Table of Contents

Advertisement

Quick Links

Installation Information

Water Piping Connections

Startup Procedures

Preventative Maintenance

TEC-IOM-G-0523v1

n

s

Electrical

l

s

s

Troubleshooting

g

e

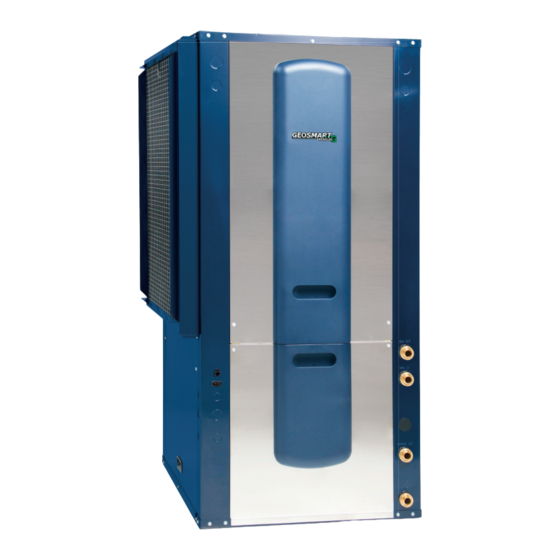

Premium Forced Air

Comfort System

Geothermal/Water Source Heat Pumps

• R-410A Refrigerant

• 1 - 6 Ton Single Speed

1 6 Ton Si

• 2 - 6 Ton Du

• 2 - 6 Ton Dual Capacity

Advertisement

Table of Contents

Summary of Contents for GeoSmart PremiumG GT Series

- Page 1 Premium Forced Air Comfort System Geothermal/Water Source Heat Pumps • R-410A Refrigerant • 1 - 6 Ton Single Speed 1 6 Ton Si • 2 - 6 Ton Dual Capacity • 2 - 6 Ton Du Installation Information Water Piping Connections Electrical Startup Procedures Troubleshooting...

-

Page 3: Table Of Contents

PREMIUM G SERIES INSTALLATION MANUAL Table of Contents Model Nomenclature ............. . . 4 General Installation Information . -

Page 4: Model Nomenclature

PREMIUM G SERIES INSTALLATION MANUAL Model Nomenclature 17-18 12 13 Model Vintage GT – Dual Capacity * - Factory Use Water-to-Air GS – Single Speed Non-Standard Options Water-to-Air SS – Standard Unit Capacity Cabinet Options 012, 018, 022, 026, 030 L –... -

Page 5: General Installation Information

PREMIUM G SERIES INSTALLATION MANUAL General Installation Information Safety Considerations Filter Rack Conversion A 1” electrostatic air filter is shipped with the heat pump. To field WARNING: Before performing service or convert the filter rack to use 2” air filters, simply remove the plastic maintenance operations on a system, turn off main push pins from the top and bottom of the filter rack. - Page 6 PREMIUM G SERIES INSTALLATION MANUAL General Installation Information cont. Installing Horizontal Units pitched approximately 1/4-inch towards the drain in both directions to facilitate the removal of condensate. Use only the bolts provided Remove and discard the compressor hold down shipping bolt in the kit to attach hanger brackets.

- Page 7 PREMIUM G SERIES INSTALLATION MANUAL General Installation Information cont. Figure 3: Hanger Location and Assembly Hanger Dimensions Weight Distribution Unit Hanger Dimensions Horizontal Weight Distribution Hanger Kit Model Vertical Horizontal Part Number Model Front Back Weight Weight 44.7 25.1 21.4 99S500A04 113.5 63.8...

- Page 8 PREMIUM G SERIES INSTALLATION MANUAL General Installation Information cont. Duct System Never use flexible hoses smaller than 1-inch inside diameter on the unit. Limit hose length to 10 feet per connection. Check An air outlet collar is provided on vertical top and rear air discharge carefully for water leaks.

- Page 9 PREMIUM G SERIES INSTALLATION MANUAL General Installation Information cont. Material Copper 90/10 Cupronickel 316 Stainless Steel Acidity/Alkalinity 7 - 9 7 - 9 7 - 9 Calcium and (Total Hardness) (Total Hardness) (Total Hardness) Scaling Magnesium Carbonate less than 350 ppm less than 350 ppm less than 350 ppm Less than 0.5 ppm (rotten egg...

