Table of Contents

Advertisement

Quick Links

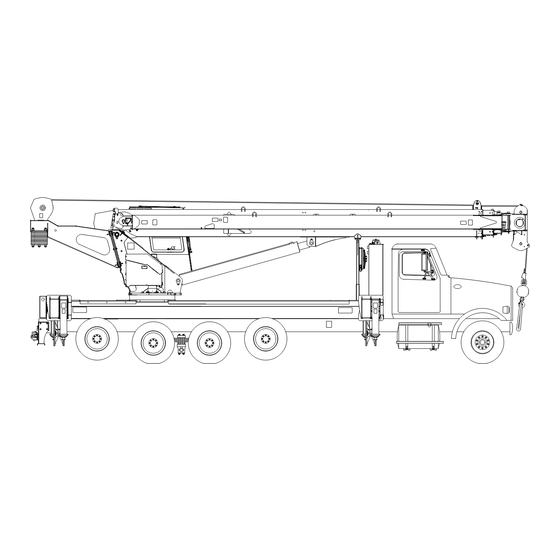

AC45 Series

Operator's Manual

www.altec.com

Altec Industries, Inc. reserves the right to improve models and change specifications without notice.

749-30188

2015

Copyright 2015 by Altec Industries, Inc.

All rights reserved. No part of this publication may be used or reproduced by any means, or stored in a

database or retrieval system, without prior written permission of the publisher. Making copies of any part

of this publication for any purpose other than personal use is a violation of United States copyright laws.

https://cranemanuals.com

Advertisement

Chapters

Table of Contents

Summary of Contents for Altec AC45 Series

- Page 1 AC45 Series Operator’s Manual www.altec.com Altec Industries, Inc. reserves the right to improve models and change specifications without notice. 749-30188 2015 Copyright 2015 by Altec Industries, Inc. All rights reserved. No part of this publication may be used or reproduced by any means, or stored in a database or retrieval system, without prior written permission of the publisher.

- Page 2 https://cranemanuals.com...

- Page 3 Safety Bulletin Electrical Hazards Always wear insulating protective equipment, use conductor cover-ups, and maintain required clear- ances when in the vicinity of energized conductors. Aerial devices and digger derricks with insulating booms can only isolate the operator from grounding through the boom and vehicle.

- Page 4 https://cranemanuals.com...

- Page 5 https://cranemanuals.com...

- Page 6 https://cranemanuals.com...

- Page 7 https://cranemanuals.com...

- Page 8 https://cranemanuals.com...

- Page 9 Preface This unit is the result of Altec’s advanced technology and quality awareness in design, engi- neering, and manufacturing. At the time of delivery from the factory, this unit met or exceeded all applicable requirements of the American National Standards Institute. All information, illustrations, and specifications contained within this manual are based on the latest product information available at the time of publication.

- Page 10 https://cranemanuals.com...

-

Page 11: Table Of Contents

Table of Contents Section 1 — Introduction About This Manual…..................... 1 Section 2 — Unit Specifications Purpose of the Unit ....................... 3 General Specifications ....................3 Component Identification ....................4 Section 3 — Safety Safety Instructions ......................5 Operator Qualifications ....................5 General Operating Information ................ - Page 12 Section 7 — Care of the Unit Hydraulic System ......................57 Structures and Mechanical Systems ................57 Appendix Glossary Shift/Monthly Inspection Checklist Wire Rope Inspection Checklist Annual Inspection Checklist Standard Hand Signals for Controlling Crane Operations Altec LMAP Operation Hirschmann Operating Console LMAP System https://cranemanuals.com...

-

Page 13: Section 1 - Introduction

Section 1 — Introduction the industry terms and phrases used in Altec manuals. About This Manual… Throughout the manual, the term unit is used to describe the Altec device, subbase, outriggers, and the associated This manual provides instruction for the operation of the interface with the vehicle. - Page 14 2 • Section 1 — Introduction https://cranemanuals.com...

-

Page 15: Section 2 - Unit Specifications

Section 2 — Unit Specifications operators and are familiar with the hazards of contact Purpose of the Unit with energized conductors. Operators must maintain safe clearances from electrical power lines in accordance This unit has been designed and built for service to the with applicable government regulations and safe work construction industry. -

Page 16: Component Identification

Component Identification Anti-Two-Block Upper Boom Switch Telescopic Intermediate Boom Sections Overhaul Ball and Hook Load Line Boom Pin Winch LMAP Display Oil Cooler Main Lift Cylinder Boom Controls Reservoir Rest Operator’s Seat Foot Throttle Outrigger Controls Front Outrigger Operator’s Rear Outrigger Outrigger Platform Cylinders... -

Page 17: Section 3 - Safety

Section 3 — Safety Operator Qualifications Safety Instructions General Operating Information This unit is designed and manufactured with many fea- • Do not operate the unit without proper training. tures intended to reduce the likelihood of an accident. Safety alerts throughout this manual highlight situations in which accidents can occur. -

Page 18: Operator Physical Requirements

• Inspectors who have completed all operator trainee Qualification of Operators qualification requirements. Operation by these Operator and trainees shall meet the following qualifica- persons should be limited to those crane functions tions. necessary to accomplish the inspection. • Satisfactory completion of a written examination Operator Physical Requirements covering operational characteristics, controls, and Operator and trainees shall meet the following physical... -

Page 19: Operator Conduct

• Satisfactory completion of a combination written and — Set controls in the off or neutral position verbal test on load/capacity chart usage that covers — Secure the crane against accidental travel a selection of the configurations (the crane may be —... -

Page 20: Preparation For Lifting The Load

Each outrigger shall be visible to the operator or to a • Personnel shall not be permitted to ride the bare hook signal person during extension or setting. The person or a load of material suspended from the hook. directing the lift shall see that the crane is level and, where •... -

Page 21: Crane Inspection

Operational aids must be in proper working order for Crane Inspection operation to begin. When an operational aid is being repaired, the employer uses the specified temporary Inspection procedures for cranes in regular service are divided into three general classifications based upon the alternative measures. -

Page 22: Monthly Inspection

be inspected; if so, the qualified person must inspect Monthly Inspection Each month the unit is in service it must be inspected in those items or conditions. accordance with the shift inspection. The unit must not • If a deficiency is found, the employer must follow the be used until a complete shift and monthly inspection requirements found in this manual under Identified shows that no corrective action is required. -

Page 23: Wire Rope Monthly Inspection

The inspection must consist of observation of wire ropes to be used. Joining lengths of wire rope by splicing (running and standing) that are likely to be in use during is prohibited. Repair of wire rope that contacted an the shift for apparent deficiencies as listed in this section. energized power line is also prohibited. -

Page 24: Tag Out

• Crane placed where it will cause the least interference under this paragraph, the employer must ensure that the drum will still have three wraps of wire when the with other equipment or operations in the area. load and/or boom is in its lowest position. •... - Page 25 Figure 3.1 — Sample Range Diagram and Capacity Placards for Short Span Outriggers (refer to chart on machine for capacities to be used for lifting) Section 3 — Safety • 13 https://cranemanuals.com...

