Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Winterhalter MT Series

- Page 1 MT Series Translation of the original operating instructions Version 1...

-

Page 2: Table Of Contents

4.2.10 Units ................................26 4.2.11 CONNECTED WASH ..........................26 4.2.12 Water back-flow counter ..........................26 5 Commissioning ................................27 5.1 Installing the warewasher............................. 27 5.2 Connecting the warewasher..........................27 5.2.1 Water connection ............................27 89014484; Version 1 Operating instructions MT Series... - Page 3 9 Disassembly and disposal ............................46 9.1 Taking the warewasher out of operation for long production stops..............46 9.2 Disassembly................................. 46 9.3 Disposal ................................46 10 Annex .................................... 47 10.1 Declaration of Conformity............................. 47 Operating instructions MT Series 89014484; Version 1...

-

Page 4: Introduction

– The warewasher is intended only for washing dishes, cutlery, glasses, kitchen utensils, pots, trays, plates, and GN containers for gastronomic and similar use. – Operate the warewasher with chemicals from Winterhalter. If other chemicals are used, please contact Winterhalter or an authorised customer service team in advance. -

Page 5: Symbols Used

The signal word WARNING indicates a potential danger; ignoring it may lead to serious injury or death. CAUTION The signal word CAUTION indicates a potential danger; ignoring it may lead to minor or moderate injury. NOTE The signal word NOTE indicates potential damage to property. Operating instructions MT Series 89014484; Version 1... -

Page 6: Safety Notes

– Refer users to the safety notes and inform them of potential dangers. Repeat training sessions at regular intervals to prevent accidents. – Arrange for the Winterhalter customer service team or a specialist dealer to provide instruction in operating and using the warewasher. -

Page 7: Qualification Requirements For Personnel

– If the mains cable is damaged, it must be replaced by Winterhalter, its customer service team or another qualified per- son to prevent danger. The mains cable must be a H07RN-F type or equivalent. The mains cable must be an oil-res- istant, sheathed and flexible cable. -

Page 8: Handling Of Chemicals

– Only install and operate warewashers with heat pumps in rooms that are at least 18 m² in size (with a ceiling height of 2.5 m). 89014484; Version 1 Operating instructions MT Series... -

Page 9: Maintenance, Repair And Spare Parts

Winterhalter cannot assume liability. – Only original Winterhalter spare parts may be used for maintenance and repairs. If original spare parts are not used, the warranty is invalidated. The information in the spare parts catalogue is definitive in this respect. -

Page 10: Machine Description

Door Main switch Strainer Exhaust air vent Wash arm Exhaust air hood (only on machines without air Rack conveyor with push bars knife drying zone/drying zone) Dirt removal plate Grease filter Strainer drawer 89014484; Version 1 Operating instructions MT Series... - Page 11 In the air knife drying zone, water is removed from recesses in the wash items by means of a stream of air from above. Item Name Air tray Ventilator jet Door Rack conveyor with push bars Operating instructions MT Series 89014484; Version 1...

-

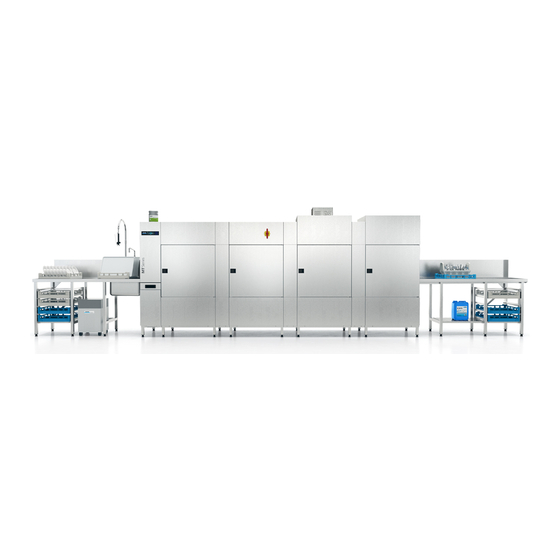

Page 12: Machine Sizes

Illustration of working direction left to right MTR S 2-tank rack conveyor dishwasher Item Name Inlet zone Pre-wash zone 350 mm (optional) Main wash zone Neutral zone (optional) Rinse zone Exhaust air hood 89014484; Version 1 Operating instructions MT Series... -

Page 13: Display

Display area for error pictograms Selection of alternative wash mode Start button Screen saver If the display is not used for a long time, the selected transport speed will appear and fill the display. Operating instructions MT Series 89014484; Version 1... -

Page 14: Wash Modes

The wash mode can be changed during the washing process. page 35). Special programme Pictogram / special programme Meaning Basic cleaning programme Higher detergent dosing for thorough cleaning of wash items, e.g. to remove starch residues 89014484; Version 1 Operating instructions MT Series... -

