Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Rtelligent S Series

- Page 1 S Series Sensorless Driver Manual V1.2...

-

Page 2: Foreword

Foreword Thank you for choosing Shenzhen Rtelligent Mechanical Electrical Technology CO., LTD BLDC series sensorless driver. This manual provides the knowledge and precautions required to use this system. Improper operation may cause accidents. Before using this system, be sure to read this ... -

Page 3: Table Of Contents

Contents FOREWORD ................................I CONTENTS ................................II 第一章 PRODUCT INFORMATION ........................1 1.1 I ..........................1 NTRODUCTION TO DRIVE Overview ............................. 1 Product Model Description ........................1 Product characteristics ........................1 Product Size ............................2 第二章 INSTALLATION INSTRUCTIONS ......................3 2.1 I ..........................3 NSTALLATION OF DRIVES Installation sites ...........................3 Environmental conditions ........................3 2.2 I... - Page 4 第四章 RUNNING ...............................11 4.1 B ..............................11 ASIC SET Pre-operational inspection ........................ 11 4.2 M ......................12 OTOR PARAMETERS IDENTIFICATION 4.3 A ..........................13 PPLICATION PATTERN potentiometer speed regulation function ..................13 PWM speed regulation function: .......................18 Communication control functions: .....................19 第五章...

-

Page 5: 第一章 Product Information

BLDC series of non-inductive drives, is a general-purpose brushless DC motor speed drive developed by Rtelligent. equipped with 485 communication interface to realize the communication control of the drive. The driver board USB turns TTL serial port chip, which is convenient for customers to use general Micro-USB line monitoring / modification parameters. -

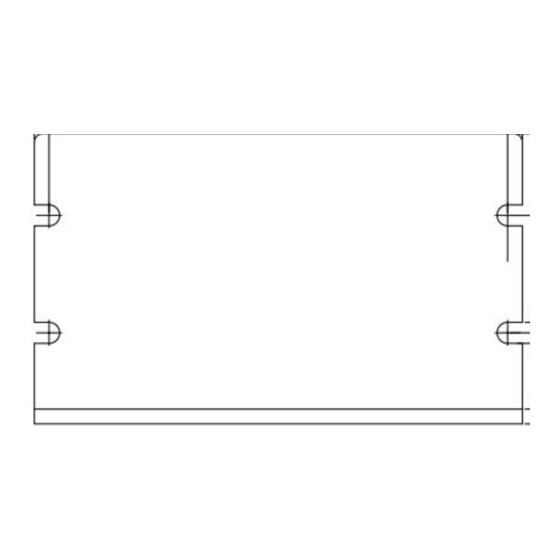

Page 6: Product Size

The speed instruction can be set. Using FOC magnetic field location technology and SVPWM technology; Support potentiometer speed regulation or 0~5 V analog input signal; Configurable function of 3 digital input /1 digital output interface; Product Size... -

Page 7: 第二章 Installation Instructions

第二章 Installation instructions 2.1 Installation of drives Installation sites Please install in the sun-free installation cabinet; Do not use this product near corrosive and flammable gas environment such as hydrogen sulfide, chlorine gas, ammonia, sulfur, chlorinated gas, acid, alkali, salt, etc. Do not install in high temperature, wet, dusty, metal dust environment;... -

Page 8: Installation Of Motor

Altitude Below 1000 m 2.2 Installation of motor Installation sites Do not use this product near corrosive and flammable gas environment such as hydrogen sulfide, chlorine gas, ammonia, sulfur, chlorinated gas, acid, alkali, salt, etc. In grinding fluid, oil mist, iron powder, cutting and other places, please choose the type with oil seal; ... -

Page 10: 第三章 Connection

第三章 Connection 3.1 Wiring definition Power input port Identification Note Positive input DC power supply :+24 V~+48 V Input DC source: V 0 Motor line ports Identification Note Electrical power line U phase Electrical power line V phase Electrical power line W phase Control signal port Identification Note... -

