Summary of Contents for Diamond Products PRO Series

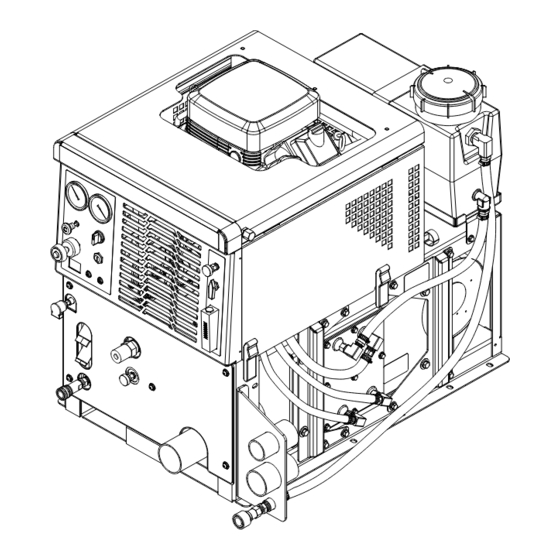

- Page 1 PRO SERIES GT TRUCKMOUNT OPERATOR'S MANUAL IMPORTANT: READ OPERATOR'S MANUAL CAREFULLY Please fill out & return your warranty card! DP80800 Diamond Products www.diamondproductsus.com Printed in the U.S.A.

-

Page 2: Warranty Information

Diamond Products US. Warranty Information Thank you for purchasing a Diamond Products US product. Warranty registration is quick and easy. Your registration will allow us to serve you better over the lifetime of the product. To register your product, email your warranty card information to: info@diamondproductsus.com... -

Page 3: Receiving Your Unit

8. Installation bolting kit. 9. Installation mounting plates. 10. Operation and service manuals for engine, water pump, and vacuum pump. 11. Carpet wand. 12. 5 gallon jug and holder. 13. Hose clamps for fuel & vacuum hoses. Diamond Products Operator's Manual... -

Page 4: How To Use This Manual

NOTE: The manual part number is located on the machine. Levels of hazards are identified that could lower left corner of the front cover. result in product damage, personal injury, or severe injury resulting in death. Diamond Products Operator's Manual... -

Page 5: Important Safety Instructions

Always wear hearing protection when unit is running. Always comply with your company’s Personal Protection Equipment (PPE) plan. Always comply with local noise ordinance when operating units. Diamond Products Operator's Manual... - Page 6 Use only Diamond Products US supplied fuel installation kits. Ensure to use the kit specific for the truckmount model and van model being used. When traversing the vehicle floor with fuel lines, always use a bulkhead adapter.

-

Page 7: Hazard Intensity Level

In Flammable or Explosive areas. In areas with possible falling objects. WHEN SERVICING MACHINE: Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use Diamond Products US approved replacement parts. Diamond Products Operator's Manual... -

Page 8: Safety Labels

10. FOR QUICK HEAT-UP REFER TO THE OPERATING INSTRUCTION MANUAL. P/N 86352580 SOLUTION SCREEN Installation on vehicle fuel door. SOLUTION OUTLET Lower Front Panel Decal with warning labels P/N 86316190 Warning Label P/N 86186520 Caution Label P/N 86186530 Diamond Products Operator's Manual... -

Page 9: Installation

Ten percent (10%) of the overall unit weight, should be on tongue. Example: If loaded trailer weight is 2,000 lbs., tongue weight needs to be a minimum of 200 lbs. to tow properly. Diamond Products Operator's Manual... -

Page 10: Bolting Down Unit And Waste Tank

Install mounting plates underneath vehicle floor. c. Screw 3/8-16 hex head locknuts on mounting screws and tighten them until console and waste tank are firmly secured to vehicle floor. Diamond Products -10- Operator's Manual... - Page 11 3X 37 2X 6 2X 1 2X 12 WASTE TANK 6X Ø LENGTH 6X Ø7/16" X 5/8" SLOT 2X 18 2X 12 2X 2 CONSOLE 3X 22 TOP VIEW WASTE TANK HEIGHT CONSOLE HEIGHT FRONT VIEW Diamond Products -11- Operator's Manual...

