Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kelvin Mini Series

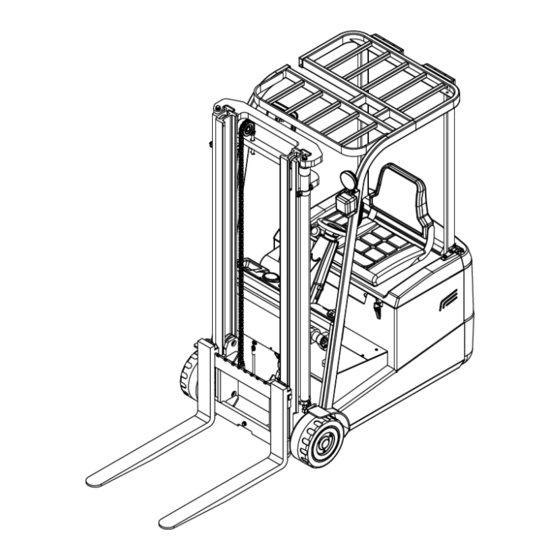

- Page 1 KELVIN Mini series electric counterbalance forklift Maintenance Instruction Manual T: 01342 832101 | E: accounts@kelvinengineering.co.uk | W: www.kelvinengineering.co.uk A:UK Headquarters | Waterend Farm | Epping Road | Ongar | Essex | CM5 0DE | Company Reg Number 08189288 | Vat Reg 260080637 |...

- Page 2 If you do not follow this instruction manual, our company's quality guarantee automatically expires. If the customer or a third party arbitrarily makes non-standard operations to the equipment, or Kelvin Engineering will not assume any responsibility for the resulting losses.

-

Page 3: Table Of Contents

Contents Chapter 1 Safe Regulations Chapter 2 Warning, Nameplate And Symbols Chapter 3 Forklift Introduction 1. Forklift suitable occasion 2. Forklift forbidden occasions 3. Technical specifications 4. Capacity chart 5. Safety Signs Chapter 4 Main Components And Control Devices Chapter 5 Driving 1. -

Page 4: Chapter 1 Safe Regulations

Chapter 1 Safe Regulations Safe Regulation Overview Before using the forklift, all safety switches and equipment should be inspected beforehand to ensure that these safety facilities are in good condition. Inspection of all warnings and design parameters signs on the vehicle. The battery must be securely fixed in the battery box. - Page 5 Maintenance can prevent accidents, please refer to the chapter about maintenance. All replacement spare parts should be parts approved by Kelvin Engineering Ltd. The maintenance or modification of the forklift which will affect the safety or functions is not permitted.

-

Page 6: Chapter 2 Warning, Nameplate And Symbols

Chapter 2 Warning, Nameplate and Symbols The Battery forklift has the following symbols: (Please read the related content on the labels) 1. Lifting and lowering control. 2. Safety marks nameplate. 3. Load chart label. 4. Lifting point. -

Page 7: Chapter 3 Forklift Introduction

Chapter 3 Forklift Introduction Kelvin Mini series battery counterbalance forklift is powered by electric energy. It uses a foot accelerator to control speed and the steering wheel to control steering. We adopt a 24V electronic system, and steplessly adjust its speed with an integrated circuit controller to ensure available stable speed and acceleration during the running process. - Page 8 Ambient temperature: The forklift truck is suitable for 5 to 40 in the working environment. If the forklift needs to be used for a long time in the environment of great changes in temperature or humidity, special equipment must be installed. Kelvin Engineering Limited's permission must be obtained.

- Page 9 3.3 Hydraulic schematic diagram Spare parts name above 1.Pump station or gear pump 2. Multi-way valve 3. Block valve 4. Lift cylinder 5. Tilting cylinder...

- Page 10 3.4 Electrical schematic diagram...

-

Page 11: Capacity Chart

4. Capacity chart 5.Safety signs Do NOT Stand on or off Caution nipping hand Lifting position No access to the back of the mast... -

Page 12: Chapter 4 Main Components And Control Devices

Chapter 4 Main Components and Control Devices 1. Overhead guard 2. Brake fluid injection port 3. Headlight switch 4. driver seat 5. Pedal horn switch 6. Counterweight 7. Driving boxes 8. Folder 9. USB Power Interface 10. Emergency Stop Switch 11. -

Page 13: Chapter 5 Driving

Chapter 5 Driving 1.Start Please proceed in the following order, otherwise the truck will not operate normally: 1.1 Make sure the power connector is plugged in firmly. 1.2 Turning on emergency stop switch 1.3 Turn the key switch to the open position. 1.4 Make sure the battery has enough power. -

Page 14: Steering

2.4 The maximum noise value of the ear of the forklift truck is not more than 80dB (A). The test method is according to JB/T3300; the vibration is not more than 0.4m/s2. The uneven road surface will increase the noise and vibration. 3. -

