Advertisement

Quick Links

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

GENERAL INFORMATION

1. Purge the lines of all foreign material, (welding slag, pipe scale, dirt, thread chips etc.). The installation of an

upstream strainer may be necessary in dirty systems.

2. Air should be purged from the system prior to startup to assure quiet operation and to avoid water hammer.

3. Hays PurePIC™ Pressure Independent Control Valve should be installed upwards with respect to horizontal

plane as shown under installation section. The actuator should always be coupled with the valve body. Straight

sections of pipe upstream or downstream of the Hays valve are not necessary for proper operation.

4. Hays PurePIC™ Pressure Independent Control Valve are marked with direction of flow and the range of

design flow rates that can be controlled on that specified model.

THE FLOW ARROW MUST POINT IN THE DIRECTION OF FLOW FOR PROPER OPERATION.

5. The actuator has a linear stroke and the PurePIC™ should be ordered based on design flow rate which will be

preset when shipped. During operation under modulation, the flow can be set below design flow with respect

to stroke proportional to voltage signal and new set flow rate will be maintained constant across the published

pressure differential range. See Figure 1 below for a representation of the general operation of PurePIC™

model.

6. Hays PurePIC™ Pressure Independent Control Valve are factory assembled, and individually calibrated.

When properly installed, the valves are warranted to be accurate within 10% of rated set flow rate in the field.

7. Contact Hays for part numbers, instructions, and other details.

OPERATION

1. For optimum operation, air entrainment in the system must be eliminated. The flow control valve must remain

filled with fluid. The system must be clean and free of foreign materials.

PurePIC-IOM-June2023 Rev01

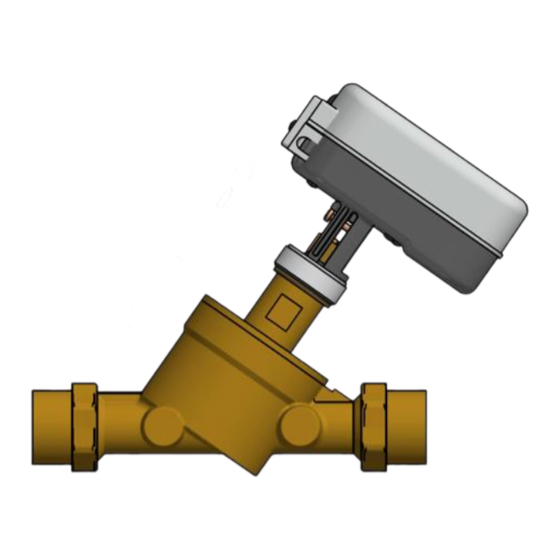

Figure 1: PurePIC® Pressure Independent Control Valve model

PurePIC™

Pressure Independent

Control Valve

Page 1 of 3

Advertisement

Summary of Contents for Hays Fluid Controls PurePIC Series

- Page 1 PurePIC™ Pressure Independent Control Valve INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS GENERAL INFORMATION 1. Purge the lines of all foreign material, (welding slag, pipe scale, dirt, thread chips etc.). The installation of an upstream strainer may be necessary in dirty systems. 2.

- Page 2 2. Hays PurePIC™ Pressure Independent Control Valve must only be used with fluids that are compatible with, Brass, and EPDM materials. The temperature during operation must be limited to the range of 32 F to 225 F. 3. The use of fluids having a specific gravity different from that of water will require adjustment. Valves specified for fluids other than water will be marked and the factory calibration will take the specific fluid’s properties into consideration.

- Page 3 O-rings that will come along with the service kit order. 4. The actuator is equipped with a cable for electric connection and does not need maintenance. LIMITED WARRANTY See Hays Fluid Controls Current Terms & Conditions for warranty information. PurePIC-IOM-June2023 Rev01 Page 3 of 3...

Need help?

Do you have a question about the PurePIC Series and is the answer not in the manual?

Questions and answers