Subscribe to Our Youtube Channel

Summary of Contents for Grunbeck GENO-control

- Page 1 We understand water. Hardness control measuring device | GENO-control Operation manual...

- Page 2 Central Contact Germany Sales Phone +49 (0)9074 41-0 Technical Service Phone +49 (0)9074 41-333 Fax +49 (0)9074 41-120 Availability Monday to Thursday 7:00 am - 6:00 pm Friday 7:00 am - 4:00 pm Subject to technical modifications. © by Grünbeck Wasseraufbereitung GmbH Original operation manual Edition: May 2021 Order no.: 100198960000_en_034...

-

Page 3: Table Of Contents

Intended use ............10 Fault ................26 Product components ..........11 Shutdown ..............27 Functional description ..........12 GENO-control release times ........12 10.1 Temporary standstill ..........27 Accessories ............. 13 10.2 Restart ..............27 Transport and storage ..........14 Dismantling and disposal ........28 Dispatch/delivery/packaging ........ -

Page 4: Introduction

Illustrations in this manual are for basic understanding and may differ from the actual version. Validity of the manual This manual applies to following product: ● Hardness control measuring device GENO-control Other applicable documents ● None Product identification You can identify your product by means of the product designation and the order number on the type plate. -

Page 5: Symbols Used

Introduction The type plate is located on the control unit in the housing. Designation Designation “Operation” display Weight “Hard water” display Protection Product designation Mains connection Order no. Ambient temperature Serial no. Water temperature Observe the Operation Manual Flow rate CE mark Operating pressure Disposal information... -

Page 6: Depiction Of Warnings

Introduction Depiction of warnings This manual contains information that you must comply with for your personal safety. The information is marked with a warning sign and has the following structure: 1.5.1.2 SIGNAL WORD 1.5.1.3 Type and source of danger 1.5.1.1 ●... - Page 7 Introduction 1.6.2 Authorisations of personnel The following table describes which activities are allowed to be performed by whom. Operator/ Owner/op Qualified Technical user erating specialist service company Transport and storage Installation and mounting Start-up Operation and handling Cleaning Inspection Maintenanc Troubleshooting Repair Shutdown and restart...

-

Page 8: Safety

Safety Safety Safety measures ● Only operate your product if all components are installed properly. ● Adhere to the applicable local guidelines on drinking water protection, accident prevention and occupational safety. ● Do not make any changes, conversions, extensions or program modifications to your product. -

Page 9: Product-Specific Safety Instructions

Safety 2.1.3 Electrical dangers There is an immediate danger of fatal injury from electric shock when touching live components. Damage to the insulation or individual components can be life-threatening. ● Only have a qualified electrician carry out electrical work on the product. ●... -

Page 10: Product Description

Product description Product description Intended use ● The GENO-control automatic hardness control measuring device is used to monitor fully softened water. The hardness control measuring device protects downstream systems from hard water. ● The GENO-control hardness control measuring device continuously monitors the residual hardness without using chemicals or water. -

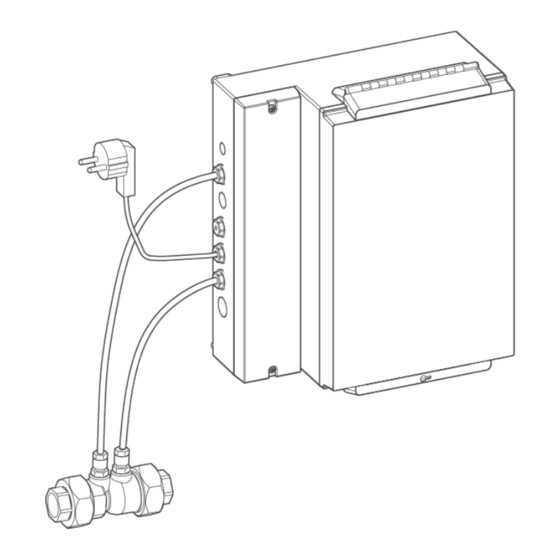

Page 11: Product Components

Product description Product components Designation Function Mains plug for Schuko socket, 230 V/50 Hz Cover for line connections made of transparent plastic Shut-off valve Measuring water inlet Transmitter unit with reed contact with special resin on a resin expansion/shrinkage basis to check the measuring Hardness sensor water for hardness breakthrough Controlled via a transmitter unit with reed contact and display of the operating... -

