Table of Contents

Advertisement

Quick Links

Published 08/22

This Operator's Manual is an integral part of the safe operation of

this machine and must be maintained with the unit at all times.

READ, UNDERSTAND, and FOLLOW the Safety and Operation

Instructions contained in this manual before operating the

equipment.

Important Operating and Safety Instructions are found in the Mower

Safety Video that can be instantly accessed on the internet at:

www.algqr.com/bve

BUSH HOG

®

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

OPERATOR'S MANUAL

C01-Cover_B str

©2022 Alamo Group Inc.

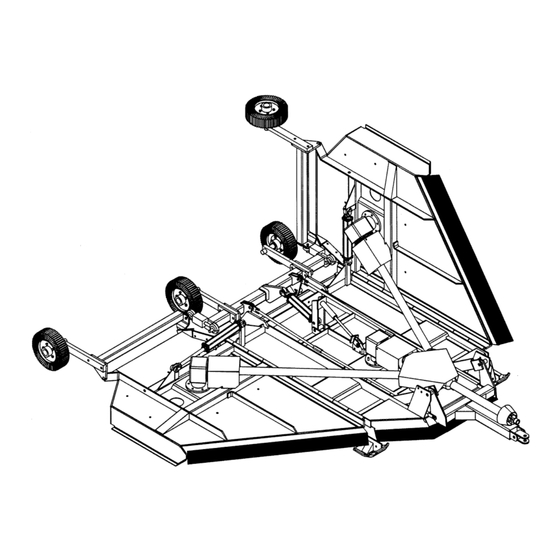

RMB 1880F

RMB 2080F

REAR MOUNT BOOM MOWER

Part No. 50081516

Advertisement

Chapters

Table of Contents

Summary of Contents for Bush Hog RMB 1880F

- Page 1 RMB 1880F RMB 2080F REAR MOUNT BOOM MOWER Published 08/22 Part No. 50081516 OPERATOR’S MANUAL This Operator's Manual is an integral part of the safe operation of this machine and must be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment.

- Page 3 In order to reduce accidents and enhance the safe operation of mowers, Bush Hog, in cooperation with other industry manufacturers has developed the AEM/FEMA Industrial and Agricultural Mower Safety Practices video and guide book. The video will familiarize and instruct mower-tractor operators in safe practices when using industrial and agricultural mowing equipment.

- Page 4 Bush Hog will provide one (1) AEM Mower Safety Practices Video Please Send Me: VHS Format – AEM/FEMA Mower Operator Safety Video DVD Format – AEM/FEMA Mower Operator Safety Video Mower Operator’s Manual AEM Mower Operator’s Safety Manual...

- Page 5 A Manual canister is provided on the implement where this manual can be properly stored. If you lose or damage this manual a free replacement manual can be obtained from an authorized Bush Hog dealer or by down loading the manual from the Bush Hog website www.bushhog.com...

- Page 6 DEALER to CUSTOMER Pre-Delivery / Operation Instructions Dealer should inform the Purchaser of this product of Warranty terms, provisions, and procedures that are applica- ble. Dealer should also inform the Purchaser to review the contents of the Operator’s Manual including safety equipment, safe operation and maintenance, to review the Safety Signs on the implement (and tractor if possible) and of Purchaser’s responsibility to train his/her operators in safe operation procedures.

-

Page 7: Table Of Contents

INTRODUCTION SECTION ................2 - 1 FEATURES ..............................2 - 3 ATTENTION OWNER/OPERATOR ........................ 2 - 4 BUSH HOG LIMITED WARRANTY ........................ 2 - 5 ASSEMBLY SECTION...................3 - 1 TRACTOR SELECTION ..........................3 - 2 Minimum Tractor Weights - including ballast weight if necessary: ............3 - 2 TRACTOR PREPARATION .......................... - Page 8 Boom Unit Pre-Operation Inspection and Service .................. 4 - 11 TRACTOR PRE-OPERATION INSPECTION ....................4 - 16 BUSH HOG BOOM MOWER PRE-OPERATION INSPECTION ..............4 - 17 MACHINE CONTROLS - EVOLUTION......................4 - 18 Arm Operation Controls........................... 4 - 19 Keypad Control Buttons...........................

- Page 9 Table of Contents Bystanders/Passersby Precautions ......................4 - 38 Engaging the Power Take Off (PTO)....................... 4 - 38 Operating the Mower ..........................4 - 39 Operating the Attached Mower Heads ....................4 - 39 Shutting Down the Attached Head ......................4 - 41 TRACTOR, BOOM, AND ATTACHED HEAD STORAGE ................

- Page 10 Table of Contents PTO SHAFT ..............................5 - 11 TELE ARM WEAR PADS ..........................5 - 12 CABLES ................................. 5 - 15 CYLINDER ROD MAINTENANCE......................... 5 - 15 BOOM CYLINDER REMOVAL AND REPLACEMENT INSTRUCTIONS ............. 5 - 16 HYDRAULIC COMPONENT MAINTENANCE SCHEDULE ................5 - 17 PROPER TORQUE FOR FASTENERS ......................

-

Page 11: Safety Section

SAFETY SECTION Safety Section 1-1 © 2022 Alamo Group Inc. -

Page 12: Safety Messages

NOTE: If you want a translation of this safety section in one of the following Languages, please contact: Translations at 1502 E. Walnut Street Seguin, TX 78155; Fax: (830) 372-9529; Safety Section Translations are available in Spanish, Portuguese, French, German, Russian. GS01str RMB 1880F/2080F 08/22 Safety Section 1-2 © 2022 Alamo Group Inc. -

Page 13: Operator Safety

DO NOT EXCEED IMPLEMENT RATED PTO SPEED AVOID exceeding rated PTO speeds that may result in broken drivelines or blade failures. • SAFETY SIGNS: • REPLACE missing, damaged or unreadable safety signs immediately. PN OSBM-01str RMB 1880F/2080F 08/22 Safety Section 1-3 © 2022 Alamo Group Inc. -

Page 14: Crushing Hazards

NEVER ALLOW children to play on or around Tractor or Implement. • DO NOT operate without operator CAB or OVERHEAD protection. Falling limbs and debris can cause injuries. PN CHBM-01str RMB 1880F/2080F 08/22 Safety Section 1-4 © 2022 Alamo Group Inc. -

