Table of Contents

Advertisement

Quick Links

12030 Manta (CN) - Via Galimberti, 64 - Tel. 0175 289070 - Fax 0175 289016

C

I

R

C

I

R

TECHNICAL MANUAL OF USE AND MAINTENANCE FOR THE USER

www.balfor.it e-mail: info@balfor.it

C

U

L

A

R

S

A

C

U

L

A

R

S

A

S

H

S

H

SHARK 700 – 750 C

SHARK 700 EM – 700 ET – 750 ET

SHARK 700 – 750 SB

SHARK EXPERT 700 – 750

SHARK EXPERT PLUS 700 – 750

SHARK EXPERT PRO 700 – 750

"Contains Declaration of Conformity" (CE)

Read this Manual carefully before using the machine

"Original instructions"

W

F

O

R

F

I

R

W

F

O

R

F

I

R

A

R

K

A

R

K

:

Models

E

W

O

O

D

E

W

O

O

D

Advertisement

Table of Contents

Summary of Contents for balfor SHARK Series

- Page 1 12030 Manta (CN) - Via Galimberti, 64 - Tel. 0175 289070 - Fax 0175 289016 www.balfor.it e-mail: info@balfor.it Models SHARK 700 – 750 C SHARK 700 EM – 700 ET – 750 ET SHARK 700 – 750 SB SHARK EXPERT 700 – 750 SHARK EXPERT PLUS 700 –...

- Page 3 Use and maintenance manual CE DECLARATION OF CONFORMITY BALFOR s.r.l. company REGISTERED OFFICE – PLANT AND ADMINISTRATION: Via Galimberti, 64 – 12030 MANTA (CN) ITALIA - Tel. 0175 289070 Declares under its own responsibility that the machine: CIRCULAR SAW FOR FIREWOOD...

- Page 4 Use and maintenance manual CIRCULAR SAW FOR FIREWOOD CARDAN (C), CONVEYOR BELT (CNT), INTERNAL COMBUSTION ENGINE (SB) MODELS It complies with all relevant provisions of the following European Directive: Directive 2006/42/CE on machinery and amending directive 95/16/CE. Having applied the following harmonised standards and technical specifications for the adaptation of the machine, to the extent that they are relevant: UNI EN ISO 12100:2010 “Safety of machinery –...

- Page 5 Use and maintenance manual CIRCULAR SAW FOR FIREWOOD ELECTRIC MODELS (EM – ET) It complies with all relevant provisions of the following European Directive: Directive 2006/42/CE on machinery and amending directive 95/16/CE. Directive 2014/30/UE on the approximation of the laws of the Member States relating to electromagnetic compatibility.

-

Page 6: Table Of Contents

Use and maintenance manual INDEX GENERAL INFORMATION ..............................7 ABOUT THIS MANUAL ..............................8 MACHINE IDENTIFICATION .............................. 8 INFORMATION ABOUT THE MACHINE ..........................9 1.3.1 Intended uses ................................9 1.3.2 Machine description ..............................11 COMPONENTS AND TECHNICAL DATA ......................... 12 1.4.1 Cardan shaft models ............................... - Page 7 Use and maintenance manual MAINTENANCE ..................................50 CUTTING DISC REPLACEMENT ............................. 51 DRIVING BELTS TENSIONING ............................53 ADJUSTMENT AND REPLACEMENT OF THE LOADING CARPET..................53 STORAGE ..................................... 54 SCRAPPING ................................... 55 WARRANTY ..................................56 SPARE PARTS ..................................57 November 2021 Edition PLEASE NOTE! FAILURES ON ELECTRICAL PARTS DUE TO INADEQUATE CONNECTIONS, VOLTAGE FLUCTUATIONS AND INCORRECTLY SIZED CABLE EXTENSIONS WILL...