Page 11: Rs485 Communications Port

RS485 Communications Port Name of signal Needle pin Function RS485+ RS485- RS485 communication port Communication signal Reservations Reserved, not connected... -

Page 12: Principle Of Digital Input/Output Interface

输入IO接线说 3.2 Principle of digital input/output interface Digital Input Interface IO接线说 驱动器 数字输入接口电路 伺服驱动器 伺服驱动器 外部+24VDC 外部+5VDC COM24V COM5V COM24V EN/IN1 EN/IN1 继电器 继电器 外部GND 外部GND PUL/IN1 数字输入接口电路 数字输入接口电路 伺服驱动器 伺服驱动器 外部+24VDC 外部+5VDC COM24V COM5V DIR/IN2 EN/IN1 EN/IN1 外部GND 外部GND ENA/IN3 Figure 3-1 Digital Input Interface Principle the driver can receive 24 V or 5 V of input signals (only one can be selected), use the COM24V... -

Page 13: Digital Output Interface

接线说 外部GND 外部GND ENA/IN3 数字输入接口电路 数字输入接口电路 伺服驱动器 伺服驱动器 外部+24VDC 外部+5VDC COM24V COM5V EN/IN1 EN/IN1 外部GND 外部GND Fig .5-3 Schematic diagram of open circuit output of collector Attention: PNP input not supported 输出IO接线说 Digital Output Interface DRV series contains a photoelectric isolation output signal: ALM/OUT1 output current capacity of 30 mA ... - Page 14 出电路外接继电器 续流二极管极性错误 继电器 伺服驱动器 DC24V 伺服驱动器 输出电路外接继电器 Wrong wiring: 伺服驱动器 DC24V 继电器 OUT1 续流二极管极性错误 未接入继电器 继电器 COM0V DC24V 伺服驱动器 DC24V 伺服驱动器 OUT1 COM0V DC24V 外部地 继电器 外部地 OUT1 OUT1 继电器 COM0V COM0V 外部地 外部地 外部 Fig .5-6 Schematic diagram of wrong wiring of relay input of upper computer ...

-

Page 15: 第四章 Running

第四章 Running 4.1 Basic set Pre-operational inspection A check is required before the drive and motor are operated: Serial Records Content number Connection Drive power input terminals (VCC、GND) must be properly connected and distinguish between □ positive and negative. Drive motor power line output terminals (U、 V、 W) and motor power line cables (U、 V、 W) must □... -

Page 16: Motor Parameters Identification

range. 4.2 Motor parameters identification S400 when adapting a motor, it is necessary to use the pole logarithm, inductance, resistance, inverse EMF coefficient of the motor, which can be operated by the following steps: 1、 Ask the user to set the pole logarithm parameter of the motor correctly Pn1, the wrong set value will cause the running speed to be incorrect;... -

Page 17: Application Pattern

motor, only the parameter import can be carried out. 4.3 Application pattern potentiometer speed regulation function In this control mode, the speed instruction is given by the potentiometer or the external analog input of the user. It reads as follows: ... - Page 18 模拟通道输入0V时电压 Y(mV) 零漂校正后电压 采样电压 偏置后电压 死区设置后电压 死区设置后电压 偏置 零漂 X(mV) 50 50 模拟通道输入电压 死区 Filtering: driver provides analog filtering function by setting parameters Pn123 analog channel low pass filter cutoff frequency. It can prevent the motor instruction fluctuation caused by the instability of analog input voltage, and can also weaken the motor error action caused by interference signal.

- Page 19 analog input to 0 V. Offset: set the sampling voltage to 0 V, the corresponding analog input voltage value. As shown, pre-set sampling voltage y =0, the corresponding actual input voltage x=500 mV, This 500 is called bias. Manually set Pn122=500 mV, after bias, sampling voltage y =x-500=y -500.

- Page 20 Description of associated parameters Facto Settin Entry Param Name of Scope of setting Units Function into eters name settin Mode force Runni Analog input Setting the bias of the analog Next Pn122 0~65535 bias input channel settin Runni Analog input Setting the analog input channel Next Pn123...