- Page 26 Figure 3.2 — Sample Range Diagram and Capacity Placards for Mid and Full Span Outriggers (refer to chart on machine for capacities to be used for lifting) 14 • Section 3 — Safety https://cranemanuals.com...

- Page 27 Figure 3.3 — Platform Operation Sample Range Diagram and Capacity Placards Section 3 — Safety • 15 https://cranemanuals.com...

-

Page 28: Cold Weather Capacity

If the unit is remounted degrees Fahrenheit (-4 degrees Celsius), reduce the or if the vehicle is modified in any way affecting stabil- ity, contact Altec to determine if a new load capacity capacity values by the following percentages. chart is required. -

Page 29: Accident Prevention Signs Diagram

Accident Prevention Signs Diagram Both Sides 23 7 8 18 Platform Back of Door, Inside Cab Reservoir 12 20 Inside of Cab Tailshelf Section 3 — Safety • 17 https://cranemanuals.com... - Page 30 9 16 3 DANGER CONTACT WITH A ROTATING DRIVELINE WILL CAUSE SERIOUS INJURY OR DEATH KEEP AWAY * KEEP CLEAR OF ROTATING DRIVE SHAFT. * NEVER WORK ON AN INSTALLED POWER 970013536 A TAKE-OFF WITH THE ENGINE RUNNING. 970013530 A 18 •...

- Page 31 BOOM DOWN 970014543 A Section 3 — Safety • 19 https://cranemanuals.com...

- Page 32 20 • Section 3 — Safety https://cranemanuals.com...

- Page 33 Section 3 — Safety • 21 https://cranemanuals.com...

- Page 34 NOTICE 22 • Section 3 — Safety https://cranemanuals.com...

-

Page 35: Section 4 - Before You Operate

Section 4 — Before You Operate… All operators involved in the use and/or care of this unit CAUTION must know the location and understand the operation of Injury and property damage can result from abrupt each control on the unit. Control locations are pointed out reversals in direction, starts, or stops. -

Page 36: Shift Preoperational Inspection

DANGER DANGER Death or serious injury will result from hydraulic oil ELECTRICAL HAZARDS burning or exploding in the event of electrical con- Death or serious injury will result from contact with tact. Maintain minimum clearances from energized load, unit, vehicle or vehicle attachments if the boom electrical equipment. -

Page 37: Inspection Diagram

Inspection Diagram Sheave/Rope Guide Retaining Pins Fasteners, Slide Pad Retainers Sheave/Rope Guide Retaining Pins Anti-Two- Block Switch Boom Retract Cable Connection Load Line Overhaul Ball and Hook Boom Pin Load Moment Cylinder Rod Pin Area Protection (LMAP) Winch Mounting Bolts Steel Tubes Lift Cylinder Hoses... - Page 38 a. Without engaging the outrigger selector and with Seek medical attention if injured by escaping hy- draulic oil. Serious infection or reaction can result if all outriggers fully stowed, place the lower boom medical treatment is not given immediately. control in the Raise position. Spilled hydraulic oil creates slick surfaces and can b.

- Page 39 c. Turn the engine off. Turn the ignition switch to the down or if movement occurs, the emergency stop On position to provide electrical power to the unit. is not functioning properly. d. Move the crane/outriggers functions selector to c. Disengage the emergency stop, and restart the the Crane position.

-

Page 40: Personnel Handling

Checklist in the Appendix). Ensure proper reeving reservoir. If necessary, add oil as described in the of the winch line onto the drum. Use a genuine Altec Maintenance Manual. The need to add oil regularly replacement part to ensure that the proper rope and indicates a leak in the hydraulic system that should design is used. - Page 41 Spilled hydraulic oil creates slick surfaces and can b. If movement occurs, the outrigger interlock system is not functioning properly. Proceed to step 13. cause personnel to slip and/or fall. Keep the unit and work areas clean. 12. Test the outrigger interlock system for units with electro-hydraulic controls.

- Page 42 d. Move the crane/outriggers functions selector to c. Disengage the emergency stop, and restart the the Crane position. engine. e. Hold one outrigger control in the Raise position WARNING while watching that outrigger for movement. Death or serious injury can result from two-blocking the unit.

- Page 43 properly functioning upper controls and LMAP system platform is installed on the main boom or the jib. set to the personnel handling chart. Refer to the personnel handling range diagram. Set the boom at an appropriate angle so that when 18.

-

Page 44: Preparing For Operation

23. Make sure the booms are properly stowed, raise section. Do not operate the pump or engine at more the outriggers, disengage the PTO, and turn off the than a fast idle until the hydraulic oil has warmed up. engine. 5. -

Page 45: Section 5 - Protection Systems

Section 5 — Protection Systems • Winch raise • Boom extend The unit is equipped with operator aids that are intended to assist the operator in the safe use of this unit. How- • Boom lower ever, even with these systems, the unit can be damaged While these functions are temporarily shut off, the following if the operator overrides the system or disregards the recommended methods and procedures described in... - Page 46 The LMAP system is intended to help the operator pre- Move the boom to any one of these functional positions vent overloading of the unit when lifting a load. Repeated and press the set button. This setting assists the operator operation at load levels that activate the LMAP system by sounding an alarm when the boom exceeds the previ- ously established limit (refer to LMAP in the Appendix).

-

Page 47: Section 6 - Operation

Section 6 — Operation CAUTION Death or serious injury can result if the unit becomes unstable. Properly stow the booms before raising Injury and property damage can result from abrupt the outriggers. reversals in direction, starts, or stops. Operate the controls smoothly. - Page 48 Riding Seat Outrigger Controls Left Hand Control Pod Tailshelf Electric Outrigger Controls Figure 6.1 — Outrigger Controls 36 • Section 6 — Operation https://cranemanuals.com...

-

Page 49: Properly Setting The Outriggers

located at the top of the subbase, beside the rotation bear- ing (refer to Figure 6.3). Levels provided at the tailshelf Full Span and turntable are for reference only, and must be checked periodically against the master for accuracy. Mid Span Short Span Turntable Level... - Page 50 Swing Brake Pedal Location Operator’s Seat Dual Lever Option Joystick Option Figure 6.4 — Control Station (Left Hand) 38 • Section 6 — Operation https://cranemanuals.com...

- Page 51 LMAP Throttle Display Operator’s Seat Single Winch Option Dual Winch Option Figure 6.5 — Control Station (Right Hand) Section 6 — Operation • 39 https://cranemanuals.com...

