Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Topwell PROMIG 250SYN DPulse

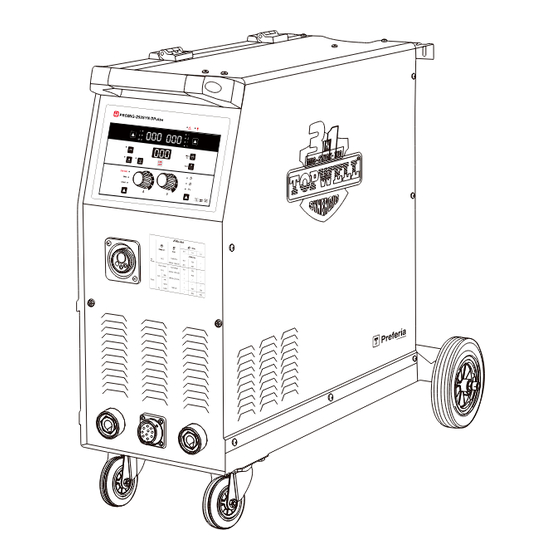

- Page 1 PROMIG 250SYN DPulse Quick guide | English...

-

Page 2: Check The Package Contents

A. Preparation. Check the package contents. Electrode holder Gas hose and earth clamp MIG-24KD (Teflon liner for AL) You will also need. Argon regulator CO2 regulator V groove roller for M.S/S.S (0.8/1.0mm) 300mm wire spool Helmet Liner for M.S/S.S... - Page 3 Connect to the main supply and switch on. Voltage of power source: 1-PH 230 V ±10% ;3-PH 380 V ±10% Frequency: 50/60 Hz Connect to the shielding gas. M.S. S.S. 100%CO2 98% Ar + 2% CO2 100% Ar 82% Ar + 18% CO2...

-

Page 4: Gas Check

Gas Check. Gas Check And Flow Adjust Typical flow rate for shielding gas is 20 to 30 CFH (cubic feet per hour). -

Page 5: Machine Description - Quick Overview

B. Machine description - quick overview. Machine control - operating elements. Item Description Item Symbol Description Symbol Welding amperage Wire feeding speed Job-list: Job-list number selection Metal thickness (M.S. only) Welding voltage: -5 V to 5 V Inch feeding Arc length: -5 V to 5 V Induction: Softer arc or harder arc Check the gas (0 to 10, 5 in the middle) -

Page 6: Front View

Front view. Item Symbol Description Machine control See Machine control – operating elements chapter on page 05 Connection socket Connect to MIG torch Connection socket, “+” welding current • MMA welding: workpiece connection • MIG/MAG welding: welding current connection for the welding torch •... -

Page 7: Method Of The Operation

C. Method of the operation. MIG welding. Connect the filler wire. 1.Load and secure spool, 2.Check and adjust filler wire drive roll. adjust the break force V-groove roller for M.S./S.S.; U-groove roller for AL. 3.Push wire through guides into gun; 4.Close and tighten pressure assembly, and let go of wire. - Page 8 10.Connect the earth clamp 10.1 Solid wires welding with a positive wire electrode. 10.2 Flux-cored wires welding with a negative wire electrode...

-

Page 9: Start Welding

Start welding. 3 steps to achieve weld perfection Item Symbol Description Select SYN MIG Regarding the JOBs-list, set the job list number Set the welding output parameters (set either one in enough) See machine description on page 05 You may also need to check the following knobs for some optional functions Dynamic control Item Symbol Description... - Page 10 The program Program is used to set all the settings during the complete welding phase. PROGRAM ADJUSTMENT RANGE DEFAULTS Pre-gas Time 0.0-10.0s Slow-feeding Adjustment 1.0 - 10.0 m/min Hot-start Amp 100-200% 100% Hot-start Arc Voltage -5.0 to 5.0 V Hot Start Hot-start Continue Time 0.0 - 10.0 s Up/Down-slope Time from Hot-start...

- Page 11 Welding phases Start Phase Welding Phase End Phase (P16) (P06) (P07) (P17) (P08) (P09) (P15) (P18) (P19) (P20) (P00) (P02) *Avaliable to set the Arc Start together with Hot Start or without (P03) (P05) (P04) Pre-gas Time(P00) GPr:Gas pre-flow Hot Start (P02-P05) I-H:Hot start current phase:In cold conditions, the wire is heated firstly, so it becomes the normal temperature state at the moment of welding to reduce defects.