Page 12: Functional Description

GENO-control release times The GENO-control hardness control measuring device is not, or only conditionally, applicable upstream from systems/processes that constantly require water with a total hardness <... -

Page 13: Accessories

Illustration Product Order no. Spare sensor 172 304 as hardness sensor for the GENO-control hardness control measuring device Differential pressure sensor made of brass with straight screw connections (male thread 1/4") for sampling lines, non-return valve type RV 281 and with additional PVC union nuts and adhesive sockets DN 20 (Ø... -

Page 14: Transport And Storage

Transport and storage Transport and storage Dispatch/delivery/packaging ► Check immediately upon receipt for completeness and transport damages. ► Proceed as follows if there is visible transport damages: • Do not accept the delivery or only under subject to reservation. • Note the extent of damage on the transport documents or on the delivery note of the forwarder. -

Page 15: Installation

Installation Installation The installation of the system represents a major intervention in the drinking water system and only a qualified specialist may install such systems. Installation example Designation Designation Safety device protectliQ Activated carbon filter AKF Drinking water filter pureliQ Water softener such as Delta-p System separator GENO-DK 2 Requirements with regard to the installation site... -

Page 16: Checking The Scope Of Supply

Installation ● A floor drain suitable for the system size must be available at the installation site or a protection device e.g. protectliQ or a protection device with water stop of the same quality must be installed. ● A Schuko socket is required for the electrical connection at a distance of approx. 1.2 m from the system. - Page 17 Installation 1. Remove the cover for line connections - loosen 2 screws. 2. Position the hardness control measuring device near the flow fitting - in doing so take note of the lengths for mains power cables and sampling lines. 3. Fasten the housing vertically to the wall using fastening accessories (recommendation: stainless steel flat head screws) - take note of the dimensions and size of the holes.

-

Page 18: Electrical Installation

Installation 1. Install the differential pressure transmitter in the soft water pipe immediately after the softening system. a Take note of the flow direction on the differential pressure transmitter. b Ensure that the hose connections are pointing upwards. 2. Connect the sampling lines to the differential pressure transmitter. 3. -

Page 19: Start-Up

3. Slowly open both shut-off valves. 4. Check all joints for leak tightness. Electrical connection to reverse osmosis system ► Connect the contact to the terminals of the reverse osmosis system. Device/system Terminals GENO-control GENO-OSMO-MSR X1/116 3K1 42 HL-300 resp. HL-X X1/21... -

Page 20: Handing Over The Product To The Owner/User

Start-up When connecting to a GENO-OSMO-X reverse osmosis system, set the residual hardness logon in the reverse osmosis system control to "Comfort" (refer to customer service instructions order no. 750 929). ► Place the spare sensor in the device. ► Close the cover for line connections and the lid. »... -

Page 21: Operation/Handling

Operation/handling Operation/handling The operation of the hardness control measuring device is automatic. ► Observe the release times (refer to Section 3.4). Designation Designation “Hard water” display “Operation” display ► Regularly check whether the visual indicator displays Operation. If a voltage-free contact is connected for actuating a visual or acoustic signal or for switching off a reverse osmosis system, Hard Water is signalled. -

Page 22: Maintenance And Repair

Maintenance and repair Maintenance and repair Maintenance includes cleaning, inspection and servicing of the product. The responsibility for inspection and maintenance is subject to local and national requirements. The owner/user is responsible for compliance with the prescribed maintenance work. By concluding a maintenance contract you ensure that all maintenance work will be performed in due time. -

Page 23: Inspection

Maintenance and repair The following interval table shows the minimum intervals for the activities to be performed. Task Interval Activities • Visually check for function and leaks Inspection 2 months • Leak test Maintenance 6 months • Functional check • Replace sensor •... - Page 24 Maintenance and repair 1. Remove the used sensor. 2. Test the function of the transmitter unit (with the sensor removed). a Press the internal transmitter metal slightly upwards with your finger. » The control unit must indicate Operation – the green indicator lights up. »...

