Summary of Contents for Magnetic MHTM MicroDrive Access XL2

- Page 1 Operating Instructions Barrier MHTM™ MicroDrive Access XL2 and XXL Doc.ID: 5815,0009EN Version: 08...

- Page 2 Translation of the Original Operating Instructions MAGNETIC AUTOCONTROL GMBH Grienmatt 20 79650 Schopfheim Germany Telephone +49 7622 695 5 Fax +49 7622 695 802 info@magnetic-germany.com www.magnetic-access.com...

-

Page 3: Table Of Contents

Access XL2 and Access XXL Contents Contents General ..................7 Information regarding the operating instructions ... 7 Pictogram explanation ........... 8 Limitation of liability ............9 Copyright protection ............9 Scope of delivery ............10 Warranty ..............10 Customer service ............10 EU-Declarations of conformity ........ - Page 4 Access XL2 and Access XXL Contents 4.2.3 Operating conditions ........31 4.2.4 Maximum permissible wind load classes EN 12424 ............. 32 4.2.5 Operating times ........... 32 Control unit ..............33 Plug-in module "Detector A–B" ........34 Plug-in module "Radio" ..........34 Design and function ............

- Page 5 Access XL2 and Access XXL Contents 8.12 Conversion "left version" – "right version" ....73 8.12.1 Left and right version ........73 8.12.2 Converting barrier boom up to 6 metres ..73 8.12.3 Converting barrier boom as of 6 metres ..77 8.13 Check and set the balancing springs in the lever system ................

- Page 6 Access XL2 and Access XXL Contents 12 Malfunctions ..............115 12.1 Reset the barrier ............115 12.2 Closing or opening the barrier boom in case of power failure .............. 116 13 Repair ................. 118 13.1 Safety ................ 118 13.2 Spare parts ..............119 13.3 Replacing the barrier boom ........

-

Page 7: General

General General Information regarding the operating instructions These operating instructions provide crucial information on handling of Magnetic barriers MHTM MicroDrive Access XL2 and Access XXL. Pre-requisite for safe working is the observance of all specified safety notes and instructions. In addition, the local accident prevention regulations valid at the barrier's area of application and general safety regulations have to be complied with. -

Page 8: Pictogram Explanation

Access XL2 and Access XXL General Pictogram explanation Warning notes Warning notes are characterised by pictograms in these operating instructions. The warning notes are followed by signal words expressing the scale of the hazard. It is absolutely essential to observe the notes and to proceed with caution in order to prevent accidents as well as bodily injuries and property damage. -

Page 9: Limitation Of Liability

Access XL2 and Access XXL General Limitation of liability All specifications and notes in these operating instructions were compiled with consideration to the valid standards and regulations, the state of the art as well as to our long-standing knowledge and experience. -

Page 10: Scope Of Delivery

Magnetic grants a warranty on all mechanical and electrical components of product to the extent as stated in its standard terms of sales and delivery or as contractually agreed in writing. -

Page 11: Environmental Protection

Access XL2 and Access XXL General 1.10 Environmental protection NOTICE Danger for the environment by improper disposal of components or the barrier! In case of improper disposal of components or the barrier, damage to the environment may result. – Observe the local and national laws and directives. -

Page 12: Safety

Additional safety installations must be provided for motorcycles. For this case such contact the Magnetic Service. 2.1.2 Barrier, pedestrian traffic impossible In vehicle barriers where personal traffic is excluded and use by pedestrians is not intended. -

Page 13: Barrier, Pedestrian Traffic Not Impossible

In vehicle barriers where personal traffic cannot be excluded and use by pedestrian traffic is intended. If persons and animals may be present, only the following barriers may be used in connection with Magnetic safety light barriers. Access XL2 with barrier booms up to 6.5 m ... -

Page 14: Operator's Responsibility

Access XL2 and Access XXL Safety Operator's responsibility The operator must comply with the statutory obligations regarding work safety. In addition to the work safety notes in these operating instructions, the safety, accident prevention and environmental provisions applicable for the area the barrier is used in must be complied with. In particular, the operator must: gather information on applicable work protection provisions. -

Page 15: Specialists And Operating Personnel

Additionally, these electricians are trained and authorised by Magnetic to perform special repair and service work at MHTM MicroDrive barriers. It must be expected that only those people are deployed who carry out their work reliably. -

Page 16: Personal Protective Equipment

Access XL2 and Access XXL Safety Personal protective equipment It is necessary to wear personal protective equipment when dealing with the barrier so as to minimise health hazards. Before carrying out any work, properly dress in the necessary protective equipment such as work clothes, protective gloves, safety shoes, helmet and wear during work. -

Page 17: Hazard Notes And Occupational Safety

Access XL2 and Access XXL Safety CAUTION Hot surfaces Danger of burns! … indicates the presence of a hot surface. Non- observance of the safety instructions can lead to minor injuries. This pictogram is fixed on the following component: – Motor in the barrier housing. –... - Page 18 Access XL2 and Access XXL Safety DANGER Electric voltage – missing safety installations Mortal danger by electric voltage! The safety installations that are required according to regional and local regulations must be provided by the customer. Usually these are: – Residual current device (RCD) –...