-

Page 52: Right Hand Control Console

The joystick or lever controls on the left hand control pod Pole Guide provide for turntable rotation and boom extend/retract. The pole guide if equipped may be opened or closed and tilted forward or back with these controls. WARNING Cabin Heater When equipped with a cabin heater this control may be Death or serious injury can result from two-blocking the unit. - Page 53 the distance the hand control is shifted. The foot throttle Signal Horn or engine speed switch may also be used to increase The signal horn switch is located directly in front of the function speed when operating the boom function. When right hand controls.

-

Page 54: Foot Throttle

Consult the transmitter is in the docking station. Set the LMAP to your Altec representative for the maximum recommended platform mode to ensure the proper load chart is selected engine speeds for the vehicle’s particular engine, trans- before operating the unit. -

Page 55: Rpm

BOOM BOOM LOWER LOWER EXTEND RAISE RETRACT RAISE WINCH SWING SWING AUX 2 START/STOP HIGH RPM+ MAN BASKET MODE 100% RPM- AUX 3 WINCH SPEED Figure 6.6 — Radio Controls RPM +/- Boom Lift Joystick The joystick located on the operator’s right raises and The engine speed may be selected to one of three set- tings. -

Page 56: Tilt Switch

Tilt Switch DANGER The transmitter is equipped with a tilt switch that will Death or serious injury will result from unprotected cause the transmitter to stop sending signals when it contact with energized conductors. Maintain safe is tilted more than 45 degrees in any direction for 4 to clearance from electrical power lines and apparatus. -

Page 57: Boom Storage

As the boom extends, pay out the winch line to compen- Secure the Hook sate for the increased rope length required between the Before travel it is necessary to stow the hook. Attach the winch drum and the boom tip sheave. If the winch line is lanyard through the eye located on the driver side of the not payed out sufficiently during boom extension, damage front bumper outrigger and attach the other end to the... -

Page 58: Winch

Winch When raising the winch line with a load, do not use the Never allow anyone to ride the load line. Use only Altec LMAP system to determine the load the unit will lift. The LMAP is intended to help the operator prevent overloading approved personnel platform attached to the boom or jib for personnel lifting. -

Page 59: Winch Line

If The unit may be equipped with a steel two-man personnel the winch line was provided by Altec Industries, contact platform mounted at the upper boom tip for use in aerial your Altec representative for information concerning the operations. - Page 60 Route Line Over Top Route Line Center Sheave Over Top Center Sheave Connect ATB Weight to Line Connect Beckett Anchor to Boom Tip Connect Becket Anchor to Load Ball Connect ATB Weight to Dead End of Line One Part Load Line Two Part Load Line Connect Becket Anchor...

-

Page 61: Inspection

CAUTION Load Line Must Have Slack at Lowest Boom Injury can result from being pinched or trapped be- Angle as Shown tween moving components. Keep hands clear. Secure Beckett 7. Once the top platform mounting pin is fully engaged With Pin into the tip mounting ears, align the holes for the bottom mounting pin. -

Page 62: Operation

Death or serious injury can result from falling from DANGER the platform. All platform occupants must properly ELECTRICAL HAZARDS use an appropriate OSHA approved personal fall Death or serious injury will result from contact with protection system. load, unit, vehicle or vehicle attachments if the boom or load line should become electrically charged. -

Page 63: Lanyard Anchor

Before performing a test lift, inspect slings, shackles, Figure 6.9 — Personnel Platform and other mounting hardware for damage. Replace any faulty components with genuine Altec replacement parts Platform Brake prior to performing a test lift. A caliper brake is used to lock the platform into a level position. -

Page 64: Jibs

clear of the ground, the test weight hangs suspended Installation and Stowing Procedure from the bottom of the platform for a specified period. The jib installation and stowing procedures are described The test weight is then removed from the platform and here and also on a placard on the unit. - Page 65 Jib Stow Pin Right Side Pins Jib Stow Bracket Boom Jib Stow Bracket Load Line Left Side Pins Retainer Pin Jib Stow Bar Load Line Front Jib Stow Bracket Load Line Pin Stow Bracket Figure 6.12 — Jib Installation and Stowing 12.

-

Page 66: Manual Extend Jib

the holes on the right side of the boom tip until the WARNING jib stow pin is installed in the jib stow bracket. Death or serious injury can result from uncontrolled movement of the jib. Make sure the jib extension pin 10. -

Page 67: Other Methods Of Lowering/Stowing The Unit

Foot Throttle Swing Brake Glide Swing Pedal Pedal Switch Figure 6.14 — Left Hand Control Pod A glide swing out of seat horn (refer to Figure 6.15) will sound if the operator is not on the seat when the glide swing is in the On mode. - Page 68 56 • Section 6 — Operation https://cranemanuals.com...

-

Page 69: Section 7 - Care Of The Unit

This indicator alerts the operator when the return line filter At no time should an Altec unit be altered or modified cartridge needs to be replaced or when the hydraulic oil without specific written approval from Altec Industries, is cold. - Page 70 58 • Section 7 — Care of the Unit https://cranemanuals.com...

-

Page 71: Appendix

Appendix https://cranemanuals.com... - Page 72 https://cranemanuals.com...

-

Page 73: Glossary

Glossary 2nd stage boom — see intermediate boom. arm — 1: the primary load-carrying structure of an articulating arm. 2: the primary load-carrying structure of a single elevator. 3: the articulat- 3rd stage boom — see upper boom. ing structure which supports the arbor bar for reel lifting. A-frame outrigger —... - Page 74 from the winch to the load. 2: the lower sheave in a digger derrick up- basket — see platform. per boom tip containing two sheaves, which carries the winch line as it battery charger — a device used to restore the electrical charge in travels from the upper sheave (boom tip idler sheave) to the load.

- Page 75 cable stringing system — the group of steel rollers, bullwheel as- charge pump — the hydrostatic hydraulic system pump that provides fluid at low pressure to make up for internal leakage, provides cooling semblies, strand sheave assemblies and fairlead which directs com- fluid flow, and tilts the hydrostatic pump swash plate.

- Page 76 control bar — when manually activated, controls the movement of detent — a device for positioning and holding one mechanical part in feed roll(s) on a chipper. relation to another so that the device can be released by force applied to one of the parts.

- Page 77 double-pole, single-throw (DPST) switch — a four-terminal electrical end gland — a hollow, cylindrical part that screws into or is retained switch or relay that, at the same time, opens or closes two separate in the open end of a hydraulic cylinder barrel, through which the rod circuits or both sides of the same circuit.

- Page 78 firm footing — outrigger placement and extension in accordance with gradient control device — a device at the upper end of an insulating boom that reduces electrical stress level(s) below that considered to the instructions in a unit’s operator’s manual to ensure proper leveling of the vehicle and adequate stability when operating the unit.

- Page 79 keyway — a groove that is cut in a shaft or bore for a key to fit into. hydraulic leveling system — an automatic hydraulic control system which keeps the bottom of a platform parallel to or at a fixed angle to kilovolts (kV) —...