-

Page 8: General Information

The BALFOR s.r.l. company has compiled this manual to assist you in the maintenance and use of this machine, which, despite being an easy-to-use tool, requires you to scrupulously observe what follows in order to avoid damage to the machine and accidents to the operator. -

Page 9: About This Manual

Use and maintenance manual 1.1 ABOUT THIS MANUAL This manual provides all the information for the use and maintenance of the machine. Good operation and longevity will depend on good maintenance and careful use. It is recommended that you read this Use and Maintenance Manual carefully, and strictly follow the instructions described before any use, check and operation to be carried out with and on the machine. -

Page 10: Information About The Machine

Use and maintenance manual 1.3 INFORMATION ABOUT THE MACHINE Before leaving the production plant, this specific model undergoes stringent testing to ensure maximum reliability and safety. 1.3.1 Intended uses The models presented in this manual are exclusively designed for cutting solid wood into chunks to be fed into fireplaces, stoves, wood-burning ovens, boilers, thermal cookers, barbecues and more, or to be subsequently cut with other machines (e.g., woodcutter). - Page 11 Use and maintenance manual For models with log splitter (PLUS / PRO) When operating the log splitter, you must always be positioned on the right side of the machine, at the controls for operating the splitting wedge (A), as shown in the figure (“Two-hand control” – During the cutting operation, the hands are always in a safe position).

-

Page 12: Machine Description

The cutting blade made of widia, the three-belt drive and the crankcases that segregate all moving parts make it possible to work safely and very quickly. BALFOR s.r.l. company produces this type of circular saw in different versions to meet specific customer needs. -

Page 13: Components And Technical Data

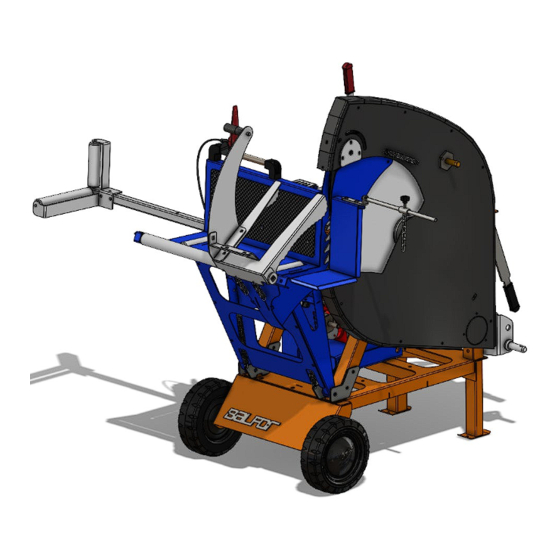

Use and maintenance manual COMPONENTS AND TECHNICAL DATA 1.4.1 Cardan shaft models Description Description Fixed cutting blade crankcase Cardan shaft coupling protective cap Log locking handle Log support Tilting table locking hook Lifting arm hitch Cutting blade Fixed drive belts crankcase Third-point hitch Wheels for manual transfer Tilting table handle... -

Page 14: Electric Models

Use and maintenance manual 1.4.2 Electric models Description Description Fixed cutting blade crankcase Tilting table Log locking handle Electric engine Tilting table locking hook Log support Cutting blade Chainsaw holder Switch with power socket Fixed drive belts crankcase Tilting table handle Wheels for manual transfer Spanner for blade replacement Tilt release lever... -

Page 15: Internal Combustion Engine Models

Use and maintenance manual 1.4.3 Internal combustion engine models 1.4.3.1 SB version Description Description Fixed cutting blade crankcase Spanner for blade replacement Log locking handle Tilting table Tilting table locking hook Brake lever Cutting blade Tilt release lever Internal combustion engine Log support Tilting table handle Wheels for manual transfer... -

Page 16: Sb-Road Version

Use and maintenance manual 1.4.3.2 SB-ROAD version Description Description Fixed cutting blade crankcase Tilting table Log locking handle Brake lever Tilting table locking hook Tilt release lever Cutting blade Log support Internal combustion engine Wheels for manual transfer Tilting table handle Ball hitch 50mm (1 ⅞”) Spanner for blade replacement Models... -

Page 17: Conveyor Belt Models

Use and maintenance manual 1.4.4 Conveyor belt models 1.4.4.1 Expert version Description Description Conveyor belt Tilting table Log fall protection Adjustable stabilising foot Steel rope Fixed drive belts crankcase Lowering/raising conveyor belt winch Log collection hopper Oil tank Lifting arm hitch Fixed cutting blade crankcase Support foot Log locking handle... - Page 18 Use and maintenance manual The length of the conveyor belt is: 5 metres. The machine can be equipped with two different cutting blades with diameters of 700 mm and 750 mm respectively. Shark Expert 700 Shark Expert 750 Models 5/250PI 5/250PI Dimensions A-B (mm) 2300 x 3100...