Page 15: Connecting Or Disconnecting Implement Safety

Using a PTO adapter can cause: • Excessive vibration, thrown objects, blade and implement failures by doubling operating speed. • Increased working length exposing unshielded driveline areas and entanglement hazards. PN CDBM-01str RMB 1880F/2080F 08/22 Safety Section 1-5 © 2022 Alamo Group Inc. -

Page 16: Thrown Object Hazards

INSPECT AREA thoroughly before mowing to REMOVE potential THROWN OBJECT HAZARDS. • NEVER ALLOW BLADES to CONTACT SOLID OBJECTS like wire, rocks, post, curbs, guardrails, or ground while mowing. PN TOBM-01str RMB 1880F/2080F 08/22 Safety Section 1-6 © 2022 Alamo Group Inc. - Page 17 STOP mowing when EXCESSIVE VIBRATION occurs: • STOP PTO and tractor ENGINE. • INSPECT mower for vibration source. REPLACE any damaged parts and bent or damaged BLADES. PN TOBM-02 str RMB 1880F/2080F 08/22 Safety Section 1-7 © 2022 Alamo Group Inc.

-

Page 18: Run Over Hazards

ONLY mount or dismount when tractor and moving parts are stopped. • STOP ENGINE AND PTO, engage parking brake, lower implement, allow all moving parts to stop and remove key before dismounting from tractor. PN ROBM-01str RMB 1880F/2080F 08/22 Safety Section 1-8 © 2022 Alamo Group Inc. -

Page 19: Pto Entanglement Hazards

DO NOT USE PTO ADAPTER. Using a PTO adapter can cause excessive vibration, thrown objects, blade and implement failures by doubling operating speed. Increased working length exposing unshielded driveline areas. PN PE01str RMB 1880F/2080F 08/22 Safety Section 1-9 © 2022 Alamo Group Inc. -

Page 20: Mower Blade Contact Hazards

DO NOT approach Sickle Bar head until Tractor Engine has been shut off. • STOP LOOK and LISTEN before approaching the mower to make sure all rotating motion has stopped. PN MBBM-01str RMB 1880F/2080F 08/22 Safety Section 1-10 © 2022 Alamo Group Inc. -

Page 21: High Pressure Oil Leak Hazards

• Allow oil to cool before removing cap. • Relieve oil pressure before removing cap slowly. • Stay away from hot oil that may spray from tank. PN HPBM-01str RMB 1880F/2080F 08/22 Safety Section 1-11 © 2022 Alamo Group Inc. -

Page 22: Electrical & Fire Hazards

DO NOT operate if oil is leaking. Repair oil leak and remove all accumulated oil before operating. • CLEAR any grass clippings or debris buildup around mower hydraulic pumps, valves or tanks. • SHUT OFF ENGINE while refueling. PN EFBM-01str RMB 1880F/2080F 08/22 Safety Section 1-12 © 2022 Alamo Group Inc. -

Page 23: Transporting Hazards

TURN ON tractor FLASHING WARNING LIGHTS. • ALLOW clearance for implement swing while turning. KEEP raised boom mower 10 feet or greater distance from all power lines and overhead obstructions. PN THBM-01 str RMB 1880F/2080F 08/22 Safety Section 1-13 © 2022 Alamo Group Inc. -

Page 24: Hazards With Maintenance Of Implement

DO NOT modify or alter implement, functions or components. • DO NOT WELD or repair rotating mower components. These may cause vibrations and component failures being thrown from mower. PN HMBM-01 RMB 1880F/2080F 08/22 Safety Section 1-14 © 2022 Alamo Group Inc. - Page 25 Skirts and Skid Shoes in place and in good condition. • REPLACE any missing, broken or worn safety shields, guards and safety devices. Cancer and Reproductive Harm www.P65Warnings.ca.gov. PN HMBM-01 (2) str RMB 1880F/2080F 08/22 Safety Section 1-15 © 2022 Alamo Group Inc.

-

Page 26: Parts Information

These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce mower performance, void warranties, and present a safety hazard. Use genuine Bush Hog mower parts for economy and safety. -

Page 27: Decal Location

SAFETY DECAL LOCATION NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 28 Keep Clear - Automatic Breakaway Return D716 WARNING Stabilizers in Position D618 WARNING Boom Multi-Hazard 50065309 LOGO Bush Hog Logo (14.85”) 50081483 NAME RMB 1880F Model Name 50081484 NAME RMB 2080F Model Name 50061049 LOGO Bush Hog Logo (22”) D625 WARNING Pressurized Tank 83380 REFLECT...

- Page 29 DANGER Thrown Object Hazard - Maintain Deflectors D720 WARNING Blade Bolt Torque D724 INSTRUCT Lubrication Chart D559 WARNING Use Genuine Bush Hog Parts D717 DANGER Thrown Objects Hazard 50061049 LOGO Bush Hog Logo SERIAL PLT Serial Number Plate 1458393 REFLECT...

-

Page 30: Rotary Head

Bush Hog Logo 1458392 REFLECT Red Reflector 1458393 REFLECT Yellow Reflector Rivets SERIAL PLT Serial Number Plate D559 WARNING Use Genuine Bush Hog Parts D1008 WARNING Blade Torque D621 IMPORTANT Lube Spindle D626 DANGER Thrown Object Hazard D619 WARNING Blade Rotation... -

Page 31: Decal Description

SAFETY DECAL DESCRIPTION RMB 1880F/2080F 08/22 Safety Section 1-21 © 2022 Alamo Group Inc. - Page 32 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-22 © 2022 Alamo Group Inc.

- Page 33 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-23 © 2022 Alamo Group Inc.

- Page 34 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-24 © 2022 Alamo Group Inc.

- Page 35 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-25 © 2022 Alamo Group Inc.

- Page 36 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-26 © 2022 Alamo Group Inc.

- Page 37 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-27 © 2022 Alamo Group Inc.

- Page 38 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-28 © 2022 Alamo Group Inc.

- Page 39 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-29 © 2022 Alamo Group Inc.

- Page 40 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-30 © 2022 Alamo Group Inc.

- Page 41 SAFETY RMB 1880F/2080F 08/22 Safety Section 1-31 © 2022 Alamo Group Inc.

-

Page 42: Federal Laws And Regulations

(Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) RMB 1880F/2080F 08/22 Safety Section 1-32 © 2022 Alamo Group Inc. - Page 44 Table of Contents Acknowledgment ..............2 Foreword .................3 Safety Alerts ................4 A Word to the User/Operator ..........5 Types of Industrial/Agricultural Mowers ......6 Follow a Safety Program............8 Prepare for Safe Operation ..........13 Start Safely ................22 Operate Safely ..............24 Shut Down Safely ..............38 Perform Maintenance Safely ..........39 Final Word to the User ............55 Acknowledgment...

