Summary of Contents for GESTRA FPS Station

- Page 1 IM-P744-01-EN-ISS2 CMGT Steam-Powered Condensate-Return Station FPS Station Original Installation Instructions 850925-01 English...

- Page 2 850925-01 IM-P744-01-EN-ISS2 CMGT...

-

Page 3: Table Of Contents

Contents 1 Safety information 2 General product information 3 Single FPS Station installation and commissioning 4 Duplex FPS Station installation and commissioning 5 Maintenance 6 Fault finding IM-P744-01-EN-ISS2 CMGT 850925-01... -

Page 4: Safety Information

Determine the correct installation situation and direction of fluid flow. iv) GESTRA products are not intended to withstand external stresses that may be induced by any system to which they are fitted. It is the responsibility of the installer to consider these stresses and take adequate precautions to minimise them. - Page 5 Allow time for temperature to normalise after isolation to avoid danger of burns. Tools and consumables Before starting work ensure that you have suitable tools and/or consumables available. Use only genuine GESTRA replacement parts. Protective clothing 1.10 Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and dangers to eyes and face.

- Page 6 Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to GESTRA they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk.

-

Page 7: General Product Information 2

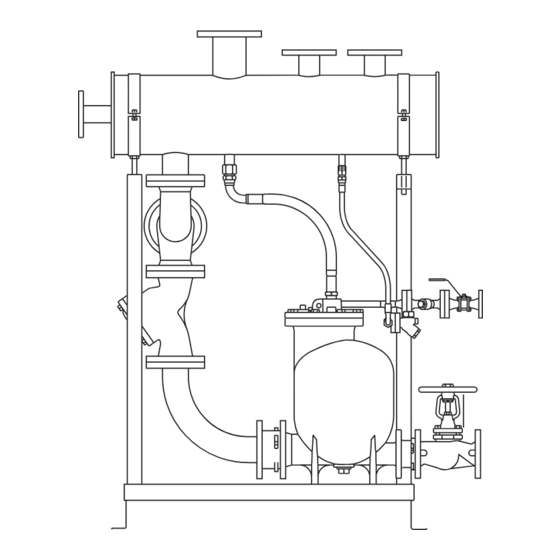

The FPS Station is available with either single or duplex pumps, mounted on a single base plate, that can be used for duty only or duty/stand-by applications. - Page 8 198 °C @ 13.8 bar g FPS Station SS 188 °C @ 10.96 bar g Minimum operating temperature 0 °C Note: For lower operating temperatures consult GESTRA Designed for a maximum cold hydraulic test pressure of: 24 bar g 850925-01 IM-P744-01-EN-ISS2 CMGT...

- Page 9 Sizes and pipe connections - Single FPS Station Single FPS Station (see Section 3 regarding installation, location and commissioning) Pipe Pump unit size connection (Con out) (Motive) (Overflow) (Vent) (Inlet) PN16 DN25 DN15 DN50 PN16 DN80 DN40 DN25 1" ½"...

- Page 10 2.5 Sizes and pipe connections - Duplex FPS Station Pipe Pump unit size connection (Con out) (Motive) (Overflow) (Vent) (Inlet) PN16 DN40 DN15 DN50 DN150 DN50 DN40 1½" ½" 2" 6" 2" (1½") ASME 150 ASME 150 ASME 150 ASME 150...

-

Page 11: Single Fps Station

Important note: Please acknowledge the safe lifting points indicated on Figure 4. Location The FPS Station should be located in a suitable position e.g. against a wall where the vent can be easily piped to atmosphere. It is recommended that reasonable clearance is maintained around the unit for ease of access. - Page 12 Fig. 3 3.3 Commissioning 1. Slowly open the steam motive supply isolating valve (item 7) to provide pressure to the FPS Station. Check that the motive drain trap (item 9 where fitted) is operational. 2. Open any isolation valves between the process being drained and the FPS Station at point (Z).

- Page 13 Materials Fig. 4 8 + 9 Spare parts Please contact GESTRA for available ancillary spares. The only safe lifting points No Part Material No Part Material Receiver Mild steel PC10 Quick-fit connector Stainless steel Base plate and frame Mild steel...

-

Page 14: Installation And Commissioning

4.2 Location The FPS Station should be located in a suitable position e.g. against a wall where the vent can be easily piped to atmosphere. It is recommended that reasonable clearance is maintained around the unit for ease of access. - Page 15 Connection to atmospheric vent line 'U' bend water seal overflow point Connect to a safe discharge point Recommended 305 mm (12") minimum Fig. 5 IM-P744-01-EN-ISS2 CMGT 850925-01...

- Page 16 FPS Station. Check that the motive trap (item 9 where fitted) is operational. Open any isolation valves between the process being drained and the FPS Station at points (Z). Open the inlet isolation valve (item 5) and the condensate outlet isolation valve (item 5) in the condensate return line (point V).

- Page 17 8 + 9 Safe lifting point Safe lifting point Fig. 6 Spare parts Please contact GESTRA for available ancillary spares IM-P744-01-EN-ISS2 CMGT 850925-01...

-

Page 18: Maintenance

When dismantling the pump, care should be taken to prevent personal injury from the strong snap mechanism. Always handle with care. For full maintenance instructions, on each component of the station, contact GESTRA. Spare parts For availability of spare parts contact GESTRA. -

Page 19: Fault Finding 6

Installation and troubleshooting should be performed by qualified personnel. Before disconnecting any connections to the FPS Station, every effort should be made to ensure that any internal pressure has been relieved and that the motive supply line is isolated to prevent inadvertent discharge of the pump. - Page 20 Agencies all over the world: www.gestra.com GESTRA AG UK Importer: GESTRA UK Ltd Münchener Straße 77 28215 Bremen Unit 1 Sopwith Park, Royce Close, Deutschland West Portway Business Park, Andover, Telefon +49 421 3503-0 Hampshire SP10 3TS Telefax +49 421 3503-393 United Kingdom E-mail info@de.gestra.com...

Need help?

Do you have a question about the FPS Station and is the answer not in the manual?

Questions and answers