- Page 19 Access XL2 and Access XXL Safety Improper operation WARNING Danger from improper operation of the barrier! Improper operation of the barrier can cause severe or lethal injuries! – The barrier closes automatically in certain programme modes. Passing of two vehicles within a single opening process must be prevented by the construction and appropriate signs or signals.

- Page 20 CAUTION the barrier – Pedestrian traffic possible Danger from entering the danger area! The Magnetic MHTM MicroDrive barriers are intended exclusively for closing off passages for motor vehicles and trucks. For vehicles that cannot be detected by induction loops, additional safety measures must be provided.

- Page 21 – Install safety installations, such as a Magnetic safety light barrier as surveillance device. The surveillance device must prevent the closing of the barrier in case a person or a vehicle is standing below the barrier.

- Page 22 Access XL2 and Access XXL Safety WARNING Falling components Risk of injury from falling components! Falling components such as the barrier boom can cause severe injury! – Only place the barrier boom horizontally. – Only install the barrier boom when there is no or little wind.

- Page 23 Access XL2 and Access XXL Safety WARNING Danger of crushing, barrier boom and flange Danger of crushing between barrier boom and barrier housing! Moving parts may cause serious crushing injuries! – Only skilled personnel are allowed work on the barrier housing and barrier boom. –...

-

Page 24: Danger Area

Access XL2 and Access XXL Safety Danger area WARNING Danger of crushing and shearing, barrier boom Danger of crushing and shearing if the safety distance between the barrier boom and other objects is too low! A closing or opening barrier boom can cause severe injuries from crushing if the safety distance to other objects is too low! –... -

Page 25: Identification

Access XL2 and Access XXL Identification Identification Type plate The type plate is provided inside at the barrier housing, next to the hood attachment. Fig. 2: Type plate Type code Serial number Power supply, Frequency Current consumption Power consumption Operating time (Opening time/closing time) Protection class Duty cycle Wind load classification... -

Page 26: Type Code

Access XL2 and Access XXL Identification Type code – Position Description 1 – 13 Product group: Access XL2 Barrier Access long in Access XXL housing Access XXL Barrier Access extra long – L = Left version R = Right version A = Standard wide range 85 –... -

Page 27: Technical Data

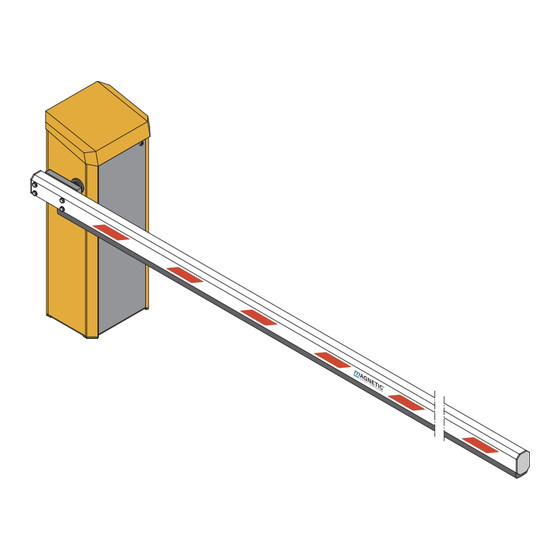

Access XL2 and Access XXL Technical data Technical data Access XL2 4.1.1 Dimensions and weight Fig. 3: Dimensions barrier system and barrier boom profile – "Access XL2" series (dimensions in mm) Object such as wall, building, etc. MicroBoom-XL (barrier boom) with octagon boom profile Barrier, left version Barrier, right version... -

Page 28: Electrical Connection

Access XL2 and Access XXL Technical data Designation Unit Access XL2 Blocking width 6000 to 8500 Barrier housing → See page 27, Fig. 3. (width x depth x height) (435 x 360 x 1169) Barrier housing weight 1) Starting at a blocking width of 6 m, a pendulum support or nesting post is required. Table 1: Dimensions and weight –... -

Page 29: Maximum Permissible Wind Load Classes En 12424

Access XL2 and Access XXL Technical data 4.1.4 Maximum permissible wind load classes EN 12424 Designation Unit Access XL2 up to 6 m With nesting post With pendulum support Max. permissible wind – load class EN 12424 Wind speed km/h Wind speed Designation Unit... -

Page 30: Access Xxl

Access XL2 and Access XXL Technical data Access XXL 4.2.1 Dimensions and weight Fig. 4: Dimensions barrier system and barrier boom profile – "Access XXL" series (dimensions in mm) Object such as wall, building, etc. MicroBoom-XL (barrier boom) with octagon boom profile Barrier, left version Barrier, right version... -