Page 15: Info Menu

Access to the warewashing staff menu / chef Date / time menu Hygiene check (in case of fault) CONNECTED WASH (optional) Machine number Telephone number for service technician and chemical supplier Display area for error pictograms Machine model Operating instructions MT Series 89014484; Version 1... -

Page 16: Chemicals

Rinse aid is automatically dispensed using an external dosing device. Winterhalter dosing devices can dispense two different types of rinse aid (e.g. one for glasses and one for canteen trays). Each of the configured types of rinse aid can be assigned to a particular transport speed. -

Page 17: Technical Data

Temperature at the installation site °C 0 - 40 Relative air humidity at the installation site < 95 Storage temperature °C > -25 Max. height of the installation location above sea 3000 level Operating instructions MT Series 89014484; Version 1... -

Page 18: Software

1 2 3 Item Description Continue to the next window by tapping or “swiping” Exit the menu “Chef menu” symbol Number of windows on the same level One level back Scroll up or down 89014484; Version 1 Operating instructions MT Series... -

Page 19: Hygiene Logbook

Switch-on time of wash pump in hours and minutes Configuring a filter The hygiene logbook entries can be filtered to display only certain errors and events. Item Description Activate and deactivate error display Deactivate all Activate all Operating instructions MT Series 89014484; Version 1... -

Page 20: Operating Data

The dosing amounts for detergent, rinse aid and defoamer (depending on configuration) can be set separately for each different transport speed. Item Description Transport speed 1 Transport speed 2 Transport speed 3 Set dosing devices or control signals Reset to default settings 89014484; Version 1 Operating instructions MT Series... - Page 21 Note: A second detergent and a second rinse aid can only be configured if using Winterhalter dosing devices. If using dosing devices not made by Winterhalter, a maximum of one dosing unit for detergent and one dosing unit for rinse aid or defoamer can be connected.

-

Page 22: Timer

Software Configuring and selecting alternative rinse aids If using Winterhalter dosing devices, two rinse aids can be configured and used (e.g. one for dishes and one for canteen trays). Note: You can only configure two rinse aids if both rinse aids are configured via the selection “Device”. If a de- foamer is configured, you cannot configure a 2nd rinse aid. - Page 23 If the door is open at the time of the time-controlled switch-off, the warewasher will be pumped empty and switched off, but the inside will not be cleaned. Displaying the programmed time Operating instructions MT Series 89014484; Version 1...

-

Page 24: Descale

Water-bearing lines and the boiler can only be descaled by an authorised service technician. For descaling, you require an acid-based descaler suitable for commercial warewashers. Winterhalter recommends A 70 LS descaler. WARNING Risk of chemical burn due to contact with descaler Contact between descaler and the skin or eyes can lead to severe burns or serious eye damage. -

Page 25: Brightness

Note: Time must be changed for the summer/ winter time changeover. Item Name Set date Set time 4.2.9 Language In this menu the language of the display texts is set. Item Name Reset to last language set Operating instructions MT Series 89014484; Version 1... -

Page 26: Units

This menu is used to set the total capacity of an external water treatment system. If the external water treatment system has been regenerated or replaced, the water countdown meter will need to be reset. Item Description Set the total capacity Reset the water countdown meter 89014484; Version 1 Operating instructions MT Series... -

Page 27: Commissioning

Ø Connect the waste water pipe (1) firmly to the ware- washer. Ø Guide the waste water pipe to the on-site waste water connection at a downwards angle (of at least 3 °) and connect it. Operating instructions MT Series 89014484; Version 1... - Page 28 Working direction left to right: to the left of the machine Working direction right to left: to the right of the machine Dimensions ≥ Diameter 70 mm with trap Version Waste water pipe between the machine and the waste water connection 89014484; Version 1 Operating instructions MT Series...

-

Page 29: Electrical Connection

Ø Determine the cable cross-section of the mains cable using the following table: On-site fuse protection [A] Cable cross-section [mm The mains cable must be an oil-resistant, sheathed and flexible cable. The cable type H07RN-F is recommended. Operating instructions MT Series 89014484; Version 1... - Page 30 Note: If a three-phase mains supply (200 V and 230 V) is used without a neutral conductor (N), there is no blue neutral conductor terminal. Establishing equipotential bonding Ø Connect the warewasher to the on-site equipotential bonding system. Ø See the drawing for the position of the connecting screw (1). 89014484; Version 1 Operating instructions MT Series...