- Page 80 load moment and area protection (LMAP) — monitors load on the material handling — having the ability to use the boom or attachments unit and also monitors the working area. on the boom to lift and position materials. load moment limiter (LML) system — the system on a digger derrick material handling system —...

- Page 81 noncontinuous rotation — a rotation system in which the turntable is outrigger controls — the controls for operating the outriggers. prevented from rotating more than approximately one revolution about outrigger cylinder — the hydraulic cylinder which extends and retracts the centerline of rotation. or unfolds and folds an outrigger leg.

- Page 82 pilot operated check valve — a check valve that can be opened apply to the use of the derrick with the platform occupied, with no lifting to allow flow in the normally blocked direction by applying hydraulic of loads with the winch line. pressure to a pilot port.

- Page 83 all possible configurations of lower boom angle, boom extension, upper pressure transducer — a pressure measuring device which produces a variable electrical signal that is proportional to the hydraulic pressure boom angle, articulating arm travel, and/or elevator lift travel. applied to a port on the device. rear jack stand —...

- Page 84 secondary stowage DC pump — a low flow hydraulic pump driven by rod — the cylindrically shaped part of a cylinder which extends and retracts from the barrel to actuate or move a component. a direct current electric motor. This pump is used to provide hydraulic flow to stow the unit when the system for normal operation has failed.

- Page 85 side load protection system — the system on a digger derrick that sprocket — a wheel with teeth along the circumference which are helps prevent damage to the digger derrick structure when excessive shaped so as to engage with a chain, used to support and guide the side loads are applied to the booms.

- Page 86 — a winch located on a cable placer which is used boom away from its stowed position. for tensioning suspension strand or self-supporting cable or towing a unit — the Altec device(s), subbase, outriggers, body and associated cable lasher. interface items mounted on a chassis, but not including the chassis tow vehicle (towing vehicle) —...

- Page 87 extended or unfolded, and which supports the boom tip sheave and/ vortex — a whirlpool of liquid. or platform(s). waist harness — a belt device worn by the operator of a radio remote upper boom cylinder — the hydraulic cylinder that moves the upper control system to which the transmitter is attached.

- Page 88 https://cranemanuals.com Appendix — Glossary...

-

Page 89: Shift/Monthly Inspection Checklist

Shift/Monthly Inspection Checklist Vehicle No. _________________________ Location ___________________________ Date __________________ Service Request # ____________________ Model # ____________________ Serial # ______________________ Odometer ________________ Hours Meter ________________ Inspector ________________________________ All items must be checked prior to use each shift and monthly. The monthly inspection must be documented and maintained for a minimum of three months. - Page 90 Appendix — Shift/Monthly Inspection Checklist https://cranemanuals.com...

-

Page 91: Wire Rope Inspection Checklist

Wire Rope Inspection Checklist Vehicle No. _________________________ Location ___________________________ Date __________________ Service Request # ____________________ Model # ____________________ Serial # ______________________ Odometer ________________ Hours Meter ________________ Inspector ________________________________ The shift/monthly inspection must be conducted prior to use each shift the equipment is in service and monthly. When conducting a monthly inspection, the inspection must be documented and maintained for three months. - Page 92 Appendix — Wire Rope Inspection Checklist https://cranemanuals.com...

-

Page 93: Annual Inspection Checklist

Annual Inspection Checklist Vehicle No. _________________________ Location ___________________________ Date __________________ Service Request # ____________________ Model # ____________________ Serial # ______________________ Odometer ________________ Hours Meter ________________ Inspector ________________________________ This inspection must be documented and maintained for a minimum of 12 months. Begin the inspection by complet- ing the monthly inspection. - Page 94 Labels and Decals Originally Supplied by Originally Equipped Operator Seat, the Manufacturer or Otherwise Required Steps, Ladders, Handrails, and Guards Missing Missing Unreadable Unusable Unsafe condition Comments __________________________________________________________________________________ _____________________________________________________________________________________________ Name (printed) ___________________________________ Signature ___________________________________ Appendix — Annual Inspection Checklist https://cranemanuals.com...

-

Page 95: Standard Hand Signals For Controlling Crane Operations

Standard Hand Signals for Controlling Crane Operations STOP: Arm extended, palm down, EMERGENCY STOP: Both arms ex- HOIST: With forearm vertical, SWING: Arm extended, point with LOWER: With arm extended finger in direction of swing of move arm back and forth horizon- tended, palms down, move back forefinger pointing up, move downward, forefinger pointing... - Page 96 https://cranemanuals.com...

-

Page 97: Altec Lmap Operation

Altec LMAP (Load Moment and Area Protection) Telescopic Boom Cranes Operation https://cranemanuals.com... - Page 98 https://cranemanuals.com Greer Part Number: W450240A...

- Page 99 Contents Introduction ......................................1 System Components ................................1 Anti Two Block (ATB) ................................1 Area Alarm ....................................1 Boom Angle Sensor ................................. 1 Display ......................................1 Extension Sensor ..................................2 Function Kick-Out ..................................2 Pressure Transducers ................................2 Operator Alarms ..................................2 LMAP Display ....................................

- Page 100 https://cranemanuals.com...

-

Page 101: Introduction

Introduction System Components • LMAP Display Unit • LMAP Computer Unit • Pressure Transducers • Extension Reel with length and angle sensors • Anti Two-Block (ATB) switches • Cables The Load Moment Area Protection (LMAP) system is intended to aid the crane operator by continuously monitoring the load and warning of an approach to an overload or two-block condition. -

Page 102: Extension Sensor

On-screen messages provide the operator with visual warnings of conditions that occur during operation of the system. Extension Sensor The extension sensor provides an increasing voltage proportional to the extension of the boom. A cable attached to the boom head provides a low current electrical path for the ATB signal. Function Kick-Out Electrically operated solenoids disconnect the control lever functions for boom hoist lower, telescope out, and winch up whenever an overload or an ATB condition occurs. -

Page 103: Lmap Display

LMAP Display 9 10 TEST Overload Warning – This red LED illuminates when you reach or exceed 100% of rated capacity. It is accompanied by solid tone alarm and when maximum rated capacity is exceeded will result in boom function lockout. Approaching Overload Warning –... - Page 104 13 14 15 TEST Erected Jib – Enables the selection of the jib to be used on the boom. Selects extended or retracted jib when crane is equipped with two stage jib. Basket Operation – Enables the selection of the platform for man basket operation. Outrigger Configuration –...