Page 31: Electrical Connection

Access XL2 and Access XXL Technical data Designation Unit Access XXL Blocking width 6000 to 10000 Barrier housing → See page 30, Fig. 4. (width x depth x height) (435 x 360 x 1169) Barrier housing weight 1) Starting at a blocking width of 6 m, a pendulum support or nesting post is required. Table 6: Dimensions and weight –... -

Page 32: Maximum Permissible Wind Load Classes En 12424

Access XL2 and Access XXL Technical data 4.2.4 Maximum permissible wind load classes EN 12424 Designation Unit Access XXL up to 10 m With nesting post With pendulum support Max. permissible wind – load class EN 12424 Wind speed km/h Wind speed 1) Applies to maximum blocking widths, no attachments. -

Page 33: Control Unit

Access XL2 and Access XXL Technical data Control unit Designation Unit (Magnetic Gate Controller) Supply voltage V DC Current consumption ─ max. 1 A max. 300 mA + current consumption of the different plug-in modules Power consumption ─ max 24 W. -

Page 34: Plug-In Module "Detector A-B

Access XL2 and Access XXL Technical data Plug-in module "Detector A–B" Designation Unit Plug-in module "Detector A–B" Current consumption Number of loop detectors – 2 (A and B) Inductance range 70 to 500 µH Number of induction loop – 10 levels sensitivity levels Response sensitivity Selectable: 0.01 to 2.0... -

Page 35: Design And Function

Access XL2 and Access XXL Design and function Design and function Design Fig. 5: Barrier system design Series "Access XL2" and "Access XXL" Starting at a blocking width of 6 m, a pendulum support or nesting post is required. Barrier housing MicroBoom-XL (barrier boom) Pendulum support from 3.5 m barrier boom length (accessory) Nesting post (accessory) -

Page 36: Function

The safety installations must ensure that the barrier closes only after the vehicle has passed through. Safety installations, such as induction loops can be purchased from Magnetic. The safety light barriers must be Magnetic ones. -

Page 37: Transport And Storage

Access XL2 and Access XXL Transport and storage Transport and storage Safety notes for transport WARNING Improper transport Danger from improper transport of the barrier boom and housing! The weight of the barrier boom or housing can severely injure a person! –... -

Page 38: Transport Inspection

Access XL2 and Access XXL Transport and storage Improper transport NOTICE The barrier system can be damaged by improper transport! Substantial material damages can result from improper transport. – Have all transport work performed by specialists only. – When unloading the packages and during in- plant transportation always proceed with greatest care and caution. -

Page 39: Transport

Access XL2 and Access XXL Transport and storage Transport Barrier housing and barrier boom are delivered separately. The lifting gear must be designed for the weight of the barrier housing and barrier boom. For transport barrier modules refer to the safety notes on page 37, chapter 6.1. -

Page 40: Design Notes For Induction Loops

Access XL2 and Access XXL Design notes for induction loops Design notes for induction loops → For assembly and inspection, see page 53, chapter 8.4. Please observe following points when dimensioning the induction loops: Induction loops respond only to metal. The mass is thereby not ... - Page 41 Access XL2 and Access XXL Design notes for induction loops Arrangement of lorry looks at longer barrier booms Fig. 7: Lorry looks at longer barrier booms Safety loop Opening loop Barrier...

- Page 42 Access XL2 and Access XXL Design notes for induction loops Arrangement of passenger car loops – passage with long opening loop Fig. 8: Passenger car loops – passage with long opening loop Safety loop Opening loop Barrier Due to a long opening loop vehicles can drive through without needing to stop.

- Page 43 Access XL2 and Access XXL Design notes for induction loops Arrangement of lorry/ passenger car loops at longer barrier booms Fig. 10: Lorry/passenger car loops at longer barrier booms Safety loop lorry (inductance "L1") Safety loop passenger car (inductance "L2") Opening loop lorry and passenger car Barrier Observe overall inductance "L...

- Page 44 The overall inductance must be between 70 and 500 µH. Calculation of the overall Ltotal inductance for series circuits Calculation of the overall • 1 Ltotal inductance for parallel circuits NOTE! For special cases such as loops for motorcycles, contact the Magnetic Service.

-

Page 45: Assembly And Installation

Access XL2 and Access XXL Assembly and installation Assembly and installation Safety → See also safety notes on page 16, chapter 2.6 "Occupational safety and special dangers". WARNING General Danger by inappropriate installation! Inappropriate installation can cause severe injuries! – Only specialist personnel or electrical specialists must perform any assembly and installation tasks. -

Page 46: Required Steps

Access XL2 and Access XXL Assembly and installation Personal protective equipment The following must be worn during all assembly and installation work: Work clothes Protective gloves Safety shoes Protective helmet. Required steps The following steps are to be completed prior to assembly and installation: Laying the foundation with reinforcement for the barrier and ... -

Page 47: Foundation And Empty Conduits

Access XL2 and Access XXL Assembly and installation Foundation and empty conduits Fig. 11: Assembly boom system (dimensions in mm) Object like wall, building, etc. Keep a safety distance of at least 500 mm between the barrier boom and other objects, such as walls, masonry or houses Posts, e.g. -

