Table of Contents

Advertisement

Quick Links

Installation, Operating and Service Instructions

Models:

• SWA16

• SWA20

• SWA24

Manual Contents

1.

Read Before Proceeding . . . . . . . . . . . . . . . . . 2

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Locating Boiler . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Hydronic Piping . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.

Electrical Connections/Wiring . . . . . . . . . . . 11

8. Sequence of Operation . . . . . . . . . . . . . . . . . 16

9. Control Operation . . . . . . . . . . . . . . . . . . . . . 17

10. Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11. General Maintenance . . . . . . . . . . . . . . . . . . 21

12. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 22

13. Service Parts . . . . . . . . . . . . . . . . . . . . . . . . 25

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TO THE INSTALLER:

Affix these instructions adjacent to boiler.

Provide model number and serial number when

seeking information and support.

TO THE CONSUMER:

Retain these instructions for future reference.

Contact heating installer or technician for all issues

and support.

112364-05 - 11/23

4

D

Page

C

B

A

4

Electric

Installation, Operating & Service Manual

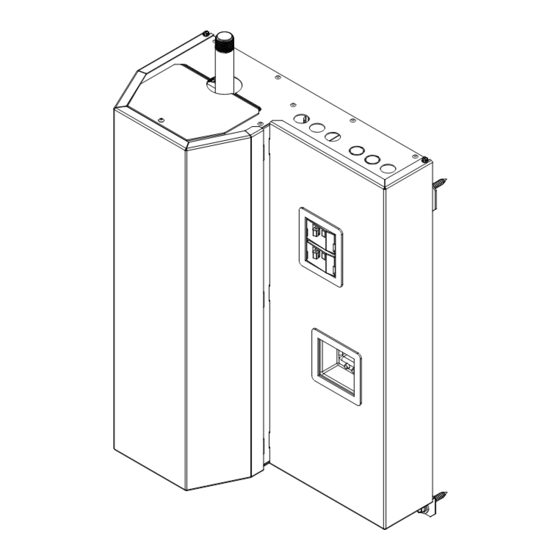

Electric Hot Water Boiler

9700609

3

3

2

2

1

Advertisement

Table of Contents

Summary of Contents for SPARQ SWA16

-

Page 1: Table Of Contents

Installation, Operating & Service Manual Electric Hot Water Boiler Installation, Operating and Service Instructions 9700609 Models: • SWA16 • SWA20 • SWA24 Manual Contents Page Read Before Proceeding ....2 2. -

Page 2: Read Before Proceeding

Electric Installation, Operating & Service Manual Read Before Proceeding Read and understand this document before proceeding with installation or maintenance. Boiler is listed with Massachusetts Board of Plumbers and Gas Fitters. See Massachusetts Boards of Plumbers and Gas Fitters website for the latest Approval Code (https://licensing.reg.state.ma.us/pubLic/pl_products/pb_pre_form. - Page 3 Electric Installation, Operating & Service Manual Read Before Proceeding (continued) Installer or Qualified Service Agency Read 8. Inspect shipment carefully for signs of damage. Any claim for damage for shortage in shipment Before Proceeding must be filed immediately against carrier by consignee.

-

Page 4: Introduction

Electric Installation, Operating & Service Manual Introduction Introduction Product Description • Size boiler based on total heat load of the Electric Boiler is a heating device that converts building. electrical energy to hot water. • Calculate maximum hourly heat loss for each Kilowatts of Electricity Used per Hour x 3412 = British heated space following procedures described in Thermal Units (BTUH) Available Per Hour for Heating. -

Page 5: Specifications

Amps Size 140oF 167oF 140oF 167oF Number (AC) Amps (kW) (Watts) BTU/hr. (Watts) (60oC) (75oC) (60oC) (75oC) SWA16 16,000 54,600 66.7 4,000 72.7 90.8 SWA20 20,000 68,200 83.3 5,000 89.3 111.7 125 2/01 SWA24 24,000 82,000 100.0 6,000 106.0 132.5 150 WARNING * Minimum Recommended Field Wire Size per National Electric Code (NEC). -

Page 6: Locating Boiler

Electric Installation, Operating & Service Manual Locating Boiler 10. Minimum clearances to combustible surfaces: WARNING TOP........9 in. Electrical Shock Hazard. FRONT......... 2 in. Do not install boiler underneath a water source. LEFT SIDE......12 in. Failure to do so could result in severe personal injury and death. -

Page 7: Hydronic Piping

Table 5-2: Maximum Temperature Rise °F Boiler Model @ 3.0 GPM 1. Size circulator(s) based on total hydronic system pressure drop and designed flow rate. SWA16 2. To prevent rapid cycling on the high limit, SWA20 adequate flow is required. SWA24 3. - Page 8 Electric Installation, Operating & Service Manual Hydronic Piping (continued) 112364-05 - 11/23...

