Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kaixun KX-CDSD

- Page 1 KX-CDSD Semi-Electric Stacker Instructions Manual...

-

Page 3: Table Of Contents

CONTENT 1. CORRECT USAGE..........................1 Usage specification........................1 Operation instructions........................1 Safety precautions........................1 2. DESCRIPTION OF STACKER......................2 Technical data..........................3 Application........................... 3 Explosive drawing........................4 Operating skill..........................5 3. MAITENANCE AND SERVICE......................5 Maintenance..........................5 4. MALFUNCTION ANALYSIS AND SOLUTION.................6 5. HYDRAULIC CIRCUIT........................7 6. -

Page 4: Correct Usage

Welcome to use KX-CDSD semi-electric stacker series! Warning Please read this instruction manual carefully before using the KX-CDSD semi-electric stacker. This manual works for all KX-CDD series electric tow truck, and we reserve our rights for technical reform. Pictures and object maybe slightly different, please in kind prevail. -

Page 5: Description Of Stacker

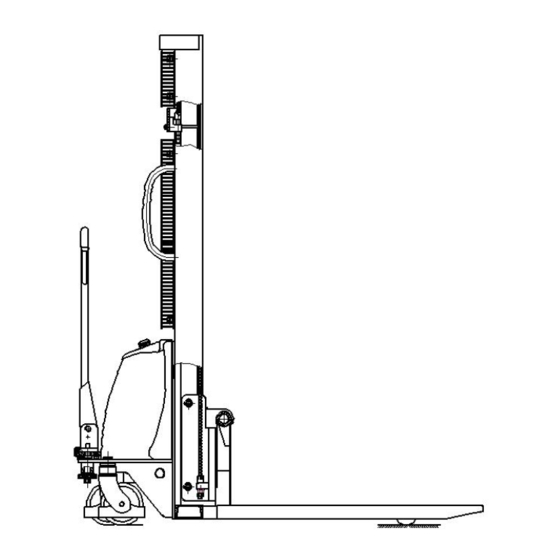

2.DESCRIPTION OF STACKER... -

Page 6: Technical Data

2.1 Technical data Articles/model unit KX-CDSD Rated load capacity Q 2200 3300 4400 Loading center distance C 19.6 Lifting height h 62.9/78.7/98.4/118 Door frame retract height h1 61.7/71.5/81.4 Door frame max. working height h2 81.4/101/120/140 Fork lowest height h3 Fork length L 35.8(45) -

Page 7: Explosive Drawing

2.3 Explosive drawing Name quantity Name quantity Hexagon bolt C class M12 Cover Deep groove ball bearing 6204 Bending wheel frame Wheel gasket Bending wheel shaft Big wheel Inner door frame Protector Outer door frame Hexagon nut C class M12 Steel ball Straight wheel frame Pulley spindle... -

Page 8: Operating Skill

Thrust ball bearing 51206 Deep groove ball bearing Deep groove ball bearing 6005 Axle Battery Bracket seat Hydraulic station Main chain wheel Handle Brake assembly 2.4 Operating skill 1. Turn on power switch. 2. Unlock the electric door lock. 3. Lower the forks to appropriate height. 4. -

Page 9: Malfunction Analysis And Solution

battery damage (charging time: 8 hours). 4.MALFUNCTION ANALYSIS AND SOLUTION Malfunction Cause Solution The 10A fuse of electric system is Voltmeter has no display after Change fuse power burn out or the power switch is opening electric door lock switch damaged. -

Page 10: Hydraulic Circuit

5.HYDRAULIC CIRCUIT... -

Page 11: Electric Circuit

6.ELECTRIC CIRCUIT 7.PACKING LIST Name Usage part Quantity Remake Key of electric door lock Open electric door lock Charger Charge battery DH scraper seal Lifting oil cylinder Fuse 250A Accessories Include technical documents... -

Page 12: Operating Diagram

8.OPERATING DIAGRAM...