Subscribe to Our Youtube Channel

Summary of Contents for ZIMM ZA-25

- Page 1 Instruction manual Installation – Operation – Maintenance – Inspection ZIMM Actuator ZA-25 to ZA-200 2023-10...

- Page 2 Reproduction or distribution and release of this instruction manual to third parties is prohibited. Offenders are liable to pay damages. The ZIMM GmbH accepts no liability for damages arising from disregard of this instruction manual.

-

Page 3: Table Of Contents

ZIMM Actuator 1 About this document Contents About this document ........................5 Use of this instruction manual...................... 5 Symbols and identifying marks ....................5 Safety ..............................6 Use for the intended purpose ...................... 6 Duties of the operating company ....................6 Scope of supply .......................... - Page 4 1 About this document ZIMM Actuator Further interesting information on lifting systems and suitable components and their design can be found in our "screw jacks" catalog. Version 0.6 2023...

-

Page 5: About This Document

1 About this document About this document Use of this instruction manual This instruction manual forms part of the ZIMM Actuators. Before using the equipment read the instruction manual carefully. Keep the instruction manual safe throughout the working life of the equipment. -

Page 6: Safety

The ZIMM Actuator has been produced to modern standards and recognised safety regulations. Nevertheless hazards to life and limb of the users or third parties, or risks of damage to the ZIMM Actuator and other property may arise during use. -

Page 7: Scope Of Supply

ZIMM Actuator 3 Scope of supply Scope of supply The ZIMM Actuator is delivered in sufficiently secure packaging to prevent possible damage in transit. The scope of supply of the ZIMM Actuators includes the following parts: Actuator • ZIMM •... -

Page 8: Rating Plate

4 Description of the product ZIMM Actuator Rating plate Fig. 2 Example of a rating plate ZIMM contact data Rated speed Type designation Serial number Maximum static load actuator Serial number as (spindle etc. not considered) Data Matrix Code Version 0.6... -

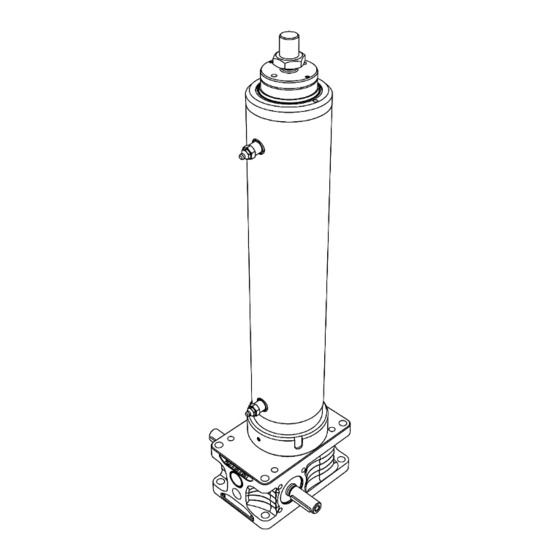

Page 9: Versions/Variants

ZIMM Actuator 4 Description of the product Versions/variants Variant ZA-series, (with Trapezoidal screw spindle Mounting head Housing, ZE series Thrust tube Drive shaft Head nut Lubrication of spindle and anti-rotation lock Cylinder tube ZA-series, (with Ball screw drive KGT) Mounting head... -

Page 10: Grease Nipple

4 Description of the product ZIMM Actuator Grease nipple ZIMM Actuators have grease nipples that ensure easy and clean lubrication of the screw drives and the anti-rotation lock. HINWEIS For optimal lubrication, use an automatic and controlled lubricator (PLC-capable). -

Page 11: Transport And Storage

Damage to the ZIMM Actuator! On receipt, check the packaging for signs of damage. Do not let the ZIMM Actuator drop, and do not subject it to impacts. Use appropriate lifting gear as necessary. Bending of the thrust tube or spindle! ... - Page 12 Examples for transporting the ZIMM Actuator When lifting with a crane, attach the slings to the lifting points provided. When lifting the ZIMM Actuator for transport, spread the weight as evenly as possible across all the lifting points. Version 0.6...

-

Page 13: Storage

Do not store for more than a brief period in areas that although roofed still allow free circulation of air from outside. Perform commissioning not later than 1 year after delivery (the dispatch from ZIMM is the relevant date). For other storage conditions and storage times: Consult ZIMM GmbH. -

Page 14: Installation

Safety clearance between moving and fixed parts is maintained. Lack of self-locking! Material damage to the entire system and the ZIMM Actuator due to lack of self-locking for spindles with ball screw drive KGT. Spring pressure brake FDB or brake motor provided. - Page 15 ZIMM Actuator 6 Installation CAUTION The system will run on! Material damage to the entire system and the ZIMM Actuator due to running on. • The run-on travel may increase after the running-in phase. If necessary provide a spring pressure brake FDB or brake motor.

- Page 16 ZIMM Actuator Fig. 6: Flatness, parallelism and angular accuracy 1. Set up the ZIMM Aktuator and ensure compliance with the installation accuracy, and ensure straight alignment of the spindle attachment (e.g. with precision machine spirit level). 2. Install the ZIMM Actuator with bolts, tighten the installation bolts.