-

Page 45: Safety Alerts

Safety Alerts Signal Words Safety Alert Symbol Signal words are distinctive words that are typically This Safety Alert Symbol means: “Attention! Stay alert! found on safety signs on the mower and other job site Your safety is involved!” equipment. These words may also be found in this manual and the manufacturer’s operator's manuals. -

Page 46: Types Of Industrial/Agricultural Mowers

Types of Industrial/Agricultural Mowers Industrial/Agricultural Mower Types Mowers are used for clipping pastures, shredding crop residue, cutting heavy brush, and mowing waterways, right–of–ways, roadsides or highways. Also, these Flail mowers are used for cutting grass and other growth in public areas such as parks and cemeteries. Rotary Boom Folding wing rotary... -

Page 47: Follow A Safety Program

Follow a Safety Program For Safe Operation You must be a qualified and authorized operator An operator taking prescriptions or over-the-counter medication must consult a medical professional to safely operate this machine. You must clearly understand the written instructions supplied by the regarding any side effects of the medication that would hinder their ability to safely operate this equipment. - Page 48 Follow a Safety Program Know the Rules Most job sites have rules governing equipment use and • Only qualified and authorized individuals may operate maintenance. Before you start work at a new location, this equipment. check with the supervisor or safety coordinator. Ask •...

-

Page 49: Prepare For Safe Operation

Follow a Safety Program Know the Equipment IMPORTANT: This manual covers safe practices for Read and understand the DANGER, WARNING, industrial/agricultural mower equipment. If your machine CAUTION, and NOTICE safety labels and other is equipped with other devices or special attachments, informational signs on the machine, the attachments, and in the manufacturer’s operator's manuals. - Page 50 Prepare for Safe Operation Inspect the Machines Before beginning your workday, check for the • Operator station platform is clear of tools, objects, following as applicable and repair or replace as and debris. Associated steps, handholds, or railings needed. Additional details and descriptions are are clean and functional.

- Page 51 Prepare for Safe Operation Avoid Injury From Raised Equipment Pressurized Fluid Injection Hazard Avoid possible crushing injury from falling mower or WARNING! Accidental injection of pressurized fluid other raised equipment. into the hands or body is dangerous and could result in death or serious injury.

- Page 52 Prepare for Safe Operation Ultra-Low Sulfur Diesel (ULSD) Clean Up Fuel Hazard Clean windows, lights, and safety signs. Avoid Static Electricity Risk When Fueling Make sure the operator’s area, steering levers, pedals, joysticks, steps, and grab handles are clean. Oil, grease, WARNING! Ultra-Low Sulfur Diesel (ULSD) poses a grass, leaves, needles, snow, ice, mud, or debris in greater static ignition hazard than earlier diesel...

- Page 53 Prepare for Safe Operation Know the Working Area Learn as much about your working area as possible. Analyze mowing area to determine: • The most efficient mowing procedure. Check at Ground or Floor Level • The height of the material to be mowed. Before you operate, inspect the surface over which •...

-

Page 54: Start Safely

Start Safely Starting the Engine WARNING! Start the engine from the operator’s seat • Clear the area of all persons. only. Never attempt to start the engine by shorting • Sound the horn. across starter terminals or reaching the key from •... -

Page 55: Operate Safely

Operate Safely Masked Visibility Areas Remember These Rules Machines have areas where the operator’s visibility Stay in the operator's seat with the seat belt fastened of the job site can be affected by the machine itself. when operating. ROPS posts, attachments, even items in the cab, could Make sure you have adequate visibility and sufficient limit your view of the surrounding area and possibly lighting during operation. - Page 56 Operate Safely Watch Out for Hazardous Traveling on Job Site Working Conditions Take it slow and easy when traveling through congested areas. Traffic courtesy pays off. Be alert for hazards. Know where you are at all times. Watch for branches, cables, or doorways. Give the right-of-way to loaded machines.

- Page 57 Operate Safely Transporting Safety Tips Always wear your seat belt when loading or unloading • Cover or remove rear-facing SMV sign on the your machine from a transport device, such as a flatbed machine, if equipped, to avoid confusing drivers truck.

- Page 58 Operate Safely Pull-type hitch-mounted mowers: Skid steer-mounted mowers • Refer to mower and tractor manufacturer’s operator's • Refer to mower and skid steer loader manufacturer's manuals. operator's manuals. • Remove three-point hitch quick coupler, if equipped. • Lower the lift arms and title the loader's coupler forward.

- Page 59 Operate Safely Mower-Thrown Objects Depending on the designed purpose, mowers are The risk of serious injury or death from thrown objects designed to cut grass, weeds, brush and crops. The can be significantly reduced by following three rules. If mower blades have been designed and tested for all of these safety rules are not followed, the mowing rugged use.

- Page 60 Operate Safely Extremely Tall Grass Mowing Watch Equipment Clearances You may need to mow extremely tall, non-crop grass Three-point hitch and side-mounted mowers have a twice. (See page 32, Mower-Thrown Objects.) larger turning arc than pull-type mowers. Allow sufficient clearance for mower swing while turning. First mowing pass: Do not allow bystanders near the tractor and mower •...

- Page 61 Operate Safely Wing and Side Mount Mowers Ditch Bank Mowing Safety Practices Safety Practices Use care when mowing ditch banks. Watch for washouts, eroded areas and mowing obstructions along Raised wing positions reduce shielding protection and the ditch banks. Hitting obstructions with side-mount increases the thrown object and blade contact hazard or boom mowers may swerve the tractor’s front end risks.

-

Page 62: Shut Down Safely

Shut Down Safely Select a Proper Parking Site When shutting down, park the machine in a designated • Raise operator seat/restraint bar(s), if equipped. area out of traffic, select level ground whenever • Unbuckle seat belt/restraint. possible. Lower raised equipment to the ground. •... - Page 63 Perform Maintenance Safely Mower Parts and Your Safety WARNING! Avoid death or serious injury from entanglement. Do not wear loose clothing or Mower manufacturers use specific fasteners and accessories. Stay away from all rotating components specially designed parts to meet mowing operations when the engine is running.