Page 15: Chapter 6 Attachments

Chapter 6 Attachment Forklifts can be equipped with different accessories to further enhance safety. 1. Load-backrest When the height of the goods is too high, you can add a load-backrest to increase the stability of the goods. -

Page 16: Chapter 7 Cargo Transportation

Chapter 7 Cargo transportation 1. Transport 1.1 The weight of the goods should be within the permitted lifting capacity of the forklift. 1.2 When loading and unloading cargo, it should be stable and safe. Be careful with ultra-high and long goods. 1.3 When loading or unloading ultra-high cargo, the forklift should be equipped with suitable retaining shelves. - Page 17 Danger! Do not lift the goods during the driving of the forklift to avoid overturning. 3. Unloading 3.1 Decelerate parking and positioning before the shelf. 3.2 Raise the fork to the desired position. 3.3 Slowly move the forklift forward so that the goods are accurately positioned on the shelf. 3.4 Lower the fork to remove the cargo.

-

Page 18: Chapter 8 Battery And Charger

Chapter 8 Battery and motor Check that the battery is charged. 1. Replace battery The replacement battery must be the same with the original battery model and weight. (Battery weight can affect forklift performance and brake function) Attention! Do not change battery weight and size, otherwise it will affect the forklift gravity centre. The weight must be the same with digital on the nameplate. -

Page 19: Battery Maintenance

3 Remove power sully socket, connect battery plug with battery socket. 4 Open battery plus liquid hole cover to make it ventilated. 5 Switch on AC current and start charging. Warning! When charging, make sure there is good ventilation. Keep an open fire and spark far away, otherwise it may lead to an explosion. -

Page 20: Motor Maintenance

8 Equalizing charge method a. Normally charge first b. Stop 1 hours when full charge, then charge 1 hour with 0.05C means battery rated capacity) Repeat b with times until battery has fierce bubble when switch off 9 When not using a period of time, you must charge fully 10 The battery should avoid direct sunlight, keep at least 2M distance from heat source 11 Avoid contact with any liquids and hazardous substances, any metal impurities cannot fall into the battery. -

Page 21: Chapter 9 Fault Analysis

Chapter 9 Fault analysis Programmer fault diagnosis menu and status display LED Fault display Programmer display Fault reason phenomenon code Hardware invalid HW FAILSAFE 1.Controller damage protection error 1.M-output to ground short circuit 2.The directional contactor does not have M-output short M-FAULT actuation... - Page 22 Beyond 1.Temperature >85 or <-25 operating THERMAL 2.Vehicle is overloading temperature area, CUTBACK 3.Wrong controller installation current 4.Working in extreme environment decreases For example, LED display code, (2,4): ☼☼ ☼☼☼☼ means LED light flash 2 times, pause for a few seconds and then flash four more times.

-

Page 23: Chapter 10 Maintenance

For forklift maintenance, replacement spare parts should be provided by our company to ensure quality. It is recommended to contact Kelvin Engineering Ltd or the company's after-sales service department. So that your forklift can operate more safely and economically. -

Page 24: Maintenance Safety Rule

2. User can complete the maintenance work 2.1 Daily maintenance and safety inspection. (1) It is the operator's responsibility to perform routine maintenance and inspection of the forklift. (2) If the forklift does not perform routine maintenance, it will affect the safety and reliability of the forklift and may easily lead to serious accidents. -

Page 25: Forklift Cleaning

3. Cleaning forklift It is important to conduct routine cleaning every week to ensure its reliability. Please remove the power socket before cleaning to avoid damage to the electrical system caused by a short circuit. 3.1 External cleaning (1) Every day to remove attachments on the wheel, to maintain flexible rotation. (2) After cleaning, lubricating oil should be added to the parts to be lubricated according to the given parts in the table of lubrication parts. - Page 26 Check oil level Check noise Change oil Wheel Remove the rope and debris from the wheel Check the drive wheel wear and bolts Remove and lubricate the wheel bearing Brake Clean the brake part Check the wear of the brake pads Check the brake condition when the brake is released Controller board Cleaning and installation inspection...

-

Page 27: Lubrication Parts Table

Checking Check the installation Mast 10.1 Check for damage and cracks 10.3 Check the running of the roller 10.4 Whether the lifting chain and pin are damaged and the sprocket wear 10.5 Check if the oil pipes and joints are leaking 10.6 Check for signs of broken forks 5.Lubrication parts table... -

Page 28: Lifting Forklift

Chapter 11 Transport & storage 1.Lifting forklift When lifting the whole truck, use lifting equipment to lift the forklift from the lifting point. Danger! Do not lift the forklift from other lifting points, otherwise the vehicle may lose its balance, roll over, and injure people and equipment. -

Page 29: Chapter 11 Forklift Transport And Storage

Chapter 12 Product warranty and after-sales service For product warranty and after-sales service, please refer to our after-sales service description.

Need help?

Do you have a question about the Mini Series and is the answer not in the manual?

Questions and answers