-

Page 25: Spare Parts

Maintenance and repair 8.4.2 Regenerating the sensor The sensor must always be kept moist during storage. When occupied with hardness, the sensor's transmitter resin bed is curved inwards. Designation Transmitter resin bed 1. Swivel the sensor in brine for approx. 1 minute - use brine from the brine tank. »... -

Page 26: Fault

Fault Fault The Hard Water display flashes. 1. Change the sensor (refer to Section 8.4.1). 2. Check whether there is soft water. 3. Put the device into operation. » The Operation display lights up. If a fault cannot be rectified, further measures can be taken by the technical service. ►... -

Page 27: Shutdown

Shutdown Shutdown 10.1 Temporary standstill Should you wish to temporarily shut down your water supply due to a system standstill/conversion, proceed as follows: 1. De-energise the device. 2. Shut off the soft water supply - close the shut-off valves. 10.2 Restart 1. -

Page 28: Dismantling And Disposal

Dismantling and disposal Dismantling and disposal 11.1 Dismantling The work described herein represents an intervention into your drinking water system. ► Have this work performed by qualified specialists only. 1. Disconnect the device from the mains. 2. Close the shut-off valves at the water pipe and the device. 3. -

Page 29: Technical Specifications

Technical specifications Technical specifications Dimensions and weights GENO-control Width Height B1 Height with closed lid Depth 142.5 Height with open lid ~ 622 Retracted length ¾“ Differential pressure transmitter (without screw 1¼" 2" connection) Shipping weight without differential pressure transmitter approx. - Page 30 Technical specifications Performance data Nominal pressure ≤ 1.0/10 Operating pressure MPa/bar ≤ 2500 Flow rate Pressure loss LED display Operation/hard water General data 5 – 35 Water temperature °C 5 – 40 Ambient temperature °C ≤ 70 Air humidity (non-condensing) Order no.

-

Page 31: Operation Log

Operation log Operation log ► Document the initial start-up and all maintenance activities. ► Copy the maintenance report. Hardness control measuring device GENO-control Serial no.: ______________________________ 13.1 Start-up log Customer Name: Address: Installation/Accessories Filter (make, type) Softening system (make, type):... - Page 32 Operation log Maintenance no.: ___ Enter the measured values and operating data. Confirm the tests with OK or record any repairs carried out. Work performed ☐ Inspection ☐ Maintenance ☐ Repair Description Execution confirmed Company: Name: Date: Signature: 32 | 36...

- Page 33 Operation log Maintenance no.: ___ Enter the measured values and operating data. Confirm the tests with OK or record any repairs carried out. Work performed ☐ Inspection ☐ Maintenance ☐ Repair Description Execution confirmed Company: Name: Date: Signature: 33 | 36...

- Page 34 EU guidelines in terms of its design, construction and execution. This certificate will become invalid if the system is modified in a way not approved by us. Hardness control measuring device GENO-control Serial no.: refer to type plate Furthermore, we confirm compliance with the essential requirements of the EMC Directive 2014/30/EU.

- Page 36 Grünbeck Wasseraufbereitung GmbH Josef-Grünbeck-Str. 1 89420 Hoechstaedt; Germany +49 (0)9074 41-0 +49 (0)9074 41-100 info@gruenbeck.com For more information go to www.gruenbeck.com www.gruenbeck.com...

Need help?

Do you have a question about the GENO-control and is the answer not in the manual?

Questions and answers