-

Page 12: Welding Mode

Welding Mode Symbol 2T mode (P20) (P00) “2T mode” is suitable for - Tacking work - Short weld seams - Automated and robot welding S2T mode (P06) (P16) (P07) (P17) (P00) (P08) (P09) (P15) (P18) (P20) *Hot Start prior to Start Arc(P02-P05) "S2T mode"... - Page 13 4T mode (P00) (P20) “4T mode” is suitable for longer weld seams. S4T mode (P06) (P07) (P16) (P17) (P00) (P08) (P09) (P15) (P18) (P20) *Hot Start prior to Start Arc(P02-P05) "S4T mode" is particularly suitable for welding aluminium materials. The special slope of the welding current curve takes account of the high thermal conductivity of aluminium.

- Page 14 Setting Double Pulse P14:High/Low Pulse Wave Correction (P14) (P14) Peak (High Pulse) Base (Low Pulse) P10:Base-pulse Amp P11:Base-Pulse Voltage Double Pulse Frequency (P12) Peak Pulse Ration (P13) 1.Peak:A/V(adjust the Peak current and voltage) 2.Base:A/V(set P10-P11 in program) 3.Peak Pulse Ration(set P13 in program) 4.Double Pulse Frequency(set P12 in program) 5.High/Low Pulse Wave Correction(set P14 in program)

-

Page 15: Mma Welding

MMA welding. Description Item Symbol Select MMA Set the amperage... -

Page 16: Gmaw Welding (Mig) Guidelines

D. Gmaw Welding (mig) Guidelines. SECTION 11 GMAW WELDING (MIG) GUIDELINES Typical GMAW (MIG) Process Connections 11-1. Typical GMAW (MIG) Process Connections Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. Place work clamp as close to the weld as possible. -

Page 17: Holding And Positioning Welding Gun

Holding And Positioning Welding Gun 11-3. Holding And Positioning Welding Gun Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trig- ger, be sure wire is no more than 1/2 in. (13 mm) past end of nozzle, and tip of wire is positioned cor- rectly on seam. -

Page 18: Gun Movement During Welding

Gun Movement During Welding 11-5. Gun Movement During Welding Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. Stringer Bead Steady Movement Along Seam... -

Page 19: Troubleshooting − Excessive Spatter

Troubleshooting − Excessive Spatter 11-8. Troubleshooting Excessive Spatter Excessive Spatter scattering of molten metal particles that cool to solid form near weld bead. S-0636 Possible Causes Corrective Actions Wire feed speed too high. Select lower wire feed speed. Voltage too high. Select lower voltage range. -

Page 20: Troubleshooting − Lack Of Penetration

Troubleshooting − Lack Of Penetration 11-11. Troubleshooting Lack Of Penetration Lack Of Penetration shallow fusion between weld metal and base metal. Lack of Penetration Good Penetration S-0638 Possible Causes Corrective Actions Improper joint preparation. Material too thick. Joint preparation and design must provide access to bottom of groove while maintaining proper welding wire extension and arc characteristics. - Page 21 11-14. Troubleshooting Waviness Of Bead Troubleshooting − Waviness Of Bead Waviness Of Bead weld metal that is not parallel and does not cover joint formed by base metal. S-0641 Possible Causes Corrective Actions Welding wire extends too far out of nozzle. Be sure welding wire extends not more than 1/2 in.

- Page 22 Troubleshooting Guide For Semiautomatic Welding Equipment 11-17. Troubleshooting Guide For Semiautomatic Welding Equipment Problem Probable Cause Remedy Wire feed motor operates, but Too little pressure on wire feed rolls. Increase pressure setting on wire feed rolls. wire does not feed. Incorrect wire feed rolls.

-

Page 23: Electrical Schematics

AC27V2 DRV+ G3R1 G3R1 E3B1 E3B1 Gas_Relay GND1 G4Y1 G4Y1 GND1 If1+ E4B1 E4B1 Motor+ Motor+ Gun/Man_SW GND1 If1+ OUT+ OUT- +15V1 -15V1 DRV+ AC19VA1 AC19VA2 +15V1 -15V1 AC9V1 AC9V2 OUT+ OUT- Web & Mail Phone (+86)571-88231791 www.cn-topwell.com (+86)571-88231792 sales@topwellwelders.com...

Need help?

Do you have a question about the PROMIG 250SYN DPulse and is the answer not in the manual?

Questions and answers