Page 48: Foundation And Empty Conduits

Access XL2 and Access XXL Assembly and installation 8.3.1 Foundation and empty conduits Assembly site The assembly site must meet the following requirements: The barrier must not be put up where there is a danger of flooding. Keep a safety distance of at least 500 mm between the barrier ... - Page 49 Access XL2 and Access XXL Assembly and installation Laying the foundation, Installing empty conduits Fig. 12: Foundation plan Access XL2 and Access XXL (dimensions in mm) Bore for foundation anchors (4 pcs.) Optional when using loop connection; empty conduit for loop connection, diameter: 29 mm Empty conduit for induction loop, Diameter: 29 mm Empty conduit for control lines, Diameter: 29 mm Concrete foundations (C35/45 XD3 XF2)

- Page 50 Access XL2 and Access XXL Assembly and installation Dig foundation hole pursuant to Fig. 11 and Fig. 12. Fig. 13: Reinforcement grid Access XL2 and Access XXL (dimensions in mm) Place reinforcement grid pursuant to Fig. 13 in the foundation hole.

-

Page 51: Foundation And Empty Conduits For Nesting Post Or Light Barrier Post

Access XL2 and Access XXL Assembly and installation 8.3.2 Foundation and empty conduits for nesting post or light barrier post Danger of crushing CAUTION Crushing danger between the fork at the nesting post and the barrier boom! Fingers and hands can be crushed when the barrier boom runs into the nesting post when closing. - Page 52 Access XL2 and Access XXL Assembly and installation Foundation The foundation must meet the following requirements: → See page 47, Fig. 11 and page 52, Fig. 15. Have sufficient load-carrying capacity. (concrete foundations: C35/45 XD3 XF2) Water cement value: 0.5 ...

-

Page 53: Assembly And Installation Of Induction Loops

The safety installations must ensure that the barrier closes only after the vehicle has passed through. Safety installations, such as induction loops can be purchased from Magnetic. 8.4.1 Directions for the assembly and installation of induction loops On barriers with an automatic closing function induction loops are used for the detection of vehicles. - Page 54 Access XL2 and Access XXL Assembly and installation Please observe following points when installing the induction loop: Loop geometry and clearances Install the loop symmetrically to the barrier boom. Please make sure that the barrier boom is attached to the side of the barrier housing.

-

Page 55: Induction Loops

Assembly and installation 8.4.2 Induction loops The induction loops are available as ready assembled cables in various lengths from Magnetic. Alternatively a loop can be manufactured from single wire. The following requirements must be fulfilled: Wire cross section: 0.75 to 1.5 mm ... - Page 56 Access XL2 and Access XXL Assembly and installation Lay the loop carefully into the groove and push it down by means of a blunt object, such as a piece of wood. The insulation must by no means be damaged. To avoid slipping of the loop, fix the loop using small wooden wedges.

-

Page 57: Installing Induction Loops Under Interlocking Stone Paving

Sand bed Substructure When installing induction loops under interlocking stone paving, following points must be observed additionally: Use only pre-assembled cables provided by Magnetic. Install the induction loop in sand only. The induction loop must not be installed in gravel or split. -

Page 58: Unpacking

Access XL2 and Access XXL Assembly and installation Unpacking The individual packages are packed according to the expected transport conditions. Only environment-friendly materials have been used for the packaging. The packaging should protect the individual components against transport damages, corrosion, etc up to the assembly. Therefore do not destroy the packaging and remove only directly before assembly. -

Page 59: Assemble Housing

You can order a mounting set consisting of a foundation anchor, washers, spring rings and hexagon head screws from Magnetic Autocontrol GmbH as accessories. Requirements mounting material If you are using your own mounting material, it must meet the... - Page 60 Access XL2 and Access XXL Assembly and installation Assemble housing The foundation must have cured. Drill holes for the sleeves with inner threads according to the foundation plan. Compliance with the indicate sizes. → Access XL2: See page 49, Fig. 12. →...

-

Page 61: Assemble Nesting Post Or Light Barrier Post

Tensile strength: at least 9 kN Foundation anchors that are optionally available from Magnetic achieve the tensile strength of 9 kN at a drilling depth of 80 mm. 4 washers DIN 9021 d8,4, stainless steel 4 spring washers DIN 128 A8, stainless steel ... -

Page 62: Assemble Safety Light Barrier

Access XL2 and Access XXL Assembly and installation Assemble safety light barrier Only Magnetic safety light barriers must be used. 8.9.1 Assemble transmitter Fig. 21: Assemble of the transmitter’s light barrier housing on the barrier housing (dimensions in mm) View A... -

Page 63: Assemble Receiver

Access XL2 and Access XXL Assembly and installation 8.9.2 Assemble receiver Fig. 22: Assemble the receiver's light barrier housing on the post (dimensions in mm) Light barrier post Nesting post Light barrier housing Drill holes for blind rivet nut Hexagon socket screws 5 AF Receiver Receiver connection line Press the two blind rivet nuts into the two intended bores at... -

