Subscribe to Our Youtube Channel

Summary of Contents for Ditch Witch SK3000

- Page 1 SK3000 Yanmar® 4TNV86CT Operator’s Manual Issue 3.0 053-3198 CMW® Original Instruction...

-

Page 2: Table Of Contents

SK3000 Operator’s Manual Overview - 1 Overview Chapter Contents Serial Number Location ..... 2 Intended Use ......3 Equipment Modification . -

Page 3: Serial Number Location

SK3000 Operator’s Manual Overview - 2 Serial Number Location Serial Number Location Record serial number and date of purchase in spaces provided. Serial number is located as shown. t62om001w19.eps Item Date of manufacture Date of purchase Machine serial number... -

Page 4: Intended Use

This machine is intended for operation only according to the instructions in this manual. Operate machine in ambient temperatures from 10° to 115°F (-12° to 46°C). Contact your Ditch Witch® dealer for provisions required for operating in extreme temperatures. Use in any other way is considered contrary to the intended use. -

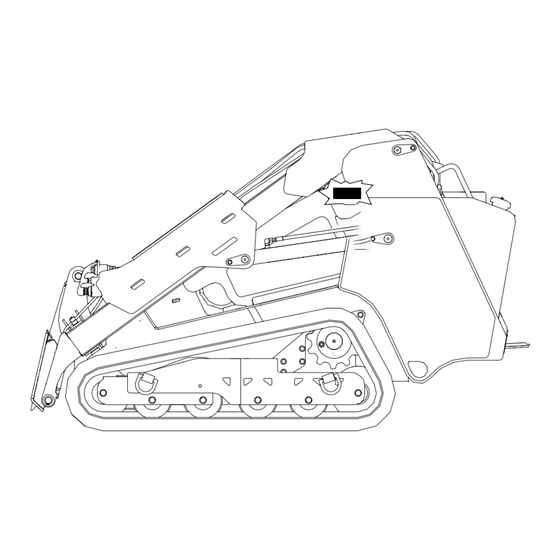

Page 5: Machine Components

SK3000 Operator’s Manual Overview - 4 Machine Components Machine Components t62om002w19.eps 1. Operator station platform 4. Lift arms 2. Tracks 5. Attachment plate 3. Engine compartment... -

Page 6: Operator Orientation

SK3000 Operator’s Manual Overview - 5 Operator Orientation Operator Orientation IMPORTANT: Top view of machine is shown. 1. Front 2. Right side 3. Rear 4. Left side t62om003w19.eps Operating Area IMPORTANT: Top view of machine is shown. Operator should stand only in the location shown. -

Page 7: About This Manual

SK3000 Operator’s Manual Overview - 6 About This Manual About This Manual This manual contains information for the proper use of this machine. Cross references such as “See page 50” will direct you to detailed procedures. Bulleted Lists Bulleted lists provide helpful or important information or contain procedures that do not have to be performed in a specific order. -

Page 8: Foreword

If you sell your equipment, be sure to give this manual to the new owner. If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a dealer, visit our website at www.ditchwitch.com or write to the following address: The Charles Machine Works, Inc. - Page 9 Part number 053-3198 Copyright 2019, 2020, 2021, 2023 by The Charles Machine Works, Inc. and Ditch Witch are registered trademarks of The Charles Machine Works, Inc. This product and its use may be covered by one or more patents at http://patents.charlesmachine.works.

- Page 10 SK3000 Operator’s Manual Contents - 9 Contents Overview Machine serial number, information about the type of work this machine is designed to perform, basic machine components, and how to use this manual Foreword Part number, revision level, and publication date of this manual, and factory contact...

- Page 11 SK3000 Operator’s Manual Contents - 10 Support The warranty policy for this machine and procedures for obtaining warranty consideration and training...