-

Page 105: Operation

Operation Power up Self-Test Immediately following electrical power up, or by manually pressing the key, the system will TesT execute a self-test lasting for approximately eight seconds. TEST TEST During this time, the numerical display segments and bar graph segments are all turned on, the audible alarm will sound, and alarm indicator lights and all other LED’s are illuminated. -

Page 106: Stowing The Jib

Stowing the Jib STOWED JIB key will select between stowed jib sTowed jib or no stowed jib. The key is also used to sTowed jib stow the erected jib. For cranes that do not have jib options, the message “No Other Stowed Jib Options” will appear in the information window. -

Page 107: Setting The Parts Of Line

Setting the Parts of Line PARTS OF LINE Parts of line are set by pressing the up or down arrow. The number of parts of line will appear in the display next to the arrow. When an alternate winch is selected, it is necessary to reset the parts of line for the alternate winch. -

Page 108: Operator Alarms

Operator Alarms mWArnIng ALL OPErATOr DEFInED ALArMS ArE WArnIng DEvICES. ALL CrAnE FunCTIOnS rEMAIn OPErATIOnAL WhEn An OPErATOr ALArM IS ACTIvE. Accessing the Operator Alarms Press the key to access the operaTor alarm operator alarms. The information window will show the current status of the alarms. -

Page 109: Setting Maximum Boom Length Alarm

Setting Maximum Boom Length Alarm Extend the boom to the desired maximum length. Press the key to access the operaTor alarm operator alarm screen. Press the key adjacent to “Max Length” to set to the current position. If the length of the boom increases beyond the maximum length set, the red warning light will flash TEST and the audible alarm will sound. -

Page 110: Swing Alarms

Swing Alarms Swing alarms define a working arc and an exclusion zone by two set points. The following diagram illustrates the working arc and exclusion zone. Right Swing • A left swing alarm is activated when swinging to the left. WORKING •... - Page 111 Press the key adjacent to “Set Left and Right Alarms?”. 12,900 31.0 77.5 1,000 SET LEFT AND RIGHT ALARMS? NEXT SET WORKING AREA ALARM? NEXT TEST Set Left And Right To set a new swing area, you must first reset the left and right points.

-

Page 112: Enabling The Preset Exclusion Zones

Press the key adjacent to “Next” to proceed. 12,900 31.0 77.5 1,000 CURRENT SWING ANGLE EXIT NEXT TEST Next Rotate the boom to the right swing point and press the key adjacent to “Off”. 31.0 12,900 77.5 1,000 SWING RIGHT AND SET RIGHT POINT CURRENT SWING ANGLE EXIT TEST... - Page 113 Press the key adjacent to “Swing Alarms”. 12,900 31.0 77.5 1,000 SWING ALARMS WORKING AREA ALARM TEST Press the key adjacent to “Preset Working Area”. 31.0 12,900 77.5 1,000 PRESET WORKING AREA SET WORKING AREA MANUALLY TEST Press the key adjacent to one of the four predefined exclusion zones: Front, Rear, Curbside, 31.0 12,900...

-

Page 114: Setting The Swing Left And Swing Right Alarms

WORKING AREA For example, selecting “Front” will set the working area from 270° through 90° and set the exclusion zone as shown in the illustration. 270° 90° EXCLUSION ZONE Confirm your selection by pressing the key adjacent to “Yes”. This will cancel all existing swing alarms 31.0 12,900 including manually set alarms. - Page 115 Press the key adjacent to “Swing Alarms”. 12,900 31.0 77.5 1,000 SWING ALARMS WORKING AREA ALARM TEST Press the key adjacent to “Set Working Area Manually”. 31.0 12,900 77.5 1,000 PRESET WORKING AREA SET WORKING AREA MANUALLY TEST To set a new swing area, you must first reset the left and right points.

- Page 116 Move the boom to the middle of the swing area and press the key adjacent to “Set”. 12,900 31.0 77.5 1,000 SWING TO THE MIDDLE OF SAFE AREA & STOP SET CURRENT SWING ANGLE EXIT TEST Set Middle Swing Press the key adjacent to “Next” to proceed. 31.0 12,900 77.5...

-

Page 117: Setting The Work Area Alarm

Setting the Work Area Alarm This alarm, when set properly, enables the operator to define a safe operating zone by setting only two points. This results in an enhanced work area and defines the exclusion zone area. The exclusion zone area can be visualized by connecting the two set points with a horizontal line and extending the line upwards to create a vertical plane or wall. - Page 118 Press the key adjacent to “Set Working Area Alarm”. 12,900 31.0 77.5 1,000 SET LEFT AND RIGHT ALARMS? NEXT SET WORKING AREA ALARM? NEXT TEST Set Working Area To set a new working area, you must first reset 31.0 12,900 the left and right points.

- Page 119 To turn off the Working Area Alarm, press key twice to access the operaTor alarm 12,900 31.0 Working Area Alarm menu. 77.5 1,000 FULL SPAN OUTRIGGERS MAIN BOOM STOWED 31' JIB TEST Operator Alarm Button Press the key adjacent to “Set Working Area Alarm”.

- Page 120 https://cranemanuals.com...

- Page 121 Operating console Contents LMAP system Altec Telescopic Crane Safety instructions Product description Operating Mode Selection Operation Service and Maintenance Appendix Operator’sManual Issue A - 02/2014 This document has the order no. xx-xxx-xx-xxxx_XXXXXX_en https://cranemanuals.com...

- Page 122 TABLE OF CONTENTS Safety instructions ...................6 EC conformity declaration................6 Product description..................7 Product identification .................7 Use for the intended purpose ..............8 Overview of functional elements..............9 Operating Mode Selection ................10 Switching device on and off ..............10 Adjust LMAP to latest set-up status............12 3.2.1 Set up boom configuration..............13 3.2.2...

- Page 123 Camera view (optional)................44 Service and Maintenance ................45 Service menu ...................45 Monitor chassis ..................47 System Menu ...................50 5.3.1 Status of LMAP sensors ..............51 5.3.2 Status of digital inputs................52 5.3.3 Status of digital outputs ...............53 5.3.4 Switching units ..................54 5.3.5 Switching language................54 5.3.6 vSCALE settings..................55 5.3.7...

- Page 124 Introduction Introduction This manual is a component of the equipment or systems supplied by Hirschmann Automation and About this manual Control GmbH. Keep this manual in a safe place and ensure that it is available to all users. The contents of this manual are subject to change. Hirschmann Automation and Control GmbH do not Liability disclaimer provide any guarantee for this material, including the associated guarantee regarding marketability and suitability for certain intended purposes.

- Page 125 Introduction Marking of notices Dangers and other important notices are marked as follows in this user manual: WARNING Warning of direct threat of personal injury and damage to property. Instructions on precautions to avert the danger. CAUTION Warning of dangerous situations. Also warns of damage to property. Instructions for averting the danger.

