Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ICM Controls GRA-C

- Page 1 TREE SHEAR GRA-C GRA-C USER AND MAINTENANCE MANUAL...

- Page 2 Manual version: 1, 05-04-2024 It is strictly forbidden to translate, copy, reproduce or transmit this manual or parts thereof in any way without the express consent of the manufacturer. The manufacturer accepts no liability for damage or problems caused by incorrect or partial interpretation of this manual.

-

Page 3: Table Of Contents

INDEX Foreword ___________________________________________________________________ 4 User and maintenance manual _________________________________________ 4 Limitations of use ___________________________________________________________ 4 Updates ______________________________________________________________________ 5 Target audience _____________________________________________________________ 5 Regulatory information _____________________________________________________ 5 General Information _______________________________________________________ 6 Manufacturer’s identification data _________________________________________ 6 Nameplate __________________________________________________________________ 6 Warranty Conditions ________________________________________________________ 7 Safety _________________________________________________________________________ 9 Warnings and prescriptions _______________________________________________ 9 Checks _______________________________________________________________________ 10... -

Page 4: Foreword

FOREWORD OPERATION AND MAINTENANCE MANUAL In this manual, the following will be referred to as abbreviations: • Manufacturer or construction company: The manufacturer of the equipment is always imprinted on the product’s identification plate. • Equipment: Attachment or equipment is a product consisting of one or more parts installed on the end of the boom of the operating machine, enabling it to perform a job, be it demolition, forestry, handling or lifting. -

Page 5: Updates

• Use of non-original spare parts • Non-compliance with the following manual and instructions • Use of equipment with non-compatible machine • Exceptional events UPDATES The manufacturer reserves the right to change the design and manual of the equipment without notifying the customer. -

Page 6: General Information

(EN 12100-1 and EN 12100-2) Security component: • Means a component that also has a protective or safety function. • UNI EN 349:2008 Safety of machinery - Minimum clearances to prevent crushing of body parts • UNI EN 474-1:2007 Earth-moving machinery - Safety - General requirements •... -

Page 7: Warranty Conditions

WARRANTY CONDITIONS The warranty conditions are listed below: • The manufacturer guarantees that all products manufactured are free of defects attributable to the materials or processes used. • The manufacturer’s obligation under this warranty is limited to repair or replacement with an interchangeable replacement part at the company’s premises provided that the product is returned within 10 working days of the defect being discovered, and if the defect is correctly identified by photographs or the product is returned with postage paid in advance. -

Page 8: Safety

Warranty coupon Installer company Model Serial number Year Signature Send this coupon at the time of sale by email info@icmequipments.com SAFETY WARNINGS AND PRESCRIPTIONS Ensuring the safety of people and property is one of the most important issues for any manufacturer of machinery and equipment, so when designing a new product, an attempt is made to foresee all possible hazardous situations, and the manufacturer therefore declines all responsibility for failure to comply with the safety and prevention rules set out in this manual. - Page 9 The manufacturer is released from any liability for damage caused by the equipment to persons, animals or property in the following cases: • Improper use of equipment • Hydraulic supply faults • Use of equipment by inadequately trained personnel • Incorrect installation •...

-

Page 10: Checks

• The oil can reach high temperatures and is extremely harmful to the environment, skin and eyes. Before doing any work, wait until the oil has cooled down completely and absolutely avoid having the oil dispersed in the environment or in contact with our bodies. •... -

Page 11: Residual Risks

RESIDUAL RISKS Danger cannot be totally reduced by design and protective techniques, there are always residual risks that cannot be foreseen and cannot be eliminated. In order to operate and maintain the equipment safely, it is necessary to be familiar with the general safety rules, to read this manual thoroughly and to follow the instructions below: •... -

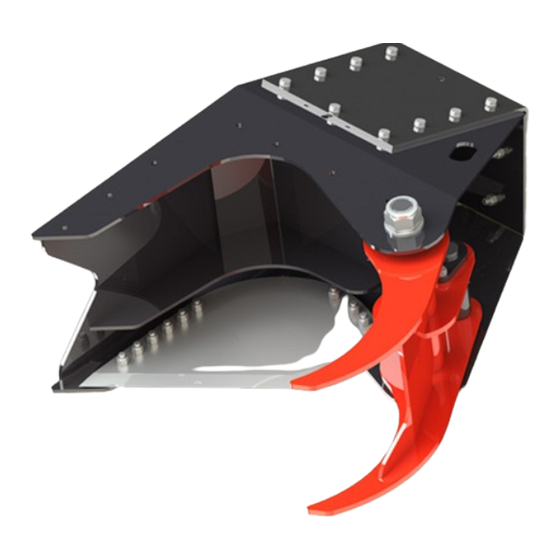

Page 12: Equipment

(D) which will then make the cut. The shear is normally bolted to a quick coupling which allows it to be mounted on the excavator. GRA-C 20 matricole G00001 - higher GRA-C 30 matricole G00001 - higher... - Page 13 Pagina 1 di 1 Note: Questo disegno è di proprietà esclusiva della I.C.M. s.r.l., disegni ed informazioni in esso conenute non possono essere, senza autorizzazione scritta, divulgate, copiate o riprodotte anche solo in parte MODELLO GRA-C 20 GRA-C 30 GRA-C 45 PESO...