-

Page 12: Safety

SK3000 Operator’s Manual Safety - 11 Safety Chapter Contents For additional precautions, see “Prepare” chapter. Safety Alert Classification ....12 Guidelines ....... 13 Emergency Procedures . -

Page 13: Safety Alert Classification

SK3000 Operator’s Manual Safety - 12 Safety Alert Classifications Safety Alert Classifications These classifications and the icons defined on the following pages work together to alert you to situations which could be harmful to you, jobsite bystanders or your equipment. When you see these words and icons in the book or on the machine, carefully read and follow all instructions. -

Page 14: Guidelines

Mark jobsite clearly and keep spectators away. • Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all personnel before work begins. Safety videos are available from your Ditch Witch dealer or at www.ditchwitch.com/safety. Safety Data Sheets (SDS) are available at www.ditchwitch.com/support. •... -

Page 15: Emergency Procedures

SK3000 Operator’s Manual Safety - 14 Emergency Procedures • Contact your Ditch Witch dealer if you have any questions about operation, maintenance, or equipment use. • Complete the equipment checklist located at www.ditchwitch.com/safety. Emergency Procedures Underground utilities. Contact can cause death or serious injury. -

Page 16: If An Electric Line Is Damaged

SK3000 Operator’s Manual Safety - 15 Emergency Procedures If an Electric Line is Damaged If you suspect an electric line has been damaged, DO NOT MOVE. Take the following actions. The order and degree of action will depend on the situation. -

Page 17: If A Fiber Optic Cable Is Damaged

SK3000 Operator’s Manual Safety - 16 Emergency Procedures If a Fiber Optic Cable is Damaged Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur. Contact utility company. If Machine Catches on Fire Perform emergency shutdown procedure and then take the following actions. The order and degree of action will depend on the situation. -

Page 18: Machine Safety Alerts

SK3000 Operator’s Manual Safety - 17 Machine Safety Alerts Machine Safety Alerts Underground utilities. Contact can cause death or serious injury. Locate and verify underground utilities before digging or drilling. High noise levels. Exposure can cause hearing loss. Wear hearing protection. - Page 19 SK3000 Operator’s Manual Safety - 18 Machine Safety Alerts Lift point. See Transport chapter for more information. Misuse of machine can cause death or serious injury. Read and understand operator’s manual and all other safety instructions before use. Know how to use all controls.

-

Page 20: Prepare

SK3000 Operator’s Manual Prepare - 19 Prepare Chapter Contents See “Safety” for additional precautions. Wear proper personal protective equipment. Prepare Jobsite ......20 •... -

Page 21: Prepare Jobsite

SK3000 Operator’s Manual Prepare - 20 Prepare Jobsite Prepare Jobsite Underground utilities. Contact can cause death or serious injury. Locate and verify underground utilities before digging or drilling. To help avoid injury: • Expose lines by careful hand digging or soft excavation before operating equipment. Use appropriate equipment and procedures for exposing utility lines. -

Page 22: Identify Hazards

SK3000 Operator’s Manual Prepare - 21 Prepare Jobsite Identify Hazards Inspect jobsite before transporting equipment. Check for the following: • overall grade or slope • changes in elevation such as hills or open trenches • obstacles such as buildings, railroad crossings, or streams •... -

Page 23: Locate Utilities

SK3000 Operator’s Manual Prepare - 22 Prepare Jobsite Locate Utilities Notify One-Call Services Mark proposed path with white paint and have underground utilities located before working. • In the US or Canada, call 811 (US) or 888-258-0808 (US and Canada). Also contact any local utilities that do not participate in the One-Call service. -

Page 24: Classify Jobsite

SK3000 Operator’s Manual Prepare - 23 Prepare Jobsite Classify Jobsite Select a Classification Jobsites are classified according to underground hazards present, not by line being installed. Jobsite may have more than one classification. If working . . . then classify jobsite as . . . -

Page 25: Arrange For Traffic Control

SK3000 Operator’s Manual Prepare - 24 Prepare Jobsite Crystalline Dust Jobsite Precautions Silica dust. Exposure can cause lung disease or cancer. Use breathing protection. Crystalline silica dust is a naturally occurring substance found in soil, sand, concrete, granite, and quartz. -

Page 26: Prepare Operator

Check that you will have access to a telephone. • Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all personnel before work begins. Safety videos are available from your Ditch Witch dealer or at www.ditchwitch.com/safe. Safety Data Sheets (SDS) are available at www.ditchwitch.com/support. •... -

Page 27: Prepare Equipment

SK3000 Operator’s Manual Prepare - 26 Prepare Equipment Prepare Equipment Check Supplies • fuel • diesel exhaust fluid (DEF), if needed • keys • marking flags or paint • notepad and pencil • spare fuses • lubricants Check Equipment Fluid Levels •... -

Page 28: Assemble Accessories

It should meet legal and regulatory requirements. Connect Attachment NOTICE: Use only Ditch Witch-approved attachments. Attachments can change the stability and operating characteristics of the machine. See attachment operation manual for instructions regarding proper operation of attachments. - Page 29 SK3000 Operator’s Manual Prepare - 28 Prepare Equipment 7. Ensure pins (shown) are engaged by rotating attachment down. t62om007w19.eps...