- Page 21 0: downtime 1: start - up + direction mode 2: turn on 3: reversal mode start Analog Dead Runni Set the drive dead mode Imme Zone Pn131 0~1 Please refer to the analog diate Processing settin part of the graphic description effect Mode Runni...

-

Page 22: Pwm Speed Regulation Function

PWM speed regulation function: this control mode, the duty cycle signal is input through the IN1(en) digital input port of PWM servo driver. the frequency of the PWM signal is required to be more than 100 Hz and is controlled below 10 KHz as far as possible. -

Page 23: Communication Control Functions

The motor is operated by setting IN terminal function as FunIN.27(FUNC7: PWM forward) and FunIN.28(FUNC8: PWM reverse); Communication control functions: During the control mode, the motor can start and stop by RS485 communication mode, and the motor running speed can be modified: ... - Page 24 Read: motor waiting for response instruction Writer: The motor is running and the driver changes the Pn24 to 5 after responding to the instruction Read: motor waiting for response instruction Write: The motor starts running, the direction of operation is determined by the symbol of the Pn47, and the Pn24 is modified to 5 after the driver responds to the instruction Read: motor waiting for response instruction Writer: The motor stops and the driver changes the Pn24 to 5...

-

Page 25: 第五章 Parameter Description

第五章 Parameter description Modify the drive parameters by communication, just send the parameter values to the RAM area of the drive, after the drive restarts, the parameter values will be restored back to the values before the modification. If you need to permanently save the parameters (still valid after power down restart), write the value 1 by Pn90(save parameters button on the sharp technical debugging software) so that the parameter values are saved to the FLASH sector of the drive. - Page 26 Pn27 Reservations Re-calibration stator Pn28 0~1 resistance Pn29 Enable user parameters 0~1 Pn30 Enable bias calibration 0~1 Pn31~Pn32 Reservations Pn33 Prohibition PI self-identification 0~1 Pn34 Reservations Pn35 Running state Display Pn36 Controller State Display Pn37 State of the estimator Display Pn38 Control mode Display...

- Page 27 Pn78 A phase voltage bias Display V 0.01 Pn79 B phase voltage bias Display V 0.01 Pn80 C phase voltage bias Display V 0.01 phase current sampling Display Pn81 values phase current sampling Display Pn82 values phase current sampling Display Pn83 values phase...

- Page 28 Input port conduction trigger Display Pn114 state Input port disconnect trigger Display Pn115 state Pn116 Input flag register Display Pn117 Output flag register Display Pn118 System state Display Analog channel input sampling Display Pn119 values Pn120 PWM input pulse duty cycle Display 0.01% PWM output motor speed duty...

-

Page 29: Parameters

5.2 Parameters Motor parameters note: unless specifically noted, the following motor parameters need to be written to the value 1 by Pn90(the "save parameters" button on the sharp technical debugging software) so that the parameter values are saved to the FLASH sector of the drive after restarting the drive takes effect. Name of Relevant Type of motor... - Page 30 setting setting Name of Relevant Motor stator D shaft inductance name models Pn6/7 Scope of Factory 1~2147483648 Units 0.001 uH 335235 setting setting Name of Relevant Motor stator Q shaft inductance name models Pn8/9 Scope of Factory 1~2147483648 Units 0.001 uH 335235 setting setting...

- Page 31 Scope of Factory 0~65535 Units 2500 setting setting Name of Relevant Motor rated current name models Pn15 Scope of Factory 0~65535 Units 7500 setting setting Name of Relevant Flux estimation name models Pn16 Scope of Factory 20~50 Units setting setting Name of Relevant Motor R/L estimation frequency...

-

Page 32: Control Parameters

Scope of Factory 0~2000 Units Hz 0.01 setting setting Name of Relevant Reservations Pn21~ name models Pn22 Scope of Factory Units setting setting Control parameters Name of Relevant Enable control name models Pn23 Scope of Factory 0~1 Units setting setting for starting and stopping control of the motor, the Pn23 must be set to 1 to enable the drive. - Page 33 name models Scope of Factory 0~1 Units setting setting Name of Relevant Reservations name models Pn27 Scope of Factory Units setting setting Name of Relevant Re-calibration of stator resistance name models Pn28 Scope of Factory 0~1 Units setting setting Set whether to estimate the stator resistance of the motor at each start run. Stator estimation takes a certain amount of time, if you need to start fast, set to 0.