- Page 64 Perform Maintenance Safely Common Maintenance Attach a “DO NOT OPERATE” warning tag to the control levers. Lockout/tagout the unit according to Safety Practices the manufacturer’s operating manual. If there is a key, Use Proper Ventilation remove it and take it with you. If it is necessary to run an engine in an enclosed area, Install approved support device(s) when working under remove the exhaust fumes from the area with an...

- Page 65 Perform Maintenance Safely Ultra-Low Sulfur Diesel (ULSD) Hazard Hydraulic System Hazards WARNING! Ultra-Low Sulfur Diesel (ULSD) poses a Be sure to follow manufacturer’s instructions for relieving greater static ignition hazard than earlier diesel fluid pressure before performing any maintenance. The formulations with higher sulfur content.

- Page 66 Perform Maintenance Safely Before working on the electrical system, disconnect the If liquid from the battery contacts your eyes, flush battery cable(s). immediately with clean water and get medical attention. Wear chemical-resistant gloves and protective clothing • Remove the battery negative (–) cable(s) first. to keep liquid off your skin.

- Page 67 Perform Maintenance Safely Tire and Wheel Maintenance Check your tires and wheels daily because the stability WARNING! The types of wheels and tires usually of the machine can be dramatically affected by tire found on this equipment require special care when pressure or damage to tires or wheels.

- Page 68 Perform Maintenance Safely Mower Blade Maintenance Roll-Over Protective Structure (ROPS) and Falling Object Protective Do not take chances using damaged or bent blades. Structure (FOPS) Safety Precautions The mower manufacturers from the Association of Equipment Manufacturers (AEM) and the Farm Do not remove the ROPS/FOPS except for service.

- Page 69 Notes...

-

Page 70: Final Word To The User

A Final Word to the User You have just finished reading the AEM Industrial/Agricultural Mower Safety Manual. It is impossible for this manual to cover every safety situation that you may encounter on a daily basis. Your knowledge of these safety precautions and your application to the basic rules of safety will help to build good judgment in all situations. - Page 99 INTRODUCTION SECTION Introduction Section 2-1 © 2022 Alamo Group Inc.

- Page 100 Identifies special instructions or procedures that, if not strictly observed, could result in damage to, or destruction of the machine, attachments or the environment. NOTE: Identifies points of particular interest for more efficient and convenient operation or repair. RMB 1880F/2080F 08/22 Introduction Section 2-2 © 2022 Alamo Group Inc.

- Page 101 These hydraulically driven hedge cutters are designed for light-duty work. They can control grass and weeds on highways or industrial sites. The ultimate in versatility, Bush Hog’s rugged rear mounted boom mowers are designed to trim trees, brush, or hedges and mow behind guardrails, over fences, down embankments, and around ponds.

- Page 102 NOTE: Warranties are honored only if completed “Owner Registration and Warranty” forms are received by Bush Hog within thirty days of delivery of the implement. 3. Record the Model and Serial Numbers on the Warranty page at the front of the Operator’s Manual. Keep this as part of the permanent maintenance file for the implement.

- Page 103 2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgment of Bush Hog such use affects its performance, stability or reliability.

- Page 105 ASSEMBLY SECTION Assembly Section 3-1 © 2022 Alamo Group Inc.

- Page 106 Check Chains or stabilizers must be fitted and tightened. TRACTOR OPERATOR STATION Bush Hog recommends installing the Boom Mowers on fully enclosed cab tractors equipped with impact resistant glass windows. Do Not Operate if Tractor is damaged. RMB 1880F/2080F 08/22 Assembly Section 3-2 ©...

- Page 107 Spray the film surface so you can squeegee the film to the glass surface leaving no dry spots so squeegee will glide smoothly over the film. Only use enough mounting solution to accomplish this task. RMB 1880F/2080F 08/22 Assembly Section 3-3...

- Page 108 Upon completing your installation it is recommended to clean the surface of the recently installed film by using a window film cleaner or simply spray the interior surface with your mounting solution and lightly squeegee off RMB 1880F/2080F 08/22 Assembly Section 3-4...

- Page 109 Do this in as continuous a manner as possible avoiding stops and starts and go around the entire perimeter of the window. Make certain that sealant is completely filling the cavity between the frame and the glass. RMB 1880F/2080F 08/22 Assembly Section 3-5 © 2022 Alamo Group Inc.

- Page 110 10%. All factors must be addressed in order to match the type and nature of the equipment added to the circumstances under which it will be used. The center of gravity on a Bush Hog 1880F-2080F Boom Mower will constantly change as the boom or cutting attachment moves. Maintaining proper balance during operation and transport is critical.

- Page 111 ‘A’ and the sling shackle fitted at location ‘B’ for machines without a mower head attached or location ‘C’ for machines with a mower head attached. RMB 1880F/2080F 08/22 Assembly Section 3-7 © 2022 Alamo Group Inc.

- Page 112 Pivot out the dipper arm until the tension link can be connected and secure in position with pin and hardware. RMB 1880F/2080F 08/22 Assembly Section 3-8 © 2022 Alamo Group Inc.

- Page 113 Bolt on stabilizer tongues are available in a wide variety of versions to suit differing makes and models of tractors and are reversible to accommodate for greater variation in tractor linkage designs. Refer to following page for details. RMB 1880F/2080F 08/22 Assembly Section 3-9 © 2022 Alamo Group Inc.

- Page 114 ASSEMBLY Stabilizer Tongue Options & Specifications RMB 1880F/2080F 08/22 Assembly Section 3-10 © 2022 Alamo Group Inc.

- Page 115 Ensure the same hole position is selected on both sides of the machine. Insert lower linkage pins and spacers and secure in position with lynch pins. Any lifting equipment used to position the machine may now be removed. RMB 1880F/2080F 08/22 Assembly Section 3-11 © 2022 Alamo Group Inc.

- Page 116 NOTE: The bolt on nose of the stabilizer is reversible in order to accommodate variations of tractor linkage designs. Bush Hog offers various versions of stabilizer noses for different types and makes of tractors. For further advice or information contact your local dealer or the Bush Hog Parts Department.

- Page 117 Ensure no one is standing on, between, or near the linkage arms or bars during this procedure Adjust the top link to bring the machine frame into the vertical position. RMB 1880F/2080F 08/22 Assembly Section 3-13 © 2022 Alamo Group Inc.

- Page 118 Replace leg pins and secure in place with ‘R’ clips. Adjust check chains to prevent sideways movement of the tractor’s linkage. Measure and cut the PTO shaft. Refer to PTO driveshaft installation page for details. RMB 1880F/2080F 08/22 Assembly Section 3-14 © 2022 Alamo Group Inc.