-

Page 19: Plus / Pro Version

Use and maintenance manual 1.4.4.2 Plus / Pro version Description Description Conveyor belt Tilting table Log fall protection Adjustable stabilising foot Steel rope Fixed drive belts crankcase Lowering/raising conveyor belt winch Log collection hopper Oil tank Lifting arm hitch Fixed cutting blade crankcase Support foot Log locking handle Log splitter with adjustable knife... - Page 20 Use and maintenance manual The length of the conveyor belt is: 5 metres. The machine is equipped with a 700 mm diameter cutting blade. PLUS version can be fitted with a 10-tonne log splitter with adjustable knife. version can be fitted with a 16-tonne log splitter with adjustable knife. Models Shark 700 Expert PRO Shark 700 Expert PLUS...

- Page 21 Use and maintenance manual Description Description Knife S Levers for two-hand control Opening angle adjustment U Hydraulic knife lift cylinder Log splitter hydraulic cylinder V Secondary knife (vers. PRO) Knife height adjustment lever Circular saw SHARK...

-

Page 22: Noise Level

Use and maintenance manual 1.5 Noise level The values quoted are emission levels and are not necessarily safe working levels. Although there is a correlation between emission and exposure levels, this cannot be used reliably to determine whether or not additional precautions are required. Factors influencing the current exposure level of the workforce include the characteristics of the working environment, other noise sources etc., i.e., the number of adjacent machines and other processes. -

Page 23: Vibration Level

Use and maintenance manual 1.5.1 Vibration level The machine is designed and constructed to minimise operation-induced vibrations and the operator is not affected by these because he is not standing on the machine. The level of vibrations transmitted by the machine to the worker (HAV hand-arm system) during the work phase (during cutting, the operator holds the log locking lever with one hand and the push handle in conjunction with the release lever with the other) is less than 2.5 m/ s 1.5.2 Dust emission... -

Page 24: Safety Requirements

Maintenance Manual. Proper maintenance is a guarantee of excellent work performance. The circular saw has been constructed exclusively for cutting logs. Any other use must be expressly authorised in writing by BALFOR s.r.l. The warnings in this manual only concern permitted and reasonably foreseeable uses. The indications below should be supplemented by the common sense and experience of the operator, which are indispensable measures for accident prevention. -

Page 25: General Safety And Accident Prevention Rules

The Use and Maintenance Manual must always be at hand so that it can be consulted to check the operating cycle. If it is lost or damaged, a replacement copy must be requested from BALFOR s.r.l. ATTENTION! The machine is designed to be used by one operator only who must always be positioned in front of the tilting table. - Page 26 In particular, ensure that the log rests perfectly on the tilting table. Cutting curved logs is not recommended. Report to your supervisor or directly to the BALFOR s.r.l. Assistance Service or to your local authorised dealer any anomalies, faults or malfunctions that may occur during normal operation of the machine.

-

Page 27: Specific Safety Requirements

Use and maintenance manual 2.2 SPECIFIC SAFETY REQUIREMENTS 2.2.1 Cardan models ATTENTION! Any maintenance, adjustment and cleaning work must be carried out with the machine on the ground, the tractor engine switched off, the handbrake on, the ignition key switched off and removed from the ignition switch. DANGER! Check that the drive shaft guards are intact and in good condition. -

Page 28: Internal Combustion Engine Models

Use and maintenance manual ATTENTION! Always use approved and fully protected electrical cables. Check that the cable section of the system, their condition, and their capacity are suitable for the power absorbed by the device, which is indicated on the plate. -

Page 29: Conveyor Belt Models

Use and maintenance manual 2.2.4 Conveyor belt models 2.2.1 In addition to what is specified in sec. Check the wear and tear condition of the hydraulic hoses. In the event of deterioration (or at least every 6 years) replace them. ... -

Page 30: Residual Risk

Use and maintenance manual RESIDUAL RISK Even when the machine is used properly and all safety requirements are observed, there remain some residual risks due to the particular type of machine: In the event of improper handling, there is a risk of injuring your hands with the blade (during replacement) or with logs or pieces of wood. -

Page 31: Safety Signs

Use and maintenance manual SAFETY SIGNS Make sure that the safety pictograms are legible. Clean them using a cloth, soap and water. Replace damaged labels by placing them in the exact position as described in the following section. The safety signs attached to the machine provide a number of very important indications: observing them serves your safety. - Page 32 Use and maintenance manual ON CARDAN AND CONVEYOR BELT MODELS ONLY 6. ATTENTION! Read the Use and Maintenance Manual. Stop the tractor engine and remove the key from the dashboard before carrying out any work on the machine. 7. ATTENTION! DANGER of entanglement and dragging.

