Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for QubicaAMF XLi

- Page 1 Pinspotter Motor and Gearbox Manual P/N 400-088-038 Rev. F QubicaAMF Worldwide, L.L.C. ♦ Technical Support ♦ International – (804) 569-1000 ♦ Domestic – 866-460-QAMF (7263) Copyright © 2017 QubicaAMF Worldwide, LLC, 8100 AMF Dr. Mechanicsville, VA 23111...

- Page 3 All rights to this manual, including the diagrams, figures, and technical specifications, are the property of QubicaAMF Worldwide, LLC. Reproduction or transmission of any of the material contained in this guide without the prior written permission of QubicaAMF Worldwide, LLC is strictly prohibited. All of the product information contained in this manual was carefully prepared based on the latest information available and was believed to be correct at the time of printing.

- Page 5 QubicaAMF XLi Pinspotter Motor & Gearbox Manual 400-088-038, Rev. F Summary of Changes Change No. ECR No. Rev. A 12-0316 Rev. B 13-0091 Rev. C 13-0132 Rev. D 15-0130 Rev. E 15-0251 Rev. F List of Effective Pages Page Change No.

-

Page 7: Table Of Contents

Contents Section 1 Front End Gearbox Purpose ................................1 Scope ................................1 Procedures ..............................2 1.3.1 Initial Setup ..........................2 1.3.2 Servicing the Sweep Gearbox ....................... 3 1.3.3 Servicing the Table Gearbox ......................4 1.3.4 Changing the Gearbox Oil ......................6 1.3.5 Detecting Gearbox Problems ....................... - Page 8 Procedures ..............................26 3.3.1 Initial Setup ..........................26 3.3.2 Servicing the Back End Motor and Gearbox................. 27 3.3.3 Oil Draining ..........................28 3.3.4 Oil Seal Replacement: Input Shaft....................29 3.3.5 Oil Seal Replacement: PBL Drive Shaft ..................30 3.3.6 Oil Seal Replacement: Distributor Drive Shaft ................31 3.3.7 Oil Seal Replacement: Elevator Drive Shaft .................

-

Page 9: Front End Gearbox

XLi Pinspotter front end gearboxes. Scope This section contains instructions for performing the initial setup and periodic maintenance of the XLi front end gearboxes. The front end gearbox is a speed reducing type gearbox with a single input and a single output. This gearbox is available in two different gear ratios for use with 50-hertz or 60-hertz motors. -

Page 10: Procedures

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Procedures This section provides instructions for the initial setup of the front end gearboxes as well as procedures for servicing the gearbox, changing the gearbox oil, detecting gearbox problems, and separating the gearbox and motor. -

Page 11: Servicing The Sweep Gearbox

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 1.3.2 Servicing the Sweep Gearbox Perform this procedure every 100,000 frames in conjunction with servicing the Sweep Drive Motor. Tools Required Cranking Tool 5/16-inch Wrench Flat Blade Screwdriver 3/8-inch Drive Ratchet 9/16-inch Wrench... -

Page 12: Servicing The Table Gearbox

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Wipe the old grease and anti-seize compound from the sweep drive shaft splines. Apply a liberal amount of anti-seize compound to the splines of the sweep drive shaft and the bore of the output shaft of the gearbox. - Page 13 QubicaAMF XLi Pinspotter Motor and Gearbox Manual Remove the table motor from the gearbox. Clean all surfaces of the table motor and gearbox with a cloth dampened with a water-based cleaner. Check the gearbox for any signs of oil leakage. Repair as needed.

-

Page 14: Changing The Gearbox Oil

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 1.3.4 Changing the Gearbox Oil Replace the gearbox oil following every 100,000 frames of pinspotter operation. The amount of oil needed for each front end gearbox is 45 ounces. The oil can be drained with the gearbox installed on the pinspotter or removed to a work area. -

Page 15: 1.3.5 Detecting Gearbox Problems

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 1.3.5 Detecting Gearbox Problems Inspect the gearboxes at least once every 60 days to identify the need for service or replacement. The following symptoms can be detected without any disassembly. Oil Leakage Oil leakage from seals may indicate shaft and/or seal wear. -

Page 16: 088-004-50X-03 Exploded View Diagram

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 400-088-038 Revision F... -

Page 17: 088-004-50X-03 Parts List

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Front End Gearbox (088-004-50X-03) Parts List Item # Description Spec Housing SCR, HX CP GR5 5/16NC X 3/4 Spec Worm, INTG 38/1 Bearing, Ball 6303 or Eq. Bearing, Ball 9105PP or Eq. Seal, TCM 25X47X7TC or Eq. -

Page 18: 088-004-50X-02 Exploded View Diagram

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 400-088-038 Revision F... -

Page 19: 088-004-50X-02 Parts List

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Front End Gearbox (088-004-50X-02) Parts List Item # Description Housing GR5 5/16NC X 3/4 Hex Cap Screw INTG 38/1 Worm 6303 Ball Bearing N5000-185 Retaining Ring 9105PP Ball Bearing §* 1-27/32 EXP Plug §*... -

