Subscribe to Our Youtube Channel

Summary of Contents for CleanFreak PressureMower PM24-10HR

- Page 1 Safety, Operation, Breakdown, and Troubleshooting Manual Pressure Mower Do not use or operate machine until this manual has been read and fully understood...

-

Page 2: Table Of Contents

TABLE OF CONTENTS INTRODUCTION & IMPORTANT SAFETY INFORMATION..... S SETUP....................1-1 INSPECTION and IDENTIFICATION........1-2 LOCATION................1-2 MACHINE SETUP..............1-2 INITIAL MACHINE STARTUP..........1-2 OPERATING INSTRUCTIONS............2-1 SPECIFICATIONS................3-1 MAINTENANCE................4-1 TROUBLESHOOTING..............5-1 LEGAL NOTICES................7-1 Model Number __________________________ Serial Number ___________________________ Date of Purchase _________________________ The model and serial numbers are found on a decal attached to the pressure washer. -

Page 3: Introduction & Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION Thank you for purchasing this machine. We reserve 3. Stay alert - watch what you are doing. the right to make changes to the pressure washer at 4. All installations must comply with local codes. any time, without incurring any obligation. - Page 4 IMPORTANT SAFETY INFORMATION WARNING WARNING: Grip the cleaning 12. The manufacturer is not liable for any changes wand securely with both hands made to our standard pressure washers or any before starting. Failure to do this components not purchased from us. could result in injury from a 13.

- Page 5 IMPORTANT SAFETY INFORMATION We can not anticipate every possible circumstance • Never allow children or any unauthorized persons that might involve potential hazard, The warnings, to operate the machine. Keep all persons at a safe cautions and safety suggestions in this manual are distance when using the machine.

- Page 6 IMPORTANT SAFETY INFORMATION OSHA Lockout/Tagout Rule Discharge Hose Warning The discharge hose supplied with the machine is To prevent unexpected energizing, start·UP or release designed for use on steam and high pressure of energy that could cause injury to the employees cleaners.

-

Page 7: Setup

SETUP INSPECTION and IDENTIFICATION LOCATION MACHINE SETUP INITIAL MACHINE STARTUP... - Page 8 SETUP INSPECTION and MACHINE SETUP IDENTIFICATION Connecting the Water Supply Machine Delivery Inspection Connect the machine to a cold water supply tap at least 1.5 times the gallons per minute (gpm) output of Examine the shipping crate and machine carefully for the machine.

-

Page 9: Operating Instructions

OPERATING INSTRUCTIONS OPERATING INSTRUCTIONS SHUTTING DOWN AFTER USE PRESSURE CLEANING TIPS... - Page 10 OPERATING INSTRUCTIONS OPERATING INSTRUCTIONS WARNING: Always wear full eye protection HIGH PRESSURE GUN (preferably a face shield), protective clothing, rubber gloves, and boots when operating the machine to protect yourself from burns caused by high pressure spray and detergents, fluid injection, or debris dislodged by the high pressure spray.

- Page 11 OPERATING INSTRUCTIONS OPERATING PRESSURE WASHER WARNING: The high pressure gun control gun is equipped with a built-in VALVE OPEN: trigger safety latch. Fold the latch in the fully WATER outward (down) position to guard against SUPPLIED TO accidental trigger release and potential HOSE REEL FOR dangerous high pressure spray wand or OPERATION OF...

- Page 12 OPERATING INSTRUCTIONS SHUTTING DOWN AFTER USE GASOLINE ENGINE 1. A separate engine Owners Manual is supplied by the To shut down after use: engine manufacturer for each machine model. Read 1. Turn the engine off by throttling down and cutting fuel and study this manual carefully for all engine pre-start supply.

- Page 13 OPERATING INSTRUCTIONS PRESSURE CLEANING TIPS If the machine is used to apply wax after the cleaning and rinsing process, the gun should be held farther High Pressure Cleaning from the surface to get a “misting” effect when applying the wax. For best results, follow the directions supplied The wash gun nozzle supplied with the machine pro- by the manufacturer for applying wax.

-

Page 14: Specifications

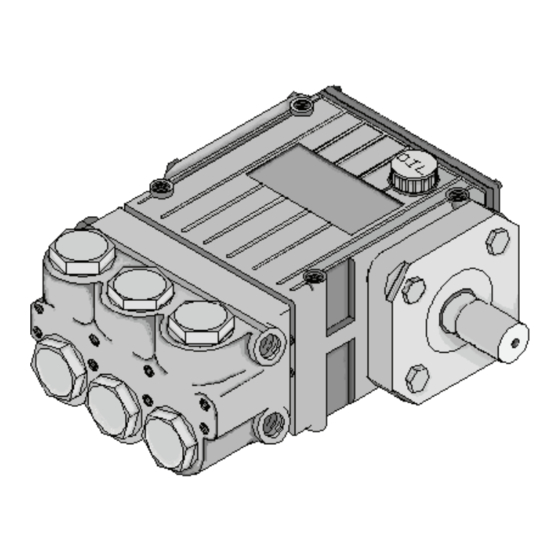

SPECIFICATIONS... - Page 15 SPECIFICATIONS Model Drive Pump Nozzles Hose PM24-10HR 3000 Direct Triplex Plunger 0°/15°/25°/40° 3/8” x 25’ PM30-14HR 3500 Direct Triplex Plunger 0°/15°/25°/40° 3/8” x 25’ PM24-10 3000 Direct Triplex Plunger 0°/15°/25°/40° 3/8” x 4’ PM30-14 3500 Direct Triplex Plunger 0°/15°/25°/40° 3/8” x 4’...

-

Page 16: Maintenance

MAINTENANCE ROUTINE MAINTENANCE... - Page 17 MAINTENANCE & SERVICE A Properly Maintained Machine is a Safe Machine It is the operator’s responsibility to make daily inspections of the machine for anything that could cause a potential service, fire, or safety problem. ROUTINE MAINTENANCE Service & Maintenance Schedule Preventative maintenance is the easiest and least expensive type of maintenance.

- Page 18 MAINTENANCE & SERVICE Pump Lubrication Requirements The pump is pre-lubed from the factory. After the first 50 hours of operation, change the crankcase oil. Change oil every three months or 500 hours (whichever occurs first) thereafter. Use SAE 30W non- detergent motor oil.

- Page 19 Pressure Hose Winterizing and Storage Inspect the hose for damage and/or wear. Replace the To protect the machine from severe damage hose if it is damaged in any way. resulting from water freezing inside the pump or other components, or from corrosion resulting from long peri- •...

-

Page 20: Troubleshooting

TROUBLESHOOTING... - Page 21 TROUBLESHOOTING WARNING: Before attempting any repairs or maintenance, be sure the machine is shut off and disconnected Troubleshooting is an organized study of the problem and a planned method or procedure for investigation and correction of the difficulty. The following troubleshooting guide includes some of the problems that you may encounter during the service life of the machine.

- Page 22 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION 1. Worn or oversized spray nozzle. 1. Replace the worn nozzle. 2. Clogged water and/or detergent inlet strainer. 2. Clean or replace the fouled strainers. 3. Air leak in inlet plumbing. 3. Locate the air leak. Reseal the connection or replace the Low Pressure damaged part.

-

Page 23: Legal Notices

LEGAL NOTICES... - Page 24 LEGAL NOTICES California Proposition 65 WARNING: This product contains chemicals known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information: www.P65Warnings.ca.gov...

Need help?

Do you have a question about the PressureMower PM24-10HR and is the answer not in the manual?

Questions and answers