-

Page 33: Machine Transport

Use and maintenance manual MACHINE TRANSPORT During transport: For cardan models: disconnect the cardan joint and pay attention to driving to avoid possible damage to the machine. For electric models: always disconnect the electricity supply. For road transport appropriate road clearance warning signs must be attached and the current highway code must be strictly adhered to. - Page 34 Use and maintenance manual Directions for lifting TRANSPORTER BELT models. During lifting, the conveyor belt must be in the lowered and folded position. The position of the lifting eyebolt has been designed in such a way that, if the harness has been correctly fitted, there can be no untimely movements or hazards due to instability when the machine and/or its elements are handled.

-

Page 35: Checking The Lifting Capacity And Stability Of The Tractor

Use and maintenance manual 3.1 CHECKING THE LIFTING CAPACITY AND STABILITY OF THE TRACTOR FOR CARDAN MODELS ONLY ATTENTION! – DANGER! It is mandatory to check the lifting capacity and stability of the tractor (prior to coupling with the machine) to avoid overturning and/or loss of grip of the steering wheels. -

Page 36: Road Conditions

Use and maintenance manual ROAD CONDITIONS FOR CARDAN MODELS ONLY WARNING! For road transport: Attach appropriate road clearance warning signs. Strictly adhere to the current highway code. If the machine covers the tractor's rear lights, it is necessary to fit a bar with rear signal lights. In addition to complying with the regulations, it should be remembered that when driving on public roads, great attention must be paid, in addition to any special requirements noted in the tractor's registration certificate, to the choice of an appropriate transfer speed, especially with carry-type... -

Page 37: Connections

Use and maintenance manual CONNECTIONS CARDAN AND CONVEYOR BELT MODELS CONNECTIONS 4.1.1 Connection to the tractor’s three-point hitch The tractor's three-point hitch must coincide or be adapted. In the area of the arm tie-rods of the tractor's rear lift, there is a danger of injury due to crushing and shearing points. -

Page 38: Cardan Shaft Installation

Only CE-marked cardan shafts should be used for the correct and safe operation of the machine. Only use cardan drive shafts with intact guards. BALFOR s.r.l. company is not liable for damage caused by incorrect assembly and use of the cardan drive. -

Page 39: Hydraulic Connections (For Conveyor Belt Models Only)

Use and maintenance manual (for conveyor belt models only) 4.1.3 Hydraulic connections Before connecting the hydraulic couplings (quick couplings) to the combined machine's spool valves, make sure that the tractor-side circuit is not under pressure by operating the spool valve levers in both directions, with the engine switched off. -

Page 40: Electrical Connections

Use and maintenance manual ELECTRICAL CONNECTIONS Check that the mains voltage corresponds to that indicated in the technical specifications. Check that the electrical system is equipped with an isolating switch (circuit breaker) and a grounding cable. Connect a suitable extension cord (not supplied) that does not exceed a length of 10 metres to the plug on the machine. -

Page 41: Safety Equipment

Use and maintenance manual SAFETY EQUIPMENT The machine has been designed and built to ensure maximum operator safety, as required by current regulations, and in particular: Blade guards are thicker than 3 mm. The tilting table has an angle equal to 90°, and on its surface an embossed plate is assembled to prevent rotation of the workpiece during cutting. - Page 42 Use and maintenance manual Specifications on cardan models The graft tree of the cardan shaft is protected with a protective cap so that it overlaps with the cardan shaft guard when connected. Specifications on electric models The machines are equipped with a thermal engine protection relay, which comes into operation if the engine overheats or the supply voltage drops.