-

Page 34: Display Parameters

set at each start whether to recalibrate the current sampling, voltage sampling bias of the drive. Name of Relevant Reservations name models Pn31~ Pn32 Scope of Factory Units setting setting Name of Relevant Prohibition PI self-identification name models Pn33 Scope of Factory 0~100 Units... - Page 35 Scope of Factory Display Units setting setting Name of Relevant State of the estimator name models Pn37 Scope of Factory Display Units setting setting Name of Relevant Control mode name models Pn38 Scope of Factory Display Units setting setting Name of Relevant Error code name...

- Page 36 Scope of Factory Display Units A 0.01 setting setting Name of Relevant Q current given name models Pn45 Scope of Factory Display Units A 0.01 setting setting communication reset driver fault status: a communication reset driver fault is performed by writing "1" to this parameter. This parameter value becomes 0 after reset is complete.

- Page 37 Name of Relevant Reservations name models Pn50~ Pn53 Scope of Factory Units setting setting Name of Relevant Estimated torque name models Pn54 Scope of Factory Display Units 0.001 Nm setting setting Name of Relevant Reservations name models Pn55 Scope of Factory Units setting...

- Page 38 Name of Relevant Estimate stator D axis inductance name models Pn62/Pn6 Scope of Factory Display Units 0.001 uH setting setting Name of Relevant Estimate stator Q axis inductance name models Pn64/Pn6 Scope of Factory Display Units 0.001 uH setting setting Name of Relevant Estimation of back EMF...

- Page 39 setting setting in speed control mode, the motor running acceleration setting value when the speed instruction source is set to "0". Name of Relevant C phase current name models Pn71 Scope of Factory Display Units A 0.01 setting setting In speed control mode, the motor running deceleration setting value when the speed instruction source is set to "0". Name of Relevant A phase voltage...

- Page 40 name models Scope of Factory Display Units setting setting Name of Relevant C phase current bias name models Pn77 Scope of Factory Display Units setting setting Name of Relevant A phase voltage bias name models Pn78 Scope of Factory Display Units V 0.01 setting...

- Page 41 name models Scope of Factory Display Units setting setting Name of Relevant C phase current sampling values name models Pn83 Scope of Factory Display Units setting setting Name of Relevant A phase voltage sampling values name models Pn84 Scope of Factory Display Units...

-

Page 42: Parameter Management

name models Scope of Factory Units setting setting Name of Relevant Driver version number name models Pn89 Scope of Factory Display Units setting setting Parameter Management Name of Relevant Save parameters name models Pn90 Scope of Factory 0~1 Units setting setting Writing 1 to this parameter saves the parameter. -

Page 43: Gain Parameters

Need to operate when the motor stops running, otherwise it will cause abnormal operation When writing 1, the motor parameters in the Pn0~Pn19, as well as the RS485 communication parameters in the Pn97Pn0~Pn19Pn99, remain original and will not be modified (unless specified by the manufacturer), and the other parameters will be restored to the default value. -

Page 44: Rs485 Parameters

Name of Relevant Current integral gain Ki name models Pn96 Scope of Factory 0~65535 Units setting setting RS485 parameters Name of Relevant RS485 station number name models Pn97 Scope of Factory 1~247 Units setting setting set the slave station number of the RS485 communication drive. ... -

Page 45: Digital Input/Output Parameters

Scope of Factory 0~5 Units setting setting RS485 Communication Data Format: Set set Note 8 bit data ,1 bit stop, no check 8 bit data ,2 bit stop, no check 8-bit data ,1-bit stop, even check 8-bit data ,2-bit stop, even check 8-bit data ,1-bit stop, odd check 8-bit data ,2-bit stop, odd check ... - Page 46 The 16-bit data register is defined as follows: Reservations Polar Functional Position Reservations position Polar bit Input polarity setting Frequently closed Regular Functio Functio n Bit n Bit Input function Input function Setting Setting General rsvd( reservations) rsvd( reservations) rsvd( reservations) rsvd( reservations) SpdDirSel( Speed Direction Setting) rsvd( reservations)