- Page 30 SK3000 Operator’s Manual Prepare - 29 Prepare Equipment Hydraulic Connection If attachment requires hydraulic power for operation, connect hydraulic hoses. Pressurized fluid or air. Injection can cause death or serious injury. Refer to operator’s manual for correct use. To help avoid injury: •...

- Page 31 SK3000 Operator’s Manual Prepare - 30 Prepare Equipment Electrical Connection If attachment requires electrical power for operation, connect electrical connector from attachment to machine where shown. Ref. Connection Live always Momentary switch Momentary switch Momentary switch Ground t62om008w19.eps Switch on/off Live always t62om042w19.eps...

-

Page 32: Controls

SK3000 Operator’s Manual Controls - 31 Controls Chapter Contents Battery Disconnect ......32 Display ........33 Gauges and Indicators . -

Page 33: Battery Disconnect

SK3000 Operator’s Manual Controls - 32 Battery Disconnect Battery Disconnect t62om012w19.eps Item Description IMPORTANT Battery disconnect switch To disconnect, move left. NOTICE: To connect, move right. • Do not disconnect with engine running. • To avoid equipment damage, wait two minutes after turning engine off before disconnecting battery. -

Page 34: Display

SK3000 Operator’s Manual Controls - 33 Display Display Gauges and Indicators t62om001w21.eps 1. Real time clock 9. Ride control/Self-level indicator 2. Engine coolant/oil pressure indicator 10. Engine warning/stop indicator 3. Engine coolant temperature gauge 11. Operator presence indicator 4. Voltmeter 12. - Page 35 SK3000 Operator’s Manual Controls - 34 Display Item Description IMPORTANT 3. Engine coolant Displays engine temperature gauge coolant temperature. 4. Voltmeter Displays system voltage. 5. Engine load gauge Displays engine load. 6. Hydraulic fluid Lights when hydraulic temperature indicator fluid temperature is high.

- Page 36 SK3000 Operator’s Manual Controls - 35 Display Item Description IMPORTANT 15. Exhaust cleaning Lights when operator NOTICE: Failure to complete an disabled indicator has disabled exhaust exhaust cleaning when required can cleaning. cause engine damage.

- Page 37 SK3000 Operator’s Manual Controls - 36 Display Gauges and Indicators t62om002w21.eps 1. Tachometer setpoint indicator 5. Spool mode indicator 2. Tachometer 6. Fuel gauge 3. Throttle mode indicator 7. Ground drive speed 4. Attachment lock/Flow selection indicator 8. Hourmeter Item...

- Page 38 SK3000 Operator’s Manual Controls - 37 Display Item Description IMPORTANT 4. Attachment lock/Flow Lights when auxiliary Only auxiliary A (high/low) circuit is selection indicator function is not locked. lockable. Lights when auxiliary See “Auxiliary lock switch” on function is locked.

- Page 39 SK3000 Operator’s Manual Controls - 38 Display Soft Keys t62om003w21.eps 1. Previous key 5. Throttle up control 2. Next key 6. Throttle down control 3. Autothrottle key 7. Service reminder/spool mode selector key 4. Hide/Recall key 8. Main menu key...

- Page 40 SK3000 Operator’s Manual Controls - 39 Display Item Description IMPORTANT 5. Throttle up control To increase engine speed when in display throttle mode, press. 6. Throttle down control To decrease engine speed when in display throttle mode, press. 7. Spool mode select/...

- Page 41 Throttle mode and ride control speed press. can be adjusted in this screen. 4. Diagnostics key To display engine and For use only by qualified Ditch Witch controller diagnostic technicians. codes, press. If diagnostic codes are displayed, contact your Ditch Witch dealer.

- Page 42 SK3000 Operator’s Manual Controls - 41 Display Item Description IMPORTANT 6. User settings menu key To customize settings, See “User Settings Menu” on page 44. press. 7. Service menu key To display service Total hours for engine, pump and menu, press.

- Page 43 SK3000 Operator’s Manual Controls - 42 Display Auxiliary Setup Menu t62om043w19.eps IMPORTANT: Use the auxiliary control menu to invert auxiliary control function and to change hydraulic fluid flow selection. Auxiliary control setup options are saved until changed. Item Description IMPORTANT 1.