- Page 12 Layout with 60 Gallon Waste Tank & Optional Auxiliary Water Tank 2X 1 3X 37 2X 6 2X 12 WASTE TANK 2X 1 6X Ø AUXILIARY WATER TANK 2X 20 LENGTH 2X 40 CONSOLE TOP VIEW 3X 34 OVERALL HEIGHT WASTE TANK FRONT VIEW Diamond Products -12- Operator's Manual...

- Page 13 2X 6 2X 1 2X 12 WASTE TANK 6X Ø 9X Ø7/16" X 5/8" SLOT LENGTH 2X 24 2X 18 2X 12 2X 2 CONSOLE 3X 22 TOP VIEW WASTE TANK HEIGHT CONSOLE HEIGHT FRONT VIEW Diamond Products -13- Operator's Manual...

- Page 14 Layout with 100 Gallon Waste Tank & Optional Auxiliary Water Tank 2X 1 3X 49 2X 6 2X 12 WASTE TANK 2X 1 6X Ø AUXILIARY WATER TANK 2X 20 LENGTH 2X 40 CONSOLE TOP VIEW 3X 34 OVERALL HEIGHT WASTE TANK FRONT VIEW Diamond Products -14- Operator's Manual...

-

Page 15: Waste Tank To Console Connection

We recommend that a fire extinguisher, preferably 4. Do not connect the power cord to the truckmount rated for A, B, & C type fires, be installed inside the console wiring harness until installation is vehicle. complete. Diamond Products -15- Operator's Manual... -

Page 16: Van Bulkhead Installation

HOSEBARB ELBOW FUEL HOSE LOCTITE TO CONSOLE BULKHEAD ADAPTER BULKHEAD GASKET 5/8" DIA HOLE VEHICLE FLOOR BULKHEAD GASKET BULKHEAD NUT HOSEBARB ELBOW HOSE CLAMP FUEL HOSE FROM BYPASS FUEL FILTER HOSE MOUNTING CLAMPS USE AS NEEDED Diamond Products -16- Operator's Manual... -

Page 17: Fuel Supply & Return Line Installation

PUMP ASSEMBLY FROM VEHICLE FUEL SUPPLY FUEL FLOW FUEL FILTER ELECTRICAL CORD BUSHING 5/16" SUPPLY HOSE BULKHEAD CONNECTOR 5/16" SUPPLY HOSE 5/16" SUPPLY HOSE BYPASS FUEL FILTER FRONT OF VAN HOSE MOUNTING CLAMP USE AS NEEDED Diamond Products -17- Operator's Manual... -

Page 18: Battery Connection

(+) terminal on the battery and tighten the holding nut. 2. Next, attach the black negative (-) battery cable from the console ground to the negative (-) terminal on the battery and tighten the holding nut. Diamond Products -18- Operator's Manual... -

Page 19: Initial Operational Settings

500 psi pressure throttle should be 13"Hg. If the unit is drawing a Full None 3200 rpm stronger vacuum (at full sealed suction) than 13" Hg, adjust the vacuum relief spring to 13" Hg. *±50 rpm tolerance Diamond Products -19- Operator's Manual... -

Page 20: Technical Specifications

100 gallon waste tank, water tank & accessories 1935 lbs. with full waste and water tanks TORQUE VALUES Engine rear / vac pump pulley 21 foot lbs Engine front / water pump pulley 8 foot lbs Diamond Products -20- Operator's Manual... -

Page 21: Fuel Requirements

50 hours using Diamond Products US line of chemicals. For standard petroleum based oil before switching to information on using the cleaning compounds, refer to synthetic oil. -

Page 22: Water Requirements

NOT covered under If you require a water softener, your dealer has a model the warranty. to meet your needs. Please contact your nearest distributor for information, price, and abailability. Diamond Products -22- Operator's Manual... - Page 23 Operations Components Diamond Products -23- Operator's Manual...

- Page 24 10. LUBRICATION CUP the engine will continue to run. To turn power off, The lubrication cup allows lubricant spray to reach rotate key counter clockwise to stop position, the vacuum blower. engine will then stop. Diamond Products -24- Operator's Manual...

- Page 25 DO NOT run this unit in an enclosed area. DO NOT operate this unit where the exhaust may enter any building doorway, win- dow, vent, or opening of any type Diamond Products -25- Operator's Manual...

- Page 26 The air is then filtered and rushes into the section. vacuum pump. HOT AIR TO HEAT EXCHANGER LUBRICATION VACUUM RELIEF VACUUM VALVE GAUGE VACUUM INLET VACUUM SILENCER VACUUM PUMP LEVEL SENSOR (ENGINE SHUT-OFF SWITCH) FILTER STRAINER WASTE TANK Diamond Products -26- Operator's Manual...