-

Page 31: Establishing The Electrical Connection Of The Dosing Devices

Continuous voltage / phase 1 Rinse aid 2 / defoamer Note: Dosing devices that are not made by Winterhalter can only be connected to terminal O5 or O3 (detergent) and terminal O4 (rinse aid). Voltage is applied to the RINSE (O4) and DETERGENT (O5) terminals depending on the settings made in the Dosing menu. -

Page 32: Establish The Electrical Connection Of The Suction Tubes

Rinse aid 2 / defoamer suction tube Note: For dosing devices that are not made by Winterhalter, the suction tubes have to be connected to input I6 (item 1) and I5 (item 2) so that the display shows when these agents are empty. -

Page 33: Checking For Completeness

(water, waste water, electrical system). Ø After connecting the water and the power properly, contact the relevant Winterhalter dealership or your dealer to ar- range for commissioning of the warewasher. Arrange for the operator and operating personnel to be trained in operat- ing the warewasher. -

Page 34: Operation

Ø Space glasses to prevent them from rubbing against each other. This will avoid scratches. Ø For tall glasses, choose a wash rack with appropriate divisions so that the glasses are held in a stable position. 89014484; Version 1 Operating instructions MT Series... - Page 35 The alternative wash mode stays active until it is deactivated, another wash mode is selected or the warewasher is switched off. Deactivating alternative wash mode Wash breaks Ø Do not switch the warewasher off during wash breaks. Operating instructions MT Series 89014484; Version 1...

-

Page 36: Using Alternative Detergents

Operation Using alternative detergents If using Winterhalter dosing devices, two detergents can be configured and used alternately (e.g. one for dishes and one for glasses). After changing the type of detergent, the tank water must be changed. Changing the tank water Change the tank water if it is very dirty and if wash results deteriorate. -

Page 37: Malfunctions

Press the pictogram and make a note of the error code. Contact an authorised service technician. Error in external osmosis system Contact an authorised service technician. Lack of salt in external softening system Top up with salt. Operating instructions MT Series 89014484; Version 1... -

Page 38: Displaying The Error Code Of A Serious Error

Contact an authorised service techni- cian. Note: Water quality affects the washing and drying result. We therefore recommend supplying the warewasher with softened water in areas with water of a total hardness above 3 °dH (0.53 mmol/l). 89014484; Version 1 Operating instructions MT Series... -

Page 39: Emergency Programme (Optional)

Ø To start the transport belt, hold the magnet against the cover over the reed switch (2). Ø If the transport belt is stopped (e.g. by opening the door), restart the transport belt using the magnet. Operating instructions MT Series 89014484; Version 1... -

Page 40: Cleaning And Maintenance

Ø For warewashers with an exhaust air hood: Remove grease filter and wash in the warewasher. Ø If present, remove grease filter from the heat pump and wash in the warewasher. Ø Remove and clean strainer drawer from inlet zone. 89014484; Version 1 Operating instructions MT Series... - Page 41 After the first programme step, the self-cleaning programme is interrupted and a video with further steps is shown on the display. If no notice is taken of the video, the self-cleaning programme will start automatically. Operating instructions MT Series 89014484; Version 1...

- Page 42 Ø Note: Risk of damage to heat pump! The warewasher must not be switched off using the main switch. Switch off the warewasher using the display and wait 15 seconds before switching off the main switch. 89014484; Version 1 Operating instructions MT Series...

-

Page 43: Replacing The Canister

Ø If the cartridge is empty, replace it. Ø If the cartridge is not yet empty, tap the cartridge to loosen the detergent powder. Ø If the dosing line or funnel is clogged, contact a service technician. Operating instructions MT Series 89014484; Version 1... -

Page 44: Changing The Chemicals

The dosing device and the dosing hoses must therefore be flushed with water before a new chemical product is used. If this is not done, the Winterhalter Gastronom GmbH warranty and product liability will be void. Ø Remove the suction tube from the canister and place it in a water-filled container. -

Page 45: Descaling The Warewasher

The warewasher control unit specifies the number of operating hours or wash cycles at which the pic- togram for service is shown. Note: This function is deactivated ex-works. On request, the service technician can activate this function. Operating instructions MT Series 89014484; Version 1... -

Page 46: Disassembly And Disposal

Ø WARNING! Fire hazard! Have the heat pump disposed of by a certified refrigeration engineer. The fluorinated greenhouse gases contained in the heat pump must be recovered and then recycled, processed or destroyed during disposal. Ø Send packaging material for recycling. 89014484; Version 1 Operating instructions MT Series... -

Page 47: Annex

Annex English Annex 10.1 Declaration of Conformity Operating instructions MT Series 89014484; Version 1... - Page 49 Winterhalter Gastronom GmbH Winterhalter Gastronom GmbH Gewerbliche Spülsysteme Commercial Dishwashing Systems Winterhalterstr. 2-12 Winterhalterstr. 2-12 88074 Meckenbeuren 88074 Meckenbeuren Deutschland Germany Tel. + 49 7542 402-0 Telephone: +49 (0) 7542 4 02-0 www.winterhalter.de www.winterhalter.com info@winterhalter.de info@winterhalter.com 89014484; 2024-04...

Need help?

Do you have a question about the MT Series and is the answer not in the manual?

Questions and answers