- Page 119 The tap should be kept open and only closed for any future shipping or as an added safety precaution when storing the machine detached from the tractor. RMB 1880F/2080F 08/22 Assembly Section 3-15 © 2022 Alamo Group Inc.

- Page 120 Tractor operator’s seat with the seat belt securely fastened. Inadvertent contact with the boom controls could allow a component to fall. A sudden or inadvertent fall by any of these components could cause serious injury or even death. (SBM-23) str RMB 1880F/2080F 08/22 Assembly Section 3-16 © 2022 Alamo Group Inc.

- Page 121 With the attachment bolts correctly located through the brackets fit the self-locking nuts and tighten alternately until the brackets are drawn flush before finally tightening them to a torque setting of 150 ft.-lbs (203Nm). RMB 1880F/2080F 08/22 Assembly Section 3-17...

- Page 122 – ensure the hose tray is replaced once the hoses have been connected. RMB 1880F/2080F 08/22 Assembly Section 3-18 © 2022 Alamo Group Inc.

- Page 123 Millmax 46 Millmax HV46 Millmax HV 46 MORRIS Liquimatic 5 Liquimatic 6 Liquimatic HC 46 Liquimatic HC 68 Triad 46 Triad 68 TOTAL Equivis ZS 46 Equivis ZS 68 RMB 1880F/2080F 08/22 Assembly Section 3-19 © 2022 Alamo Group Inc.

- Page 124 A. Unplug the electrical connection from base of joystick. B. Remove the four screws from the top of the joystick. C. Remove the eight screws from armrest base and remove armrest. RMB 1880F/2080F 08/22 Assembly Section 3-20 © 2022 Alamo Group Inc.

- Page 125 Ensure no structural components or surfaces with hidden electrical wiring are drilled when selecting a mounting location for the joystick. RMB 1880F/2080F 08/22 Assembly Section 3-21 © 2022 Alamo Group Inc.

- Page 126 Care must be taken to avoid any movement of the levers when the machine is not being op- erated. Ensure arm sets are lowered fully to the ground when the machine is parked up or not in use. RMB 1880F/2080F 08/22 Assembly Section 3-22 © 2022 Alamo Group Inc.

- Page 127 From the tractor cab, release the latch catches by pulling their cords. Operate the draft links to lower the machine to the ground. Check that PTO is fully engaged. RMB 1880F/2080F 08/22 Assembly Section 3-23 © 2022 Alamo Group Inc.

- Page 128 Disconnect draft links, PTO shaft and remove the control unit from the tractor cab. Store electric control units in a warm, dry and clean environment. Carefully drive tractor clear of the machine. Replace check chain/stabilizer bars. The axle plates can remain permanently in position. RMB 1880F/2080F 08/22 Assembly Section 3-24 © 2022 Alamo Group Inc.

- Page 129 Inspect Hydraulic hoses and connection for leaks and damage and that all guards are in place and good condition. RMB 1880F/2080F 08/22 Assembly Section 3-25 © 2022 Alamo Group Inc.

- Page 131 OPERATION SECTION Operation Section 4-1 © 2022 Alamo Group Inc.

- Page 132 BUSH HOG RMB 1880F & 2080F BOOM MOWER OPERATING INSTRUCTIONS Bush Hog Boom mowers are manufactured with quality material by skilled workers. These mowers are designed for cutting grass and small weeds. The mower is equipped with protective deflectors to prevent objects being thrown from the mower by the blades.

- Page 133 Controls Evolution Controls Two-Way Rotor Engagement (Joystick/Keypad Combination) - Electric Control (ERC) Machine Equipment Safety Breakaway - Hydraulic Standard Standard Road Light Kit Standard Standard Power Slew Standard Standard RMB 1880F/2080F 08/22 Operation Section 4-3 © 2022 Alamo Group Inc.

- Page 134 Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. (SG-27) str RMB 1880F/2080F 08/22 Operation Section 4-4 © 2022 Alamo Group Inc.

- Page 135 Never operate the Tractor and Mower Unit without an OPS (Operators Protective Structure) or Cab to prevent injury from objects thrown from ground or from overhead trimming. Stop mowing if workers or passersby are within 300 feet. (SBM-9str) RMB 1880F/2080F 08/22 Operation Section 4-5 © 2022 Alamo Group Inc.

- Page 136 Never operate the tractor PTO with the PTO master shield missing or in the raised position. OPS-U- 0004str RMB 1880F/2080F 08/22 Operation Section 4-6 © 2022 Alamo Group Inc.

- Page 137 3.7 3-Point Hitch RMB 1880F and RMB2080F boom mowers can attach to tractors with a CAT II or III hitch. Refer to the tractor operator’s manual for the category of the tractor used.

- Page 138 Use all handrails and steps for support and never rush or jump off the tractor. OPS-U- 0009 str RMB 1880F/2080F 08/22 Operation Section 4-8 © 2022 Alamo Group Inc.

- Page 139 Start tractor only when properly seated in the Tractor seat. Starting a tractor in gear can result in death or serious injury. Read the Tractor operators manual for proper starting instructions. (SG-13) str RMB 1880F/2080F 08/22 Operation Section 4-9 © 2022 Alamo Group Inc.

- Page 140 Engine coolant level and condition • Power brake fluid level • Power steering fluid level • Fuel condition and level • Sufficient lubrication at all lube points • Air filter condition OPS-U-0030 str RMB 1880F/2080F 08/22 Operation Section 4-10 © 2022 Alamo Group Inc.

- Page 141 Maintain these important safety features on the mower in good condition to ensure the information is available to the operator at all times. KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement and possible death or serious injury. (SG-24)str RMB 1880F/2080F 08/22 Operation Section 4-11 © 2022 Alamo Group Inc.

- Page 142 Use a piece of heavy paper or cardboard to check for hydraulic oil leaks. • Inspect the condition of the valve weldment. • Ensure fitting is properly connected. • Inspect condition of nylon bushings. OPS-B- 0023_J str RMB 1880F/2080F 08/22 Operation Section 4-12 © 2022 Alamo Group Inc.

- Page 143 Relieve hydraulic pressure before performing maintenance or repairs. Use gloves and eye protection when servicing hot components. Contact with a hot surface or fluid can cause serious injury from burns or scalding. (SG-34str) RMB 1880F/2080F 08/22 Operation Section 4-13 © 2022 Alamo Group Inc.