Page 64: Assemble Barrier Boom

Access XL2 and Access XXL Assembly and installation 8.10 Assemble barrier boom 8.10.1 Assemble barrier boom up to 6 metres Danger of injury CAUTION Danger of injury! There is a danger of injury when assembling the barrier boom. – Barrier booms must be installed by two persons. Opening the barrier housing and Secure barrier danger area e.g. - Page 65 Access XL2 and Access XXL Assembly and installation Mount end caps Mount end caps. Check vertical alignment of the Check vertical alignment of the barrier boom with the spirit barrier boom up to 6 metres and level. correct if required WARNING! Danger of crushing between balancing springs and spring traverses! Reduce spring tension.

- Page 66 Access XL2 and Access XXL Assembly and installation Access XXL Loosen hexagon socket screws Fig. 25: Access XXL – Loosen hexagon socket screws Spacer sleeve Clamping lever left, hexagon socket screws M12 (10 AF) Flange shaft Clamping lever right, hexagon socket screws M12 (10 AF) After correction of hexagon socket 11.

-

Page 67: Assemble Barrier Boom As Of 6 Metres

Access XL2 and Access XXL Assembly and installation Switch on power supply and 13. Switch on power supply. Mode "Service " 14. Switch the "Service" switch on the control device. The LED lights red. The display backlighting flashes. 15. Manually close the barrier with the middle right button at the control unit. - Page 68 Access XL2 and Access XXL Assembly and installation Assemble barrier boom Push small boom profile onto connector of the large boom profile. Fig. 26: Push small boom profile onto connector. Small boom profile Connector Large boom profile Install the small boom profile with 6 screws to the large boom profile.

- Page 69 Access XL2 and Access XXL Assembly and installation WARNING! Danger of crushing between barrier boom and barrier housing! Switch off power supply. Ensure that the system is powered down. Secure against reactivation. The balancing springs in the lever system are relaxed. The flange is vertical. Put barrier boom of 6 metres or more into horizontal position WARNING!

- Page 70 Access XL2 and Access XXL Assembly and installation Access XXL Loosen hexagon socket screw Fig. 29: Access XXL – Loosen hexagon socket screw Spacer sleeve Clamping lever left, hexagon socket screws M12 (10 AF) Flange shaft Clamping lever right, hexagon socket screws M12 (10 AF) Assemble barrier boom as of Push square tube into the barrier boom according to figure 6 metres...

- Page 71 Access XL2 and Access XXL Assembly and installation Put barrier boom with 6 metres or Set the barrier to the vertical position with 2 persons. more into vertical position and 10. Check vertical position by spirit level. align vertically 11. Align barrier boom by turning the flange shaft. →...

-

Page 72: Assemble Edge Protection

Access XL2 and Access XXL Assembly and installation Switch off Mode "Service", 20. Switch the "Service" switch on the control device. The LED close barrier housing must light green. 21. Install the barrier housing door. 22. Attach and lock the barrier housing hood. 8.11 Assemble edge protection Missing edge protection at WARNING... -

Page 73: Conversion "Left Version" - "Right Version

Access XL2 and Access XXL Assembly and installation 8.12 Conversion "left version" – "right version" 8.12.1 Left and right version All MHTM MicroDrive barriers are available as "left version" and "right version". → See type code, page 26 and starting on page 27, Fig. - Page 74 Access XL2 and Access XXL Assembly and installation Uninstalling barrier boom up to 6 metres (continued) Fig. 31: Remove barrier boom Flange Hexagon head screws (4 pcs) Nut (4 pcs) Washer (4 pieces) Spring disc (4 pcs) Square tube End cap (2 pcs) Edge protection Barrier boom Unhook balancing springs...

- Page 75 Access XL2 and Access XXL Assembly and installation Access XL2 Loosen hexagon socket screw Fig. 32: Access XL2 – Loosen hexagon socket screw Clamping lever left, hexagon socket screws M12 (10 AF) Flange shaft Clamping lever right, hexagon socket screws M12 (10 AF) Access XXL Loosen hexagon socket screw Fig.

- Page 76 Access XL2 and Access XXL Assembly and installation Convert flange shaft 11. Remove the flange shaft cover disc of the barrier housing. Push a long rod through the flange shaft for this and slightly push it against the cover. 12. Pull out the flange shaft with the flange by rotating movements.

-

Page 77: Converting Barrier Boom As Of 6 Metres

Access XL2 and Access XXL Assembly and installation Adjust balancing springs 20. Adjust balancing springs with the noted control size. Access XL2: Chapter 8.13.2, steps 7 to 11. → See page 84. Access XXL: Chapter 8.13.2, steps 7 to 11 7. ... - Page 78 Access XL2 and Access XXL Assembly and installation Relive balancing springs Relive balancing springs. The flange must be upright for this. Perform the following steps depending on barrier type: Access XL2: Chapter 8.13.2, steps 6 and 7. → See page 84. Access XXL: Chapter 8.13.2, steps 6 and 7.

