Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for STAUFF SPR-PRC-MP

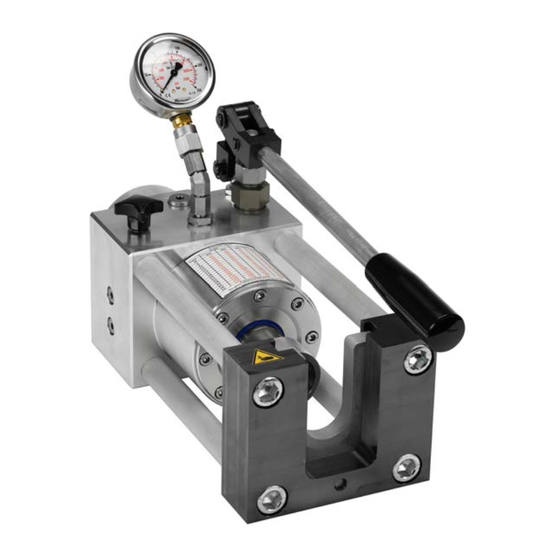

- Page 1 Instruction manual Original instructions Manual pre-assembly device for pre- assembling cutting rings SPR-PRC-MP To prevent injury and damage, read this instruction manual carefully and attentively and retain it for future reference. 08/05/2023 6010023313 Version 1...

- Page 2 Additional instructions in other languages can be downloaded from: www.stauff.com Walter Stauffenberg GmbH & Co. KG Im Ehrenfeld 4 58791 Werdohl, Germany +49 2392 916-0 sales@stauff.com www.stauff.com Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 2 / 20...

-

Page 3: Table Of Contents

Cleaning the manual pre-assembly device ......... 14 Checking and topping up the hydraulic oil ........ 15 5 Disposal .................... 16 6 EC declaration of conformity .............. 17 7 Declaration of Conformity UKCA............ 18 Keyword index .................. 19 SPR-PRC-MP www.stauff.com 3 / 20... -

Page 4: For Your Safety

The manual pre-assembly device is used for pre-assembling cutting rings from the light and heavy series onto metal tubes for outer tube diameters between 6 mm and 42 mm . A STAUFF original cutting ring FI-DS-..-W3/W5 or FI-WDDS-…-W3/W5 has to be used for this. -

Page 5: Tasks And Duties Of The Operating Company

The signal word “Caution” warns of a residual risk with CAUTION light or medium injuries. 1.5 Safety markings The following safety markings are attached in a clearly visible way and are legible: Symbol Description Place of assembly Number Warning – hand injuries Holding block SPR-PRC-MP www.stauff.com 5 / 20... -

Page 6: Personnel Qualification

• working with sharp-edged Protective gloves troubleshooting workpieces cleaning • contact with cleaning agents maintenance • contact with hydraulic oil or lubricating oil • working with hydraulic oil Eye protection troubleshooting maintenance Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 6 / 20... -

Page 7: Structure And Function

For pre-assembly, a union nut and cutting ring are placed on a tube. • Outer tube diameter: 6 to 42 mm • Union nut: FI-M • Cutting rings type FI-DS or FI-WDDS Cutting ring Union nut Tube Fig. 2: Individual parts / installed workpiece SPR-PRC-MP www.stauff.com 7 / 20... -

Page 8: Function

The type plate is located on the side of the manual pre-assembly device. Fig. 4: Type plate of the manual pre-assembly device The serial number is engraved into the housing wall below the type plate. Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 8 / 20... -

Page 9: Pressure Indicator

The pressure table shows the required pressure for each configuration. Fig. 5: Pressure gauge Tube - Ø: Outer tube diameter in mm FI-DS / FI-WDDS: Cutting ring type W3: Steel W5: Stainless steel Fig. 6: Pressure table SPR-PRC-MP www.stauff.com 9 / 20... -

Page 10: Accessories

A counter retaining plate and an assembly stud for the respective tube diameter are required as assembly accessories. Counter retaining plate Assembly stud Fig. 7: Accessories with the respective tube diameter Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 10 / 20... -

Page 11: Operation

(after multiple uses or after extended storage). This protect the assembly stud against wear. Also note the safety instructions on the oil bottle! 1 Insert the assembly stud. 2 Insert the safety clip. Fig. 8: Assembly stud on the pressure cylinder SPR-PRC-MP www.stauff.com 11 / 20... - Page 12 2 Assembly stud 3 Cutting ring 4 Union nut 5 Counter retaining plate Fig. 9: Preparation completed Fit reinforcing sleeves for thin-walled tubes in keeping with the STAUFF Product Catalogue! Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 12 / 20...

-

Page 13: Pre-Assembling The Cutting Ring

þ The pre-assembly has been completed. The assembly stud should be checked for dimensional accuracy after every 50 assembly cycles with an FI-KOL conical gauge. Worn or stretched assembly studs influence the quality of the pressed connection! SPR-PRC-MP www.stauff.com 13 / 20... -

Page 14: Maintenance And Troubleshooting

Corrosion protection Apply a light oil film as corrosion protection to the moving machine parts after removing any stubborn dirt with a cleaning agent and after an extended downtime. Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 14 / 20... -

Page 15: Checking And Topping Up The Hydraulic Oil

5. If required, top up the hydraulic oil up to the thread. 6. Close the filler screw again firmly. þ The hydraulic oil has now been topped up to the fill quantity of 0.425 l. SPR-PRC-MP www.stauff.com 15 / 20... -

Page 16: Disposal

1. Use appropriate containers to collect, store, transport and dispose of substances with water toxicity. 2. Dispose of all parts separated by materials at the appropriate disposal points. 3. Always sort by materials for recycling. Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 16 / 20... -

Page 17: Ec Declaration Of Conformity

6 EC declaration of conformity 6 EC declaration of conformity SPR-PRC-MP www.stauff.com 17 / 20... -

Page 18: Declaration Of Conformity Ukca

7 Declaration of Conformity UKCA 7 Declaration of Conformity UKCA Manual pre-assembly device for pre-assembling cutting rings www.stauff.com 18 / 20... -

Page 19: Keyword Index

Operating fluids 8 Operation 11 Personal protective equipment 6 Personnel 6 Pre-assembly 13 Preparation 11 Pressure gauge 7, 9 Pressure relief screw 7 Pressure table 7, 9 protective equipment 6 Pumping handle 7 Qualification 6 SPR-PRC-MP www.stauff.com 19 / 20... - Page 20 Walter Stauffenberg GmbH & Co. KG Im Ehrenfeld 4 58791Werdohl, Germany +49 2392 916-0 If you have any queries, thoughts or criticism about your product or this documentation, please send them to us.

Need help?

Do you have a question about the SPR-PRC-MP and is the answer not in the manual?

Questions and answers