Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Alpha Omega Instruments TY-6330P

- Page 1 Portable Gas Analyzer Users Manual...

-

Page 2: Unpacking Instructions

Foreword 1.1 Overview Before using the analyzer and its accessories, please familiarize yourself with its operation by reading this manual. If you have any questions, please do not hesitate to contact with us for assistance. 1.2 Unpacking Instructions - Inspect the shipping boxes for any sign of damage. Damaged shipping boxes increase the risk to find damaged material too. -

Page 3: Safety Information

We also recommend configuring the auto-zero function in order to make the zero drift negligible. • Please refer to the specific sections of this manual. Do not expose the analyzer to electrical shock and/or severe continuous mechanical shock. • Do not attempt to disassemble, adjust, or service the analyzer unless instructions for that procedure •... -

Page 4: Safety Information For Analyzer Utilisation

Safety information for Analyzer utilisation The Analyser is not designed for use in hazardous area. Never use the analyzer in an EX ◼ environment with potential gas explosion risks. Human safety could be seriously endangered by flame, fire and/or deflagration. The Analyser must be installed on a flat surface (if used as bench-type analyser) or ◼... -

Page 5: Notice For Electrical Connections

- Quality: free from solid particles, tar and oil traces - Temperature: < 50° C - Pressure in: max. + 100 mbar relative; Processes with lower gas pressure will require the use of a gas sampling pump. Processes with higher gas pressure will requires the installation of a pressure reducer before the analyser to keep the gas pressure constant and limited to max. -

Page 6: Notice For Maintenance

Always prevent dust, tar and oil traces for entering the analyser to avoid ◼ damages to the measuring cells. Never switch OFF & ON successively the analyzer power supply without ◼ reasons, otherwise the analyzer lifetime might be shortened, or the analyser might be damaged. -

Page 7: Features And Applications

2 Abstract The portable gas analyzer is based on NDIR technology to measure the gas concentration of CO, CO2, CH4 and CnHm(optional), based on TCD to measure he gas concentration of H2, and based on ECD to measure the gas concentration of O2 at the same time in one analyzer. The BTU calculation is available too. .1 NDIR principle CO, CO2, CH4, C3H8 and other molecules by heterogeneous atoms in the infrared wavelength region with the absorption spectrum, its absorption intensity follows Lambert - Beer's Law. -

Page 8: Specifications

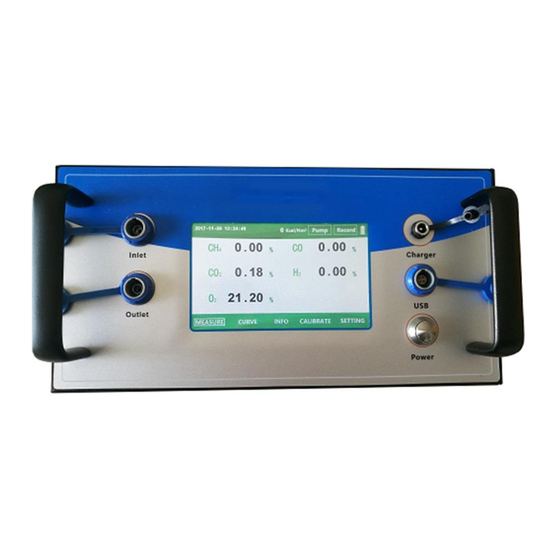

2.3 Specifications Components Method Range Resolution Precision NDIR 0-5% to 100% 0.01% ≤2% NDIR 0-5% to 100% 0.01% ≤2% 0-5% to 100% 0.01% ≤3% 0-5% to 25% 0.01% ≤3% NDIR 0-5% to 100% 0.01% ≤2% CnHm (optional) NDIR 0-5% to 10% 0.01% ≤2% Note: Measurement range can be customized by the requirement. - Page 9 Port name Descriptions Inlet Gas inlet Outlet Gas outlet Charger Power battery charge, 12V Communication port, connecting to computer ON/OFF Power switch...

- Page 10 3 Operation 3.1 Preparation before operation 1) Sample gas should connect to gas pretreatment system before using. The sample gas inletting into the gas analyzer should be clean, dry and without tar. 2) Gas outlet pipe should be leaded to outdoor; Gas outlet pipe should not no blocked. 3) Sample gas pressure should be a little bigger than atmosphere pressure 4) Gas flow into the gas analyzer should control at 0.7L-1.2L/min, recommended to at 1.0L/m 3.2 Power on...