-

Page 10: Closed Loop Ground Source Systems

PREMIUM G SERIES INSTALLATION MANUAL Closed Loop Ground Source Systems Multiple Units on One Flow Center NOTE: For closed loop systems with antifreeze protection, set SW2-1 to the “LOOP” (15°F) position. (Refer to the DIP Switch NOTE: This feature is only available in the Aurora Advanced Settings table in the Aurora Control section.) Control package (AXB board), NOT the Aurora Base Control (ABC). -

Page 11: Open Loop Ground Water Systems

PREMIUM G SERIES INSTALLATION MANUAL Open Loop Ground Water Systems Typical open loop piping is shown below. Always maintain Figure 9a: Modulating Water Valve Connection Option water pressure in the heat exchanger by placing water control Typical 0-10VDC modulating water valve. Unit must have AXB Board valves at the outlet of the unit to prevent mineral precipitation. -

Page 12: Hot Water Generator Connections

PREMIUM G SERIES INSTALLATION MANUAL Hot Water Generator Connections To maximize the benefits of the hot water generator a minimum Figure 11: Typical Hot Water Generator Installation 50-gallon water heater is recommended For higher demand Cold 3/4 x 3/4 x 1/2 tee applications, use an 80-gallon water heater or two 50-gallon water Water In Water Out... - Page 13 PREMIUM G SERIES INSTALLATION MANUAL Hot Water Generator Connections cont. Plumbing Installation Hot Water Generator Startup 1. Inspect the dip tube in the water heater cold inlet for a check 1. Close the drain valve to the water heater. valve. If a check valve is present it must be removed or 2.

-

Page 14: Electrical Connections

PREMIUM G SERIES INSTALLATION MANUAL Electrical Connections General Accessory Relay A set of “dry” contacts has been provided to control accessory Be sure the available power is the same voltage and phase as that devices, such as water solenoid valves on open loop installations, shown on the unit serial plate. -

Page 15: Electronic Thermostat Installation

PREMIUM G SERIES INSTALLATION MANUAL Electrical Connections cont. Pump Power Wiring Figure 14: Pump Wiring 208-230/60/1 See Figure 14 for electrical connections from control box to pumps. Wire Nuts FC1/FC2 style flow centers with fixed speed pumps connect to PB1 in the control box. If using a variable speed pump it should be connected to L1 and L2 on the AXB. -

Page 16: Flow Centers

PREMIUM G SERIES INSTALLATION MANUAL Electrical Information Fixed Speed Flow Center The pump(s) will be connected to the terminals on PB1 in the unit electrical box as shown in Figure 15. The pumps will automatically be cycled as required by the unit or by a signal from another unit sharing the flow center (See Figures 5 and 6). - Page 17 PREMIUM G SERIES INSTALLATION MANUAL Electrical Information cont. Variable Speed Flow Center Single Pump Variable Speed Flow Center If a variable speed single pump flow center is used, the flow center will come with two red and one green wires for the high voltage wiring.

- Page 18 PREMIUM G SERIES INSTALLATION MANUAL Electrical Information cont. Variable Speed Flow Center cont. Two Pump Variable Speed Flow Center If a variable speed two pump flow center is used, the flow center will come with four red and two green wires for the high voltage wiring.

- Page 19 PREMIUM G SERIES INSTALLATION MANUAL Electrical Information cont. Variable Speed Units cont. Two Pump Variable Speed Flow Center cont. The use of the black wire on the left hand pump is ONLY to be connected for troubleshooting of the pumps. The left hand pump will have a closed end splice connector crimped to the black wire.

-

Page 20: Auxiliary Heat Ratings

PREMIUM G SERIES INSTALLATION MANUAL Auxiliary Heat Ratings Btu/h Model Size Compatibility Model Stages Min cfm 208V 230V 208V 230V 026 - 030 036 - 042 048 - 072 EAS(H)4A 9,700 12,900 • EAM(H)5A 12,300 16,300 • • • EAM(H)8A 19,400 25,900 •... -

Page 21: Electrical Data

PREMIUM G SERIES INSTALLATION MANUAL Electrical Data Single Speed Unit with Variable Speed ECM Motor Compressor Total Voltage Blower Model Rated Voltage Loop Unit Circ Fuse/ Min/Max Pump FLA Motor FLA LRA** HACR 208-230/60/1 187/253 10.4 33.5 16.5 18.1 208-230/60/1 187/253 14.0 48.0... - Page 22 PREMIUM G SERIES INSTALLATION MANUAL Electrical Data cont. Dual Capacity Unit with Variable Speed ECM Motor Compressor Blower Total Rated Voltage Model Pump Loop Motor Unit Circ Fuse/ Voltage Min/Max LRA** HACR 208-230/60/1 187/253 18.2 11.6 58.3 21.0 21.4 24.4 208-230/60/1 187/253 23.8...