- Page 144 • Remove any grass or other debris which may be wrapped around the cuttershafts ends. • Inspect the condition of deck skid shoes and hardware. OPS-B- 0026_C str RMB 1880F/2080F 08/22 Operation Section 4-14 © 2022 Alamo Group Inc.

- Page 145 All safety devices should be inspected carefully at least daily for missing or broken components. Missing, broken, or worn items must be replaced at once to reduce the possibility of injury or death from thrown objects, entanglement, or blade contact. (SSM- 07str) RMB 1880F/2080F 08/22 Operation Section 4-15 © 2022 Alamo Group Inc.

- Page 146 The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature: ____________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT RMB 1880F/2080F 08/22 Operation Section 4-16 © 2022 Alamo Group Inc.

- Page 147 OPERATION BUSH HOG BOOM MOWER PRE-OPERATION INSPECTION IMPORTANT: Boom ID# ________________________ Scan this QR Make:____________________________ Code for an electronic copy of Date: ____________________________ this inspection Shaft: ____________________________ sheet. Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged.

- Page 148 OPERATION 7.MACHINE CONTROLS - EVOLUTION RMB 1880F/2080F 08/22 Operation Section 4-18 © 2022 Alamo Group Inc.

- Page 149 OPERATION 7.1 Arm Operation Controls RMB 1880F/2080F 08/22 Operation Section 4-19 © 2022 Alamo Group Inc.

- Page 150 OPERATION 7.2 Keypad Control Buttons RMB 1880F/2080F 08/22 Operation Section 4-20 © 2022 Alamo Group Inc.

- Page 151 OPERATION RMB 1880F/2080F 08/22 Operation Section 4-21 © 2022 Alamo Group Inc.

- Page 152 OPERATION 7.3 Rotor Operation RMB 1880F/2080F 08/22 Operation Section 4-22 © 2022 Alamo Group Inc.

- Page 153 OPERATION 7.4 Temperature Compensation - Selection & Calibration RMB 1880F/2080F 08/22 Operation Section 4-23 © 2022 Alamo Group Inc.

- Page 154 OPERATION 7.5 Bang-Bang / PWM Mode Selection - Slew & Tele Outputs RMB 1880F/2080F 08/22 Operation Section 4-24 © 2022 Alamo Group Inc.

- Page 155 OPERATION 7.6 Control Unit Calibration RMB 1880F/2080F 08/22 Operation Section 4-25 © 2022 Alamo Group Inc.

- Page 156 OPERATION 7.7 Error/Fault Reporting RMB 1880F/2080F 08/22 Operation Section 4-26 © 2022 Alamo Group Inc.

- Page 157 Extra care must be taken when working in 'SLEW’ mode with the reach fully in – IT IS POS- SIBLE FOR THE FLAILHEAD TO HIT THE TRACTOR OR MACHINE FRAME. RMB 1880F/2080F 08/22 Operation Section 4-27 © 2022 Alamo Group Inc.

- Page 158 Extra care must be taken when working in 'SLEW’ mode with the reach fully in – IT IS POSSIBLE FOR THE FLAILHEAD TO HIT THE TRACTOR OR MACHINE FRAME. RMB 1880F/2080F 08/22 Operation Section 4-28 © 2022 Alamo Group Inc.

- Page 159 Machine and/or tractor damage can easily occur if care is not taken. RMB 1880F/2080F 08/22 Operation Section 4-29 © 2022 Alamo Group Inc.

- Page 160 Too fast a speed will be indicated by over frequent operation of the breakaway system, a fall off in tractor engine revs and a poor finish to the work leaving ragged uncut tufts and poorly mulched cuttings. RMB 1880F/2080F 08/22 Operation Section 4-30...

- Page 161 Cut the side and bottom of the field side first. This leaves the maximum thickness of hedge on the road side to prevent the possibility of any debris being thrown through the hedge into the path of oncoming vehicles. RMB 1880F/2080F 08/22 Operation Section 4-31 © 2022 Alamo Group Inc.

- Page 162 OPERATION Cut the side and bottom of the road side. Top cut the hedge to the height required. RMB 1880F/2080F 08/22 Operation Section 4-32 © 2022 Alamo Group Inc.

- Page 163 Place the tractor shift lever into a low range or parking gear to prevent the tractor from rolling. Never dismount a Tractor that is moving or while the engine is running. Operate the Tractor controls from the tractor seat only. (SG-9)str RMB 1880F/2080F 08/22 Operation Section 4-33 © 2022 Alamo Group Inc.

- Page 164 When mowing grass always cut in the uphill direction with front hood fitted and roller Never operate the machine with the Flaill positioned below cutting height of the flails. Head Roller removed. RMB 1880F/2080F 08/22 Operation Section 4-34 © 2022 Alamo Group Inc.

- Page 165 When operating in traffic, always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. OPS-U- 0013 str RMB 1880F/2080F 08/22 Operation Section 4-35 © 2022 Alamo Group Inc.

- Page 166 Never allow the mower head or boom within 10 feet of any power line. When working close to overhead power lines consult your electric company for a safe code of operation. (SBM-7W)str RMB 1880F/2080F 08/22 Operation Section 4-36 © 2022 Alamo Group Inc.

- Page 167 The seat belt is your best protection from falling off the tractor and the ROPS provides protection from being crushed during a tractor roll-over. OPS-R-0023_A str RMB 1880F/2080F 08/22 Operation Section 4-37 © 2022 Alamo Group Inc.

- Page 168 Do not put hands or feet under mower decks. Blade Contact can result in death or serious injury. Stay away until all motion has stopped and the decks are securely blocked up. (SGM-09) str RMB 1880F/2080F 08/22 Operation Section 4-38 © 2022 Alamo Group Inc.

- Page 169 300 feet. Debris tends to fly out at great speed and can injure or even cause death. RMB 1880F/2080F 08/22 Operation Section 4-39 © 2022 Alamo Group Inc.

- Page 170 The mounting bracket is pivoted to permit the unit deviation from the horizontal by ±4°; this allows the machine to follow the contours of the terrain on ground cutting work, thus providing a cleaner finish. RMB 1880F/2080F 08/22 Operation Section 4-40...

- Page 171 Store the unit in a clean and dry location. • Use spray touch-up enamel where necessary on bare metal surfaces to prevent rust and to maintain the appearance of the mower. OPS-B- 0012_H str RMB 1880F/2080F 08/22 Operation Section 4-41 © 2022 Alamo Group Inc.