Page 20: 088-004-50X Exploded View Diagram

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 400-088-038 Revision F... -

Page 21: 088-004-50X Parts List

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Front End Gearbox Parts List Item # Description Housing Screw, Hex, 5/16 NC x ¾ Worm, 38:1 Bearing Beveled Retaining Ring Bearing § Expansion Plug § Seal Retaining Ring Washer, .35 x 1.08 x .12... -

Page 22: Repair Parts And Kits

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 1.3.7 Repair Parts and Kits Front End Gearbox Seal Repair Kits, 088-004-529 & 088-004-516 Use these kits to repair leaky seals or expansion plugs. The kits contain the items marked on the previous pages plus a tube of sealant. -

Page 23: Oil Seal Replacement

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 1.3.8 Oil Seal Replacement Refer to the Exploded View and Parts Lists on the previous pages. 1. To remove the output shaft seal, remove the cap screws from the flange and remove the flange. The oil seal should come off with the flange. -

Page 24: Assembly Of The Front End Gearbox

9. Clean and recoat the lower pipe socket plug with Loctite® and re-install. Fill the gearbox with 45 ounces or 1.275 liters of Mobil™ 600 W Cylinder Oil (available from QubicaAMF, Part No. 715-021-716). 10. Reattach the gearbox to the drive motor. -

Page 25: Front End Gearbox Drive Motor

A red reset button is located on the end of the motor. Allow the motor to cool before resetting, and always attempt to determine and fix the cause of the overload before returning the motor to service. The XLi front end motors are different from the back end gearbox motor, and are NOT interchangeable. -

Page 26: Procedures

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Procedures The two front end motors are individual components that attach directly to the front end gearboxes and are used to run the table and sweep. NEVER attempt to operate a motor when it is in a partially disassembled state or when it has been removed from its gearbox housing! 2.3.1... -

Page 27: Replacing The Brake

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 2.3.2 Replacing the Brake Each front end motor contains a brake assembly to stop the table or sweep quickly and precisely. The brake is an independent auxiliary device that should require little or no service other than cleaning. If a brake fails, the entire brake should be replaced since none of its internal components are user replaceable. -

Page 28: Replacing The Encoder Assembly

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 2.3.3 Replacing the Encoder Assembly Tools Required 9/64-inch Hex Wrench 5/64-inch Hex Wrench Flat Blade Screwdriver Run the sweep to the 1 Guard position. Lock out and tag out the pinspotter in accordance with your bowling center’s established procedures. -

Page 29: Brake & Encoder Replacement Parts

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 2.3.4 Brake and Encoder Replacement Parts The following parts are available as replacement items separately from the motor. Failure of any of these parts does not require replacing the motor and are easily replaced in the field. Any other warranty replacement is done by replacing the motor. -

Page 30: Replacing The Rotor Assembly

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 2.3.5 Replacing the Rotor Assembly Replacement rotor assemblies are available should the rotor shaft become damaged due to dropping, bearing failure, or improper gearbox engagement. Use care when removing the encoder and brake assemblies because they can be reused and new ones are not included with the replacement rotor assembly. - Page 31 QubicaAMF XLi Pinspotter Motor and Gearbox Manual Remove the spacer and encoder disc. Using a marker or pencil, mark a line on the upper end bell extending it onto the motor frame. Do the same for the lower end bell and frame. When reassembling the motor, align the marks on the frame with the marks on the end bells to ensure that the motor is reassembled in the same orientation that it was before disassembly.

- Page 32 QubicaAMF XLi Pinspotter Motor and Gearbox Manual With both the upper and lower end bells firmly against the motor frame, and being careful not to pinch any of the motor’s wiring, align the orientation marks on the frame with the marks on the end bells, and secure the end bells in place with the four long bolts.

-

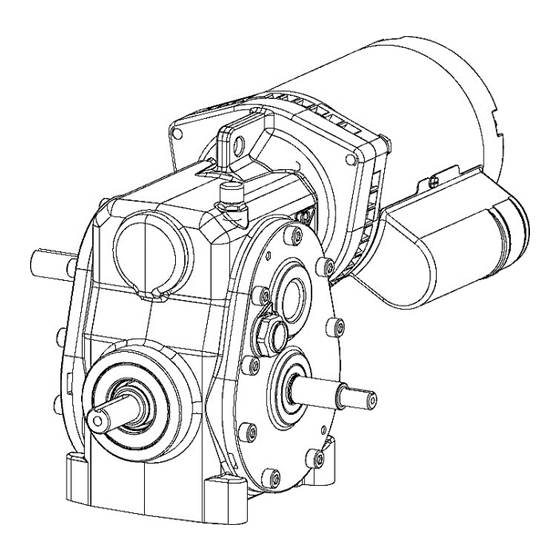

Page 33: Back End Gearbox

Section 3 Back End Gearbox Purpose The purpose for this section is to provide a description of the XLi back end gearbox as well as to provide maintenance and repair procedures for the gearbox. Scope This section provides an operating overview of the back end gearbox as well as procedures for the initial setup and subsequent maintenance and repair of the XLi pinspotter back end gearbox. -