-

Page 23: Blower Performance Data

PREMIUM G SERIES INSTALLATION MANUAL Blower Performance Data Single Speed Unit with Variable Speed ECM Motor Airflow Speed Settings Model 1025 1125 0.50 1000 1100 1200 0.50 1000 1100 1200 0.50 1000 1100 1200 1300 1400 1500 1550 0.50 1050 1150 1250 1350... - Page 24 PREMIUM G SERIES INSTALLATION MANUAL Blower Performance Data cont. Setting Blower Speed - Variable Speed ECM ECM Speed Setup - These screens allow the technician to select the “G”, low, high, and auxiliary heat blower speed for the ECM The ABC board’s Yellow Config LED will flash the current ECM blower motor.

- Page 25 PREMIUM G SERIES INSTALLATION MANUAL Blower Performance Data cont. Unit with Standard PSC Motor Airflow (cfm) at External Static Pressure (in. wg) Motor Blower Motor Model Size 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00 6 x 8...

-

Page 26: Dimensional Data

PREMIUM G SERIES INSTALLATION MANUAL Vertical Dimensional Data Top Air Discharge LEFT RETURN RIGHT RETURN 1.9in [4.8cm] 1.9in [4.8cm] K J I D E H F FRONT 2ft [61cm] Primary Service Access RIGHT SIDE LEFT SIDE Electrical Return Connection Connections Discharge Connection Overall Cabinet Water Connections... - Page 27 PREMIUM G SERIES INSTALLATION MANUAL Vertical Dimensional Data cont. Bottom Air Discharge LEFT RETURN RIGHT RETURN 1.70 (4.3 cm) LEFT SIDE RIGHT SIDE 1.90 (4.7 cm) FRONT 2ft [61cm] Primary Service Access LEFT BOTTOM DISCHARGE RIGHT BOTTOM DISCHARGE FLOOR FOOT PRINT FLOOR FOOT PRINT Electrical Water Connections...

- Page 28 PREMIUM G SERIES INSTALLATION MANUAL Vertical Dimensional Data cont. Rear Air Discharge 1.90 1.90 FRONT REAR VIEW SIDE VIEW SIDE VIEW REAR VIEW LEFT RETURN LEFT RETURN RIGHT RETURN RIGHT RETURN Electrical Return Connection Discharge Connection Overall Cabinet Water Connections Connections using std deluxe filter rack duct flange installed (±0.10 in)

- Page 29 PREMIUM G SERIES INSTALLATION MANUAL Horizontal Dimensional Data TOP VIEW 2.1in [5.4cm] MOUNT (2) HANGER BRACKETS AS SHOWN TO ALLOW ACCESS TO FILTER 2ft [61cm] Primary Service Access SIDE DISHCARGE VIEW FRONT VIEW END VIEW 1.9in [4.8cm] D E F K J I AS SHOWN LR UNIT (RR UNIT ON OPPOSITE SIDE—SAME DIMENSIONS) Electrical...

-

Page 30: Physical Data

PREMIUM G SERIES INSTALLATION MANUAL Physical Data Single Speed SINGLE SPEED Model Compressor (1 each) Rotary Scroll Factory Charge R410a, oz [kg] Vertical 36 [1.02] 42 [1.19] 56 [1.58] 64 [1.81] 80 [2.26] 82 [2.32] 84 [2.38] 88 [2.49] 134 [3.79] (Aluminum tube and fin air coil) Factory Charge R410a, oz [kg] Horizontal... - Page 31 PREMIUM G SERIES INSTALLATION MANUAL Physical Data cont. Dual Capacity DUAL CAPACITY Model Compressor (1 each) Copeland UltraTech, Dual Capacity Scroll Factory Charge R410a, oz [kg] (Aluminum tube and fin air coil) Vertical 56 [1.58] 76 [2.15] 84 [2.38] 86 [2.44] 130 [3.68] Factory Charge R410a, oz [kg] (Aluminum tube and fin air coil)