- Page 79 Access XL2 and Access XXL Assembly and installation Turn flange shaft until the barrier boom tip touches the ground. Perform step with 2 persons. Uninstalling barrier boom as of 10. Remove barrier boom. → See following figure 6 metres Fig. 36: Remove barrier boom Nut (4 pcs) Washer (4 pcs) Spring disc (4 pcs)

- Page 80 Access XL2 and Access XXL Assembly and installation Assemble barrier boom as of 18. Put the flange in the horizontal position by turning the flange 6 metres shaft. 19. Install the barrier boom with two persons with the horizontal flange. → See page 79, Fig. 36. 20.

-

Page 81: Check And Set The Balancing Springs In The Lever System

The lever force is determined not only by the spring tension but also by the number of springs used and the spring rate. Magnetic uses two spring types. Depending on application case, you will have to set the spring tension, remove the springs, use additional springs or use springs with a different spring rate. -

Page 82: Check Setting Of Balancing Springs

Access XL2 and Access XXL Assembly and installation Fig. 37: Balancing springs in the lever system left: Access XL2, right: Access XXL Barrier boom Spring shaft Upper spring traverse Balancing spring Lower spring traverse 8.13.1 Check setting of balancing springs Check balancing springs with the motor warm from operation. - Page 83 Access XL2 and Access XXL Assembly and installation Let go of barrier boom. If the barrier boom stays in the 30° position, the balancing springs are set correctly. If the barrier boom does not stay in the 30° position, the ...

-

Page 84: Setting Balancing Springs

The admissible deviation is no more than 1 mm (< 1 mm). – If required, contact Magnetic Service. Secure barrier danger area e.g. with barrier tape. Remove the barrier housing hood. Remove the barrier housing doors. - Page 85 Access XL2 and Access XXL Assembly and installation Fig. 39: Setting balancing springs Access XL2 and Access XXL Hexagon head screws M16 (24 AF) Spring shaft Counter nut M16 (24 AF) Upper spring traverse Balancing spring Evenly loosen the M16 nuts (Fig. 39, item 3). Use a 24 AF wrench to alternatingly turn the two hexagon screws in the respective direction by approx.

-

Page 86: Overview Table Balancing Springs

Access XL2 and Access XXL Assembly and installation 8.13.3 Overview table balancing springs NOTE! The following overview tables "Balancing springs" do not take into consideration any attachment parts. For barrier booms with attachment parts, the required number of springs may deviate from the number of springs in the overview table. - Page 87 Access XL2 and Access XXL Assembly and installation Blocking width [m] Number springs Number springs Control size [mm] weak strong – – – – – – – – – – – – – – – – – – – – –...

- Page 88 Access XL2 and Access XXL Assembly and installation Blocking width [m] Number springs Number springs Control size [mm] weak strong 10,6 10,7 10,8 10,9 11,0 11,1 11,2 11,3 11,4 11,5 11,6 11,7 11,8 11,9 12,0 12,1 12,2 12,3 12,4 12,5 12,6 12,7 12,8...

- Page 89 Access XL2 and Access XXL Assembly and installation Blocking width [m] Number springs Number springs Control size [mm] weak strong 14,4 14,5 14,6 14,7 14,8 – 14,9 – 1) The strong springs are marked yellow at the suspension bolt. 2) Control size: Size between the upper edge of the upper spring traverse to the upper edge of the lower spring traverse Table 14: Overview table balancing springs for barriers Access XL2 and Access XXL without pendulum support...

-

Page 90: Equipment Plan Balancing Springs

Access XL2 and Access XXL Assembly and installation 8.13.4 Equipment plan balancing springs The balancing springs are placed as follows in the Access XL2 and Access XXL barriers. Fig. 40: Equipment plan balancing springs Access XL2 and Access XXL Front Barrier boom Rear Weak springs... -

Page 91: Align Barrier Housing And Post

Access XL2 and Access XXL Assembly and installation 8.14 Align barrier housing and post WARNING Falling components Risk of injury from falling components! Falling components such as the barrier housing can cause severe injury! – When aligning the barrier housing and nesting post, loosen the attachment screws only slightly. -

Page 92: Set Nesting Post Height

Access XL2 and Access XXL Assembly and installation 8.15 Set nesting post height CAUTION Danger of crushing Crushing danger between the fork at the nesting post and the barrier boom! Fingers and hands can be crushed when the barrier boom runs into the nesting post when closing. -

Page 93: Stick On Prohibition Signs

Access XL2 and Access XXL Assembly and installation 8.16 Stick on prohibition signs The delivery includes two prohibition signs as stickers. Attach the prohibition signs to the barrier boom according to the following drawing. Fig. 42: Apply prohibition signs, shown here for barrier type NOTE! When a motorcycle loop is installed, the lower prohibition sign must be cut off. -

Page 94: Electrical Connection

Access XL2 and Access XXL Electrical connection Electrical connection Safety → See also safety notes on page 16, chapter 2.6 "Occupational safety and special dangers". DANGER Electric voltage Mortal danger by electric voltage! Touching live parts can be lethal. Damage to the insulation or to individual components can be lethal. - Page 95 Electromagnetic interferences may cause malfunctions of the barrier or adjacent devices! The barrier is approved for industrial, residential, commercial a business use. Operation in other electro-magnetic environmental conditions may cause interferences or malfunctions. – Place control lines and mains cables into separate conduits –...