-

Page 14: Installation

INSTALLATION Before acting, you must have read and understood this manual thoroughly. If you do not have the knowledge to learn this manual, you cannot install the equipment; contact a specialised company that can do this for you. The equipment is normally shipped on pallets, or in a wooden crate depending on the destination, means of transport or the customer’s request. -

Page 15: Decommissioning

hydraulically, and then measure the minimum length of the hydraulic hoses to allow the equipment to swing fully in all 4 directions. • It is recommended to use hoses with the minimum diameter allowed by the jack or hydraulic rotator connection. -

Page 16: Instructions For Use

contains to be recycled. Act as follows: • Dismantle the equipment according to the points in chapter ‘’Decommissioning’’. • Dismantle all hydraulic parts that may contain oil and empty them into suitable containers for proper disposal. Oil is very harmful to the environment and must not be dispersed in any way. •... -

Page 17: Residual Risks

Any other operation not described above is prohibited. Some of the most common operations that are prohibited are explained below: • Use the equipment to uproot. • Use the equipment to lift boulders or other uneven material. • Tie straps or chains to the bucket to lift material. •... -

Page 18: Maintenance

• The equipment does not have sufficient strength to hold the load. The pressure of the operating machine is not sufficient, increase it to the maximum allowed by the equipment • Cylinder seals are damaged. Replace them • The hydraulic rotator seals are damaged. Replace them •... - Page 19 • Check the welds for cracks or fissures. • Check the hydraulic cylinders for oil leaks or deformation. • Check that the hydraulic hoses are intact and the fittings are not leaking oil. • Check the presence of the identification plate. •...

-

Page 20: Inspection And Maintenance Log

INSPECTION AND MAINTENANCE LOG The machinery directive obliges the user of the equipment to keep a register in which all extraordinary maintenance and annual inspections carried out by the relevant bodies are recorded. The following register can be noted: • Faults and related repairs •... - Page 21 Intervention Date: Annotations: Operator: Next scheduled check: Stamp and Signature Intervention Date: Annotations: Operator: Next scheduled check: Stamp and Signature Intervention Date: Annotations: Operator: Next scheduled check: Stamp and Signature Intervention Date: Annotations: Operator: Next scheduled check: Stamp and Signature...

-

Page 22: Accessories

ACCESSORIES All forestry shears can be equipped with the following accessories to add functionality or capacity as described below: • Picking tooth: The pick-up tooth is used to hold small logs or branches with the shear when making several cuts. •... - Page 23 GRA-C 20 Ref. Name Code Body 25402 Caliper 25401 Blade 254030101G Plate 254021001G Cylinder CIL254 main pivot 25406 pin cylinder caliper 25404 body cylinder pin 25405 Bushing caliper BOC-CIL-BR-50x55x45 Cylinder BOC-CIL-BR-35x39x40 TSEI M12x30Grower TPSEI-M12x40-ZINC-8.8 10...

- Page 24 Ø12 ROND-GROWER-M12 Nut M12 DAD-M12 Screw TE M12 x 35 TE-M12x35-ZINC-8.8 Nut AB M33 DAD-AB-BAS-M33 Washer Ø33 ROND-ZINC-M33 Block valve V0111SE short eye OCC-CORTO-3/8 long eye OCC-LUNGO-3/8 GRA-C 30 Ref. Name Code Body 24902 Caliper 24901 Blade 249030101G...

- Page 25 Plate 249021001G Cylinder CIL249 Main pin 24906 Caliper cylinder pin 24904 Cylinder pin body 24905 Bushing Caliper BOC-CIL-BR-75x80x90 Bushing Cylinder BOC-CIL-BR-50x55x60 TSEI M16x60Grower TPSEI-M16x60-ZINC-8.8 washer Ø16 ROND-GROWER-M16 Nut M16 DAD-M16 TE M16x60 TE-M16x60-ZINC-8.8 TE M16x50 TE-M12x50-ZINC-8.8 Nut AB M48 DAD-AB-BAS-M48 Washer Ø48 ROND-ZINC-M48 Block valve...

- Page 26 GRA-C 30 rotation group Name Code Q.ty Lower plate 280010601G Giunto oleodinamico DA060/02 Slewing bearing 700002296 Hydraulic motor 255130A6312BAAAA Valve VLP000788 Upper plate 280140101G Upper castle 28008 Cover 280090101G Fork 280100101G Quick coupler plate 280150101G Screw M16 x 40 TE-M16x40-ZINC-8.8 Washer Ø16...

- Page 27 Screw M12 x 35 TE-M12x35-ZINC-8.8 NutM12 DAD-M12 Washer Ø10 ROND-GROWER-M10 Screw M10 x 12 TE-M10x12-ZINC-8.8 Screw M12 x 30 TE-M12x30-ZINC-8.8 Washer Ø12 ROND-GROWER-M12 Screw M16 x 60 TE-M16x60-ZINC-8.8 Nut M16 DAD-M16 Screw M8 x 35 TE-M8x35-ZINC-8.8 GRA-C 45 Ref. Name Code Q.ty...

- Page 28 Body 25302 Collet 25301 Blade 253030101G Plate 253021001 G Cylinder CIL253 Main pin 25306 Caliper cylinder pin 25304 Body cylinder pin 25305 Caliper bushing BOC-CIL-BR-100x105x90 Cylinder bushing BOC-CIL-BR-60x65x60 Screw TE M20 x 60 Grower washer Ø20 Nut M20 Shim 253021301G Nut M48 AB...

Need help?

Do you have a question about the GRA-C and is the answer not in the manual?

Questions and answers