- Page 172 Ensure that the “LIFT” and “ANGLE FLOAT” are switched “OFF”. • Select “SLEW” mode on the control assembly. • Operate “SLEW IN” function to bring the arms into position directly behind the tractor. RMB 1880F/2080F 08/22 Operation Section 4-42 © 2022 Alamo Group Inc.

- Page 173 • Close lift ram taps. • Lock slew. • Disengage PTO shaft. • Ensure power to the control unit is switched off. RMB 1880F/2080F 08/22 Operation Section 4-43 © 2022 Alamo Group Inc.

- Page 174 During transport the 'SLEW’ mode must ALWAYS be selected on the control assembly. RMB 1880F/2080F 08/22 Operation Section 4-44 © 2022 Alamo Group Inc.

- Page 175 Where fitted Slew and Lift Locks must be in the closed/locked position at all times during ma- chine transportation and storage - open/unlock only for work. RMB 1880F/2080F 08/22 Operation Section 4-45 © 2022 Alamo Group Inc.

- Page 176 On machines equipped with multi-hole stabilizers it is vital that the stabilizer position pin is always removed for machine transport and only fitted for work. Failure to observe this can result in serious damage to machine and/or tractor components. RMB 1880F/2080F 08/22 Operation Section 4-46 © 2022 Alamo Group Inc.

- Page 177 If contact is made never continue to power the machine against the stop as this will risk damage to the lift ram and/or associated components. RMB 1880F/2080F 08/22 Operation Section 4-47 © 2022 Alamo Group Inc.

- Page 178 NOTE: On machines with proportional controls, any operation of the angle float thumbwheel will override and de-activate the automatic angle float function. On release of the thumbwheel it will revert back to automatic angle float RMB 1880F/2080F 08/22 Operation Section 4-48 © 2022 Alamo Group Inc.

- Page 179 Machines with 14 core looms, use connection 10 and common connection 11. Machines with 19 core looms, use connection 15 and common connection 16. No-EDS proportional machines use, connections LF and C. RMB 1880F/2080F 08/22 Operation Section 4-49 © 2022 Alamo Group Inc.

- Page 180 During this period check for tightness of nuts and bolts every hour, re-tightening as and when required. First Day Use - Check tightness of nuts and bolts hourly RMB 1880F/2080F 08/22 Operation Section 4-50 © 2022 Alamo Group Inc.

- Page 181 All operators should perform a risk assessment before operating the machine with 32’ 8”(10m) horizontal distance of any OHPLs. See following page for details. RMB 1880F/2080F 08/22 Operation Section 4-51 © 2022 Alamo Group Inc.

- Page 182 OPERATION RMB 1880F/2080F 08/22 Operation Section 4-52 © 2022 Alamo Group Inc.

- Page 183 Keep upright and away. • Get the electricity company to disconnect the supply. Even if the line appears dead, do not touch it. Auto- matic switching may reconnect the power. RMB 1880F/2080F 08/22 Operation Section 4-53 © 2022 Alamo Group Inc.

- Page 184 Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible. When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. (SG-6)str RMB 1880F/2080F 08/22 Operation Section 4-54 © 2022 Alamo Group Inc.

- Page 185 Use caution and reduce speed if other vehicles or pedestrians are in the area. OPS-B- 0016str RMB 1880F/2080F 08/22 Operation Section 4-55 © 2022 Alamo Group Inc.

- Page 186 Contact with side or overhead structures or power lines can cause property damage or serious injury or death. If necessary lower boom to reduce height and/or remove mowing head to reduce width to the legal limits (SBM-8)str RMB 1880F/2080F 08/22 Operation Section 4-56 © 2022 Alamo Group Inc.

- Page 187 NOTE: Always transport per your State and Federal law regulations for tie down requirements. OPS-U- 0026_TKstr RMB 1880F/2080F 08/22 Operation Section 4-57 © 2022 Alamo Group Inc.

- Page 188 May be root cause of any internal leakage. Test oil and replace as required. Related to issues described in previous Review previous section. section. Boom moves under its own power. RMB 1880F/2080F 08/22 Operation Section 4-58 © 2022 Alamo Group Inc.

- Page 189 Faulty pump or pump drive. Check or test then replace or repair as required. Work port reliefs set too low. Test relief pressure and replace with proper work port relief valve. RMB 1880F/2080F 08/22 Operation Section 4-59 © 2022 Alamo Group Inc.

- Page 190 Excessive ground speed, overload or impact with solid objects. Vibration. Blades or blade bar bent, or blade missing. Poor or missing welds. Manufacturing defect. Mowing over sand or rocks. Operator training. RMB 1880F/2080F 08/22 Operation Section 4-60 © 2022 Alamo Group Inc.

- Page 191 Wrong plug installed (Maverick and Machete). Timbercat harness plug used in place of other mower plug. Reconnect with proper plug. Spindle locked up. Check by spinning blades. See section on spindle failures RMB 1880F/2080F 08/22 Operation Section 4-61 © 2022 Alamo Group Inc.

- Page 192 Motor Runs Too Engine RPM too slow. Tractor must be operated at the 540 PTO Slow (or Slows speed as indicated on the tachometer. Down Under Load) RMB 1880F/2080F 08/22 Operation Section 4-62 © 2022 Alamo Group Inc.

- Page 193 Contaminants in the system will damage the components. Repair or replace the affected components, then flush and refill with clean oil. Inspect the tank for debris. Defective pump. Confirm defect with customer service and replace. RMB 1880F/2080F 08/22 Operation Section 4-63 © 2022 Alamo Group Inc.

- Page 194 Installing the incorrect bolts (too long) for the blade carrier will allow the bolts to contact the lower bearing and will lock up the spindle. Install the correct bolts. RMB 1880F/2080F 08/22 Operation Section 4-64 © 2022 Alamo Group Inc.

- Page 195 Battery failure. Test the battery and replace per the tractor manufacturer’s recommendation. Tractor issues. Follow tractor manufacturer recommendations for troubleshooting electrical problems with the tractor. RMB 1880F/2080F 08/22 Operation Section 4-65 © 2022 Alamo Group Inc.

- Page 197 MAINTENANCE SECTION Maintenance Section 5-1 © 2022 Alamo Group Inc.

- Page 198 DO NOT modify or alter implement, functions or components. • DO NOT WELD or repair rotating mower components. These may cause vibrations and component failures being thrown from mower. PN HMBM-01 RMB 1880F/2080F 08/22 Maintenance Section 5-2 © 2022 Alamo Group Inc.