-

Page 96: Installing Electrical Protective Devices

Access XL2 and Access XXL Electrical connection Installing electrical protective devices The safety installations that are required according to regional and local regulations must be provided by the customer. Usually these are: Residual current device (RCD) Circuit-breaker Lockable 2-pole main switch acc. to EN 60947-3. ... - Page 97 Access XL2 and Access XXL Electrical connection Strip-off cable and core insulation – Strip-off mains supply and cores according to the following preparation of the wiring figure. Fig. 43: Strip-off the mains supply (dimensions in mm) Phase Zero conductor Earth conductor Mains supply placement Connect the mains supply with the intended terminal clamps X1: L / N / PE) in the barrier housing according to the...

-

Page 98: Connect Customer's Control Lines (Signalling Devices)

Access XL2 and Access XXL Electrical connection Connecting the power cable Fig. 45: Connecting the power cable Access XL2 and Access XXL Power cable terminals Earth conductor PE Zero conductor N Phase L Connect customer's control lines (signalling devices) The following connections are available for control and feedback on customer’s side: 8 Digital inputs for controlling the barrier. - Page 99 Access XL2 and Access XXL Electrical connection Connecting the control lines Guide control lines into the connection space through the line penetrations. Properly place control lines behind the cable clamps. The control lines must not get into moving components. Attach control lines to metal tabs if required.

-

Page 100: Connecting Safety Devices

As safety devices, you must connect safety loops or safety light barriers to the control unit. Safety loops must only be connected to monitor vehicles. Only Magnetic safety light barriers must be used. If you connect a safety loop, the barrier closes only after the safety loop is clear. -

Page 101: Connecting Safety Loop

Access XL2 and Access XXL Electrical connection 9.4.3 Connecting safety loop The safety loop is connected to the plug-in module "Detector1 (A-B)", clamps A or clamps B. → See "Wiring diagram". The clamp function parameters can be set in the menu "Detector 1 (A-B)"... -

Page 102: Connect And Test The Safety Light Barriers

Connect the transmitter and receiver connection lines of the safety light barriers to clamps X11 and X20. By default, Magnetic installs a jumper between terminals X11 OUT and IN. When a safety light barrier is connected, the jumper must be removed. -

Page 103: Connecting Emergency Opening Contacts

Access XL2 and Access XXL Electrical connection Align receiver with transmitter. If required, hold the included reflective foil in front of the receiver as setting aid. The yellow LED at the receiver lights up when aligned correctly. Align receiver as follows: Slightly loosen the post attachment screws. -

Page 104: Digital Outputs And Output Relays

Access XL2 and Access XXL Electrical connection Factory setting Clamp Description Function Input 1 Open low priority Input 2 Open low priority Input 3 Opening with vend count Input 4 Open high priority Input 5 External opening loop exit Input 6 Close Input 7 Close... -

Page 105: Checking The Electrical Connection

Access XL2 and Access XXL Electrical connection Checking the electrical connection The following points have to be checked after the electrical installation of the barrier: Are the following electrical protective devices installed: lockable 2-pole main switch, circuit breaker and leakage current fault interrupter? Is the power cable connected to the terminal in compliance with ... -

Page 106: Start-Up And Operation

Access XL2 and Access XXL Start-up and operation 10 Start-up and operation 10.1 Safety → See also safety notes on page 16, chapter 2.6 "Occupational safety and special dangers". WARNING General Danger by inappropriate start-up and operation! Inappropriate start-up and operation can cause severe or lethal injuries. -

Page 107: Commissioning

Access XL2 and Access XXL Start-up and operation 10.2 Commissioning Check before The following inspections must be performed prior to initial start-up: to initial start-up Check electrical connections. Check barrier boom position. Check balancing springs in the lever system and adjust if ... -

Page 108: Switching On And Off The Barrier

Access XL2 and Access XXL Start-up and operation 10.3 Switching on and off the barrier NOTICE A too early mains voltage power up after a shut down can result in damage of the equipment! – Wait for at least 10 seconds after shutting off the mains voltage before you switch the mains voltage on again. -

Page 109: Open And Close The Barrier Manually

Access XL2 and Access XXL Start-up and operation Switching off Remove the barrier housing hood. Remove the barrier housing door. Switch off the barrier via the 2-pole mains switch. Depending on the settings of the lever system's balancing spring and the settings in the menu "Power failure", the barrier boom opens or closes. -