-

Page 27: Water Pumping And Heat Transfer System

The cleaning solution then passes through high- pressure solution hoses and is distributed by the cleaning tool to a surface that is being cleaned, completing the water pumping and heating cycle of the cleaning unit. Diamond Products -27- Operator's Manual... - Page 28 HOT AIR FROM VACUUM PUMP REAR HEAT EXCHANGER CORES WATER BOX FRONT WASTE TANK TEMPERATURE RELIEF VALVE SOLUTION PUMP PRESSURE GAUGE TEMPERATURE PULSE HOSE CONTROL VALVE CHEMICAL INJECTION PRESSURE REGULATOR CHECK VALVE SOLUTION SCREEN SOLUTION OUTLET Diamond Products -28- Operator's Manual...

-

Page 29: Chemical Injection System

METERING VALVE CHEMICAL PUMP OUTLET CHECK VALVE CHEMICAL JUG CHEMICAL OUTLET SCREEN CONTROL VALVE SOLUTION OUTLET PRIME FLOW METER SOLUTION PUMP Diamond Products -29- Operator's Manual... - Page 30 In the event the pump is run dry, allow the pump to cool down to ambient temperature before reintro- ducing water. Otherwise major damage may occur and void the warranty. Diamond Products -30- Operator's Manual...

-

Page 31: Priming The Chemical Pump

This will prevent water being drawn into the vacuum pump. If shut-down occurs, empty the waste tank before proceeding. If shut- down occurs due to foam created by chemicals used, add Diamond Products US defoamer. Diamond Products -31- Operator's Manual... -

Page 32: Upholstery Cleaning

5. Disconnect all hoses and tools. This unit must be operated with the vehicle or 6. Drain waste tank and rinse with clean water. trailer doors open in order to ensure adequate engine ventilation. Diamond Products -32- Operator's Manual... -

Page 33: Winterizing The Unit

We strongly recommend that you re-cycle and re- turn off both valves. use the anti-freeze. Repeat this procedure with all the remaining tools. After all tools and pressure hoses have been filled with anti- freeze, disconnect and store them. Diamond Products -33- Operator's Manual... -

Page 34: Removing Anti-Freeze From The Unit

When disposing of used anti-freeze, observe local laws and regulations. Do not drain onto the ground or into storm drainage systems. Diamond Products -34- Operator's Manual... -

Page 35: Maintenance

Check connections and hose wear Engine 200 hrs Check spark plugs for carbon deposits and proper gap Chemical Valves 200 hrs Inspect and/or adjust packing nuts Temperature Control Valve 200 hrs Inspect and/or adjust packing nuts Diamond Products -35- Operator's Manual... - Page 36 ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****Using AEON PD-XD, drain and change blower every 1000 hours or once per year, whichever comes first. Diamond Products -36- Operator's Manual...

-

Page 37: Key Checkpoints

To keep your chemical system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer. Diamond Products -37- Operator's Manual... -

Page 38: Vacuum Pump Maintenance

If service or repair is required, contact an authorized engine manufacturer’s service center. You will need to provide the serial number of the engine. Engine oil capacity including filter is approximately 46 - 48 ounces. Diamond Products -38- Operator's Manual... - Page 39 5. Bearings on the drive end of the blower require 5 seconds while the unit is running and the vac- grease lubrication every 250 hours of operation. uum inlets are sealed. Do this at the end of each working day. Diamond Products -39- Operator's Manual...

-

Page 40: Vacuum Relief Valve

16, Amoco Rykow 68, and Shell Tellus T68. 4. Check for pulley groove wear, clean belts and pul- ley grooves, check for worn belts, proper belt ten- sion, and pulley alignment after the first 25 hours and then again at 100 hours. Diamond Products -40- Operator's Manual... -

Page 41: Solution Pump Drive Belts

However, if the screen has a frequent build-up around the hinge of the float valve. Check the float of debris it should be inspected and cleaned more valve for debris at least once a month. often. Diamond Products -41- Operator's Manual... -

Page 42: Chemical Pump

Pressure Regulator Lubricate the o-rings and bullet every 50 hours. Use o- ring lubricant Part #86265430. For the procedure, see the "General Service Adjust- ments” section in this manual for details. Diamond Products -42- Operator's Manual... -