Page 34: Procedures

QubicaAMF XLi Pinspotter Motor and Gearbox Manual Procedures This section provides instructions for the initial setup of the back end gearboxes as well as procedures for replacing the oil seals, changing the gearbox oil, detecting gearbox problems, and separating the gearbox and motor. -

Page 35: Servicing The Back End Motor And Gearbox

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.2 Servicing the Back End Motor & Gearbox Perform this maintenance activity every 200,000 frames of pinspotter operation. Tool List 9/16” Wrench Torque Wrench (P/N 793-513-048) 9/16” Socket and Ratchet 4mm Allen Hex 3/8” Socket (P/N 780-503-015) -

Page 36: Oil Draining

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.3 Oil Draining The oil used in the back end gearbox is a life-long lubricant. It only needs to be changed when an oil seal(s) is replaced. The amount of oil needed for each back end gearbox is 44.8 ounces. When draining the oil from the gearbox, take adequate precautions to collect the waste oil and prevent it from dripping onto the work area. -

Page 37: Oil Seal Replacement: Input Shaft

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.4 Oil Seal Replacement: Input Shaft Be sure to follow the procedures from Section 3.3.3 – Oil Draining before replacing any oil seal. Tools Required Flat-head Screwdriver Klüber Grease (P/N 715-012-505) ® ®... -

Page 38: Oil Seal Replacement: Pbl Drive Shaft

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.5 Oil Seal Replacement: PBL Drive Shaft Be sure to follow the procedures from Section 3.3.3 – Oil Draining before replacing any oil seal. Tools Required Flat-head Screwdriver Klüber Grease (P/N 715-012-505) ®... -

Page 39: Oil Seal Replacement: Distributor Drive Shaft

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.6 Oil Seal Replacement: Distributor Drive Shaft Be sure to follow the procedures from Section 3.3.3 – Oil Draining before replacing any oil seal. Tools Required Flat-head Screwdriver Klüber Grease (P/N 715-012-505) ®... -

Page 40: Oil Seal Replacement: Elevator Drive Shaft

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.7 Oil Seal Replacement: Elevator Drive Shaft Be sure to follow the procedures from Section 3.3.3 – Oil Draining before replacing any oil seal. Tools Required Flat-head Screwdriver Klüber Grease (P/N 715-012-505) ®... -

Page 41: Oil Filling

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.8 Oil Filling The oil used in the back end gearbox is a life-long lubricant. It only needs to be changed when an oil seal(s) is replaced. The amount of oil needed for each back end gearbox is 44.8 ounces. -

Page 42: Detecting Back End Gearbox Problems

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.9 Detecting Back End Gearbox Problems Inspect the gearboxes at least once every 60 days to identify the need for service or replacement. The following symptoms can be detected without any disassembly. ... -

Page 43: Back End Gearbox Exploded View

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 400-088-038 Revision F... -

Page 44: 3.3.11 Back End Gearbox Parts List

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.11 Back End Gearbox Parts List Item # Description Housing, Backend Gearbox Cap, PBL Drive Side Cap, Distributor Drive Side Bearing, Ball Output Gear, Worm Shaft, PBL Drive Spacer, PBL Shaft 8 @#... -

Page 45: Repair Parts And Kits

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 3.3.12 Repair Parts and Kits *All part numbers can be purchased individually.* Seal Kit, 612-088-217 This kit includes one replacement seal for each shaft (enough for one gearbox). 088-004-617 – Oil Seal, PBL/Distributor Shaft (x2) ... -

Page 46: Back End Gearbox Motor

Section 4 Back End Gearbox Motor Purpose This section describes the procedures for the operation, maintenance, and repair of the XLi pinspotter’s back end gearbox drive motor. Scope Back end motor problems, while uncommon, are generally covered under warranty during the warranty period. -

Page 47: Rotor Replacement

QubicaAMF XLi Pinspotter Motor and Gearbox Manual 4.3.1.1 Rotor Replacement (Refer to illustrations below for component identification.) Tool List ¼” Nut Driver 9/16” Socket and Ratchet Flat Blade Screwdriver Rubber Mallet 6” Ratchet Extension #2 Phillips Screwdriver 5/64” Hex Wrench 9/16”... - Page 48 QubicaAMF XLi Pinspotter Motor and Gearbox Manual 12. Insert the rotor assembly into the frame and guide the upper bearing into the recess in the upper end bell. Ensure that the upper bearing is seated within the recess. Use the mallet to seat the bearing, if necessary.

Need help?

Do you have a question about the XLi and is the answer not in the manual?

Questions and answers