- Page 44 SK3000 Operator’s Manual Controls - 43 Display Spool Mode Select Screen t62om004w21.eps Item Description IMPORTANT 1. Motor spool mode To enter motor spool In this mode: mode, press. • High/low circuit will have ramp up and ramp down. • Ramping time can be adjusted by dealer.

- Page 45 SK3000 Operator’s Manual Controls - 44 Display User Settings Menu t62om049w19.eps Item Description IMPORTANT 1. Passcode setting menu To customize passcode Only accessible when logged in as settings, press. machine owner. 2. Software version key To view software version, press.

-

Page 46: Gauges And Indicators

SK3000 Operator’s Manual Controls - 45 Gauges and Indicators Gauges and Indicators t62om014w19.eps Item Description IMPORTANT 1. Hydraulic fluid level sight Shows level of hydraulic fluid glass in tank. 2. Air filter service Indicates condition of air Replace air filter when red band on indicator filter. -

Page 47: Miscellaneous

SK3000 Operator’s Manual Controls - 46 Miscellaneous Miscellaneous t62om041w19.eps Item Description IMPORTANT 1. Accumulator manual Follow procedure below Valve must be open and ride control valve before using this knob to selected at ride control/self-level prevent trapped pressure in switch for ride control to function. -

Page 48: Operator Station Console

SK3000 Operator’s Manual Controls - 47 Operator Station Console Operator Station Console t62om015w19.eps 1. Work light switch 8. Throttle 9. Lift arm control 2. Ignition switch 3. Left track drive control/Track drive joystick* 10. Medium auxiliary control 4. Right track drive control/Track drive joystick* 11. - Page 49 SK3000 Operator’s Manual Controls - 48 Operator Station Console Item Description IMPORTANT 2. Ignition switch To activate accessories, turn If needed, follow display prompts to right. enter passcode. To start engine, turn fully right. To shut off machine, turn left.

- Page 50 SK3000 Operator’s Manual Controls - 49 Operator Station Console Item Description IMPORTANT 6. Parking brake To set, pull. To release, push. c00ic055t.eps 7. Auxiliary lock switch To lock auxiliary function, Auxiliary function must be at 80% or press. greater in either direction to be locked.

- Page 51 SK3000 Operator’s Manual Controls - 50 Operator Station Console Item Description IMPORTANT 10. Medium auxiliary To rotate attachment Use this control based on attachment control forward, move up. flow requirements. See “High/Low auxiliary control” on page 48. To stop attachment movement, move to middle.

-

Page 52: Drive

SK3000 Operator’s Manual Drive - 51 Drive Chapter Contents For additional precautions, see “Safety” and “Prepare” chapters. IMPORTANT: For more information on how to operate controls, see “Controls” chapter. Start ........52 •... -

Page 53: Start

Allow hydraulic fluid time to warm before operating in cold weather. Cold hydraulic fluid can lengthen ground drive stopping time. • For starting in extreme temperatures, contact your Ditch Witch dealer. Pre-heater. Fire or explosion can cause death or serious injury. Never use starter fluid. -

Page 54: Standard Operation

IMPORTANT: If operation becomes locked out due to too many password attempts, follow on- screen prompts and contact your Ditch Witch dealer. 5. If starting machine in normal conditions, start engine and run at low throttle under light load for at least one minute before applying heavier load. -

Page 55: Steer

SK3000 Operator’s Manual Drive - 54 Steer Steer Single Joystick Ground Drive To steer while moving forward, push joystick and then move left or right. Machine will gradually turn. To steer while moving in reverse, pull joystick and then move left or right. Machine will gradually turn. -

Page 56: Slope Guidelines

SK3000 Operator’s Manual Drive - 55 Operate Slope Guidelines Tipover. Crushing can cause death or serious injury. Follow procedure in operator’s manual. Drive cautiously. To help avoid injury: • Operate at slow speed when on rough terrain. • Avoid driving across slopes. -

Page 57: Smartthrottle

SK3000 Operator’s Manual Drive - 56 Operate SmartThrottle™ The SK3000 is equipped with two automatic throttle modes: autothrottle and platform throttle. Autothrottle IMPORTANT: • Engine coolant temperature must be at least 140°F (60°C) for autothrottle to function. • See “Autothrottle key” on page 38. -

Page 58: Reduce Track Wear

SK3000 Operator’s Manual Drive - 57 Shut Down Reduce Track Wear Rubber tracks are best suited at soil-based jobsites with minimal rocks and debris. To reduce track wear drive slowly and make wide turns. Avoid the following: • spinning tracks under heavy load •... - Page 59 SK3000 Operator’s Manual Drive - 58 Shut Down...