-

Page 126: Safety Instructions

Safety instructions 1 Safety instructions WARNING Imminent threat of personal injury and damage to property due to incorrect system settings! The correct adjustment of the LMAP to the current set-up status is essential for the correct func- tion of the system and of the crane. The LMAP can only operate correctly if all settings are entered correctly according to the cur- rent set-up status during the SETUP procedure. -

Page 127: Product Description

Product description 2 Product description The vSCALE D3 console is the operable interface of the programmable Load Moment and Area Protec- tion system, referred to below as the “LMAP”. The LMAP detects the readings from different sensors and recognizes crane overload statuses depending on further parameters. Visual and audible signals alert the user of the overload status. -

Page 128: Use For The Intended Purpose

Product description 2.2 Use for the intended purpose The vSCALE D3 is the interface of the Load Moment and Area Protection system (LMAP). The LMAP detects a crane overload status depending on various parameters. The crane driver is warned well before the onset of an overload status via visual and audible warning signals. -

Page 129: Overview Of Functional Elements

Product description 2.3 Overview of functional elements TFTcolor display Function keys F1 - F12 Light sensor and status displays (LED) Rotary control (encoder) with pushbutton function SETkey for silencing alarms and setting system settings HOME key for return to LMAP main menu ESCAPE key for returningto previous menus or previous setups. -

Page 130: Operating Mode Selection

Operating Mode Selection 3 Operating Mode Selection This chapter contains information, advice and instructions for choosing an operating mode. 3.1 Switching device on and off The load limiting device has no on/off switch. The console automatically switches on after engaging the PTO. - Page 131 Operating Mode Selection confirm: Otherwise, press the ESCAPEkey and carry out the set-up procedures. In the event of a system malfunction an error code is displayed in the bottom right of the display: System malfunction? Error code The error codes and what they mean are explained in the error codes table in the Appendix. The device is not ready for operation until all faults have been rectified and no error codes are dis- played.

-

Page 132: Adjust Lmap To Latest Set-Up Status

Operating Mode Selection 3.2 Adjust LMAP to latest set-up status The LMAP must be adjusted to the current crane setup status by completing the full SET-UP procedure SETUP procedure after any change to the crane configuration. Operation is done with the function keys and the rotary control. -

Page 133: Setup Boom Configuration

Operating Mode Selection Selection of counter weight Selecting the outrigger position (dynamically done with power up of the LMAP) 3.2.1 Setup boom configuration Boom configuration is used to select any jib that is being used or stowed. Boom configuration from main menu Boom/jib indicator On screen Stowed jib... - Page 134 Operating Mode Selection Instructions Select by repeatedly pressing the boom configuration function key or by rotating the rotary control select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid: The main menu is displayed with a green confirmation box.

-

Page 135: Setup Platform Configuration

Operating Mode Selection If the selection is not valid: The main menu is displayed with a yellow confirmation box. The only choice is to press the ESCAPE key to abort and return to the last valid mode selection. 3.2.2 Setup platform configuration Platform configuration is used to select any platform that maybe attached. - Page 136 Operating Mode Selection Rotating platform Instructions Select by repeatedly pressing the platform configuration function key or by rotating the rotary control select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid, the LMAP main menu is displayed with a green confirmation box. Press the rotary control again to confirm a second time.

-

Page 137: Setup Winch Configuration

Operating Mode Selection 3.2.3 Setup winch configuration The winch configuration is used to select between the main and auxiliary winches. Winch configuration from main menu Winch selection (green ring denotes selected winch) Possible selections depending on model: Selections Main winch ... - Page 138 Operating Mode Selection select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid, the LMAP main menu is displayed with a green confirmation box. Press the rotary control again to confirm a second time. If the selection is not valid, the main menu is displayed with a yellow confirmation box.

-

Page 139: Setup Parts Of Line

Operating Mode Selection 3.2.4 Setup parts of line Parts of line configuration is used to change the number of lines that are used. Parts of linefrom main menu Parts of line indicator Possible selections depending on model: Selections One (1) through eight (8) parts of line can be selected Instructions Select by repeatedly pressing the parts of line configuration function key or by rotating the rotary control... - Page 140 Operating Mode Selection select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid, the LMAP main menu is displayed with a green confirmation box. Press the rotary control again to confirm a second time. If the selection is not valid, the main menu is displayed with a yellow confirmation box.

-

Page 141: Setup Counterweight Configuration

Operating Mode Selection 3.2.5 Setup counterweight configuration The counterweight configuration is used to select if the counterweight is installed. Counterweight configuration from main menu Counterweight indicator On screen directions Possible selections depending on model: Selections Counterweight installed Counterweight uninstalled Instructions Select by repeatedly pressing the counterweight configuration function key or by rotating the rotary control... - Page 142 Operating Mode Selection select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid, the LMAP main menu is displayed with a green confirmation box. Press the rotary control again to confirm a second time. If the selection is not valid, the main menu is displayed with a yellow confirmation box.

-

Page 143: Setup Outrigger Configuration

Operating Mode Selection 3.2.6 Setup outrigger configuration The outrigger configuration is used to select outrigger position and load charts. Outrigger configuration from main menu Short span selection indicator Mid span selection indicator On screen Full span selection indicator directions Load chart selected Possible selections: Selections ... - Page 144 Operating Mode Selection select: After selection is complete, press the rotary control to confirm. confirm: If the selection is valid, the LMAP main menu is displayed with a green confirmation box. Press the rotary control again to confirm a second time. If the selection is not valid, the main menu is displayed with a yellow confirmation box.

- Page 145 Operating Mode Selection The right-hand side of the main menu shows the actual outrigger sensor status. Example Actual outrigger positions: Green Matches selected position Flashing Red Detected outrigger has changed since last operating mode selection Detected outrigger does not match selected position NOTE If the outriggers position selected does not match the state of the sensors on the outriggers, the...

-

Page 146: Operation

Operation 4 Operation This chapter contains information, advice and instructions for using the console. You will also find the description of function elements, functions and menus. Rotary control with pushbutton Function keys function Function keys Status display Functional Display with elements LMAP main USB port... - Page 147 Operation All settings must be checked by hoisting a known load and comparing the information with that dis- played by the LMAP. WARNING Imminent threat of personal injury and damage to property due to incorrect system settings! The correct adjustment of the LMAP to the current set-up status is essential for the correct func- tion of the system and of the crane.

-

Page 148: Functional Elements

Operation 4.1 Functional elements Function keys F1 to F12: for calling operating functions Light sensor: measures the ambient brightness for controlling the background lighting (no functionality) Operating display: shines green when the supply voltage is connected USB data display: shines yellow when data is exchanged via the front USB interface Multi-function light, colored: (no functionality) Wireless indicator: lights up during active wireless communication (no functionality) Encoder with pushbutton function: for selection and confirmation when making inputs... -

Page 149: Lmap Main Menu

Operation 4.2 LMAP Main Menu The LMAP main menu is the central operating image during crane operation and the starting point for the selection of various functions. Press the “HOME” key to display the LMAP main menu: Load Tilt level (barchart) Height of Length of main... - Page 150 Operation Function Keys Jib configuration Service menu Platform configuration System menu Parts of line configura- Chassis menu tion Winch configuration Environmental sensors Counterweight configu- User limit menu ration Outrigger configuration Camera menu © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc.