-

Page 32: The Aurora Control System

PREMIUM G SERIES INSTALLATION MANUAL The Aurora™ Control System Aurora ‘Base’ Control Aurora ‘Advanced’ Control The Aurora ‘Advanced’ Control The Aurora ‘Base’ Control (ABC) expands on the capability of the System is a complete residential Aurora ‘Base’ Control (ABC) and commercial comfort System by adding the Aurora system that brings all aspects Expansion Board (AXB). - Page 33 PREMIUM G SERIES INSTALLATION MANUAL The Aurora Control System cont. Service Device Description Aurora ‘Base’ Aurora ‘Advanced’ Allows setup, monitoring and troubleshooting of any Aurora Control. For Service For Service NOTE: Although the ABC has basic compatibility with all Aurora, new (Ver.

- Page 34 PREMIUM G SERIES INSTALLATION MANUAL The Aurora ‘Base’ Control System cont. Aurora ‘Base’ Control Field Selectable Options via Hardware DIP Switch (SW1) – Test/Configuration Button (See SW1 Operation Table) Test Mode The control is placed in the test mode by holding the push button switch SW1 for 2 - 5 seconds.

- Page 35 PREMIUM G SERIES INSTALLATION MANUAL The Aurora ‘Base’ Control System cont. Cycle with Blower - The accessory relay will cycle with the Lockout – when locked out, the blower will operate continuously in blower output. “G” speed, and PSC blower motor output will remain on. The Alarm output (ALM) and Lockout output (L) will be turned on.

- Page 36 PREMIUM G SERIES INSTALLATION MANUAL The Aurora ‘Base’ Control System cont. Cooling Operation Over/Under Voltage Shutdown - An over/under voltage condition exists when the control voltage is outside the range of 18 VAC to In all cooling operations, the reversing valve directly tracks the O 30 VAC.

- Page 37 PREMIUM G SERIES INSTALLATION MANUAL The Aurora ‘Base’ Control System cont. Aurora ‘Base’ Control LED Displays Aurora Interface and Diagnostics (AID) Tool These three LEDs display the status, configuration, and fault The Aurora Interface and codes for the control. These can also be read in plain English via Diagnostics (AID) Tool is a the Aurora AID Tool.

- Page 38 PREMIUM G SERIES INSTALLATION MANUAL Operation Logic HEATING COOLING SL1 - OPERATION LOGIC FAN ON IN ON STG1 STG2 STG3 EMERG STG1 STG2 SINGLE SPEED UNITS Compressor ECM Normal High High High High ECM Dehumidify High High High 85% Med 85% High Rev Valve Loop Pump...

-

Page 39: Reference Calculations And Legend

PREMIUM G SERIES INSTALLATION MANUAL Reference Calculations Heating Calculations: Cooling Calculations: LWT = EWT + LWT = EWT - gpm x 500 gpm x 500 LAT (DB) = EAT (DB) - LAT = EAT + cfm x 1.08 cfm x 1.08 LC = TC - SC TH = HC + HW S/T =... -

Page 40: Wiring Schematics

PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics Aurora Advanced with ECM and IntelliStart Green/Yellow Green/Yellow Ext Pump Orange(9) Pump 1/2 hp Total G G G Compr essor 208-230/60/1 Pump Brown(10) Blue Blue Blue VARIABLE VARIABLE Violet(8) SPEED PUMP SPEED PUMP HIGH VOLTAGE HIGH VOLTAGE Violet(7) - Page 41 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Aurora Advanced with ECM and IntelliStart cont. With optional EA Series 20kW Auxiliary Electric Heat Shown With optional EA Series 20kW Auxiliary Electric Heat Shown 60 AMP 60 AMP 60 AMP 60 AMP Legend Legend Legend...

- Page 42 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics Aurora Advanced with ECM and IntelliStart AXB BOARD Aurora LED Flash Codes Slow Flash 1 second on and 1 second off Fast Flash 100 milliseconds on and 100 milliseconds off Flash Code 100 milliseconds on and 400 milliseconds off with a 2 second pause before repeating Fault LED (LED 1, Red) Random Start Delay (Alternating Colors) Normal Mode...