- Page 47 Name of Relevant Input port 3 function / polarity setting name models Pn102 Scope of Factory 0~63 Units setting setting Name of Relevant Input port 4 function / polarity setting name models Pn103 Scope of Factory 0~63 Units setting setting Name of Relevant Input port 5 function / polarity setting...

- Page 48 The 16-bit data register is defined as follows: Reservations Reservatio Polar Functional Position position Polar bit Input polarity setting Frequently closed Regular Functio Functio Functio n Bit n Bit n Bit Output function Output function Output function Setting Setting Setting General rsvd( reservations) rsvd( reservations)

-

Page 49: Display Parameters

setting setting The software used to set the input port is mandatory valid / invalid. write a single register mainly through communication to control the validity/invalidity of all input ports of the drive. Reservations Reservations Bit.IN6 Bit.IN5 Bit.IN4 Bit.IN3 Bit.IN2 Bit.IN1 the corresponding bit Bit.INx of the Pn106 register is 1, which will force the function corresponding to this input port to be valid, otherwise invalid (controlled by the actual input signal of the drive). - Page 50 Name of Relevant Driver fault code name models Pn111 Scope of Factory Display Units setting setting For displaying drive fault code, you define the following: Reservations Parameter Reservatio Under Over Internal Reservations Overflow pressure pressure voltage Name of Relevant Input port state name models Pn112...

- Page 51 For displaying the state of the drive output port, you define the following: Reservations Reservations OUT4 OUT3 OUT2 OUT1 Bit Display Note Value Output optocoupler switched on Output light-coupled conduction Name of Relevant Input port conduction along lock state name models Pn114 Scope of...

- Page 52 For displaying the turn-off edge latch status of the drive input port, you define as follows: Reservations Reservations Bit Display Note Value Input port not turned off The input port has been turned off at least once Write any value to this parameter to zero the register value. Name of Relevant Input status flag register...

-

Page 53: Analog Parameters

Name of Relevant System state name models Pn118 Scope of Factory Display Units setting setting Name of Relevant Analog channel input sampling values name models Pn119 Scope of Factory Display Units setting setting Name of Relevant PWM input pulse duty cycle name models Pn120... - Page 54 name models Scope of Factory 1~65535 Units setting setting Name of Relevant Analog input dead zone name models Pn124 Scope of Factory 0~65535 Units setting setting Name of Relevant Analog Input Zero Drift name models Pn125 Scope of Factory 0~65535 Units setting setting...

-

Page 55: Extension Parameters

name models Scope of Display Factory Units setting setting Name of Relevant Analog Force Startup Command name models Pn130 Scope of Factory 0~3 Units setting setting Name of Relevant PWM duty cycle input signal polarity setting name models Pn131 Scope of Factory 0 or 2 Units... - Page 56 setting setting Name of Relevant Current step test percentage name models Pn135 Scope of Factory 0~100 Units setting setting Name of Relevant Data sampling channel 1 name models Pn136 Scope of Factory 0~20 Units setting setting Name of Relevant Data sampling channel 2 name models Pn137...

- Page 57 setting setting Name of Relevant Dial status name models Pn141 Scope of Factory Display Units setting setting...

-

Page 58: 第六章 Fault Handling

第六章 Fault handling 6.1 List of failures LED state Note Green light: drive not enabled green light flashing: drive enable, normal working condition 1 green ,1 red: drive overcurrent 1 green ,2 red: drive overvoltage 1 green ,3 red: internal voltage error 1 green ,4 red: encoder alarm 1 green ,5 red: drive undervoltage 1 green ,6 red: parameter storage error...

Need help?

Do you have a question about the S Series and is the answer not in the manual?

Questions and answers