-

Page 17: Fitting The Couplings And Connecting Shafts

Fig. 8: T version (bevel gear drive) Check the direction of rotation at installation. Fitting the couplings and connecting shafts The ZIMM Actuator to be connected must have been fully installed. The bevel gear drives must be installed where appropriate. CAUTION Moving parts! Injuries due to rotating parts. - Page 18 ZIMM Actuator 6 Installation Fig. 9: Installation of connecting shafts CAUTION Axial joining force! Damage to the roller bearings, circlips etc. Use a suitable fixture to draw the connecting parts together. Do not apply blows or impacts to the shaft extensions.

-

Page 19: Fitting The Motor

Switch off the entire system and secure it against switching on again. Fig. 13: Installing the motor 1. Fit the motor flange (1) to the ZIMM Actuator and bolt it into place. 2. Fit the coupling halves (2) to the gearbox shaft and bolt them into place. -

Page 20: Connecting The Electrical Components

6.6, page 22. 2. Repeat the trial run. High forces are generated! Damage to the ZIMM Actuator. Make sure that the limit switches or end positions are not exceeded. Make sure that attachments do not collide with other parts. - Page 21 ZIMM Actuator 6 Installation HINWEIS Make sure that the mechanism that is actuated can move along the entire stroke path. Run the screw jack over the complete travel in both directions. When doing this, comply with the following: –...

-

Page 22: Correcting The Alignment

If necessary, the alignment can be corrected without much trouble. Spindle and anti-rotation lock lubricated (for more information see section “7.2 Lubrication”, page 25) Fig. 18: Correctly aligned ZIMM Actuator Loosen the fastening screws on the gearbox housing and on the head. Fully retract the jack (1). -

Page 23: Commissioning

7.1.1.) Running-in phase The running-in phase of the ZIMM Actuator lasts as a rule between 20 and 50 operating hours. A higher torque and higher operating temperature must be expected during this period. -

Page 24: Operation And Maintenance

Lifting movements within the hazard zone! Serious injuries or death. Leave the hazard zone and secure it. Inspection For problem-free operation, the ZIMM Screw Jack must be inspected regularly: • The first inspection should be no later than after 1 month •... -

Page 25: Lubrication

7 Operation and maintenance Tr70x12 Tr80x16 4,00 If the maximum permissible wear is exceeded, replace the ZIMM Actuator. Fig. 12: Safety trap nut SIFA: Dimension "A" for comparison when checking wear 4. Visually check the coupling stars. 5. Allow the machine to run, checking for the following: –... - Page 26 ZIMM Actuator 7 Operation and maintenance 7.2.1 ZIMM Actuator Lubricate gearboxes The gearboxes of ZIMM Aktuators are sealed and filled with high-quality synthetic fluid grease. Under normal operating conditions the gearbox is lubricated for life. 7.2.2 Lubricating bevel gear drives Bevel gear drives are filled with synthetic oil and under normal operating conditions lubricated for life.

- Page 27 Do not mix greases. When changing the grease: Clean the spindle then regrease it. If necessary use special grease. Use only greases that are approved by ZIMM GmbH. ZIMM will be pleased to give advice. WARNING Warning: Burn hazards! Operating temperature too high.

- Page 28 The values from the following table can be used as guide values for lubricating ungreased BSD nuts [ml]: BSD-Ø increase NOTE The ZIMM Actuator is delivered ex works with initial lubrication Intervals Lubrication quantity during 100 km working stroke, relubricate every 5 km working stroke. Size...

- Page 29 ±2 mm. In extreme situations (high load, long duty cycle or fast travel) lubrication should be adjusted. ZIMM will be happy to advise you. Greases Standard grease for Ball screw drive KGT Part no.: Castrol Tribol GR 4747/220-2 HT,...

- Page 30 When installed horizontally, ventilate as desired (SML1 or SML2). Sintered metal silencers from pneumatics can be used for ventilation. In this case, the ZIMM Aktuator loses its IP64 protection rating. For a higher degree of protection, a different form of ventilation must be used.

-

Page 31: Troubleshooting

– with additives – possibly with solid lubricants ZIMM will be happy to advise you. Geometry error in the Check alignment: system – Parallel positioning of the ZIMM Actuators (thrust tubes, cylinder tubes) to each other –... - Page 32 Reduce load in the running-in phase. High wear on the Incorrect spindle grease Check spindle grease trapezoidal screw ZIMM will be happy to advise you (load, speed, thread etc.). Lack of lubricant 1. Relubricate the spindle. 2. Shorten lubrication intervals.

-

Page 34: Decommissioning And Recommissioning

Damage to the ZIMM Actuator after a long period out of use. Oil shiny points. Recommissioning After the ZIMM Actuator has been out of use for a long period: 1. Drive through the full working stroke. 2. After initial lubrication, lubricate lubrication points according to the table. -

Page 35: Declaration Of Incorporation

Declaration of incorporation... -

Page 36: Appendix: Inspection Certificate

ZIMM Actuator 12 Appendix: Inspection certificate Appendix: Inspection certificate Template for copying for inspections to section "7.1 Inspection", page 26. ZIMM Screw Jack (Serial number): Date Description Comment Mark Commissioning Version 0.6 2023... - Page 37 ZIMM GmbH Millennium Park 3 6890 Lustenau / Austria Phone: 0043 (0) 5577 806-0 Fax: 0043 (0) 5577 806-8 info@zimm.com www.zimm.com...

Need help?

Do you have a question about the ZA-25 and is the answer not in the manual?

Questions and answers