-

Page 151: Function Keys (Soft Keys)

Operation 4.2.1 Function keys (soft keys) The F1-F12 key functions are displayed with assigned symbols: Example Function keys with no assigned symbol are not active: The function key symbols are normally blue. Function key colors Certain statuses are indicated by the change in color: Examples Grey Significance here: no geometrical limit programmed... -

Page 152: Warning Lights / Audible Alarm

Operation 4.2.2 Warning lights / audible alarm Various warning symbols are shown in the status display as required: Error code Stroke end Example Warning sym- (A2B) User limit symbols Depending on the cause of the warning, the following also occur: ... - Page 153 Operation Warning, stroke end (A2B) This red symbol lights up to indicate that a stroke end status has occurred. A stroke end status is recorded if the load block comes into contact with the boom tip. There is a danger in this case that the lifting rope will break and the load will drop.

-

Page 154: Tilt Level Display

Operation 4.3 Tilt level display A tilt level display is shown on the main menu to monitor the crane inclination. Press the “HOME” key to display the LMAP main menu: Example The tilt level replicates the current status. When the crane is aligned horizontally, the tilt level color changes to green and stops flashing. - Page 155 Operation WARNING Warning the tilt level does NOT affect the DISPLAYED rated lifting capacity, however, it does affect ACTUAL lifting capacity. © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

-

Page 156: Setup User Limits

Operation 4.4 Setup user limits The LMAP system has programmable functions for monitoring geometrical limits of the working area: Height monitoring Radius monitoring Boom angle monitoring Rotating angle monitoring Virtual wall monitoring Boom extension monitoring Programming is carried out via an interactive menu. - Page 157 Operation User Limit Menu from main menu Symbol Radius limit Symbol Symbol Virtual walls Boom angle limit Example Symbol Symbol Symbol Limits active Height limit Rotating green – within limits angle limit Symbol Red – outside a limit Boom extension Function Keys Boom angle limit Virtual walls...

-

Page 158: Boom Angle Monitoring

Operation 4.4.1 Boom angle monitoring Programmable function for monitoring the upper/lower boom angle Boom angle limit fromuser limit menu Saved limit value of upper boom Saved limit value of Current boom angle lower boom angle angle Example Function Keys Save current angle as upper limit value & activate, or if currently active, deactivate. -

Page 159: Boom Height Monitoring

Operation HINT The maximum limit cannot be set if less than the lower limit including when it is inactive. 4.4.2 Boom height monitoring Programmable function for monitoring the maximum boom height Height limit fromuser limit menu Saved limit value of Current height maximum height Example... -

Page 160: Radius Monitoring

Operation 4.4.3 Radius monitoring Programmable function for monitoring the minimum/maximum radius Radius limit from user limit menu Saved limit value of minimum radius Saved limit value of Current maximum radius radius Example Function Keys Save current radius as the minimum limit value & activate, or if currently active, deactivate. -

Page 161: Rotation Angle Monitoring

Operation 4.4.4 Rotation angle monitoring Programmable function for monitoring the left-hand/right-hand rotation angle Rotation angle limitfrom user limit menu Saved limit value of Saved limit value of counter-clockwise clock-wise rotation Current rotation rotation angle Example Function Keys Save current rotation angle as counter-clockwise slew limit value &... -

Page 162: Virtual Wall Monitoring

Operation 4.4.5 Virtual wall monitoring Programmable function for monitoring the minimum/maximum virtual walls Virtual wall limitfrom user limit menu Example Function Keys Activate/Deactivate current walls (green – active) Set current point for current wall Press the ESCAPE key to go back to the user limit menu. Press the “HOME”... -

Page 163: Boom Extension Monitoring

Operation 4.4.6 Boom Extension monitoring Programmable function for monitoring the maximum boom extension Boom extension limit from user limit menu Saved limit value of Current boom lower boom extension Extension Example Function Keys Save current extension limit value & activate, or if currently active, deactivate. -

Page 164: Camera View (Optional)

Operation 4.5 Camera view (optional) You can (optionally) view the image from a camera in the display. Camera view from main menu Example Function Keys No functionality Press the ESCAPE key to go back to the previous display. Press the “HOME” key to display the LMAP main menu. ©... -

Page 165: Serviceand Maintenance

Serviceand Maintenance 5 Serviceand Maintenance This section describes how various sensors and outputs can be monitored, alarms are checked, and various system parameters can be changed. 5.1 Service menu The system incorporates a Service menu in which the service relatedparametersmay be monitored. Service menu from the LMAP main menu Function Keys Press the ESCAPE key to go back to the previous display. - Page 166 Serviceand Maintenance Hydraulic Oil Temperature Hydraulic oil temperature should be between 60°F and 180°F © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

-

Page 167: Monitor Chassis

Serviceand Maintenance 5.2 Monitor chassis The system allows displays information about the status of the chassis. Chassis information from main menu Information display 1 Example Information display 2 Example © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. - Page 168 Serviceand Maintenance Function Keys Displays chassis information screen 1 Displays chassis information screen 2 Press the ESCAPE key to go back to the previous display. Press the “HOME” key to display the LMAP main menu. Ratio of current volume of engine sump oil to maximum required volume. Engine Oil level Definitions Ratio of volume of liquid found in engine cooling system to total cooling...

- Page 169 Serviceand Maintenance Indicates the state of the diesel particulate filter regeneration need and urgency. This is an aggregate of bank 1 and bank 2. It is a system status and not individual bank status.000 Regeneration not needed001 Regeneration needed - lowest level010 Regeneration needed - moder- Diesel Filter Status ate level011 Regeneration needed - highest level100 reserved for SAE assignment101 reserved for SAE assignment110 reserved for SAE...