Page 43: General Service Adjustments

See the “Illustrated Parts Listing” for a parts break-down on the chemical pump. Solution and Vacuum Pump Drive Belts Use only exact replacement for system drive belts. Use only exact manufacturer and models for replacements. Diamond Products -43- Operator's Manual... -

Page 44: Packing Nut Adjustments For Chemical Valves

(cap) (while observing the pressure gauge on the control panel) until the desired pressure is obtained. Retighten the locking nut. DO NOT loosen the adjusting body (cap) all the way (counterclockwise) or remove it while the unit is running. Diamond Products -44- Operator's Manual... -

Page 45: Troubleshooting

Cleaning tool valve is malfunctioning. Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. Air leak in chemical supply line, priming Check for air leaks. Replace faulty parts. valve or metering valve. Diamond Products -45- Operator's Manual... - Page 46 Measure the pump volume. If the pump Defective cylinder in the solution volume is less than normal, refer to “Loss of pump. Pump Volume” in the Troubleshooting section in this manual. Diamond Products -46- Operator's Manual...

- Page 47 Defective float switch in the waste Check switch for proper operation, replace will not start tank. as necessary. Consult the engine manufacturer’s service Internal engine problem. and repair manual or contact engine manu- facturer’s authorized repair center. Diamond Products -47- Operator's Manual...

- Page 48 After inspecting waste pump to determine Pump-out circuit breaker on control new electrical connectors and the cause of the tripped circuit breaker, panel has been tripped. heat shrink. Inspect connection press the reset button. for watertight seal. Diamond Products -48- Operator's Manual...

- Page 49 Parts PARTS Diamond Products -49- Operator's Manual...

- Page 50 Frame Diamond Products -50- Operator's Manual...

- Page 51 BRKT, FRONT HE SUPT 86317250 GUARD, BELT, FRONT, BGT 86318810 GASKET, HOOD VIBE DAMPNR 86318880 ASSY, LEFT HOOD, BGT 86318890 ASSY, RIGHT HOOD, BGT 86006750 SCREW 5/16-18 X 1"HHCSGR5PLT NP 86373930 RIVET, 5/32 X.376-.500GL POP AL Diamond Products -51- Operator's Manual...

-

Page 52: Side Panel

Side Panel TO WASTE TANK TO WATER BOX Diamond Products -52- Operator's Manual... - Page 53 WASHER, 1/4 SPLIT LOCK 86274750 SCR, 1/4-20 X 3/4 HHCS 86179710 DSC, 3/8F X 3/8FP 86181360 FTTG, BRB 1/2P X 5/8H BR 86188210 NIP, 1/2 X 3/8 HEX BR 86177260 CLMP,HOS#10 9/16MIN 1-1/ 86270330 FLATWASHER, 1/4 Diamond Products -53- Operator's Manual...

-

Page 54: Control Panel

Control Panel Diamond Products -54- Operator's Manual... - Page 55 86181950 GAUGE, VACUUM, 30" HG INCLUDED CNTRL, THRTL, Pro Series CLR/CLNR 86177540 86315970 ASM, CONTROL PNL, BGT PC LABEL, CONTROL PNL, Pro Series GT 86316000 86316010 LABEL, FRNT HD, BGT, PC LABEL, CHEM PNL Pro Series GT 86317220 86329190 WASH, 446ID X.563OD X.010THK SST...

- Page 56 Control Panel Diamond Products -56- Operator's Manual...

- Page 57 WASHER, #10 SPLIT 86175610 BRKR, CIRCUIT, 30A 86175620 BRKR, CIRCUIT 25A 86017360 BRKT, FLOW METER 86175680 BRKT, WIKA MOUNTING 86297070 VALVE, 3-WAY BALL 1/8P 86318810 GASKET, HOOD VIBE DAMPNR 86185990 KEY, SWITCH TM (32-900174) (KEY ONLY) Diamond Products -57- Operator's Manual...

- Page 58 Engine 14 26 Diamond Products -58- Operator's Manual...

- Page 59 TUBE, EXHAUST, B&S 18HP 86317390 ENG, B&S, 18HP W/FRNT SHFT 86318050 CLAMP, THROTTLE CABLE 86318330 FILTER, FUEL, 1/4" HOSE 86174440 B&S CARTRIDGE AIR CLNR 394-018 86180090 ELEMENT (OUTER), AIR CLEANER 86174450 B&S OIL FILTER #492-932 Diamond Products -59- Operator's Manual...