-

Page 60: Transport

SK3000 Operator’s Manual Transport - 59 Transport Chapter Contents For additional precautions, see “Safety” and “Prepare” chapters. IMPORTANT: For more information on how to operate controls, see “Controls” chapter. Lift ........60 •... -

Page 61: Lift

Procedure NOTICE: Do not lift machine with attachments installed. Use a equipment capable of supporting the machine’s size and weight to lift as shown. See “SK3000” on page 94 or measure and weigh equipment before lifting. t62om045w19.eps... -

Page 62: Haul

SK3000 Operator’s Manual Transport - 61 Haul Haul Misuse of machine can cause death or serious injury. Read and understand operator’s manual and all other safety instructions before use. Know how to use all controls. To help avoid injury: •... -

Page 63: Load

SK3000 Operator’s Manual Transport - 62 Haul Load Horizontal movement. Crushing can cause death or serious injury. Read and understand operator’s manual and all safety instructions before use. To help avoid injury: Start and operate only from platform. 1. Start engine. -

Page 64: Tie Down

SK3000 Operator’s Manual Transport - 63 Haul Tie Down Points Tiedown points are identified by tiedown decals. Securing to truck or trailer at other points is unsafe and can damage machinery. Procedure Loop a transport chain around each tiedown point. See chart below for correct distances between tiedown ends. -

Page 65: Unload

SK3000 Operator’s Manual Transport - 64 Retrieve Unload Horizontal movement. Crushing can cause death or serious injury. Read and understand operator’s manual and all safety instructions before use. To help avoid injury: Start and operate only from platform. 1. Prepare trailer and ramps for unloading. - Page 66 SK3000 Operator’s Manual Transport - 65 Retrieve 3. Attach chain to tow points shown facing towing vehicle. t62om050w19.eps t62om046w19.eps 4. Disconnect hoses (1, 2) and connect ends together with connector. 5. Cap ports on ground drive pump. 6. Disconnect hoses (3, 4) and connect ends together with connector.

- Page 67 SK3000 Operator’s Manual Transport - 66 Retrieve 8. If engine will start, release parking brake. If engine will not start, disconnect brake hose (shown) and connect to external power pack to provide hydraulic pressure to release parking brake. NOTICE: Do not exceed 400psi (27.6bar).

-

Page 68: Complete The Job

SK3000 Operator’s Manual Complete the Job - 67 Complete the Job Chapter Contents For additional precautions, see “Safety” and “Prepare” chapters. Rinse Equipment ......68 Disconnect Attachment . - Page 69 Ensure all tools and accessories are loaded and properly secured on trailer. Store Machine Before storing, ensure machine is rinsed, equipment is stowed, and all fluids are filled. For more information for filling fluids, see Maintenance chapter or contact your Ditch Witch dealer.

- Page 70 Lubricate machine and apply grease to unpainted surfaces. • Cover exhaust pipe. Decommission Machine Before decommissioning machine, follow local regulations for disposing of hazardous substances. For more information on draining fluids, see Maintenance chapter or contact your Ditch Witch dealer.

- Page 71 SK3000 Operator’s Manual Complete the Job - 70 Decommission Machine...

-

Page 72: Maintenance

SK3000 Operator’s Manual Maintenance - 71 Maintenance Chapter Contents For additional precautions, see “Safety” and “Prepare” chapters. Maintenance Precautions ....72 • Welding Precaution ......... 73 •... -

Page 73: Maintenance Precautions

SK3000 Operator’s Manual Maintenance - 72 Maintenance Precautions Maintenance Precautions Jobsite hazards. Exposure can cause death or serious injury. Use correct equipment and work methods. Use and maintain appropriate safety equipment. To help avoid injury: • Wear personal protective equipment including hard hat, safety eye wear, foot protection, hearing protection, and gloves (except when near rotating equipment). -