-

Page 170: System Menu

Serviceand Maintenance 5.3 System Menu The system menu is used to view information from sensors, alarm information, and various settings. System menu from main menu © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com... -

Page 171: Status Of Lmap Sensors

Serviceand Maintenance 5.3.1 Status of LMAP sensors The system incorporates a menu in which the readings of the CAN bus sensors can be displayed: The readings include both the raw and the scaled values based on the units selected. LMAP sensor data from system menu Example ©... -

Page 172: Status Of Digital Inputs

Serviceand Maintenance 5.3.2 Status of digital inputs The system incorporates a menu in which the status of the digital inputs can be displayed. Digital inputs from system menu If green: Digital input is active Example Status of digital input © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. -

Page 173: Status Of Digital Outputs

Serviceand Maintenance 5.3.3 Status of digital outputs The system incorporates a menu in which the status of the digital outputs can be displayed. Digital outputs from system menu If green: Digital output is active Example Status of digital outputs © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. -

Page 174: Switching Units

Serviceand Maintenance 5.3.4 Switching units The system lets you choose between metric and domestic units. Toggles the units from system menu Press the function key to toggle between metric (SI) and domestic (CU). The date format also changes with the units from yy/mm/dd to dd/mm/yy respectively. 5.3.5 Switching language The system lets you choose between English, German and Spanish languages. -

Page 175: Vscale Settings

Serviceand Maintenance 5.3.6 vSCALE settings The system lets you change the LCD and key brightness and the audible alarm volume of the console and external alarm: Settings and audible alarm volume from system menu Function Keys LCD brightness Key brightness Audible alarm On/Off for both the operating console and external alarms Press the ESCAPE key to go back to the previous display. -

Page 176: Alarm Information

Serviceand Maintenance NOTE The audible alarm volume is password protected. See section on how to enter the password 5.3.7 Alarm information The system lets you know what errors you currently have present. Alarm information from system menu Error #/Total errors Type of Error Example Error information... -

Page 177: Version Overview

Serviceand Maintenance 5.3.8 Version overview The system lets you know the versions of hardware and software installed. Version information from system menu Arrow indicates addition information available. (turn the rotary knob to see additional information) Example Function Keys HMI version and information PLC version and information Device version and information Project version and information... -

Page 178: Protected Area

Serviceand Maintenance Press the “HOME” key to display the LMAP main menu. 5.3.9 Protected Area The protected area contains settings that only authorized personnel should change. Protected area from system menu The following require a user level password:(see section5.4) Line pull hoist main Line pull hoist auxiliary Function keys winch... -

Page 179: User Level Password Entry

Serviceand Maintenance System calibration of Change camera set- sensors tings Operation modes selections 5.4 User Level Password Entry The password allows an operator to change the following: Winch line pulling settings Camera setup Password entry is done by the following instructions: Instructions ... - Page 180 Serviceand Maintenance Press the ESCAPE key to abort entry and return to the previous menu. © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

-

Page 181: Administrative Level Password Entry

Serviceand Maintenance 5.5 Administrative Level Password Entry The administrative password allows atechnician to change the following: Audible alarm volume Operating mode configurations Date/Time Serial number setting Sensor Calibration NOTE Safety-relevant settings can only be carried out by authorized personnel after inputting a pass- word (Service Code). -

Page 182: Maintenance And Repair

Serviceand Maintenance Press the ESCAPE key to abort entry and return to the previous menu. 5.6 Maintenance and Repair The vSCALE D3 operating console contains no wearing parts and therefore cannot be opened. If you Maintenance notice malfunctions or differences between actual and displayed measured values, you should switch the device off and have it checked and, if necessary, repaired immediately by an authorised Hirsch- mann service partner. -

Page 183: Appendix

Appendix 6 Appendix This appendix contains additional technical information and the full table of error codes. 6.1 Technical data Operating voltage 8…36 V DC, suitable for 12 and/or 24 V on-board power supply Overvoltage protection overvoltage up to max. 48V DC / 2 minutes Reverse polarity protection up to -48V DC Display... -

Page 184: Error Codes Table

Appendix 6.2 Error codes table Error code Description Zero Event Codes 0001 - 00FF 0000 Empty / Deactivated event 0001 System Startup 0002 System Forced Initialization 0011 System Version Information 0021 Machine Information 00AA System Debug Output 00FE System Restart after Cold Reset 00FF System Shutdown 0000... - Page 185 Appendix Error code Description 0110 Load Tables - Placeholder – Not a Valid Code 0111 Load Tables - Wind speed range exceeded 0112 Load Tables - Fallen below temperature range 0113 Load Tables - Temperature range exceeded 0120 Load Tables – Pre Fallen below radius range 0121 Load Tables –...

- Page 186 Appendix Error code Description 016C User Limit – Pre Fallen below length range 016D User Limit – Pre Length range exceeded 016E User Limit – Pre Fallen below height range 016F User Limit – Pre Height range exceeded 0170 User Limit – Pre Fallen below wind speed range 0171 User Limit –...

- Page 187 Appendix Error code Description 0A2D High Voltage Detection Unit Tracking 0A2E Overall Cut 0A2F Overall Cut Tracking 0A30 Setup Mode 0A31 Rigging Mode (without tables) 0A32 Cutoff Bridged (non EN13000) 0A33 Cutoff Bypass (EN13000 key) 0A34 Enable Boom Up 0A35 A2B Switch Bridged 0A36 Third Wrap Switch Bridged...

- Page 188 Appendix Error code Description 0A67 Mode Sanity Check 7 Failed 0A68 Mode Sanity Check 8 Failed 0A6A Invalid Radius Calculated 0A6B Invalid Height Calculated 0A6C Invalid Length Calculated 0A70 Redundancy Failure for length 0A71 Redundancy Failure for height 0A72 Redundancy Failure for radius 0A73 Redundancy Failure for load 0A74...

- Page 189 Appendix Error code Description 1114 Failure for pinning 5 1115 Failure for pinning 6 1116 Failure for pinning 7 1117 Failure for pinning 8 1118 Failure for misc input 1 1119 Failure for misc input 2 111A Failure for misc input 3 111B Failure for misc input 4 111C...

- Page 190 Appendix Error code Description 1146 Failure for Engine Stop Message 1 1147 Failure for Engine Stop Message 2 1148 Failure for Joystics in Base Position 1 1149 Failure for Joystics in Base Position 2 114A Failure for High Voltage Detection Unit 1 114B Failure for High Voltage Detection Unit 2 114C...

- Page 191 Appendix Error code Description 1178 Failure for Left Output 1179 Failure for Right Output 117A Failure for Left Output 117B Failure for Right Output 117C Failure for Temperature 1 117D Failure for Temperature 2 117E Failure for misc output 1 117F Failure for misc output 2 1180...

- Page 192 Appendix Error code Description © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

- Page 193 Appendix Feedback What is your opinion about this manual? We always try to describe the products fully in our manuals, as well as providing important background knowledge to ensure trouble-free operation. We take the task of continuous improvement and reduction of errors very seriously. Your comments and suggestions help us to increase the quality and level of information for this document.

- Page 194 Appendix © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

- Page 195 Appendix Suggestions for improvement and additional information: General comments: Sender: Company / Department Name / Phone Street Zip code / City Date / Signature Dear user, please complete and return both pages of this feedback: via Fax an: +49 (0)7243 709 3222 actual QR ...

- Page 196 Appendix Thank You ! © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

- Page 197 Appendix Notes © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

- Page 198 Appendix © 2014 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com AltecManual_Feb3.docx / 1/31/2014 1:03:00 PM/ Issue A / cc. https://cranemanuals.com...

Need help?

Do you have a question about the AC45 Series and is the answer not in the manual?

Questions and answers