- Page 43 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Aurora Advanced with ECM and IntelliStart cont. Communicating Thermostat To Foss il Fuel R f rom Foss il Dual Fuel Wiring Diagr am Furnac e W input Fue l Furnac e Using Field Installed Relay Note 11 : Fiel d i ns ta lled SPST dua l f ue l rel ay FP1 –...

- Page 44 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Aurora Base with PSC Notes Ext Pump 1/2 hp Total Green/Yellow 208-230/60/1 1 - Switch blue a nd red wires for 208V operation. 2 - The blk/wh and gray/wh wi re s are removed when Aux He at is installed Compr essor Violet(7) 3 - Use manufacturer’...

- Page 45 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Aurora Base with PSC cont. With optional EA Series 10kW Auxiliary Electric Heat Shown 1 - Use copper o r aluminum conductors. 208-230/60/1 2 – When Auxil iary Heat is installe d the BLK/WHT wire from CC-L1 to PB2-2 and the GRY/WHT wire from CC-L2 to PB2-1 must be removed (located in the heat pump control box).

- Page 46 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Variable Speed Pump (UPMXL 25-124) Variable Speed Flow Center With 1 – UPMXL 25-124 Pump Wires provided Wires provided with flow center with flow center Green G G G Variable Speed Pump HIGH VOLTAGE Status Status...

- Page 47 PREMIUM G SERIES INSTALLATION MANUAL Wiring Schematics cont. Variable Speed Pump (UPMXL 25-124) Variable Speed Flow Center With 2 – UPMXL 25-124 Pumps Wires provided Wires provided with flow center with flow center Green G G G Left Hand Right Hand Variable Variable Speed Pump...

-

Page 48: Unit Startup

PREMIUM G SERIES INSTALLATION MANUAL Unit Startup Before Powering Unit, Check the Following: c. AXB Setup i. DHW Enable – Ensure air is purged from NOTE: Remove and discard the compressor hold down shipping HW system before enabling (remember bolt located at the front of the compressor mounting bracket. the HW switch on the front cabinet) ii. -

Page 49: Operating Parameters

PREMIUM G SERIES INSTALLATION MANUAL Unit Startup cont. Once sensors are installed for discharge pressure, suction pressure, suction, liquid line cooling, liquid line heating and leaving air temperature no further setup is required. a. Turn on Unit in Heating or Cooling . b. - Page 50 PREMIUM G SERIES INSTALLATION MANUAL Operating Parameters cont. Dual Capacity Models First Stage Operation Cooling -- No Hot Water Generation Entering Water Water Flow Suction Pressure Discharge Water Temp Rise Air Temp Drop Temp °F gpm/ton Superheat Subcooling psig Pressure psig °F °F DB 105 - 120...

-

Page 51: Pressure Drop

PREMIUM G SERIES INSTALLATION MANUAL Pressure Drop Dual Capacity Single Speed Pressure Drop (psi) Pressure Drop (psi) Model Model 30°F 50°F 70°F 90°F 110°F 30°F 50°F 70°F 90°F 110°F full load part load full load part load full load part load 10.7 full load 11.7... -

Page 52: Compressor And Thermistor Resistance

PREMIUM G SERIES INSTALLATION MANUAL Compressor Resistance Thermistor Resistance Thermistor Microprocessor 208-230/60/1 Compressor Model Temperature (°F) Resistance (Ohms) Model No. Start 75757-70117 GK102KAA 3.35 - 3.85 2.80 - 3.22 57392-53234 GK151KAA 2.24 - 2.58 2.84 - 3.26 43865-40771 ZP16K5E-PFV 1.39 - 1.53 2.15 - 2.30 33809-31487 ZP21K5E-PFV... -

Page 53: Heat Of Extraction/Rejection

PREMIUM G SERIES INSTALLATION MANUAL Heat of Extraction/Rejection Single Speed Heat of Extraction (kBtuh) Heat of Rejection (kBtuh) Model 30°F 50°F 70°F 90°F 30°F 50°F 70°F 90°F 110°F 12.5 16.9 16.5 15.8 10.1 12.7 17.3 16.9 16.4 15.9 16.0 10.6 12.9 17.4 16.9... -

