 and is the answer not in the manual?

Questions and answers