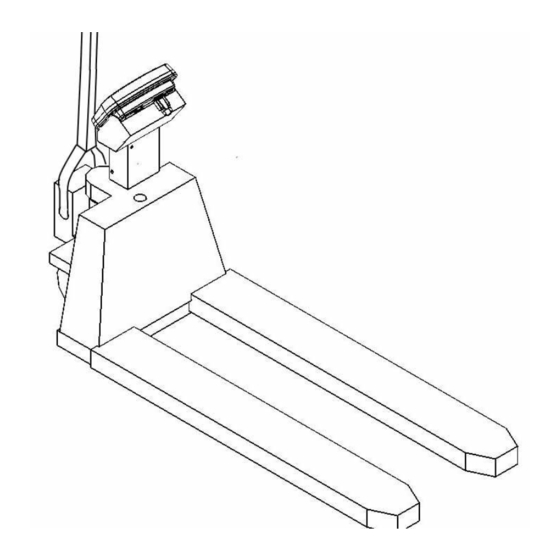

Summary of Contents for WorldWEIGH TA100 Series

- Page 1 TA100 SERIES With E402 Indicator (P.N. 3106610715, Revision E, April 2011) 81320477 en...

-

Page 2: Table Of Contents

Thank you for purchasing the Cooperativa Bilanciai PA100 Pallet Truck. For your safety and correct operation, please read the following instructions carefully before using it. CONTENT SAFETY ..........................3 INSTRUCTION ........................5 SPECIFICATIONS ......................5 PACKING LIST ......................5 INSTALLATION ......................... 7 AE 402 ASSEMBLY ...................... -

Page 3: Safety

SAFETY To prevent damage to the scale, please read these operating instructions thoroughly. When using the pallet truck, please keep the handle in the DRIVE position. This pallet truck must be operated by trained personnel only. Check the pallet truck first before using it making sure that the wheels, handles and forks are fitted correctly and secure ... -

Page 5: Instruction

INSTRUCTION PECIFICATIONS Common specifications Model TA100- 2000 TA100- 5000a Load cell Capacity 2000 kg 5000Lb Resolution 0.5 kg Fork length 1150mm (45.25“) 1220mm (48”) Fork Width (each) 160mm (6.3”) 160mm (6.3”) Fork Width (total) 540mm (21.25”) 680mm (26.77”) Fork Height 77mm increasing to 192mm 77mm increasing to 192mm (3”... - Page 6 TA100-2000...

-

Page 7: Installation

INSTALLATION Please follow the installation instructions to ensure correct operation of your TA100. In transportation the handle is removed from the truck, this needs to be installed following the instructions below: NOTE: Do not lower the handle down fully until completing the instructions below. -

Page 9: Ae 402 Assembly

E 402 ASSEMBLY Rear view of E 402 Indicator Fit the TA100 to Indicator cable as shown in the picture below: 5 pin connector fitted here... - Page 10 The Indicator bracket is fitted to the TA100 using 4 x M4 screws as the picture below shows, these should be tightened using the Allen Key supplied . M4 x 6 Screws 4 places The Indicator cable goes through the hole on the bracket and connects to the Indicator using the 7 pin connector.

- Page 11 7 pin connector fitted here. The E 402 indicator is placed into the mounting bracket, and secured using the two plastic fasteners as shown below: Plastic fasteners used to secure Indicator to the bracket.

-

Page 13: Calibration

CALIBRATION The TA100 is factory calibrated, please refer to the user manual for the indicator supplied (E 402) when further calibration when required. -

Page 14: Trouble Shooting

TROUBLE SHOOTING Problem Cause Solution Forks cannot ascend to the maximum Inadequate hydraulic oil in the chamber. Refill oil chamber. See Figure 1. height No hydraulic oil. Refill oil chamber. See Figure 1 . Forks can not be Oil is not clean. Change oil raised Relocate load. -

Page 15: Maintenance

MAINTENANCE Please check the oil every six months , we suggest you use hydraulic oil: ISO VG32 Whilst in transit air may enter into the hydraulic pump, this may result in the forks not raising when first used. Please move the handle up and down several times to allow air to escape. - Page 16 Manufacturer’s Declaration of Conformity This product has been manufactured in accordance with the harmonised European standards, following the provisions of the below stated directives: Electro Magnetic Compatibility Directive 2004/108/EC Low Voltage Directive 2006/95/EC Società Cooperativa Bilanciai Via S.Ferrari n°16 CAP 41011 Campogalliano Modena Italy This symbol on the weighing instrument you have purchased means that: •...

- Page 17 ATTENZIONE : Smaltire questa apparecchiatura tramite raccolta separata o conferimento al distributore o ai centri di raccolta differenziata...

Need help?

Do you have a question about the TA100 Series and is the answer not in the manual?

Questions and answers