Table of Contents

Advertisement

Quick Links

Product Installation Guidelines & Scope of Use

CliniMix

TMV 1500 Lead Safe

®

Cabinet

PRODUCT CODES

-

201.10.70.10

-

201.11.70.10

-

201.13.70.10

SPECIFICATIONS

®

CliniMix

Thermostatic Mixing Valve Cabinet assemblies are designed to protect users from scalding or cold

water shock by providing tempered water to the desired outlets.

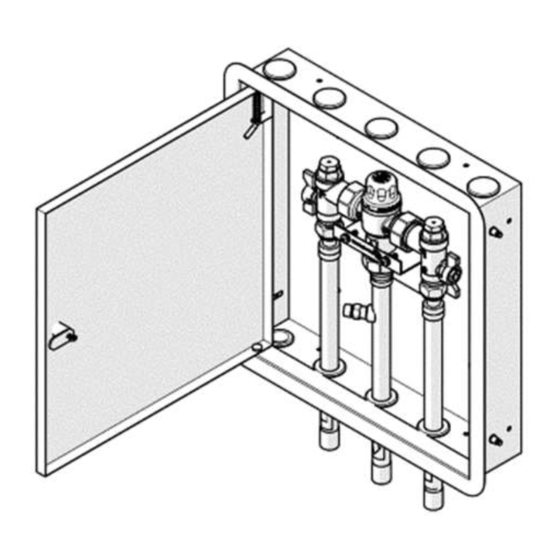

This stainless steel hinged cabinet kit is a lockable cabinet with 20mm copper fittings which allows secure

installation and safe, simple maintenance of thermostatic mixing valve.

Flat faced connections allow removal of the valve without disturbing the pipework.

In the event of either hot or cold water supply failure the valve will shut down.

Units come complete with right angle isolating ball valve, non-return valve and strainer assemblies.

Can be installed in any configuration with the water outlet in the horizontal or vertical position, and inlet

connections can be rotated to suit inlet pipework.

Complies with the requirements of AS/NZS 4032.1 - Thermostatic Mixing Valves.

WARNINGS: Special attentions to be paid on notes, photos, images, or drawings of

assembly steps marked with the warning symbol.

TABLE OF CONTENTS

1.0 DESCRIPTION

© Galvin Engineering Pty Ltd

½" Thermostatic Mixing Valve in SS

™

Version 1, 13 November 2023, Page 1 of 13

Document No: 001.00.10.32

2

2

2

3

4

5

5

5

6

8

9

10

Advertisement

Table of Contents

Summary of Contents for Galvin Engineering CliniMix TMV 1500

-

Page 1: Table Of Contents

TABLE OF CONTENTS 1.0 DESCRIPTION 2.0 TECHNICAL DATA 3.0 SAFETY 4.0 DIMENSIONS 5.0 FLOW SIZING GRAPH 6.0 WATER SUPPLY CONDITIONS 6.1 SCOPE OF USE 6.2 SUPPLY PRESSURE REQUIREMENTS 7.0 INSTALLATION 8.0 TROUBLESHOOTING 9.0 WARRANTY 10.0 APPENDIX © Galvin Engineering Pty Ltd... -

Page 2: Technical Data

Note: The mixing valve, inlet controls, pipe work and the surrounding area may become hot when installed which may cause burn injuries. Precautions should be taken to ensure that these surfaces cannot cause such injuries. © Galvin Engineering Pty Ltd... -

Page 3: Dimensions

® 201.10.70.10 – CliniMix TMV 1500 Lead Safe ½” Thermostatic Mixing Valve in SS Cabinet ™ ® 201.11.70.10 – CliniMix TMV 1500 Lead Safe ½” Thermostatic Mixing Valve with Cold Bypass in SS Cabinet ™ © Galvin Engineering Pty Ltd... -

Page 4: Flow Sizing Graph

If the TMV is to be installed and operated under unequal inlet pressures, the lower inlet pressure determines the outlet flow rate. However, for optimum performance and stability it is recommended that the TMV be installed with balanced dynamic inlet pressures (+/- 10%). © Galvin Engineering Pty Ltd... -

Page 5: Water Supply Conditions

Maximum Static Pressure (kPa) 1600 Permitted Supply Pressure Variation 10:1 Note: Tapware must be installed in accordance with the provisions of AS/NZS 3500. Installations not complying with AS/NZS 3500 may void the product and performance warranty provisions. © Galvin Engineering Pty Ltd... -

Page 6: Installation

Version 1, 13 November 2023, Page 6 of 13 7.0 INSTALLATION INSTALLATION COMPLIANCE: Galvin Engineering products must be installed in accordance with these installation instructions and in accordance with AS/NZS 3500, the PCA and your local regulatory requirements. Water and/or electrical supply conditions must also comply to the applicable national and/or state standards. - Page 7 201.70.11.09 installation instructions available from www.galvinengineering.com.au. Note: The Galvin Engineering CliniMix Fit hinged door back into cabinet and lock with supplied key. Thermostatic Mixing Valve must be installed by a licensed plumber. If the...

-

Page 8: Troubleshooting

Inlet temperatures are not within Ensure inlet temperatures are within the specified limits. specified limits. Valve is noisy. Water velocity above velocity Reduce water velocity. requirements of AS3500.1. © Galvin Engineering Pty Ltd... -

Page 9: Warranty

Version 1, 13 November 2023, Page 9 of 13 9.0 WARRANTY Galvin Engineering products are covered under our Manufacturer's Warranty. Galvin Engineering products must be installed in accordance with the installation instructions and in accordance with AS 3500 and NCC Volume Three, relevant Australian Standards and local authorities applicable to product being installed. -

Page 10: Appendix

Product Installation Guidelines Version 1, 13 November 2023, Page 10 of 13 Version 1, 13 November 2023, Page 10 of 13 10.0 APPENDIX Galvin Engineering Thermostatic Mixing Valve or Tempering Valve Commissioning Report and/or Maintenance Report Note: Please use a separate form for each valve. - Page 11 Product Installation Guidelines Version 1, 13 November 2023, Page 11 of 13 Version 1, 13 November 2023, Page 11 of 13 Galvin Thermostatic Mixing Valve or Engineering Tempering Valve Commissioning Report and/or Maintenance Report Test Results □ □ Valve considered satisfactory for use: Yes If No, state the reason and action taken: ___________________________________________________________________________________________ ___________________________________________________________________________________________...

- Page 12 Product Installation Guidelines Version 1, 13 November 2023, Page 12 of 13 Version 1, 13 November 2023, Page 12 of 13 Galvin Engineering Thermostatic Mixing Valve or Tempering Valve Commissioning Report Valve Location/Building : ____________________________________________________________________ Room or Area: ____________________________________________________________________________ Work Order No.: ___________________________________________________________________________...

-

Page 13: Version 1, 13 November 2023

Version 1, 13 November 2023, Page 13 of 13 Product Installation Guidelines Version 1, 13 November 2023, Page 13 of 13 Galvin Engineering Thermostatic Mixing Valve or Tempering Valve Commissioning/Maintenance Report The following information is to be provided by the site manager/owner/occupier.

Need help?

Do you have a question about the CliniMix TMV 1500 and is the answer not in the manual?

Questions and answers