Page 74: Welding Precaution

SK3000 Operator’s Manual Maintenance - 73 Maintenance Precautions Washing Precaution NOTICE: Do not spray water onto operator’s console or electrical center in engine compartment. Water can damage electrical components. Wipe down instead. Welding Precaution NOTICE: Welding can damage electronics. •... -

Page 75: Recommended Lubricants

Proper lubrication and maintenance protects Ditch Witch equipment from damage and failure. Maintenance intervals listed are for minimum requirements. In extreme conditions, service machine more frequently. Use only genuine Ditch Witch parts, filters, approved lubricants, TJC, and approved coolants to maintain warranty. Fill to capacities listed in “SK3000” on page 94. -

Page 76: Engine Oil Temperature Chart

This machine was filled with coolant meeting ASTM D6210 before shipment from factory. Add or replace only with coolant meeting this specification. This coolant is available, pre-diluted, from your Ditch Witch dealer as part number 255-1055. -

Page 77: Approved Fuel

In certain markets, higher blends may be used if certain steps are taken. Extra attention is needed when using biodiesel, especially when operating in cold weather or storing fuel. Contact your Ditch Witch dealer or the engine manufacturer for more information. - Page 78 SK3000 Operator’s Manual Maintenance - 77 Recommended Lubricants Exhaust Cleaning This engine has a Diesel Particulate Filter (DPF) that separates soot caused by the combustion of diesel fuel from the exhaust gases exiting the engine. The DPF must be cleaned as the soot level increases.

-

Page 79: Maintenance Interval Chart

SK3000 Operator’s Manual Maintenance - 78 Maintenance Interval Chart Maintenance Interval Chart IMPORTANT: Chart indicates first instance of repeated maintenance procedures. See detailed information below. Adjust, service, or test Change, initial Lube, initial Check Change Lube Service Battery Belt, fan... -

Page 80: Procedures

SK3000 Operator’s Manual Maintenance - 79 Procedures Service Radiator/Hydraulic fluid cooler Track tension Procedures Battery Corrosive fluid. Contact can cause death or serious injury. Avoid contact. Wear appropriate gloves. See Safety Data Sheet (SDS) for more information. To help avoid injury: •... - Page 81 SK3000 Operator’s Manual Maintenance - 80 Procedures NOTICE: • Electronic components can be easily damaged by electrical surges. Jump starting can damage electronics and electrical systems, and is not recommended. Try to charge the battery instead. Use quality large diameter jumper cables capable of carrying high currents (400 amps or more). Low quality cables may not allow enough current flow to charge a dead/discharged battery.

- Page 82 SK3000 Operator’s Manual Maintenance - 81 Procedures Charge 1. Park service vehicle close to disabled equipment but do not allow vehicles to touch. 2. Set parking brake in both vehicles. 3. Turn ignition switch off in both vehicles and turn off all electrical loads.

- Page 83 SK3000 Operator’s Manual Maintenance - 82 Procedures Belt, Fan IMPORTANT: Use Gates® Krikit belt tensioning tool to check belt tension. • New belt measurement should be 187lb (85kg). • Used belt tension measurement should be 140lb (64kg). Check at 50 hours and every 250 hours thereafter.

- Page 84 SK3000 Operator’s Manual Maintenance - 83 Procedures Coolant NOTICE: See “Approved Coolant” on page 75. Check before startup and every 10 hours. Change every 1000 hours. Check Level 1. Check at overflow bottle (2). 2. Add DEAC at fill (1) as needed to keep level at halfway point on overflow bottle.

- Page 85 SK3000 Operator’s Manual Maintenance - 84 Procedures Filter, Air NOTICE: • Only open air filter housing when red band on indicator is visible. • Change the elements. Do not attempt to clean them. • Improperly installed primary element can lead to premature engine failure.

- Page 86 SK3000 Operator’s Manual Maintenance - 85 Procedures Filter, Hydraulic Fluid Change filter (shown) at 50 hours and every 250 hours thereafter. t62om027w19.eps Filter, Water Separator Check before startup and every 10 hours. Change every 500 hours. Drain as needed. Check When red floating ring is raised, drain.

- Page 87 SK3000 Operator’s Manual Maintenance - 86 Procedures Fluid Hydraulic NOTICE: Change every 250 hours if jobsite temperature exceeds 100°F (38°C) more than 50% of the time. Check before startup and every 10 hours. Change every 500 hours. Check Level 1. Check level at sight glass (2).