-

Page 43: Conveyor Belt ( For Expert Models Only )

Use and maintenance manual for EXPERT models only CONVEYOR BELT ( BELT POSITIONING Lock the tractor with the parking handbrake. Pull out and fully extend the two stabilising feet ( ) and lock them by means of the latch ( ... -

Page 44: Belt Carpet Tensioning

Use and maintenance manual BELT CARPET TENSIONING 6.2.1 Expert model Insert quick couplings into the tractor sockets to lengthen the belt and tension the carpet. 6.2.2 Expert Direct Drive model Using the three-way valve on the belt orbital engine, the belt can be lengthened or shortened. Position 1 (horizontal) to shorten the belt. -

Page 45: Expert Plus / Pro Model

Use and maintenance manual 6.2.3 Expert PLUS / PRO model Using the three-way valve on the belt orbital engine, the belt can be lengthened or shortened. Position 1 (horizontal) to shorten the belt. Position 2 (vertical) to lengthen the belt. Belt opening ... -

Page 46: Pre-Use Checks

Use and maintenance manual PRE-USE CHECKS Check that the log fall protection net is in the lowered position. This protection prevents cut logs from falling towards the operator. Position a trailer with the body below the conveyor belt, making sure it is parked stably. ... -

Page 47: Use And Operation

Use and maintenance manual USE AND OPERATION The machine should only be started up, operated and adjusted by adequately trained and instructed personnel. ATTENTION! Always use appropriate Personal Protective Equipment (work gloves, safety footwear with reinforced toecap, hearing protection and, if necessary, respiratory protection and protective goggles). - Page 48 Use and maintenance manual FOR CARDAN MODELS Lock the tractor with the parking handbrake and set the tractor's PTO to 350 rpm (model 750) or 290 rpm (model 700). With the engine idling, run the machine for about one minute. ...

- Page 49 Use and maintenance manual During the cutting operation, do not move from the work area to prevent the cut log from falling on your feet. ATTENTION! – DANGER! NEVER leave the machine unattended during operation. ATTENTION! – DANGER! Before placing a new log to be cut make sure that the cutting guide is clean.

-

Page 50: Sb-Road Model

Use and maintenance manual 7.1 SB-ROAD MODEL This model, for ease of transport and use, is assembled on a trolley on which the internal combustion engine has been installed. The trolley is not approved for road use. Under no circumstances may the machine be moved with the circular on. Furthermore, it is forbidden to use the circular while it is still hooked up to the towing vehicle. -

Page 51: Maintenance

Use and maintenance manual MAINTENANCE Before any work is carried out, it is mandatory to remove the plug from the power socket (depending on the type of power supply). In the event of a breakdown, the operator must immediately stop the machine, ascertain the extent of the problem and carry out any necessary work on the machine. -

Page 52: Cutting Disc Replacement

ATTENTION! Wear resistant gloves and safety shoes when removing and replacing the cutting disc. Only use cutting blades supplied by BALFOR s.r.l., manufactured in accordance with EN 847-1:2013. Use blades with the diameter and thickness indicated in the table: Model... - Page 53 Use and maintenance manual Remove the covering crankcase of the cutting blade; Insert a 32" spanner on the shaft, in the appropriate seat ( ) as shown in the photograph; Remove the supplied spanner that is screwed into the ...

-

Page 54: Driving Belts Tensioning

To replace the conveyor belt in the event of breakage or excessive wear and tear, contact the BALFOR s.r.l. Assistance Service or your local authorised dealer. -

Page 55: Storage

- Check that the original safety pictograms are present in their positions and that they are intact and legible. - Grease the mechanical parts according to the previous section. BALFOR s.r.l. company declines all liability for malfunctioning and warranty in the event that the storage and maintenance recommendations are not followed. -

Page 56: Scrapping

Use and maintenance manual 9.1 SCRAPPING In the event of scrapping, the machine must be disposed of in authorised dumps in accordance with current legislation. Before scrapping, plastic or rubber parts and electrical and electronic equipment must be separated. Recover any used oil and dispose of it at the appropriate collection centres. Parts consisting only of plastic, aluminium, steel, can be recycled if collected by the appropriate centres. -

Page 57: Warranty

♦ If a defect is found in a part (or in certain parts) of a machine manufactured by the BALFOR s.r.l. company, during a period of one year from the date of delivery of the machine to the customer, BALFOR s.r.l. -

Page 58: Spare Parts

Model Year of manufacture Frame number The BALFOR s.r.l. company ensures spare parts for a minimum period of 5 years after the model ceases to be produced. This Manual has been compiled according to the regulations currently in force. It is an integral part of the machine and must accompany it together with the Declaration of Conformity in case of resale. - Page 59 Use and maintenance manual NOTES: ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… ………………………………………………………………………………………………………………… Circular saw SHARK...