-

Page 11: Measurement Screen

3.3 Measurement screen The measurement screen shows up to 6 gas compounds that are measured by the analyser and the calculated gas heating value, with their respective chemical symbol, concentration and unit, as well as the remaining battery autonomy, the date and time and some functions : Disconnection: means the gas sensor communication is disconnected or trouble. -

Page 12: Measurement Information

2) Click each gas component, you can choose display or not display curve. For example, when you click CO2 again, it will not display curve in the yellow color, as follows: 3.5 Measurement information In the INFO interface, it shows gas sensor information. The users cannot modify it, only for reference. - Page 13 3.6 Calibration In the calibration interface. It needs password to enter. The password is 9999. After input the password 9999, it will shows: Click drop-down box to select the gas you want to calibrate The real-time concentration of the gas you selected Input zero gas value when doing zero point calibration.

-

Page 14: System Settings

d. Input 0 in the blank (marked as 3 in the above picture), and click ZERO button; e. Then zero calibration is finished. 2) Span calibration a. Select the gas that needs to be calibrated; take CH4 as example b. Inlet calibration gas and check the real-time concentration. (e.g. if CH4 is 0-25% range, then please inlet 25% CH4 calibration gas, and balance should be N2);... - Page 15 3.7.1 USB connect computer Use USB cable into the USB interface, the analyzer connected to the computer, and then click on the "Connect to PC via USB”...

- Page 16 3.7.2 Change Password Note: please remember the modified password, if you accidentally lost the password, you can contact the company after service 3.7.3 Others 3.7.3.1 Clear all data Click on "Clear all data", click the "Confirm" button, appear "Empty successfully" means empty finished.

- Page 17 3.7.3.2 Update the firmware Click on "updated the firmware", click the "update" button to update the firmware; cilick return to back. 3.7.3.3 Restore factory settings Click "Restore system settings”, click the "Restore" key, appear "Recovery is successful", indicating the successful recovery of factory settings. 3.7.3.4 Modbus address The users can modify modbus address for communication.

-

Page 18: Touch Screen Calibration

3.7.4 Touch screen calibration For touch screen calibration, if the click speed is too fast, may lead to calibration failure. The correct method is: hold down "+" about 1s, there will be "completion (OK)" prompt information, indicating that the calibration is successful. - Page 19 3.7.5 Calorific value set The settings are completed as shown in the following picture:...

-

Page 20: Common Faults

4. Common Faults Fault phenomenon Reason Solutions Less flow or no flow Sampling system fault; Check the sampling system and eliminate Sampling port leakage; external faults; Inlet port or gas pipe Tighten the sampling port to connect the blocked gas pipe and replace the sampling tube; Check the air inlet port;... -

Page 21: Instrument Maintenance

5. Instrument maintenance 1. During the maintenance of equipment, power should be cut off to avoid electric shock accident. 2. Should clean the instrument surface dust after the use it. 3. The instrument should be stored in a clean, ventilated and dry environment. 4. - Page 22 6. Portable gas conditioning device user manual Sampling gas usually contain impurities such as dust, liquid water and tar, some of these impurities could pollute the gas sensor if sampling gas was not pre-treated before entering into the analyzer. It could shorten lifetime of the instrument, even breakdown the instrument.

- Page 23 analyzer by hosepipe Ø6. 2. operating procedure emission Input water to the Water bubbler Remove connection hose and extract water scrubber from the pipe clamp, open top cap then input water. Fasten the top cap after finishing water. Attention: The height of water should be lower than the highest waterline Top tap must be fasten to avoid measurement error caused by air leakage Connection of gas circuit Connect gas circuit as picture 2.

- Page 24 7. Communication Protocols ModbusRTU 1) Communication properties Baud rate: The default is 9600 Start bit: 1bit Data length: 8bit Check Type: None Stop bit: 1bit 2) Communication frame structure Host station sends command format: Start register Number of read Address field Function code CRC check low CRC check high...

- Page 25 Therefore, the concertation in the example is: Hexadecimal 044B represents the decimal integer bit 1099, the current CO concentration is 1313PPM; Syngas analyzer communication protocols Equipment address:85 Baud rate:9600 All concentration data is integral after increasing by 100 times. valid_bits means sensor is valid or not, for example 0x7D means all the sensors are valid except H2S. [sensordata] start=0x0000 length=0x0010...

Need help?

Do you have a question about the TY-6330P and is the answer not in the manual?

Questions and answers