-

Page 60: Vacuum Pump

Vacuum Pump 25 16 Diamond Products -60- Operator's Manual... - Page 61 BRACKET, BGT FRONT BLWR MTG 86394040 BRACKET, BGT REAR BLWR MTG 86177040 CLAMP, CABLE 1-1/4 ID 5/16 BLT 86279130 WASHER, 5/16 SPLT STL ZNPLT 86006760 SCREW, 5/16-18 X .75 HHCS 86189090 OIL, AEON PD-XD (28G47 SUTORBILT) Diamond Products -61- Operator's Manual...

-

Page 62: Solution Pump

Solution Pump FROM WATER BOX FROM FLOW METER Diamond Products -62- Operator's Manual... - Page 63 DIAPHRAGM, CHEM PUMP 86194630 PULSE PUMP, TOP COVER INLET 86191340 PULSE PUMP, BODY 86192920 SPACER RING, 303 SST 86195120 VALVE CAP, 303 SST, OUTPUT 86030580 KIT,CHEM PMP BDY REPL OIL, CAT-WTR PMP 86189080 86269900 PAMPHLET,INSTRUCT CAT3CP Diamond Products -63- Operator's Manual...

- Page 64 Solution Pump Diamond Products -64- Operator's Manual...

- Page 65 O-RING, BEARING CVR ORDER 1 EACH 86355310 KIT, WTR PMP HT SEAL, 3CP (COMPLETE) 86190600 PLUNGER 86176900 CAT#33258 KIT,VLV CAT 3C 1 EACH DOES 3 VALVES 86190560 PLUG, VALVE 86181800 GASKET, OIL GAUGE 86181970 GAUGE, OIL LEVEL Diamond Products -65- Operator's Manual...

-

Page 66: Heat Exchanger

Heat Exchanger TO WATER BOX FROM REGULATOR Diamond Products -66- Operator's Manual... - Page 67 WASHER, 3/8 SPLIT LOCK PLTD 86279510 WASHER, 3/8 X 1 FLAT 86043150 ASSEMBLY, HEATER CORE SS 86318840 ASSY, HEATER CORE COPPER, GT 86308920 PLATE, HEATER CORE COVER 86308930 GASKET, HEATER CORE COVER 86394220 HOUSING, BGT HEAT EXCHANGER Diamond Products -67- Operator's Manual...

-

Page 68: Pressure Regulator & Temperature Control Valve

Pressure Regulator & Temperature Control Valve OUTER SEAT INNER SEAT STEM BODY SPRINGS PRESSURE REGULATOR DETAIL Diamond Products -68- Operator's Manual... - Page 69 SCR, 1/4-20 X 3/4 HHCS SS 86278970 WASHER, 7/16 EXT STAR 86010780 WASHER, 1/4 SPLIT LOCK 86180040 ELBOW, 1/4MPX1/2H 90DEG 86312440 MNFLD, PRESSURE REG 86313740 CAP, STEEL, 3/8-18FPT 86186040 KIT, REPAIR PRESSURE REG 86185180 HOSE, PULSE 36”, 3/8MPT BS Diamond Products -69- Operator's Manual...

-

Page 70: Solution Outlet

Solution Outlet Diamond Products -70- Operator's Manual... - Page 71 86195030 VALVE, CHECK INCLUDES 19-25 86189260 O-RING 86192210 SCREEN, CHECK VALVE 86189230 O-RING 86192390 SEAT, CHK VLV ASSY 86194250 TEFLON SEAT 86190910 POPPET, CHK VLV ASSY 86193260 SPRING 86189270 O-RING, 7/8 ID 1-1/16 OD 86176350 Diamond Products -71- Operator's Manual...

-

Page 72: Water Box

Water Box FROM WATER INLET FROM HEAT EXCHANGER TO WASTE TANK TO SOLUTION PUMP Diamond Products -72- Operator's Manual... - Page 73 NUT, 1/4-20 HEX NYLOCK 86274750 SCR, 1/4-20 X 3/4 HHCS PLTD 86308940 BRKT, WTR BOX HOLDDOWN 86309000 BRKT, WTR BOX MTG 86010660 WASHER 1/4 LOCK EXT STAR SS 86192380 SEAT FLOAT VALVE TM 86189010 NUT, FLOAT VALVE Diamond Products -73- Operator's Manual...