- Page 9 Electric Installation, Operating & Service Manual Hydronic Piping (continued) To System Flow Check Valves Flow Check Valves Optional Full Port Isolation Valves Optional Full Port Isolation Valves Heating Circulators Heating Circulators Optional Full Port Optional Full Port Isolation Valves Isolation Valves Fill Valve Backflow Preventer...

-

Page 10: Water Quality

Electric Installation, Operating & Service Manual Water Quality 1. Poor water quality causes oxidation, scaling, corrosion, and fouling, which can severely damage the heating element and pressure vessel. NOTICE: Warranty does not cover component failure caused by scale build-up or poor water conditions. -

Page 11: Electrical Connections/Wiring

Electric Installation, Operating & Service Manual Electrical Connections/Wiring Boiler Wiring CAUTION WARNING Use torque device to properly tighten line to DO NOT alter any internal wiring or bypass any built-in safety limit controls. Doing so will result prevent overheating. in unsafe operation. 1. - Page 12 Electric Installation, Operating & Service Manual Electrical Connections/Wiring (continued) System Wiring CAUTION Follow directions and wiring diagrams from accessory relay panel manufacturers. Do not use the 24 VAC transformer to power zone valves or other accessories. Multizone Wiring R(T) and top DHW are electrically connected on the control board.

- Page 13 Electric Installation, Operating & Service Manual Electrical Connections/Wiring (continued) System Wiring CAUTION Follow directions and wiring diagrams from accessory relay panel manufacturers. Do not use the 24 VAC transformer to power zone valves or other accessories. Multizone Wiring T-Stat T-Stat T-Stat Power Power...

- Page 14 Electric Installation, Operating & Service Manual Electrical Connections/Wiring (continued) Heating Elements R(T) W(T) Boiler Control Board 5A Fuse [C2] [C1] CIRC 120V System Pump Connection Figure 7-4: Wiring Control Board Control Inputs (NEC Class - 2 Low Voltage) R(T) Thermostat Input (R W C) or zone valve end switch (R W), Dry Contract Close R-W W(T) Activation, 24 VAC R-C Domestic Hot Water - Thermostat Input.

- Page 15 Electric Installation, Operating & Service Manual Wiring Diagram ELEMENT 1 ELEMENT 2 ELEMENT 3 ELEMENT 4 112364-05 - 11/23...

-

Page 16: Sequence Of Operation

Electric Installation, Operating & Service Manual Sequence of Operation Heating Element LED Indicators HEATING ELEMENTS (Green) DEMAND PUMP Heating Demand Pump LED Indicator LED Indicator (Green) (Green) LED Display Mode and Power (Red) MODE/PWR DOWN Selection Button Up and Down Adjustment Buttons Figure 8-2: Boiler Controller Mode and Power Selection Button - Turns boiler on and off, selects mode and configuration settings... -

Page 17: Control Operation

Electric Installation, Operating & Service Manual Control Operation Initial Start Up • LED’s for heating elements, pump status and heat call will illuminate as each is energized. If safety • When electrical power is applied control displays circuit is open, elements will not energize and firmware revision code. - Page 18 Electric Installation, Operating & Service Manual Control Operation (continued) are open, heating elements are prevented from • Boiler must be ON and configuration setting energizing and "FLO" is displayed. Sensor input is for dFt must be set to Y. During Dry Fire Test only active while control is attempting to energize pump is energized and first heating element is heating element(s).

- Page 19 Electric Installation, Operating & Service Manual Control Operation (continued) Anti-Short Cycle Timer, Water Temperature High Limit Alarm Satisfied • High-limit alarm is always monitored except while LMC terminals are open. If the High Limit switch • While a heating call exists (TT or DHW-TT closed) opens, control will switch off all elements and and an element cycles off to maintain set point enter a 60 second purge mode.