Page 54: Troubleshooting

PREMIUM G SERIES INSTALLATION MANUAL Troubleshooting Aurora Control System Refrigerant Systems NOTE: Refer to the Aurora Base Control Application and To maintain sealed circuit integrity, do not install service gauges Troubleshooting Guide and the Instruction Guide: Aurora Interface and unless unit operation appears abnormal. Compare the change in Diagnostics (AID) Tool for additional information. - Page 55 PREMIUM G SERIES INSTALLATION MANUAL Troubleshooting cont. Water Leaving Water Blower Thermistor Coax Coil Flow Sensor Water Flow Meter Entering Water Thermistor Leaving Air Thermistor Wire Bundle In FP2 Sensor Blower D Control Option Only Compartment) Water Line View of Coax D Control Option Only Suction Suction...

- Page 56 PREMIUM G SERIES INSTALLATION MANUAL Startup/ roubleshooting Form DEALER: PHONE #: DATE: PROBLEM: MODEL #: SERIAL #: COOLING CYCLE ANALYSIS SAT °F °F Unit Amp Draw: Loop: Open Closed Line Voltage: °F °F COIL SUCTION COMPRESSOR REVERSING COAX COAX EXPANSION VALVE LOAD SOURCE...

- Page 57 PREMIUM G SERIES INSTALLATION MANUAL Troubleshooting cont. Single Speed/Dual Capacity Startup/Troubleshooting Form 1. Job Information Model # Job Name: Loop: Open / Closed Serial # Install Date: Hot Water Generator: Y / N 2. Flow Rate in gpm SOURCE COAX LOAD COAX (Water-to-Water) HEATING COOLING...

-

Page 58: Preventive Maintenance

PREMIUM G SERIES INSTALLATION MANUAL Preventive Maintenance Water Coil Maintenance Other Maintenance Filters Keep all air out of the water. An open loop system should be checked to ensure that the well head is not allowing air to Filters must be clean to obtain maximum performance. They infiltrate the water line. -

Page 59: Service Parts List

PREMIUM G SERIES INSTALLATION MANUAL Service Parts List Single Speed Units Parts List Compressor 208-230/60/1 34P591-01 34P593-01 34P581-01 34P582-01 34P583-01 34P578-01 34P579-01 34P580-01 34P646-01 Run Capacitor 208-230/60/1 16P008D18CK 16P008D19CK 16P008D18CK 16P008D20CK 16P008D20CK 16P008D21CK 16P008D21CK 16P008D25CK 16P008D24CK Sound Jacket 92P504A01 92P504A01 92P504A05 92P504A05 92P504A05... - Page 60 PREMIUM G SERIES INSTALLATION MANUAL Service Parts List cont. Dual Capacity Units Parts List Compressor 208-230/60/1 34P640-01 34P641-01 34P642-01 34P643-01 34P644-01 Run Capacitor 208-230/60/1 16P008D19CK 16P008D20CK 16P008D18CK 16P008D31CK 16P008D31CK Sound Jacket 92P504A16 92P504A16 92P504A16 92P504A16 92P504A16 Power Harness 11P781-01 11P781-01 11P781-01 11P781-01 11P781-01...

-

Page 61: Revision Guide

PREMIUM G SERIES INSTALLATION MANUAL Revision Guide Pages: Description: Date: 14,15,48,54,58 Updated with Aurora Controls 22 May 2023 Misc Updated physical data table, service parts table, troubleshooting form 14 July 2022 Released Aluminum Air Coil Option 1 Sept 2015 Wiring Schematics Updated, Electric Heating Updated 11 June 2015 First Published. - Page 62 650 Jamieson Parkway, Unit #1, Cambridge, Ontario N3C 0A5 | o: 1.866.310.6690 | f: 1.866.533.3889 SMART ENERGY.COM *IM2500AG2A* Product: Premium G Series Geothermal/Water Source Heat Pumps Type: Size: 1 - 6 Ton Single Speed 2 - 6 Ton Dual Capacity Document Type: Installation, Operation &...

Need help?

Do you have a question about the PremiumG GT Series and is the answer not in the manual?

Questions and answers

In our area of southern Ontario in summer can we turn off the furnace and still have hot water in he house? We do not need the air conditioning very much because the house has numerous trees surrounding it. Is it reasonable to use the air conditioning on an intermittent basis?