-

Page 74: Gallon Waste Tank

60 Gallon Waste Tank PART OF 4 TO VACUUM PUMP Diamond Products -74- Operator's Manual... - Page 75 LID, WST TNK, 60G PC 86321040 OUTLET, VACUUM, 2-7/8", PC 86323650 INLET, 2-1/2” VACUUM, PC 86323700 GASKET, VAC INLET 86177010 CLAMP, HOSE #48 86272720 PLG, 1/4 SOCHD BRASS 86350790 ASSY, WASTE TANK LID, 60G 86264850 ADH,GSKT (ADHESIVE) Diamond Products -75- Operator's Manual...

- Page 76 100 Gallon Waste Tank PART OF 4 TO VACUUM PUMP Diamond Products -76- Operator's Manual...

- Page 77 OUTLET, VACUUM, 2-7/8", PC 86323650 INLET, 2-1/2” VACUUM, PC 86323700 GASKET, VAC INLET 86177010 CLAMP, HOSE #48 86272720 PLG, 1/4 SOCHD BRASS 86350770 ASSY, WASTE TANK LID, 100 G 86264850 ADH, GSKT (ADHESIVE) NOT SHOWN Diamond Products -77- Operator's Manual...

-

Page 78: Battery Floor Mount

Battery Floor Mount Diamond Products -78- Operator's Manual... - Page 79 BATTERY 86012060 BOX, BATTERY, MODIFIED 86273190 SCR, 1/4-20 X 1-1/2 HXHD 86270330 FLATWASHER, 1/4 86010780 WASHER, 1/4 SPLIT LOCK PLTD 86270770 NUT, 1/4-20 HEX 86309890 BRKT, BATTERY BOX MTG 86011470 BOLT, ELEVATOR, 1/4-20 X 1 Diamond Products -79- Operator's Manual...

-

Page 80: Chemical Jug Floor Mount

Chemical Jug Floor Mount Diamond Products -80- Operator's Manual... - Page 81 PART NO. DESCRIPTION NOTES FROM 86298250 HOLDER, 5 GAL JUG 86273190 SCR, 1/4-20 X 1-1/2 HXHD 86270770 NUT, 1/4-20 HEX 86270330 FLATWASHER, 1/4 86185720 JUG,5 GAL, SINGLE HNDL, WHITE 86010780 WASHER 1/4 SPLIT LOCK PLTD Diamond Products -81- Operator's Manual...

-

Page 82: Fuel Pump

Fuel Pump TO CONSOLE THROUGH VEHICLE FLOOR RETURN TO VEHICLE USE AS NEEDED FUEL SUPPLY MOUNT TO VEHICLE FRAME 11 1 FROM VEHICLE FUEL SUPPLY Diamond Products -82- Operator's Manual... - Page 83 HOSE, 5/16" FUEL X 12', T-FLEX 86339630 VALVE, CHECK, 1/4H X 5/16H FUEL 86179930 EL, 90DEG 1/8NPT X 1/4HB 86282810 SLEEVE, 3/4 LOOM X 23" 86265730 TIE, CABL 8" WHT 86273290 SCR, SLFDR #14 X 1 HXHD Diamond Products -83- Operator's Manual...

-

Page 84: Hose Diagram

86184400 PRV NO. 790419 (26") 86280470 PRV NO.09-805397 (24") (HOSE, PULSE) REGULATOR HEAT EXCHANGER 86356870 (72") 86280080 PRV NO.09-805280 (46") SIDE PANEL 86282380 PRV NO.790497 (23") 86184120 PRV NO.10-805458 (52") 86048980 PRV NO.09-805341 (36") TO WASTE TANK Diamond Products -84- Operator's Manual... -

Page 85: Wiring Diagram

N.O. CONTACT N.O. N.O. BLOCKS #32-900205 A B C FEMALE CONNECTOR FOR PUMPOUT ENGINE SHUTOFF SWITCH #61-950621 REAR OF CONNECTORS WASTE TANK FUEL PUMP CORD #790579 EXTERNAL FUEL OPTIONAL EXTERNAL PUMP (AIRTEX) FUEL PUMP (KUBOTA) #66-945201 Diamond Products -85- Operator's Manual...