- Page 199 Skirts and Skid Shoes in place and in good condition. • REPLACE any missing, broken or worn safety shields, guards and safety devices. Cancer and Reproductive Harm www.P65Warnings.ca.gov. PN HMBM-01 (2) str RMB 1880F/2080F 08/22 Maintenance Section 5-3 © 2022 Alamo Group Inc.

- Page 200 These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce mower performance, void warranties, and present a safety hazard. Use genuine Bush Hog mower parts for economy and safety.

- Page 201 The unit is best cleaned using a high pressure air line that will clear blocked areas without risk of damage to the matrix. RMB 1880F/2080F 08/22 Maintenance Section 5-5 © 2022 Alamo Group Inc.

- Page 202 Safety Manual for more information on the safe use of a driveline during normal operation and maintenance. Or type in your internet browser the following web address: www.algqr.com/dme Ops-0009-MISC str RMB 1880F/2080F 08/22 Maintenance Section 5-6 © 2022 Alamo Group Inc.

- Page 203 Replace gearbox oil after an initial 50 hours of use and thereafter at annual or 500 hour intervals; whichever occurs earliest. Gearbox Capacity: 0.6 Liter SAE75W90 Fully Synthetic which meets the following minimum requirements: Viscosity at 104ºF (40ºC), 100.0 min. Viscosity at 212ºF (100ºC), 17.2 min. RMB 1880F/2080F 08/22 Maintenance Section 5-7 © 2022 Alamo Group Inc.

- Page 204 To reduce the risk of pump cavitation it is advisable to replace the 10 micron absolute tank breather on an annual basis under normal working conditions. For machines operating in dry dusty environments it is recommended that replacement be increased to every 6 months. RMB 1880F/2080F 08/22 Maintenance Section 5-8 © 2022 Alamo Group Inc.

- Page 205 Millmax 68 Millmax HV 46 Millmax HV 68 MORRIS Liquimatic 5 Liquimatic 6 Liquimatic HC 46 Liquimatic HC 68 Triad 46 Triad 68 TOTAL Equivis ZS 46 Equivis ZS 68 RMB 1880F/2080F 08/22 Maintenance Section 5-9 © 2022 Alamo Group Inc.

- Page 206 Soft Seal hose connections are capable of holding pressure when the nut is only ‘finger tight’. It is therefore recommended that when dismantling, the hose be manually flexed to relieve any residual pressure with the retaining nut slackened prior to complete disassembly. RMB 1880F/2080F 08/22 Maintenance Section 5-10 © 2022 Alamo Group Inc.

- Page 207 Slide the shaft shield back into place after lubrication ensuring the clasps relocate correctly in the fixing ring. Always fit torque chains to the shields to stop them from rotating with the shaft during operation RMB 1880F/2080F 08/22 Maintenance Section 5-11...

- Page 208 Removal of the tele ram (piston rod end) from the tele dipper arm. • Release of the pusher plates and withdrawal of the tele dipper arm from its socket. RMB 1880F/2080F 08/22 Maintenance Section 5-12 © 2022 Alamo Group Inc.

- Page 209 Assemble the second set of nuts on the studs and evenly tighten them against the first set to torque setting of 36.88 ft-lb (50 Nm). RMB 1880F/2080F 08/22 Maintenance Section 5-13 © 2022 Alamo Group Inc.

- Page 210 The tele arm should now be extended out to its furthest point and a coating of good quality agri-grease applied to its sliding surfaces. Re-attach all components previously removed to complete the job. RMB 1880F/2080F 08/22 Maintenance Section 5-14 © 2022 Alamo Group Inc.

- Page 211 Also remember that any other protectant must be compatible with hydraulic fluid. Bush Hog is not responsible for rust or pitting of the cylinder rod due to weather exposure or impacts from normal operation or mounting. If hydraulic cylinders and or the cylinder rods are damaged as a result of the rods rusting or pitting, the hydraulic cylinders and rods will not be covered under warranty by Bush Hog.

- Page 212 Identify the source of the leak, and resolve the issue. Upon completion of the required repairs, return to Step # 16 to recheck the cylinder for proper operation. RMB 1880F/2080F 08/22 Maintenance Section 5-16 © 2022 Alamo Group Inc.

- Page 213 NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads. RMB 1880F/2080F 08/22 Maintenance Section 5-17 © 2022 Alamo Group Inc.

- Page 214 MAINTENANCE RMB 1880F/2080F 08/22 Maintenance Section 5-18 © 2022 Alamo Group Inc.

- Page 215 4. Wear protective gear when sharpening flails. 5. Ensure that the bearing housings and hydraulic mounting nuts and bolts are kept tight. They should be checked during servicing. RMB 1880F/2080F 08/22 Maintenance Section 5-19 © 2022 Alamo Group Inc.

- Page 216 Flail rotor. Always replace blades as complete sets. Use only genuine Bush Hog replacement blades and fasteners. Other blades and fasteners may not meet the Bush Hog requirements and could fail during operation resulting in part being thrown out from under the mower.

- Page 217 D-Ring so that the cotter pin is on the opposite side of the D-Ring. This will prevent the next set of blades from swinging back and hitting the cotter pin. OPS-U-0045 str RMB 1880F/2080F 08/22 Maintenance Section 5-21 © 2022 Alamo Group Inc.

- Page 218 Use only genuine Bush Hog replacement blades, blade bolts and fasteners. Other blades and bolts may not meet the requirements of Bush Hog and fail during operation resulting in part failing and being thrown out from under the mower.

- Page 219 Connect the blue hose connection only to the blue fitting. The blade rotation on the leading edge of the mower should discharge the cut material away from the tractor and operator. RMB 1880F/2080F 08/22 Maintenance Section 5-23 © 2022 Alamo Group Inc.

- Page 220 If this occurs discontinue mowing immediately and reverse the direction of the motor rotation by correctly installing the motor pressure and return hoses. Contact your dealer or Bush Hog for specific information on the hose routing. RMB 1880F/2080F 08/22 Maintenance Section 5-24...

- Page 221 MAINTENANCE HARDWARE Most nuts and bolts will stay tight and therefore need only periodic checking. However, the following nuts and bolts are extremely important and should receive special attention: RMB 1880F/2080F 08/22 Maintenance Section 5-25 © 2022 Alamo Group Inc.

Need help?

Do you have a question about the RMB 1880F and is the answer not in the manual?

Questions and answers