- Page 88 SK3000 Operator’s Manual Maintenance - 87 Procedures Fuse Box IMPORTANT: Leave cover in place unless fuses are being checked or replaced. Check fuse box cover for damage before startup. If cover is missing or damaged, replace. Hydraulic Hoses t62om053w19.eps Pressurized fluid or air. Injection can cause death or serious injury.

- Page 89 SK3000 Operator’s Manual Maintenance - 88 Procedures Intake Air Line NOTICE: Keep dust out of the intake air line to prevent damage to the engine. Check intake air line (shown) for dirt and debris every 250 hours. If clamp is loose, apply oil to threads and retighten.

- Page 90 SK3000 Operator’s Manual Maintenance - 89 Procedures Platform Switch Adjust if auxiliary controls do not operate properly when stepping on platform. If control does not stay engaged when standing on platform: 1. Loosen two screws (1). 2. Tilt switch (2) up and tighten screws.

- Page 91 SK3000 Operator’s Manual Maintenance - 90 Procedures Radiator/Hydraulic Fluid Cooler NOTICE: Radiator may need to be cleaned more frequently in dusty or grassy conditions. Check every 50 hours. Clean as needed. Check Check radiator (shown) for dirt, grass, and other debris.

- Page 92 SK3000 Operator’s Manual Maintenance - 91 Procedures Track Tension Contents under pressure. Impact can cause death or serious injury. Relieve pressure before opening. To help avoid injury: • Service track grease cylinder only while standing away from zerk. • Cover connection with heavy cloth when relieving pressure in cylinder.

- Page 93 SK3000 Operator’s Manual Maintenance - 92 Procedures...

-

Page 94: Specifications

Chapter Contents SK3000 ........94 EU Declaration of Conformity ....97... - Page 95 SK3000 Operator’s Manual Specifications - 94 SK3000 SK3000 t62om016w19.eps Dimensions Metric Hinge pin height, max 118in 2997mm Operating height, max, standard bucket 153in 3876mm Overall height of machine 65in 1641mm Overall length of loader, no attachment 107in 2713mm Overall length of machine, standard bucket...

- Page 96 SK3000 Operator’s Manual Specifications - 95 SK3000 Dimensions Metric Dump angle, standard bucket at max dump height 47° 47° Bucket width, max 72in 1829mm Bucket width, min 60in 1524mm Swing radius, max, standard bucket 76in 1938mm Swing radius, no attachment 56.5in...

- Page 97 SK3000 Operator’s Manual Specifications - 96 SK3000 Engine Metric Engine: Yanmar® 4TNV86CT, EPS Tier 4, EU Stage V Fuel Diesel Number of cylinders Displacement 2.09L 127.5in Bore 3.39in 86mm Stroke 3.5in 90mm Manufacturer’s gross power rating (per SAE J1995) 58.9hp 43.9kW...

- Page 98 SK3000 Operator’s Manual Specifications - 97 EU Declaration of Conformity EU Declaration of Conformity The Charles Machine Works Inc., PO Box 66, 1959 West Fir Avenue, Perry, Oklahoma, USA, declares that the following unit(s): Model Serial Number Description XXXXX XXXXXXXXXXXXXXXXX...

- Page 99 SK3000 Operator’s Manual Specifications - 98 UK Declaration of Conformity UK Declaration of Conformity The Charles Machine Works Inc., PO Box 66, 1959 West Fir Avenue, Perry, Oklahoma, USA, declares that the following unit(s): Model Serial Number Description XXXXX XXXXXXXXXXXXXXXXX...

- Page 100 SK3000 Operator’s Manual Specifications - 99 UK Declaration of Conformity...

- Page 101 SK3000 Operator’s Manual Specifications - 100 UK Declaration of Conformity...

- Page 102 Support Registration If your equipment was purchased through a Ditch Witch dealer, it is already registered. If you purchased from any other source, please email productsupportwarrantyadmin@ditchwitch.com or fill out the registration card located in the back of the parts manual. Registration enables you to receive updates on this equipment as well as information on new products of interest.

- Page 103 Defects will be determined by an inspection within thirty (30) days of the date of failure of the product or part by Ditch Witch Product Support (DWPS) or its authorized dealer. DWPS will provide the location of its inspection facilities or its nearest authorized dealer upon inquiry.

Need help?

Do you have a question about the SK3000 and is the answer not in the manual?

Questions and answers