Table of Contents

Advertisement

Quick Links

Purge Vent / Sampling Port

or se

it

ire Prote tion itro en

ener tors on Dry Pipe Sprinkler Systems

Models: NGP-APV / NGP-PV-1

Installation, Operation and Maintenance Manual

P r e device n gas monitoring port installed at the end of the piping system to provide a means

to lee o y en rom t e sprinkler pipin

rin t e nitro en ill pro ess n analyze the gas purity

of the entire piping system. Used in conjunction with the

P PS

port

le

s analyzer sol

it t e itro en ener tor at the gas source, t e p r e

l e provides a simple and reliable way

.

to monitor the gas purity throughout t e sprinkler system, and purge oxygen from the piping

Licensed for use under U.S. Patents 9,144,700, 9,186,533, and 9,610,466

1-800-345-8207

Call

or visit our web site for our complete product listing

www.GeneralAirProducts.com

Rev. 1, 12-23

1

Advertisement

Table of Contents

Summary of Contents for General Air Products NGP-APV

- Page 1 Prote tion itro en ener tors on Dry Pipe Sprinkler Systems Models: NGP-APV / NGP-PV-1 Installation, Operation and Maintenance Manual P r e device n gas monitoring port installed at the end of the piping system to provide a means...

-

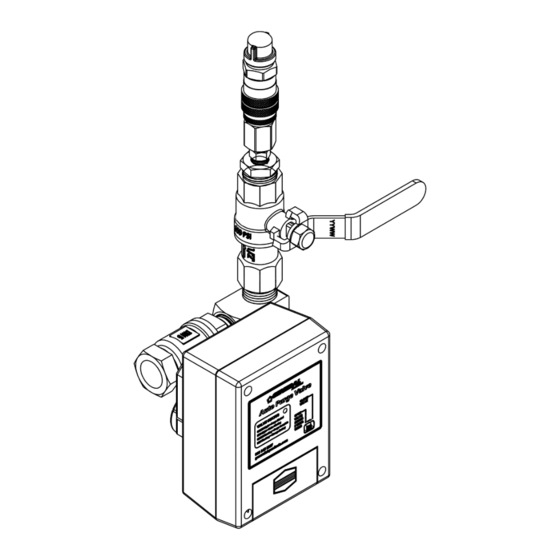

Page 2: Basic Components

The NGP-PV-1 Purge Valve assembly is comprised of a ½” manual ball valve, hex exhauster orifice, gas analyzer port, and quick connect cap to close the system. The NGP-APV Purge Valve includes these components as well as a battery operated automatic valve with a 2-week timer. - Page 3 1. Monitoring a. If not already connected, attach the gas analyzer using the quick-disconnect. b. Ensure the manual ball valve is open. If using the NGP-APV, insert a new 9- volt battery and move the slide switch to the open position.

- Page 4 NGP-PV-1 (Manual Purge Valve) General Arrangement NGP-APV (Automatic Purge Valve) General Arrangement NOTES: • VALVE REQUIRES A 9 VOLT BATTERY TO OPERATE • TO OPEN THE VALVE AND BEGIN THE TWO WEEK TIMER, SLIDE THE SWITCH TO THE "OPEN VALVE" POSITION •...

-

Page 5: Warranty

Product Disposal Instructions: The sensor, batteries, and circuit board are not suitable for regular trash disposal. Return sensor to General Air Products for proper disposal or dispose according to local guidelines. Follow local guidelines for disposal of other components. WARRANTY The N2 analyzer is designed for oxygen delivery equipment and systems. - Page 7 INTRODUCTION The following instructions describe the function; operation and maintenance of the N2 Analyzer. The N2 analyzer is engineered for long life, maximum reliability and stable performance. NOTE: In order to obtain optimum performance from your analyzer, all operation and maintenance must be performed in accordance with these instructions.

-

Page 8: Factors Influencing Accurate Readings

A new calibration is required when: • The measured N2 percentage in 79.1% N2 is above 80.1% N2 • The measured N2 percentage in 79.1% N2 is below 78.1% N2 • If you are unsure about the displayed N2 percentage. (see Factors influencing accurate readings.) OPERATION PRINCIPALS The instrument display corresponds directly to the oxygen sensor. -

Page 9: Calibration Errors And Error Codes

Press and hold the Calibration Button for three seconds to manually force a new calibration. If unit repeats this error more than three times, contact General Air Products Customer Service for possible sensor replacement. CAL Err hi: Sensor voltage too high Press and hold the Calibration Button for three seconds to manually force a new calibration. -

Page 10: Cleaning, Maintenance, And Disposal

Changing the Oxygen Sensor Should the oxygen sensor require changing, the device will indicate this by presenting “Cal Err lo” on the display after initiating a calibration. To change the oxygen sensor, begin by removing the three screws from the back of the device. A #1 Phillips screwdriver is required to remove these screws. -

Page 11: Specifications

SPECIFICATIONS Analyzer Specifications Sensor Type: ............Galvanic fuel cell Measurement Range: . -

Page 12: Warranty Policy

. inal co onents or or 0 a s hichever is longer. General Air Products, Inc. it rive 800-345-8207...

Need help?

Do you have a question about the NGP-APV and is the answer not in the manual?

Questions and answers