Subscribe to Our Youtube Channel

Summary of Contents for Ruby 010 AISI 316

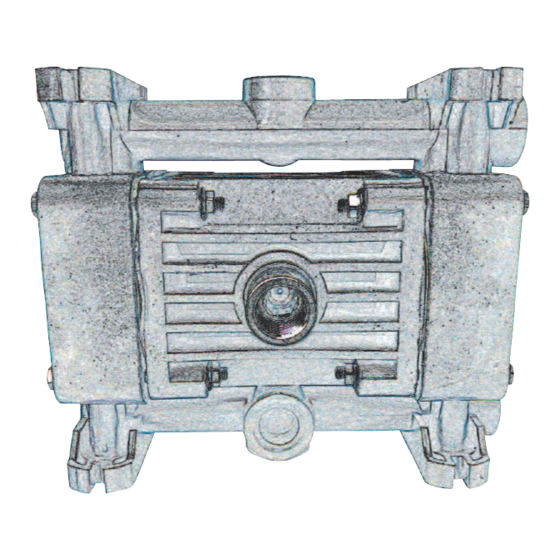

- Page 1 Air Operated Diaphragm Pumps Installation, Operation and Maintenance 010 AISI 316 Pump ΙΙ 2G Εx h IIB T4 Gb II 2D Εx h IIIB Τ135˚C Db Baseefa15ATEX13DR/RN3 Industrial Park of Kifisia - HELLAS www.alphadynamic.eu...

-

Page 2: Table Of Contents

Temperature range of the Housing material...........................13 Pump Disassembly ..................................14 Pump Assembly ....................................15 Troubleshooting....................................16 Technical data ....................................17 Dimensional Drawings ...................................17 Performances....................................18 Exploded View and Spare Parts List..............................19 6.3.1 Exploded view - Ruby 010 AISI 316 Pump ............................19 6.3.2 Spare Part list ....................................20... - Page 4 STRONG QUALITY INDUSTRIAL PUMP Type of protection: Constructional Safety “c” This declaration applies to all Metallic & Conductive Plastic Ruby Air Operated Double Diaphragm pumps. ALPHADYNAMIC PUMPS (HELLAS) declares under our sole responsibility that the product listed below conforms with the relevant provisions of EC directive 2014/34/EC for equipment and protective systems intended for use in potentially explosive atmospheres, and is self certified for safe use in Atex Group II, Category 2 area’s.

-

Page 6: Markings And General Information

II 2G Ex h IIB T4 Gb II 3G Ex h IIB T4 Gc II 2D Ex h IIIB T135°C Db II 3D Ex h IIIB T135°C Dc 1.0.3 Composition Codes Ruby umps composition codes Other Model Pump Body Center Section... -

Page 7: Warranty

1.1 Warranty The correct function of each Ruby pump is tested in the factory. However, should any defect appear, please contact the Manufacturer’s After-Sales Service, your dealer or the nearest Customer Service Centre where you will receive assistance as quickly as possible. In any case, please provide: Α- Your complete address... -

Page 8: Pump Operation

1.4 Pump operation Ruby Air Operated Diaphragm Pumps are oscillating positive displacement pumps with two pump chambers arranged opposite each other. Both of these are separated by a diaphragm each into an air and a fluid section. Both diaphragms are linked by a piston rod, so that with every stroke product is displaced to the outside from the one pump chamber and product is drawn into the opposite pump chamber. - Page 9 For installation and use in a potentially explosive environment, comply with these general precautions - ascertain that the pump is full and if possible, that the level is above it by 0.5 m; - ascertain that the fluid treated does not contain or cannot contain large solids or solids of a dangerous shape - ensure that the intake or delivery ports are not obstructed nor limited to avoid cavitation or pneumatic motor strain.

-

Page 10: Equipotential Bonding / Earthing

WARNING:The air-driven motor of the Ruby pumps is self-lubricating and will not require any greasing. Therefore a void using Iubricated and non- dried air. -

Page 11: Installation

3.0 Installation To be observed before installation 1. The installation must only be carried out by persons who have the necessary skills for this work 2. Before installation align the pump correctly and fasten it without any tension. Pipelines must be assembled in a way that the basic weight of the lines is not reasting on the pump 3. -

Page 12: Connection Of Air Supply Line

After assembly check the system for leaks 3.3 Pump in suction operation Ruby Air Operated Diaphragm Pumps are dry self-priming. Depending on the pump design a suction head of max. 9 m Wc can be reached, when the suction line is filled. -

Page 13: Noise Emissions (2003/10/Ec)

3. Connect the product intake and delivery hoses to their respective fittings whilst taking into consideration the signs on the pump: ΊΝ" = INTAKE (down) and OUT" = DELIVERY (up) or according to that indicated by the arrows. 4. Secure the hoses using the relevant clamps. WARNING: Provide appropriate support for the piping. -

Page 14: Pump Disassembly

4.0 Pump Disassembly Step 1 Step 2 Step 3 Disassemble the discharge manifold by Remove the discharge manifold , the seats Disassemble the pump housing by untying untying the retaining screws , the balls and the o-rings of the valves. the retaining screws Follow the same procedure (steps 1 &... -

Page 15: Pump Assembly

4.1 Pump Assembly To assemble the pump follow the steps bellow: Step 1 Step 2 Step 3 Insert the air control unit in the central block. Install the outer pistons, diaphragms and Install the pump housings in the central Mount the retaining ring to the central block screw the external caps block. -

Page 16: Troubleshooting

5.0 Troubleshooting The following instructions are intended exclusively for authorised skIilled maintenance engineers. In event of abnormal behaviour and in order to fix faults, please refer to the following troubleshooting instructions. WARNING: For more serious problems, we strongly recocomend that you contact the ALPHADYNAMIC PUMPS Co: our engineers will provide you assistance as quickly as possible. -

Page 17: Technical Data

6.0 Technical data 6.1 Dimensional drawings... -

Page 18: Performances

6.2 Performance Ruby 010 AISI 316 pump Flow. Rate ............21 L/min Air inlet ..............3/8" Suction – Discharge port ......3/8 ’’ BSP G Suction lift (dry)............4 m Max. Solid size ( diameter) .......0.5 mm Air Supply Pressure Air Consumption NL/min 7 bar... -

Page 19: Exploded View And Spare Parts List

6.3 Exploded View and Spare Parts List 6.3.1 Exploded view Ruby 010 AISI 316 Pump 010 AISI 316 spare part list pump 18+18B DESCRIPTION DECRIPTION CENTRAL BLOCK BALL SEAT INSIDE ORING (PVDF SEAT) MANIFOLD RETAINING RING AIR VALVE PUMP HOUSING... -

Page 20: Spare Part List

6.3.2 Spare Part list Ruby 010 AISI316 Part No POSITION DESCRIPTION No req. 10.01 R010-0252 CENTRAL BLOCK PP 10.01 R010-0253 CENTRAL BLOCK PP+CF 10.02 R010-0265 MANIFOLD AISI 316 10.04 R010-0285 PUMP HOUSING AISI316 10.05 R010-0103 INTERNAL DIAPHRAGM NBR 10.05B R010-0102 EXTERNAL DIAPHRAGM TFM 10.06... - Page 21 ALPHADYNAMIC PUMPS Industrial Park of Kifisia - HELLAS www.alphadynamic.eu Air Operated Diaphragm Pumps...

Need help?

Do you have a question about the 010 AISI 316 and is the answer not in the manual?

Questions and answers