-

Page 20: Start-Up

Electric Installation, Operating & Service Manual Start-up 6. Boiler will start to produce heat. Listen for air WARNING passing through system as water temperature Use a qualified service agency for annual increases. Water pressure will rise somewhat as inspection of boiler and heating system. Wiring temperature increases-this is normal as long as errors can cause improper and dangerous pressure remains less than 25 PSIG. -

Page 21: General Maintenance

Electric Installation, Operating & Service Manual General Maintenance Electric Boiler requires periodic maintenance. Annual maintenance allows for trouble-free operation. WARNING Electrical Shock Hazard. Turn OFF electrical power supply at main power switch before servicing unit. A qualified service agent should perform service. -

Page 22: Troubleshooting

Table 12-2: Element Connections and purge unit as necessary. Element Resistance Ohms @ Boiler Model Heating Element Change (kW) Room Temp SWA16 14 to 14.5 WARNING SWA20 11 to 12 Burn and Electrical Shock Hazard. SWA24 9 to 10 Turn OFF electrical power supply at service panels before making electrical connections. - Page 23 Electric Installation, Operating & Service Manual Troubleshooting (continued) Fault Possible Cause Corrective Action Is circulator pump functional? Check power to pump and replace as necessary. Maintain a minimum of 3 GPM. Refer to Table 5-1. Increase flow rate by using larger pump or pipe Check temperature rise across boiler.

- Page 24 Electric Installation, Operating & Service Manual Troubleshooting (continued) Fault Possible Cause Corrective Action N -Check control board jumper is in place and secure. Tighten FLO screws if needed. Y -System air locked - Purge system and add FLO Flow Switch venting as needed.

-

Page 25: Service Parts

Electric Installation, Operating & Service Manual Service Parts Part Number Boiler Models Kit Contents Left side jacket panel Right side jacket panel Boiler logo SWA16 Jacket Front Cover 112356-01 SWA20 Door trim bezel SWA24 Breaker trim bezel Screw Instructions Breaker Trim Bezel... -

Page 26: Swa16 Swa20 Swa24

Electric Installation, Operating & Service Manual Service Parts (continued) Part Number Boiler Models Kit Contents 111999-01 SWA16 Element Heating Element 111999-02 SWA20 Gasket 111999-03 SWA24 Instructions Element Gasket Part Number Boiler Models Kit Contents Boiler Control SWA16 Boiler Control 112003-01... -

Page 27: Qty

Electric Installation, Operating & Service Manual Service Parts (continued) Part Number Boiler Models Kit Contents Power Breaker SWA16 Power Breaker 112002-01 SWA20 Screws SWA24 Instructions Power Breaker Part Number Boiler Models Kit Contents SWA16 Flow Switch Flow Switch 112147-01 SWA20... -

Page 28: Qty

Electric Installation, Operating & Service Manual Service Parts (continued) Part Number Boiler Models Kit Contents SWA16 Temperature Sensor Water Temperature 112019-01 SWA20 Sensor Instructions SWA24 Water temp. sensor Part Number Boiler Models Kit Contents SWA16 Screws Cooling Fan 112005-01 SWA20... - Page 29 Electric Installation, Operating & Service Manual Service Parts (continued) Part Number Boiler Models Kit Contents SWA16 Wire Harness Power Block Wire 112163-01 SWA20 Harness Instructions SWA24 Part Number Boiler Models Kit Contents SWA16 Wire Harness High Voltage Harness 112164-01 SWA20 Element 1 &...

-

Page 30: Warranty

Damage to the boiler and/or property due to installation or operation of the boiler that is PA USA hereby extends the following limited warranties to the original owner of a SPARQ electric not in accordance with the boiler installation and operating instruction manual. - Page 31 Electric Installation, Operating & Service Manual SERVICE RECORD DATE SERVICE PERFORMED 112364-05 - 11/23...

- Page 32 Electric Installation, Operating & Service Manual Velocity Boiler Works, LLC P.O. Box 14818 3633 I Street Philadelphia, PA 19134 www.velocityboilerworks.com 112364-05 - 11/23...

Need help?

Do you have a question about the SWA16 and is the answer not in the manual?

Questions and answers