Page 110: Putting The Barrier Temporarily Out Of Operation

Access XL2 and Access XXL Start-up and operation NOTE! For reasons of safety, the first barrier boom motion after switching between programme mode and service mode is performed at slow speed. 10.5 Putting the barrier temporarily out of operation WARNING High wind speeds Risk of injury from barrier boom in case of high wind speeds! -

Page 111: Cleaning And Maintenance

Access XL2 and Access XXL Cleaning and maintenance 11 Cleaning and maintenance 11.1 Safety → See also safety notes on page 16, chapter 2.6 "Occupational safety and special dangers". WARNING General Danger by inappropriate cleaning and maintenance! Inappropriate cleaning and maintenance can cause severe or lethal injuries. -

Page 112: Cleaning

Access XL2 and Access XXL Cleaning and maintenance 11.2 Cleaning The cleaning interval essentially depends on the environmental conditions and the climate. Aggressive cleaning aids and NOTICE substances Unit damage possible! Aggressive detergents and consumables may damage or destroy components, electric cables, or the coating of the barrier. -

Page 113: Maintenance Schedule

Access XL2 and Access XXL Cleaning and maintenance 11.5 Maintenance schedule The following describes the maintenance work that is necessary for safe optimal, trouble-free operation. Maintenance intervals must be observed. If increased wear of individual components or functional groups is revealed during regular inspections, the operator must reduce the required maintenance intervals on the basis of the actual signs of wear. - Page 114 Access XL2 and Access XXL Cleaning and maintenance Interval Maintenance work To be carried out by Every 12 months Perform all monthly and semi-annual maintenance Electrician / work. specialist Check the barrier's mechanics. MHTM MicroDrive service specialist Check balancing springs for changes, such as length and thickness.

-

Page 115: Malfunctions

Access XL2 and Access XXL Malfunctions 12 Malfunctions NOTE! For troubleshooting, see separate document "Description of control unit MGC and MGC Pro for barrier MHTM MicroDrive (Doc.ID: 5816,0006)". 12.1 Reset the barrier Control unit reset is performed as follows: Switch of power supply and switch it on again after 10 seconds. ... -

Page 116: Closing Or Opening The Barrier Boom In Case Of Power Failure

Access XL2 and Access XXL Malfunctions 12.2 Closing or opening the barrier boom in case of power failure WARNING Danger of crushing, lever system! Danger of crushing at opened barrier housing at the lever system! The lever system in the barrier housing can cause serious crushing injuries! –... - Page 117 Access XL2 and Access XXL Malfunctions Access XXL Fig. 52: Access XXL, manually close or open barrier boom...

-

Page 118: Repair

Loosely stacked or lying around components and tools are accident sources. – Only use original spare parts or spare parts approved of by Magnetic. – After completion of repair work, ensure that all covers are correctly mounted. WARNING... -

Page 119: Spare Parts

– Only use original spare parts or spare parts approved of by Magnetic. Procure spare parts via your dealer. The address can be found on your delivery receipt, invoice or the rear of these instructions. -

Page 120: Decommissioning, Disassembly And Disposal

Disassemble the barrier in reverse order from assembly. The barrier has to be disposed of in accordance with the respective country-specific regulations. NOTE! For expert information regarding disposal of electric equipment contact Magnetic or competent electricians. -

Page 121: Eu-Declarations Of Conformity

EU-Declaration of conformity The manufacturer MAGNETIC AUTOCONTROL GmbH this is to certify that the delivered product: Designation Barrier MHTM MicroDrive 1), 2) Type Access XL2* Access XXL* 1) Installation of the safety devices according to operating instructions required. 2) Compliance with the impact forces pursuant to EN 13241: For barrier booms up to a blocking width up to 6.5 m only at medium and slow speed. -

Page 123: Index

Access XL2 and Access XXL Index Index Control unit MGC ..........7 Control unit MGC Pro ........... 7 Assemble Conversion Barrier boom as of 6 metres ......67 Barrier boom as of 6 metres......77 Barrier boom up to 6 metres ......64 Barrier boom up to 6 metres ......73 Barrier housing Access XL2...... - Page 124 Access XL2 and Access XXL Index Identification ............25 Radio plug-in module Induction loops ........53, 56, 57 Technical data ..........34 Planning notes..........40 Reinforcement Inspection Access XL2 ..........48, 50 During the first start-up ......... 107 Access XXL ..........48, 50 Instructed People ..........

- Page 125 Access XL2 and Access XXL Index Warning notes ............8 Warranty ............. 10...

- Page 126 Access XL2 and Access XXL...

- Page 127 Access XL2 and Access XXL...

- Page 128 MAGNETIC AUTOCONTROL GMBH Sales partner Grienmatt 20 79650 Schopfheim Germany Telephone +49 7622 695 5 Fax +49 7622 695 802 info@magnetic-germany.com www.magnetic-access.com F10044462...

Need help?

Do you have a question about the MHTM MicroDrive Access XL2 and is the answer not in the manual?

Questions and answers